Overview

The primary advantages of contract manufacturing for nutraceuticals encompass substantial cost savings, enhanced operational efficiencies, and superior product quality. These benefits collectively empower firms to achieve greater competitiveness within the health supplement market. This article illustrates that by outsourcing production, companies can concentrate on their core competencies while tapping into specialized expertise. This strategic approach not only drives growth but also enhances responsiveness to evolving market demands.

Introduction

Contract manufacturing in the pharmaceutical sector is revolutionizing the landscape for nutraceutical companies, presenting a multitude of benefits that go beyond simple cost savings. By outsourcing production, businesses can leverage advanced technologies, optimize operations, and improve product quality—all essential components in a fiercely competitive market.

However, as the demand for health supplements escalates, companies encounter the urgent challenge of sustaining agility and compliance within intricate regulatory frameworks.

What strategic advantages can contract manufacturing offer to not only address these demands but also propel growth in a continually evolving industry?

Western Packaging: Integrated Packaging Solutions for Enhanced Supply Chain Efficiency

Western Packaging expertly integrates packaging design, filling services, and third-party logistics (3PL), significantly enhancing supply chain efficiency for nutraceuticals. This consolidation empowers businesses to reduce lead times and improve product delivery, enabling them to swiftly adapt to market demands. The integrated approach simplifies operations and provides tailored solutions that cater to specific client needs, ultimately boosting brand recognition and operational efficiency.

For example, companies utilizing advanced printing technologies, such as hybrid flexo printing, have reported reduced setup times and faster job switching, contributing to quicker turnarounds without compromising quality.

Moreover, dietary supplement warehouses should implement warehouse management software for real-time inventory traceability, ensuring compliance with FDA regulations while optimizing fulfillment processes. By adopting these integrated solutions, businesses can transform their packaging and logistics into strategic assets, particularly as the demand for delivering health products through 3PLs is rapidly increasing to meet consumer needs.

Additionally, with online orders in North America rising by 80%, the urgency for these integrated solutions is more relevant than ever.

