Overview

This article examines the significant advantages of blister packs for nutraceutical manufacturers, emphasizing their essential role in achieving cost savings, ensuring product protection, enhancing consumer convenience, and maintaining regulatory compliance. Evidence supports these benefits, illustrating how blister packs effectively reduce material waste, bolster product integrity, and improve user adherence to supplement routines. Furthermore, they assist manufacturers in meeting stringent safety standards, establishing blister packs as an optimal choice in the competitive nutraceutical market.

Introduction

Blister packs have emerged as a transformative packaging solution within the nutraceutical industry, presenting manufacturers with a wealth of advantages that extend far beyond simple containment. By significantly minimizing material waste and reducing shipping costs, these innovative packages not only bolster operational efficiency but also resonate with the increasing demand for sustainable practices. As the market continues to evolve and regulatory pressures intensify, the question arises: how can nutraceutical companies harness the unique benefits of blister packaging to safeguard product integrity, foster consumer trust, and enhance brand visibility?

Western Packaging: Integrated Packaging Solutions for Nutraceuticals

Western Packaging & Distribution stands out as a leader in providing integrated solutions tailored specifically for the nutraceutical sector. Their comprehensive services encompass:

- Expert design for containers

- Filling capabilities for a variety of products including powders, gummies, and soft-gels

- Robust third-party logistics (3PL)

This cohesive strategy effectively streamlines the supply chain for nutraceutical producers, ensuring that products are not only attractively packaged but also efficiently distributed. By integrating services such as warehousing, inventory management, and logistics, Western Packaging significantly enhances operational efficiency, allowing clients to focus on their core competencies. Customized containment solutions are meticulously crafted to meet the unique needs of each client, ultimately driving improved market performance and customer satisfaction.

The benefits of such integration are underscored by industry trends, indicating that companies leveraging comprehensive solutions can achieve up to a 30% reduction in lead times and a notable increase in product visibility on retail shelves. As Cameron Bramwell, Vice President of Customer Strategy, asserts, 'We’re in an ideal position to support nutraceutical clients with their label needs, especially with new regulations regarding containers for this market approaching.'

With new regulations for natural health products set to be implemented in June 2025, Western Packaging's integrated solutions are not only timely but also critical for ensuring compliance and enhancing product integrity.