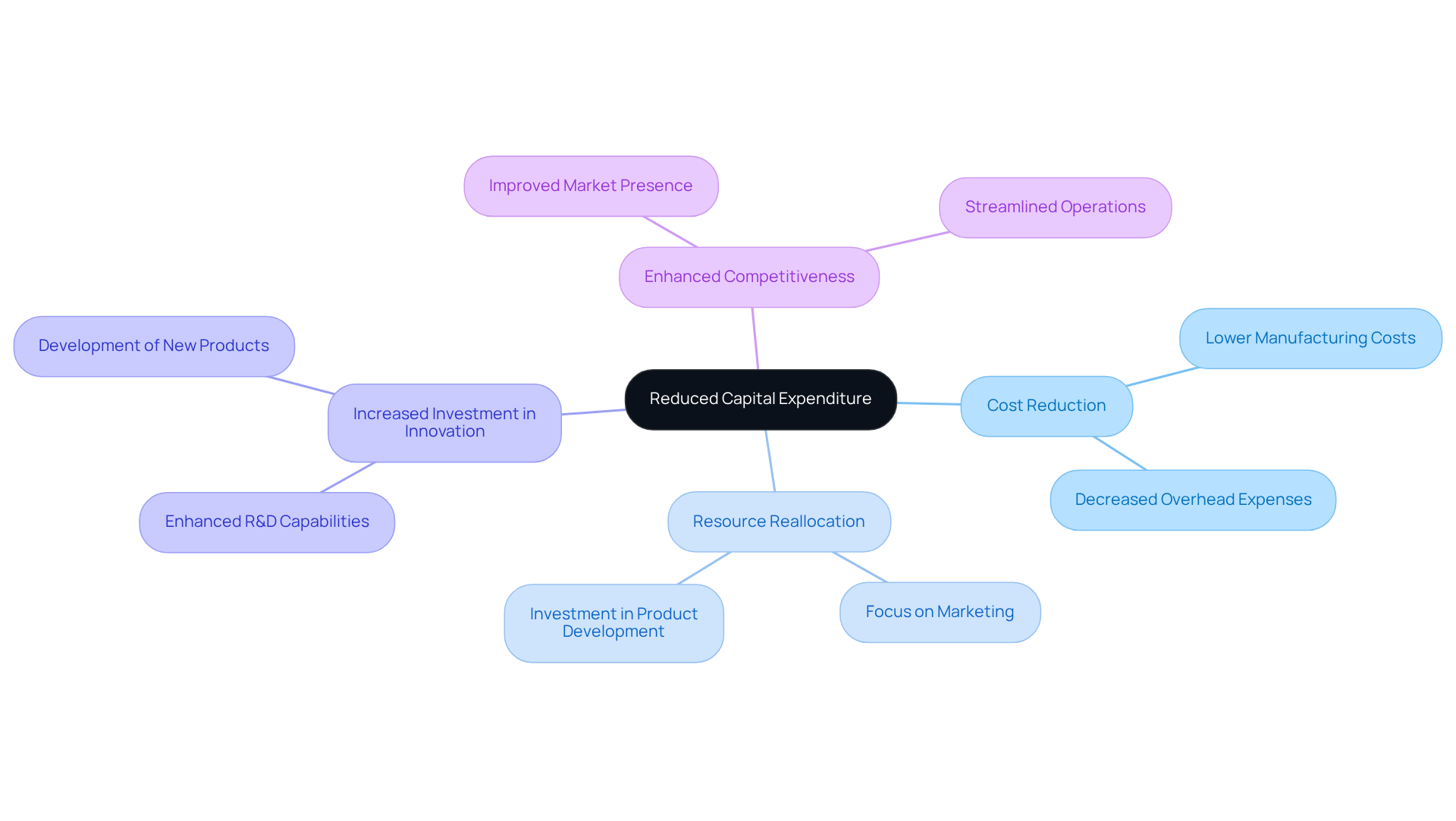

Reduced Capital Expenditure: Financial Benefits of Contract Manufacturing

Contract manufacturing pharma presents a strategic opportunity for dietary supplement firms to significantly reduce capital expenses by outsourcing their production processes. This approach enables businesses to circumvent the substantial costs associated with establishing and maintaining manufacturing facilities through contract manufacturing pharma. By reallocating these resources, organizations can focus on critical areas such as marketing and product development, thereby enhancing their overall agility and financial health.

Financial analysts emphasize that this shift not only reduces expenses but also empowers firms to invest in innovation and growth, ultimately leading to improved competitiveness in the dietary supplement sector. As Larry Elder articulates, outsourcing allows businesses to decrease costs and boost productivity, which is essential for thriving in today's competitive landscape.

Furthermore, Western Packaging's integrated strategy for packaging and logistics can streamline operations, enabling manufacturers to optimize their supply chain and elevate customer engagement, ultimately contributing to a more robust market presence.

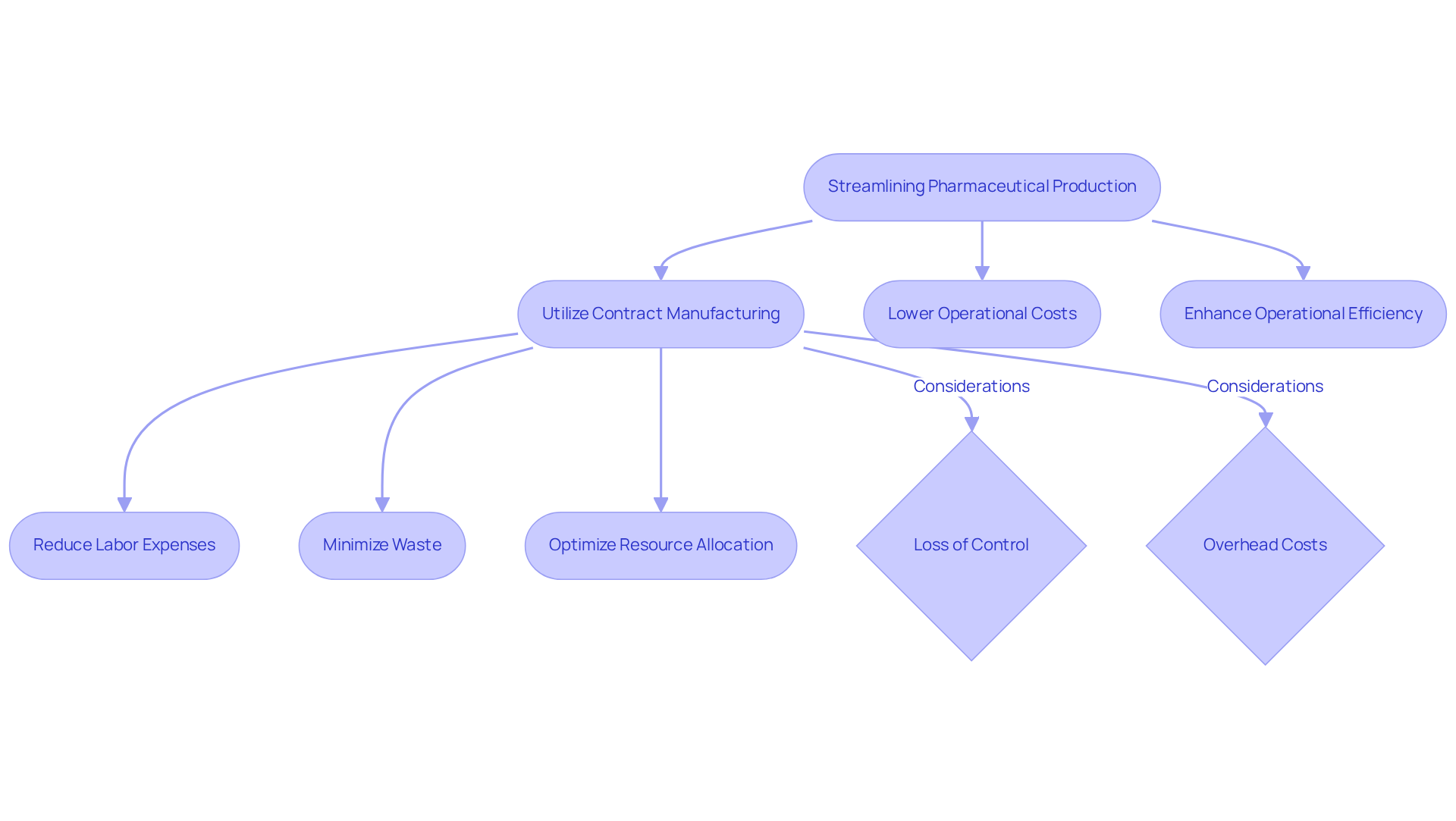

Lower Operational Costs: Streamlining Pharmaceutical Production

Utilizing contract manufacturing pharma empowers nutraceutical firms to significantly streamline their production processes, leading to lower operational costs. This strategic approach not only reduces labor expenses but also minimizes waste and optimizes resource allocation. However, it is crucial to acknowledge that businesses may encounter a loss of complete control over the production process, potentially impacting their ability to influence decisions regarding raw materials and manufacturing techniques.

Contract manufacturing pharma typically possesses established systems and processes that enhance operational efficiency, enabling firms to focus on their core competencies while ensuring high-quality production standards. For instance, companies like Just Add Cooking have effectively leveraged manufacturing agreements to manage their meal kit services, illustrating how outsourcing can yield improved production workflows and heightened customer satisfaction.

Furthermore, the financial implications of manufacturing agreements are noteworthy; for example, the low customer acquisition expense of $70 alongside a lifetime value of $400 underscores the potential profitability of this approach. By harnessing the expertise of manufacturing partners, nutraceutical companies can achieve a more flexible production model, ultimately boosting profitability and market competitiveness.

Nevertheless, businesses must also consider the overhead costs associated with managing relationships with manufacturers, as these can impact the overall financial benefits. Additionally, the geographical location of production manufacturers can influence lead times and shipping costs, adding another layer of complexity to the decision-making process.