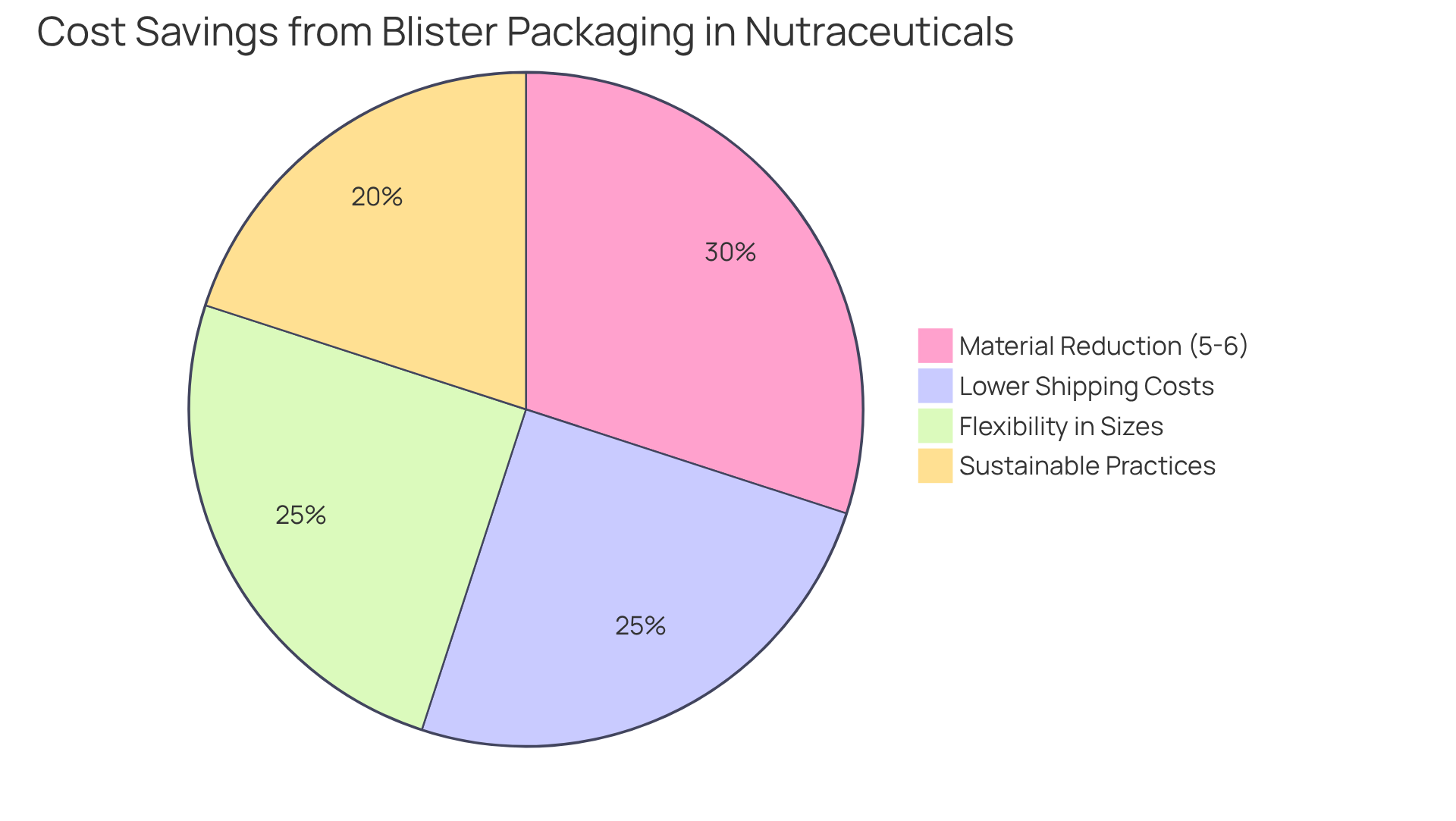

Cost Savings: How Blister Packs Reduce Packaging Expenses

Nutraceutical manufacturers benefit from blister packs as they provide significant cost savings by minimizing material usage and substantially reducing waste. Sealed wrapping decreases material waste by approximately 5% to 6%, a critical factor in an industry increasingly focused on sustainability. Additionally, the lightweight nature of sealed containers contributes to lower shipping costs, making them an economical choice for businesses aiming to optimize their material budgets.

As Gunakesh Parmar, a research consultant with over 15 years of experience, notes, 'The combination of bubble wrap can lead to a more sustainable approach, ultimately benefiting both profit margins and the environment.'

Furthermore, the flexibility in sizes and configurations of packaging enhances inventory management, allowing manufacturers to streamline operations and achieve further cost efficiencies. Companies that have adopted protective packaging have reported a notable reduction in overall packaging expenses, underscoring the practical benefits of this innovative solution.

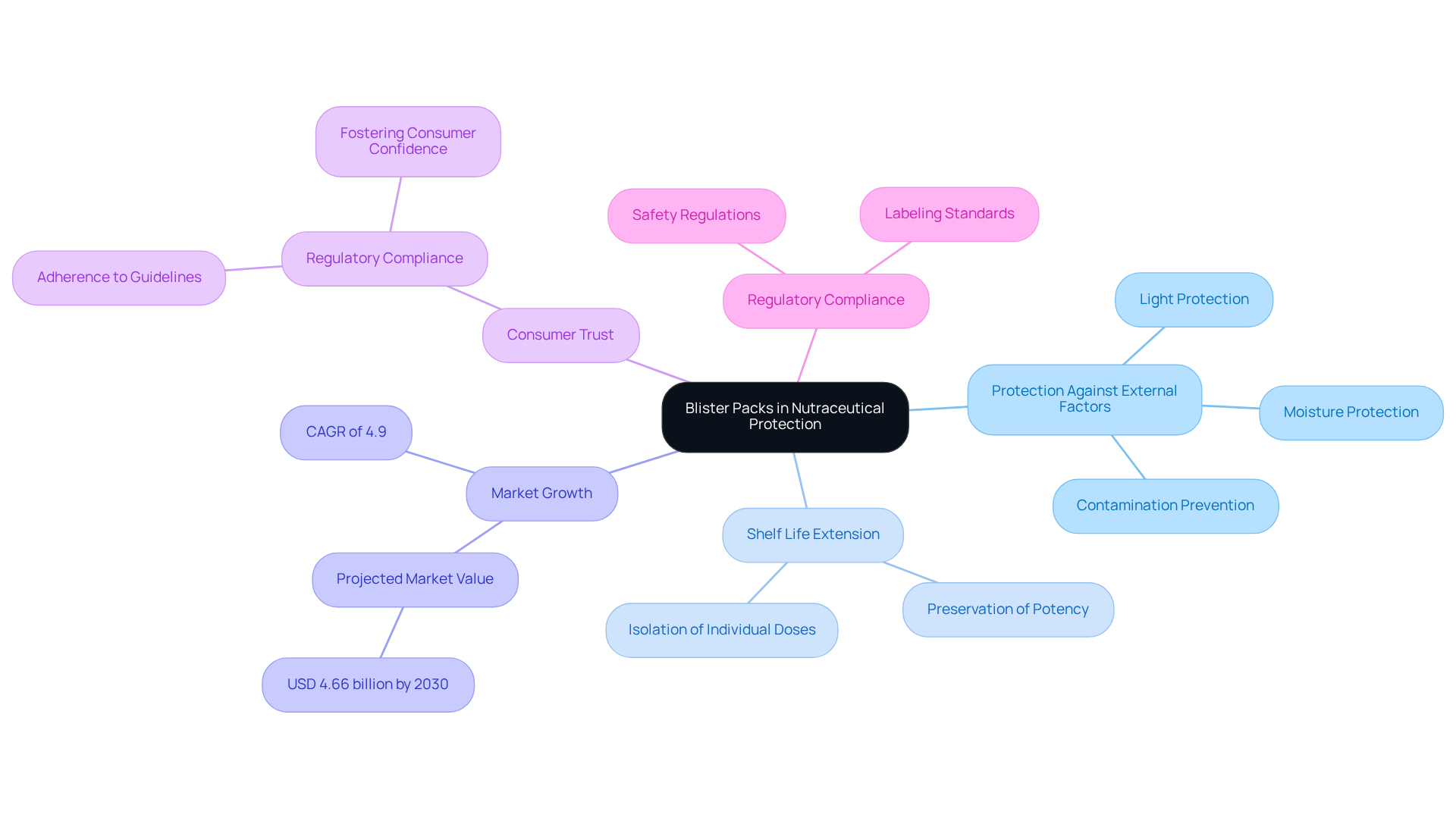

Product Protection: The Role of Blister Packs in Safeguarding Nutraceuticals

Blister packs are crucial for safeguarding nutraceutical products, providing exceptional protection against moisture, light, and contamination—factors that significantly affect product integrity and shelf life. Each sealed compartment within a packaging unit effectively isolates individual doses from external factors, thus preserving the potency of vitamins and supplements. This preservation is particularly vital for sensitive formulations that can deteriorate rapidly when exposed to air or humidity.

Industry experts emphasize that efficient container solutions are essential for maintaining product efficacy throughout its intended shelf life, as they provide crucial barriers against environmental influences. For instance, sealed containers have been proven to substantially extend the shelf life of vitamins, ensuring consumers receive products that meet their health needs without compromising quality.

As the nutraceutical market continues to grow, projected to reach USD 4.66 billion by 2030 with a CAGR of 4.9%, the importance of innovative containment solutions like sealed units becomes increasingly significant in delivering safe and effective products. Furthermore, with the rise of online shopping, sealed containers address the demand for packaging that guarantees safety during transport while also being visually appealing, enhancing brand recognition and shelf visibility.

Compliance with regulatory standards is another critical factor, as blister packs help manufacturers adhere to guidelines concerning product stability and labeling, ultimately fostering consumer trust.

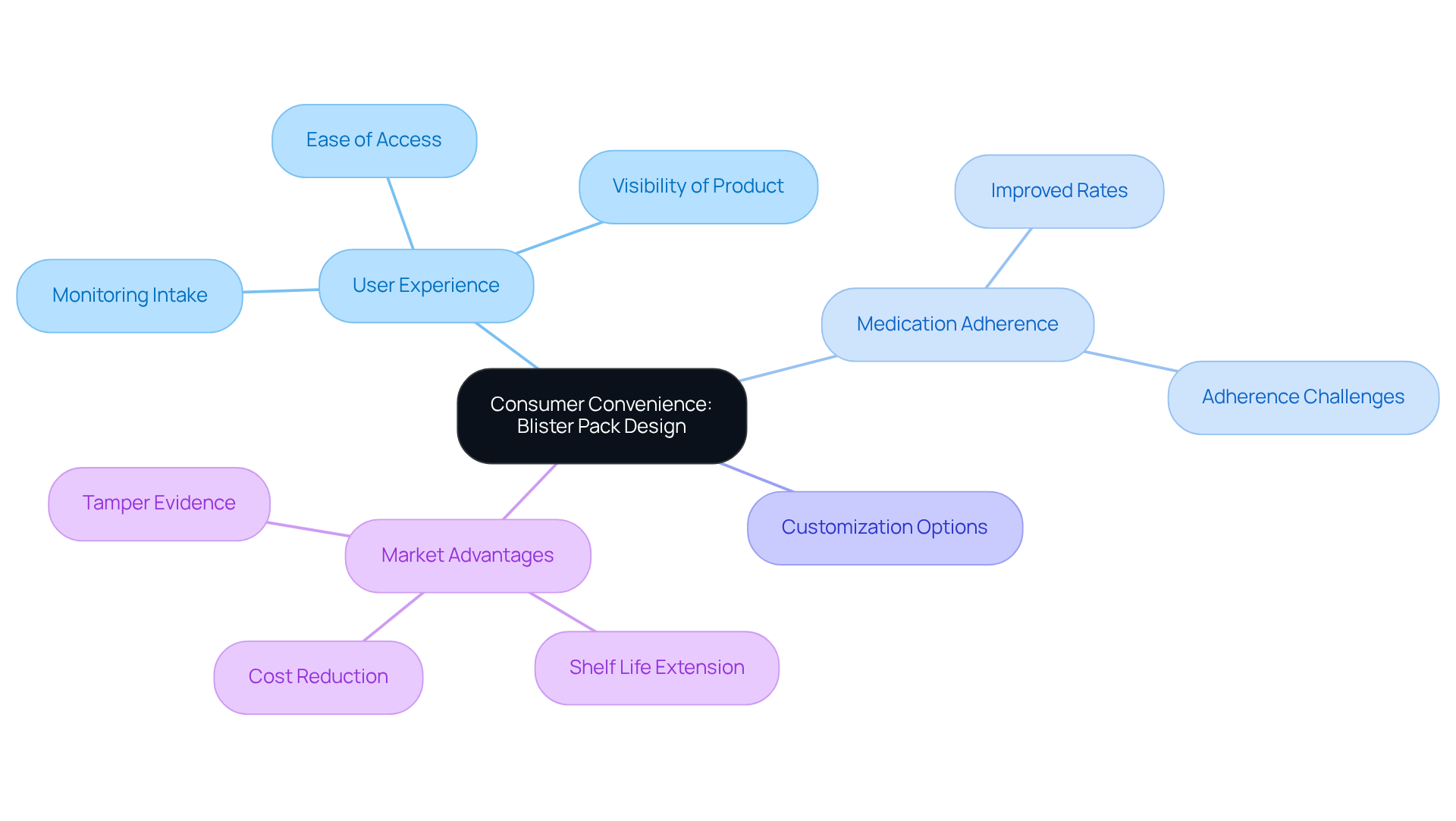

Consumer Convenience: The User-Friendly Design of Blister Packs

The design of blister packs prioritizes user convenience. Their individual compartments act like blister packs, allowing users to access single doses effortlessly and eliminating the necessity of opening an entire bottle. This thoughtful design not only enhances the user experience but also aids individuals in monitoring their intake through blister packs, significantly promoting compliance with supplement routines. The transparent packaging allows for clear visibility of the product, enabling consumers to quickly recognize contents and ensuring they can easily track their consumption.

Such user-friendly features are crucial, as research indicates that container interventions, such as blister packs, can lead to improved medication adherence rates, making them an optimal choice for nutraceutical producers aiming to enhance user engagement and satisfaction. Furthermore, with medication adherence estimated at around 50%, the significance of packaging in addressing adherence challenges cannot be overstated. The rising demand for protective wrapping, driven by its safeguarding attributes and consumer convenience, underscores its competitive advantage in the market.