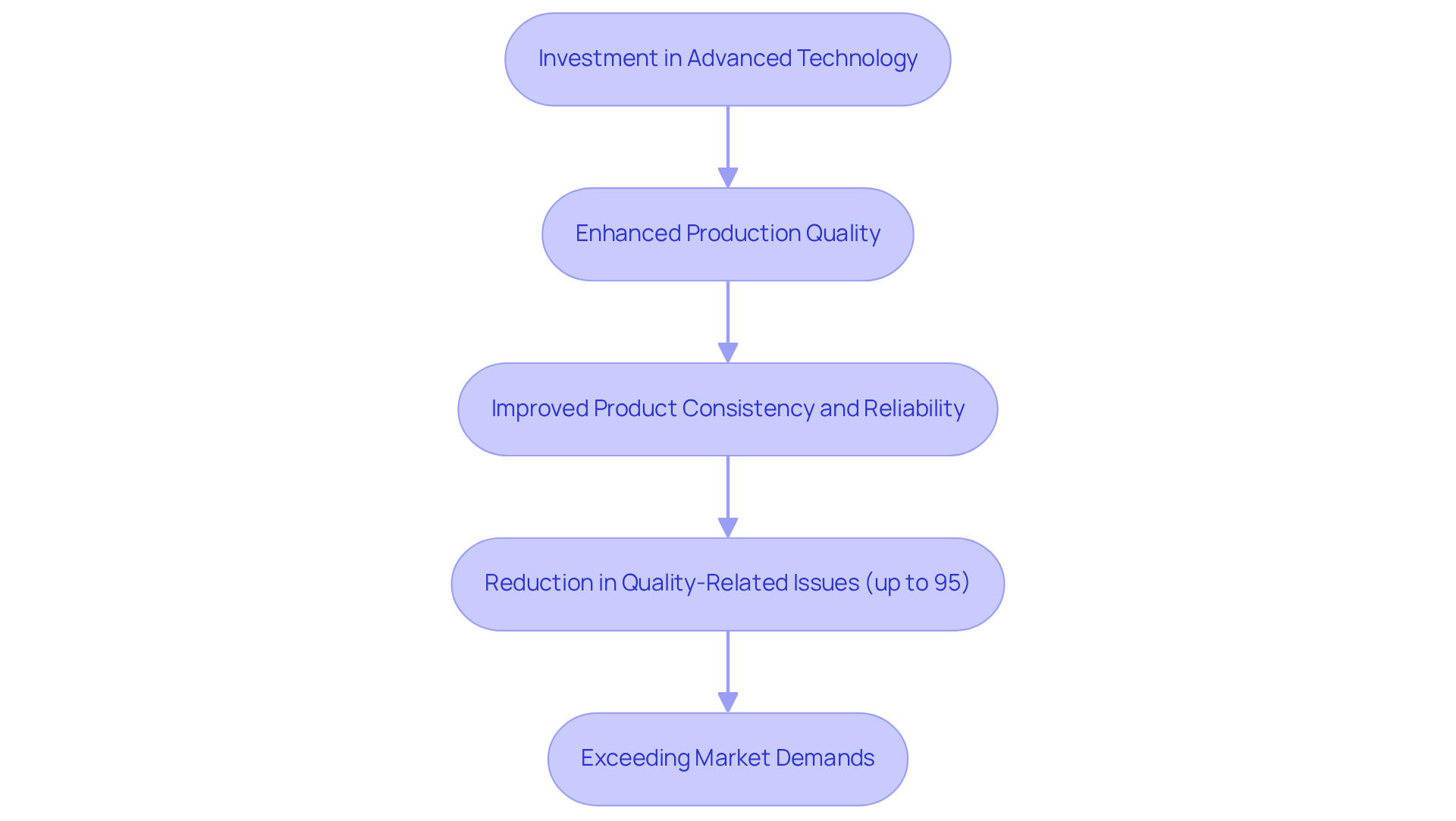

Advanced Technology and Facilities: Enhancing Production Quality

Contract manufacturing pharma is increasingly investing in advanced technology and state-of-the-art facilities, significantly enhancing the quality of health products. This strategic investment ensures that products are manufactured to the highest standards, aligning with stringent regulatory requirements and evolving consumer expectations. Notably, the dietary supplements sector, which commands the largest share in contract manufacturing pharma, benefits immensely from these advancements, enabling improved product consistency and reliability.

Statistics indicate that organizations utilizing cutting-edge equipment experience substantial improvements in production quality, with many reporting a reduction in quality-related issues by up to 95% through the adoption of advanced manufacturing processes. Furthermore, as consumer interest in clean-label products continues to rise, leveraging these advanced facilities allows health supplement firms to not only meet but exceed market demands, positioning themselves advantageously in a landscape where quality is paramount.