As noted by experts in the field, 'The customization options available in blister packs not only enhance user experience but also elevate brand awareness.' At Western Packaging, we excel in providing customized flexible packaging solutions, including large pouches for protein items and stick packs for nutraceuticals, that not only fulfill your unique requirements but also enhance your product's shelf appeal and brand recognition.

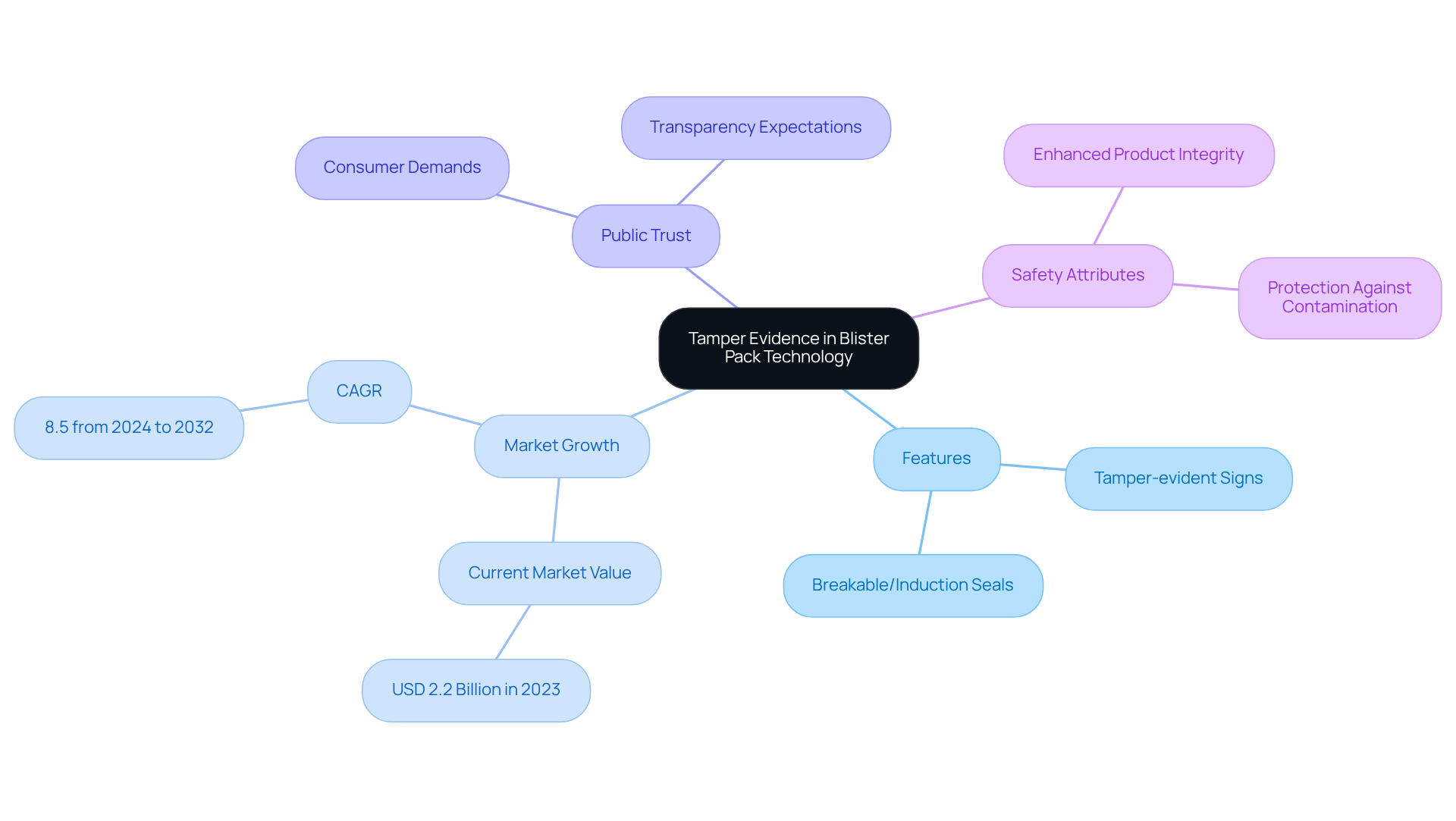

Tamper Evidence: Ensuring Safety with Blister Pack Technology

Blister packs include advanced tamper-evident features that offer unmistakable signs of package compromise, which are crucial for safeguarding nutraceutical products. This technology not only prevents unauthorized access and contamination but also significantly enhances public trust. As the demand for secure containers rises, manufacturers using blister packs can effectively meet regulatory requirements for tamper-evident solutions, which are becoming increasingly essential in the nutraceutical market.

Improved safety attributes, like breakable seals and induction seals, guarantee that users can confidently utilize items, aware that their integrity has been preserved. The tamper-proof wrapping industry was assessed at USD 2.2 billion in 2023 and is expected to expand at a CAGR of 8.5% from 2024 to 2032, indicating the increasing public concerns about safety and integrity.

As Suraj Gujar points out, "As occurrences of tampering and contamination increase, buyers are requesting containers that offer visible signs of tampering, boosting their trust in item safety." This integration of safety measures corresponds with increasing public expectations for transparency and security in packaging.

Clear Product Display: Boosting Brand Visibility with Blister Packs

Blister packs offer a clear view of the item, enabling buyers to see precisely what they are acquiring. This level of visibility not only enhances visual appeal but also builds trust in the product. By effectively showcasing the item, manufacturers can significantly boost brand visibility on retail shelves, making it easier for consumers to recognize and choose their offerings over competitors.

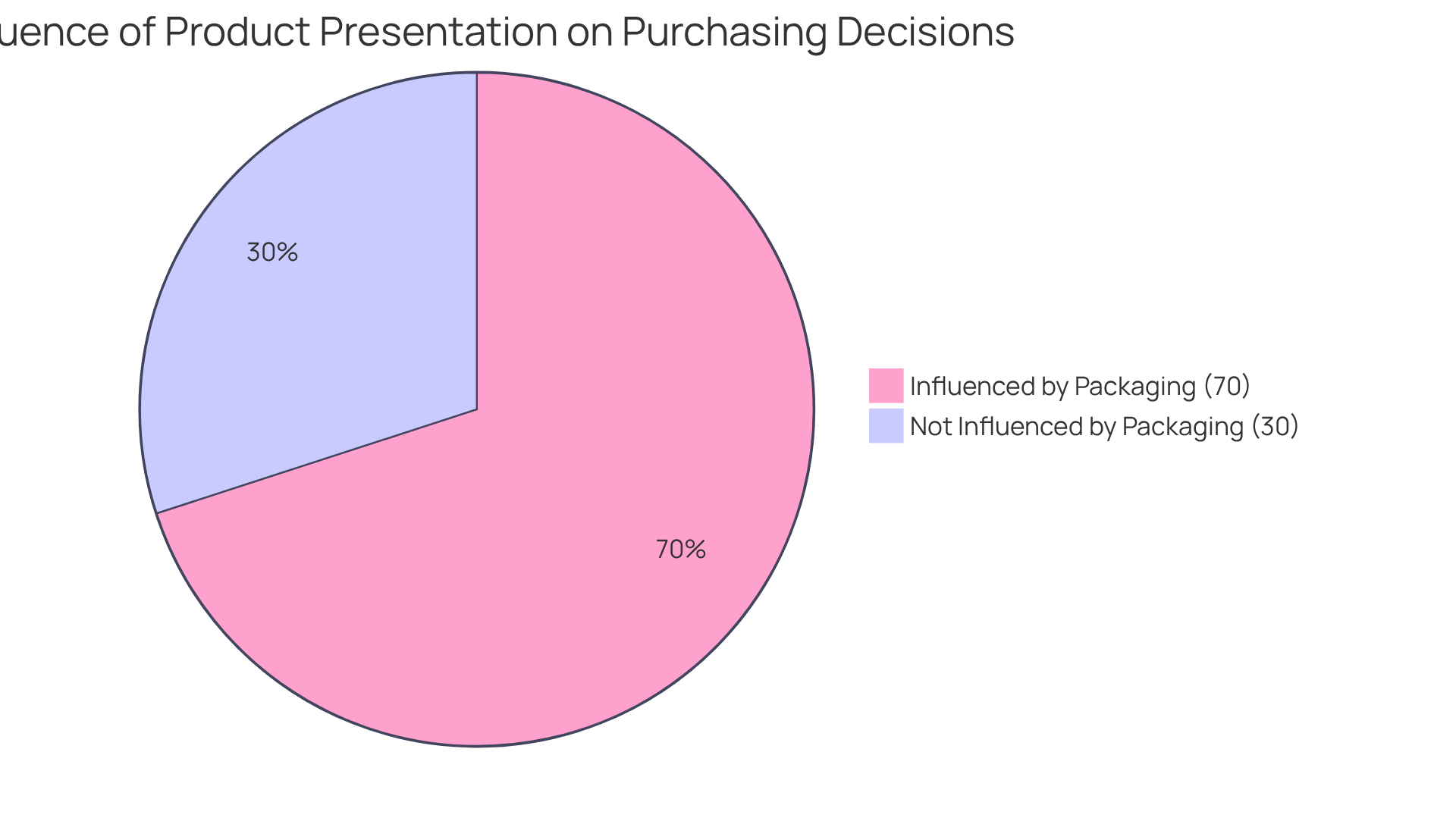

Premium packaging plays a crucial role in purchasing decisions, as consumers often associate the quality of blister packs with the quality of the product itself. Research indicates that 70% of consumers admit to buying products based on their presentation, underscoring the importance of clear displays in driving sales.

Furthermore, marketing experts emphasize that transparent packaging can cultivate a stronger connection with consumers, as it allows brands to communicate their values and product integrity more effectively. By leveraging Western Packaging's customized flexible solutions, including our innovative options, manufacturers can enhance brand awareness and strategically position their products in a competitive market.

Consider Western Packaging for your packaging needs to boost sales and foster customer loyalty.