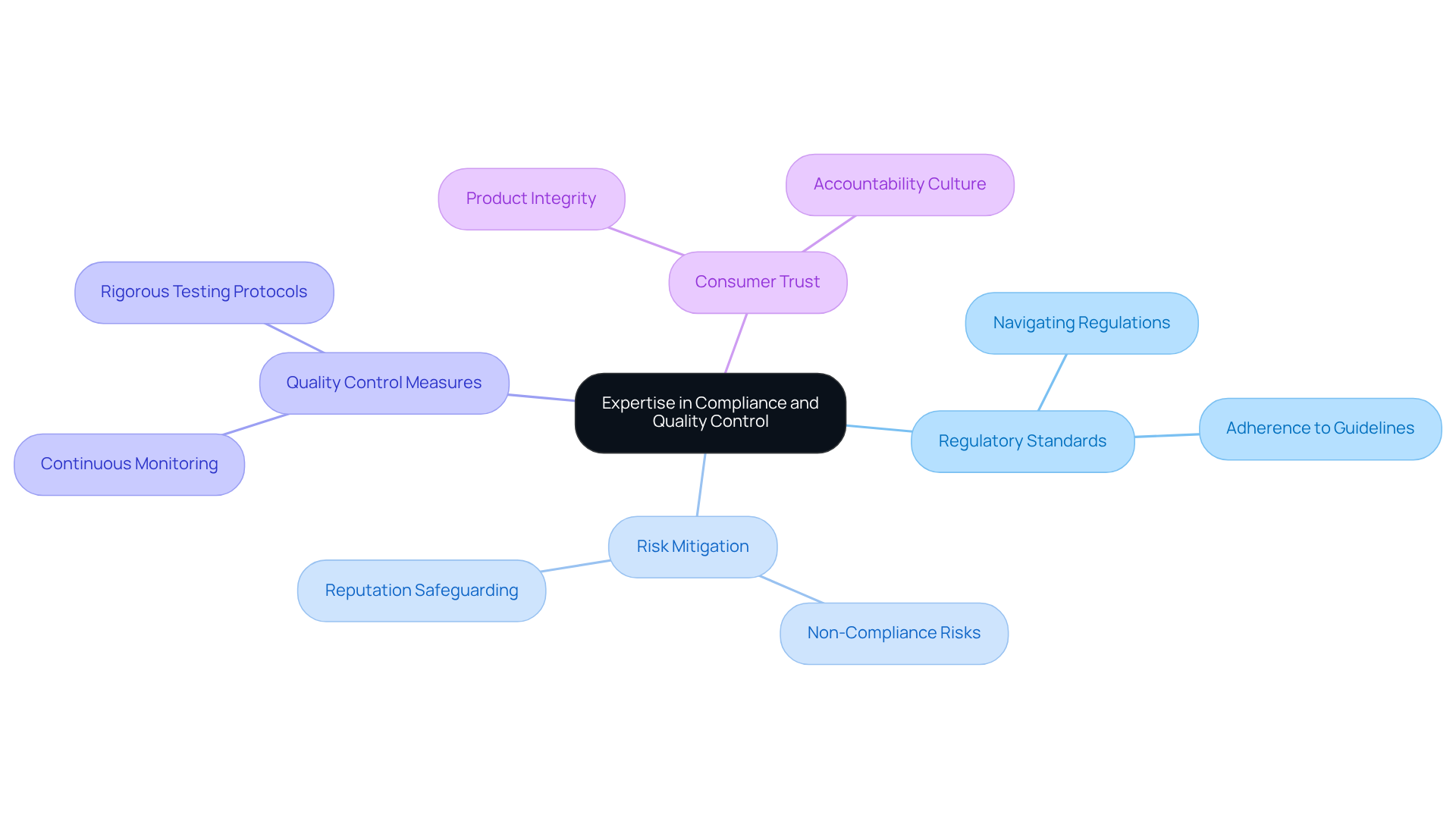

Expertise in Compliance and Quality Control: Ensuring Regulatory Adherence

Contract manufacturers possess specialized expertise in compliance and quality control, ensuring that nutraceutical products meet all regulatory standards. This expertise is invaluable for companies that may lack the resources or knowledge to navigate complex regulations. By partnering with experienced manufacturers, businesses can mitigate risks associated with non-compliance, safeguarding their reputation and ensuring consumer safety.