Environmental Benefits: The Sustainability of Blister Packs

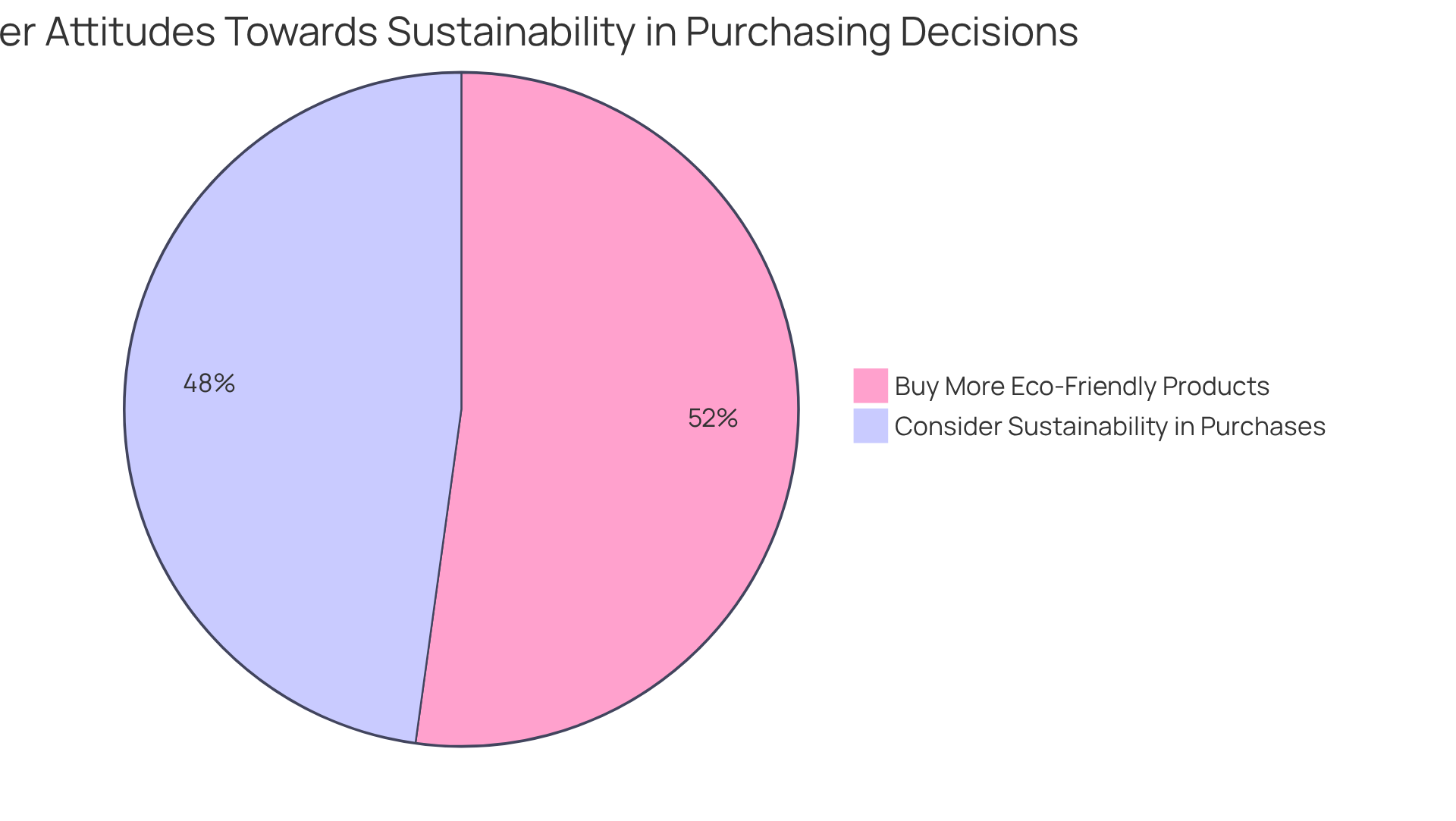

Sustainability can be at the core of blister packs, utilizing recyclable materials that significantly lessen environmental impact. A growing number of manufacturers are embracing eco-friendly blister packs, which not only minimize waste but also encourage recycling practices. This shift aligns with buyer preferences; studies indicate that:

- 66% of individuals consider sustainability when making purchasing choices.

- 72% reported acquiring more environmentally friendly products than five years ago.

By opting for sustainable materials, nutraceutical companies can effectively attract environmentally conscious consumers and enhance their brand image as responsible market players. Furthermore, industry leaders assert that transitioning to sustainable materials is beneficial not only for the environment but also for business. As Michael Mapes, CEO, stated, transitioning to sustainable materials is 'not only the right decision for the environment but also the right decision for the business.'

As the demand for sustainably sourced products continues to grow, brands that emphasize eco-friendly materials are likely to improve their market presence and profitability. For instance, Terraseed successfully transitioned to sustainable packaging, demonstrating the positive market response that can arise from such initiatives. Moreover, integrating eco-friendly materials such as cellulose and plant-based alternatives in packaging can further facilitate the industry's shift towards sustainability. With less than 30% of plastic produced by the supplement industry being recycled, the urgency for change is clear.

Versatility: Adapting Blister Packs for Various Nutraceutical Products

The remarkable versatility of blister packs makes them suitable for a wide array of nutraceutical products, including tablets, capsules, gummies, and powders. This adaptability empowers manufacturers to employ sealed containers across their entire product line, streamlining their packaging processes.

At Western Packaging, we excel in providing customized flexible packaging solutions that enhance product appeal and cater to specific needs. Our extensive personalization options allow for modifications in size, shape, and design to meet distinct product requirements. For instance, a dietary supplement producer may opt for larger packaging cavities to accommodate gummies, whereas a company specializing in herbal capsules might prefer a more compact design to optimize shelf space.

This level of customization not only addresses diverse product line needs but also elevates brand visibility and customer engagement through cohesive graphic materials such as labels and brochures. Industry experts assert that customized sealed containers significantly enhance user experience, ensuring that products are not only protected but also presented attractively on retail shelves.

A notable example is our collaboration with a leading nutraceutical brand, which resulted in a unique packaging design that improved their shelf visibility and consumer interaction. Furthermore, with the nutraceutical container market projected to reach USD 4.66 billion by 2030, the importance of effective packaging solutions becomes increasingly apparent.

As design specialists emphasize, 'Customizing protective packs not only meets regulatory requirements but also allows brands to stand out in a competitive market.' The ability to customize blister packs for various nutraceuticals positions them as an excellent choice for manufacturers aiming to enhance both functionality and aesthetics in their products.