Successful contract manufacturers implement rigorous quality control measures and continuous monitoring systems to ensure compliance throughout the production process. This proactive approach not only safeguards product safety but also fosters a culture of accountability and excellence within the industry. Regulatory experts emphasize that adherence to established guidelines is crucial for maintaining product integrity and consumer trust. As one specialist observed, 'Compliance is not merely a legal duty; it is a dedication to quality and safety that consumers anticipate from health products.

Adaptability to Market Demand: Flexibility in Pharmaceutical Manufacturing

Contract manufacturing pharma offers nutraceutical firms the essential flexibility to adapt to evolving market demands. This adaptability is critical for scaling production in response to seasonal trends and for the rapid introduction of new products.

For example, the Nutraceutical Contract Manufacturing Pharma Services Market is anticipated to expand from USD 157.0 billion in 2024 to USD 414.4 billion by 2034, highlighting the growing necessity for versatile manufacturing solutions.

Successful collaborations illustrate this adaptability; companies such as Upsher-Smith have effectively partnered with Bosch Pharma to enhance their production capabilities, concentrating on product process development and formulation.

Industry leaders assert that fostering open communication and maintaining a long-term vision are vital for navigating these shifts. As consumer preferences increasingly gravitate towards natural and plant-based products, manufacturers are adopting innovative technologies to elevate their offerings.

Moreover, with 90% of all produced vitamin B manufactured in China, and its cost fluctuating between £3,000 to £20,000 per kg, the demand for contract manufacturing pharma is becoming even more pronounced. This responsiveness not only strengthens market presence but also allows businesses to capitalize on emerging trends, ultimately driving growth in the health supplement sector.

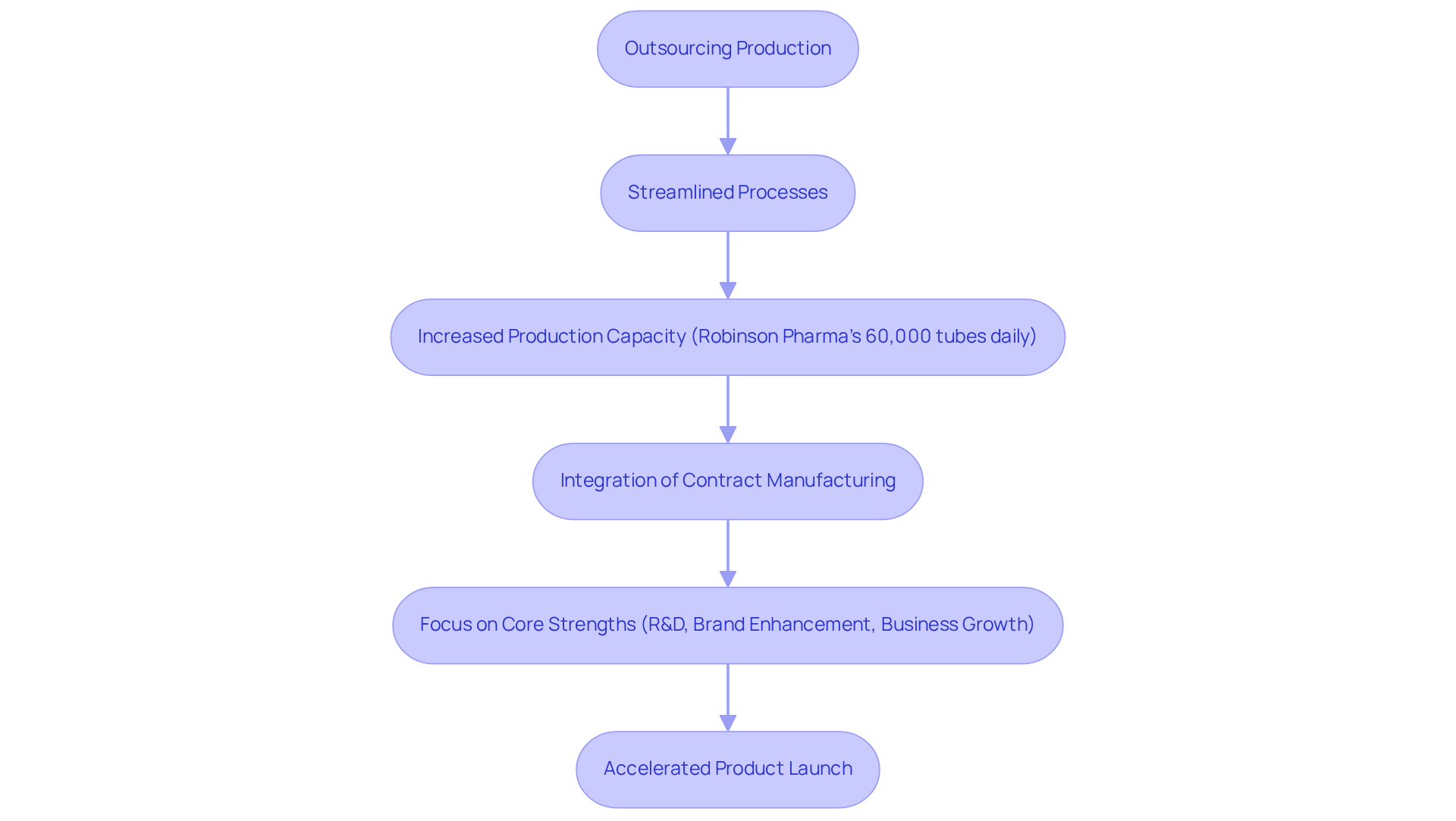

Reduced Time-to-Market: Accelerating Product Launches

By employing outsourcing for production, nutraceutical firms can significantly reduce their time-to-market for new products. Established manufacturers have streamlined processes and resources, facilitating quicker development and production cycles. For instance, Robinson Pharma's production from the packaging line has surged to 60,000 tubes daily, exemplifying the effectiveness of modern manufacturing processes. This speed is crucial for capitalizing on industry trends and meeting customer needs, ensuring that businesses can launch products at their most relevant moments.

Moreover, integrating contract manufacturing into product development strategies not only accelerates launch timelines but also enhances overall operational efficiency. By contracting specialized manufacturing activities, companies can focus on their core strengths, such as:

- Research and development

- Brand enhancement

- Business growth

This strategic arrangement is vital in a competitive landscape where speed is essential. Dr. Hemant N. Joshi underscores this point, stating, "The capability to introduce products swiftly can be a crucial factor in acquiring share and addressing consumer needs efficiently."

Furthermore, globalization and technological advancements have transformed the manufacturing landscape, making it more accessible and cost-effective for companies. In summary, leveraging contract manufacturing not only streamlines production processes but also empowers health supplement firms to respond dynamically to the fast-paced market environment, ensuring they remain competitive and relevant.