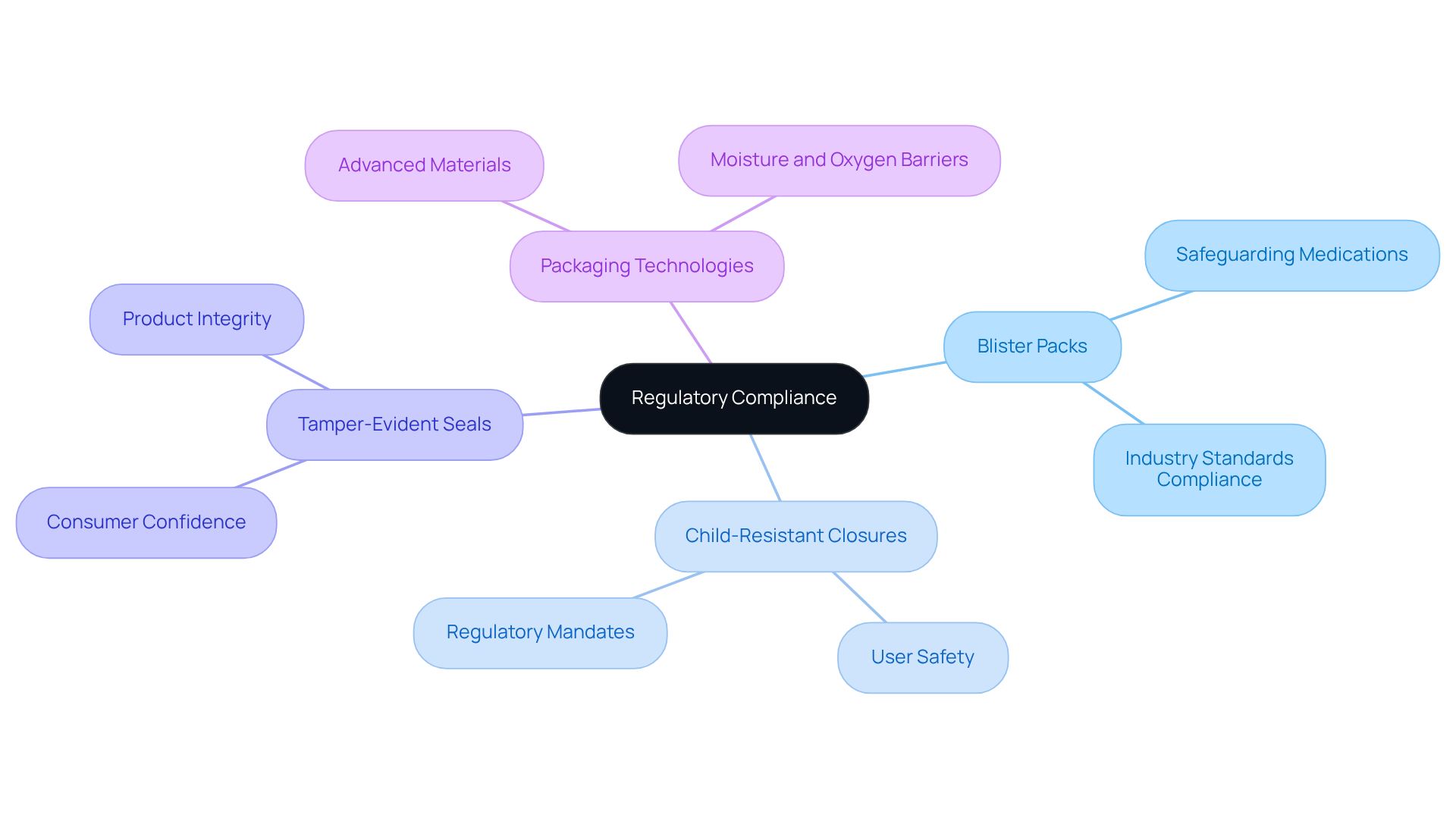

Regulatory Compliance: How Blister Packs Facilitate Adherence to Standards

Meticulously engineered blister packs comply with stringent regulatory standards, ensuring the safe and effective containment of nutraceutical products. These innovative solutions often feature essential components such as child-resistant closures and tamper-evident seals, mandated by regulatory authorities to enhance user safety. By utilizing sealed containers, manufacturers not only adhere to industry standards but also significantly diminish the likelihood of recalls, thereby bolstering consumer confidence.

As Mark Chiang notes, 'In the pharmaceutical sector, choosing a suitable contract partner for blister packs is a vital choice that impacts item presentation, safeguarding, and adherence to regulations.' This underscores the importance of selecting reliable container solutions like blister packs that meet safety standards.

Furthermore, the incorporation of advanced packaging technologies guarantees that these solutions preserve item integrity while addressing the evolving demands of the nutraceutical market.

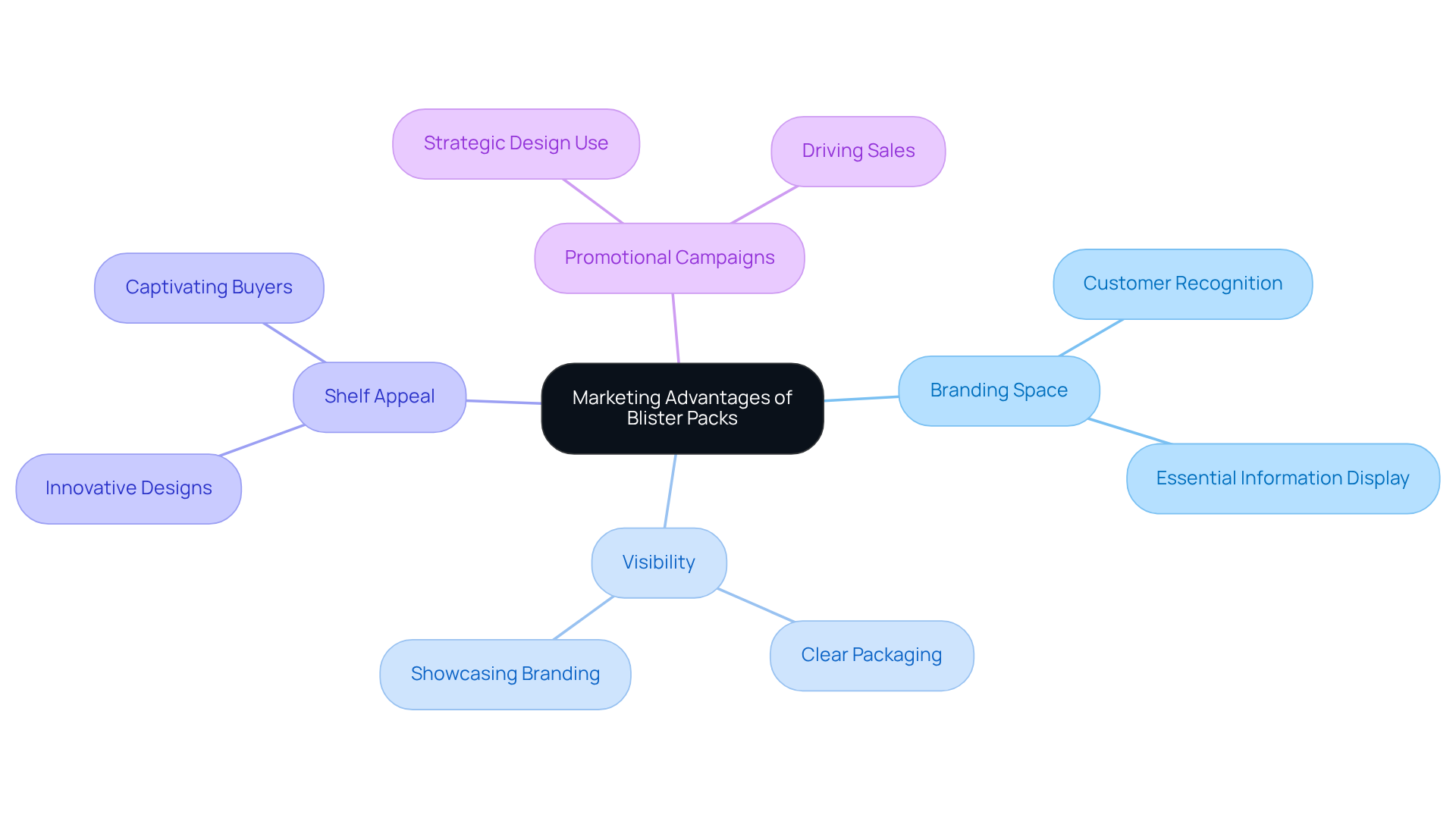

Marketing Advantages: Leveraging Blister Packs for Brand Promotion

Blister packs offer significant marketing advantages by providing ample space for branding and essential information. Their clear visibility allows manufacturers to showcase their branding effectively, thereby enhancing customer recognition and fostering loyalty.

With Western Packaging's tailored flexible packaging solutions, nutraceutical manufacturers can elevate their product's shelf appeal through innovative designs that captivate buyers.

Furthermore, the distinctive design of blister packs can be strategically leveraged in promotional campaigns, making them a formidable asset for capturing consumer attention and driving sales in a competitive marketplace.

Conclusion

Blister packs stand out as a transformative solution for nutraceutical manufacturers, delivering a range of benefits that significantly enhance product integrity and elevate consumer experience. By integrating cost savings, product protection, user convenience, and marketing advantages, blister packs are essential to the success of nutraceutical products in today’s competitive marketplace.

This article emphasizes key points, including the substantial reduction in packaging expenses and material waste achieved through the adoption of blister packs. Their capacity to protect products from environmental factors while ensuring compliance with regulatory standards underscores their critical role in the nutraceutical sector. Furthermore, the user-friendly design of blister packs not only enhances consumer convenience but also promotes adherence to supplement routines, thereby fostering brand loyalty.

As the nutraceutical market continues to expand, the demand for innovative and sustainable packaging solutions is poised to rise. Embracing blister pack technology not only bolsters operational efficiency and product safety but also aligns with consumer preferences for environmentally friendly practices. Manufacturers are urged to recognize the numerous advantages of blister packaging as they strive to elevate their products and meet the evolving needs of health-conscious consumers.

Frequently Asked Questions

What services does Western Packaging provide for the nutraceutical sector?

Western Packaging offers expert design for containers, filling capabilities for various products including powders, gummies, and soft-gels, and robust third-party logistics (3PL).

How does Western Packaging enhance operational efficiency for nutraceutical producers?

By integrating services such as warehousing, inventory management, and logistics, Western Packaging streamlines the supply chain, allowing clients to focus on their core competencies.

What are the benefits of using integrated packaging solutions for nutraceuticals?

Integrated solutions can lead to up to a 30% reduction in lead times and improved product visibility on retail shelves, ultimately driving better market performance and customer satisfaction.

What upcoming regulations are affecting the nutraceutical packaging industry?

New regulations for natural health products are set to be implemented in June 2025, making integrated solutions critical for compliance and product integrity.

How do blister packs contribute to cost savings for nutraceutical manufacturers?

Blister packs minimize material usage and reduce waste, leading to significant cost savings. Sealed wrapping decreases material waste by approximately 5% to 6%, and their lightweight nature lowers shipping costs.

What role do blister packs play in product protection for nutraceuticals?

Blister packs protect nutraceutical products from moisture, light, and contamination, which are crucial for maintaining product integrity and extending shelf life.

Why are sealed containers important for the shelf life of vitamins and supplements?

Sealed compartments isolate individual doses from external factors, preserving the potency of sensitive formulations that can deteriorate when exposed to air or humidity.

How do blister packs help manufacturers comply with regulatory standards?

Blister packs assist manufacturers in adhering to guidelines concerning product stability and labeling, which fosters consumer trust in the products.