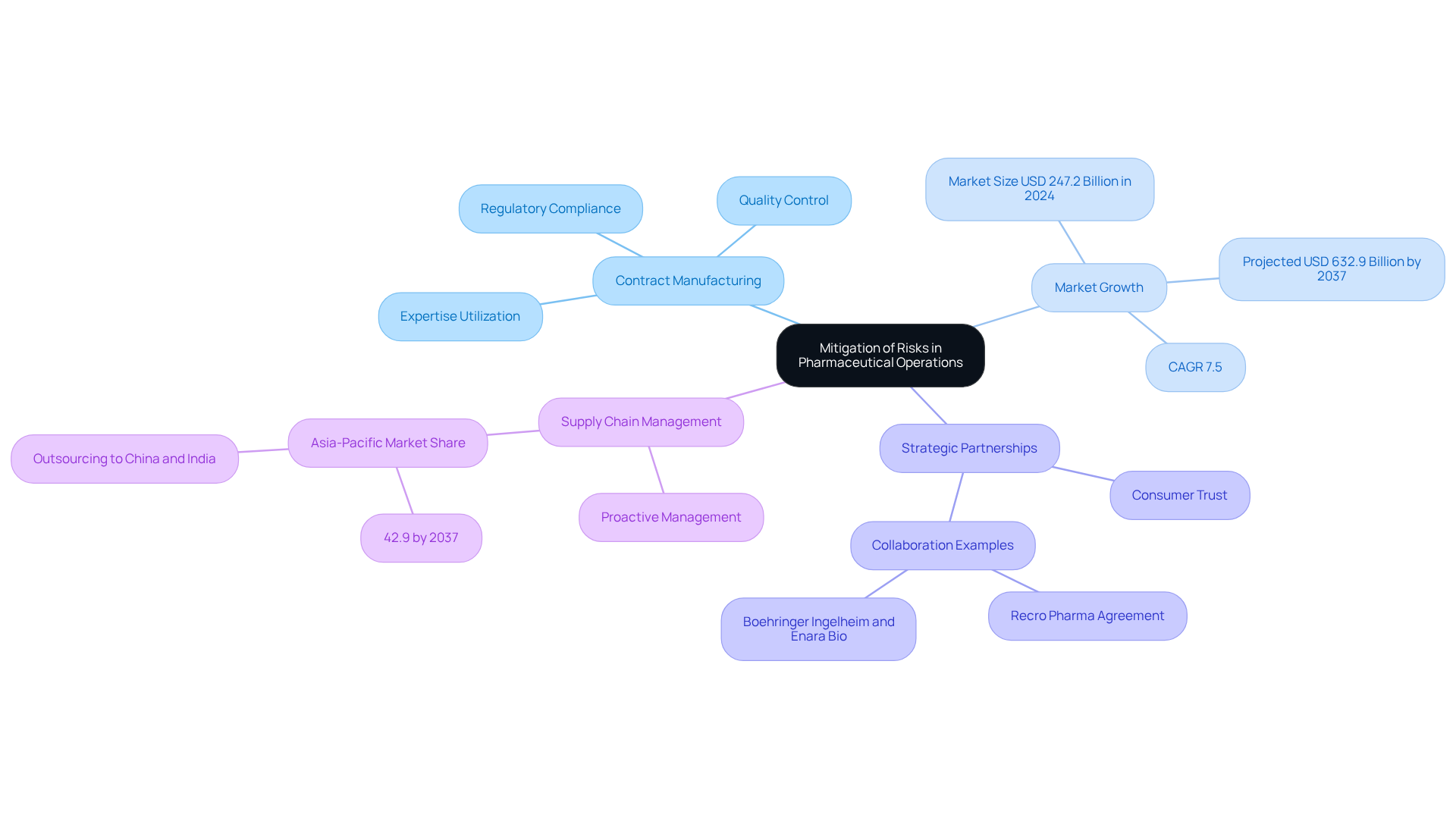

Mitigation of Risks: Safeguarding Pharmaceutical Operations

Contract manufacturing pharma is essential for mitigating risks associated with dietary supplement production, particularly amidst supply chain disruptions, quality control issues, and regulatory compliance challenges. By collaborating with experienced producers, health supplement firms can harness their expertise and established procedures, effectively navigating potential obstacles. This strategic partnership not only protects production operations but also cultivates consumer trust and brand loyalty.

The market for contract manufacturing pharma and research services, valued at USD 247.2 billion in 2024, is anticipated to grow at a compound annual growth rate (CAGR) exceeding 7.5%, reaching USD 632.9 billion by 2037. This growth underscores the increasing reliance on contract manufacturing pharma to ensure operational stability, especially for supplement firms striving to enhance their production resilience. For instance, Recro Pharma's recent agreement for formulation development and cGMP manufacturing highlights the ongoing necessity for development organizations to tackle complex formulation challenges, illustrating how such collaborations can bolster production resilience for health supplement companies.

Furthermore, industry leaders stress the significance of proactive supply chain management within contract manufacturing pharma. With the Asia-Pacific region projected to capture over 42.9% of the market share by 2037, driven by outsourcing to countries like China and India, companies are increasingly forging partnerships with manufacturers to optimize their operations. This trend not only meets immediate production demands but also equips businesses to adapt to future challenges, ensuring a robust supply chain capable of withstanding disruptions. Insights from industry leaders regarding the management of supply chain disruptions in the health supplement sector further highlight the critical nature of these collaborations.

Access to New Markets: Expanding Pharmaceutical Reach

Partnering with contract manufacturing pharma offers nutraceutical firms a strategic pathway to penetrate new markets. These producers typically possess well-established distribution systems and extensive industry knowledge, significantly easing entry into regions where businesses may lack a robust presence. This expanded access not only broadens audience reach but also enhances brand visibility and creates potential sales opportunities.

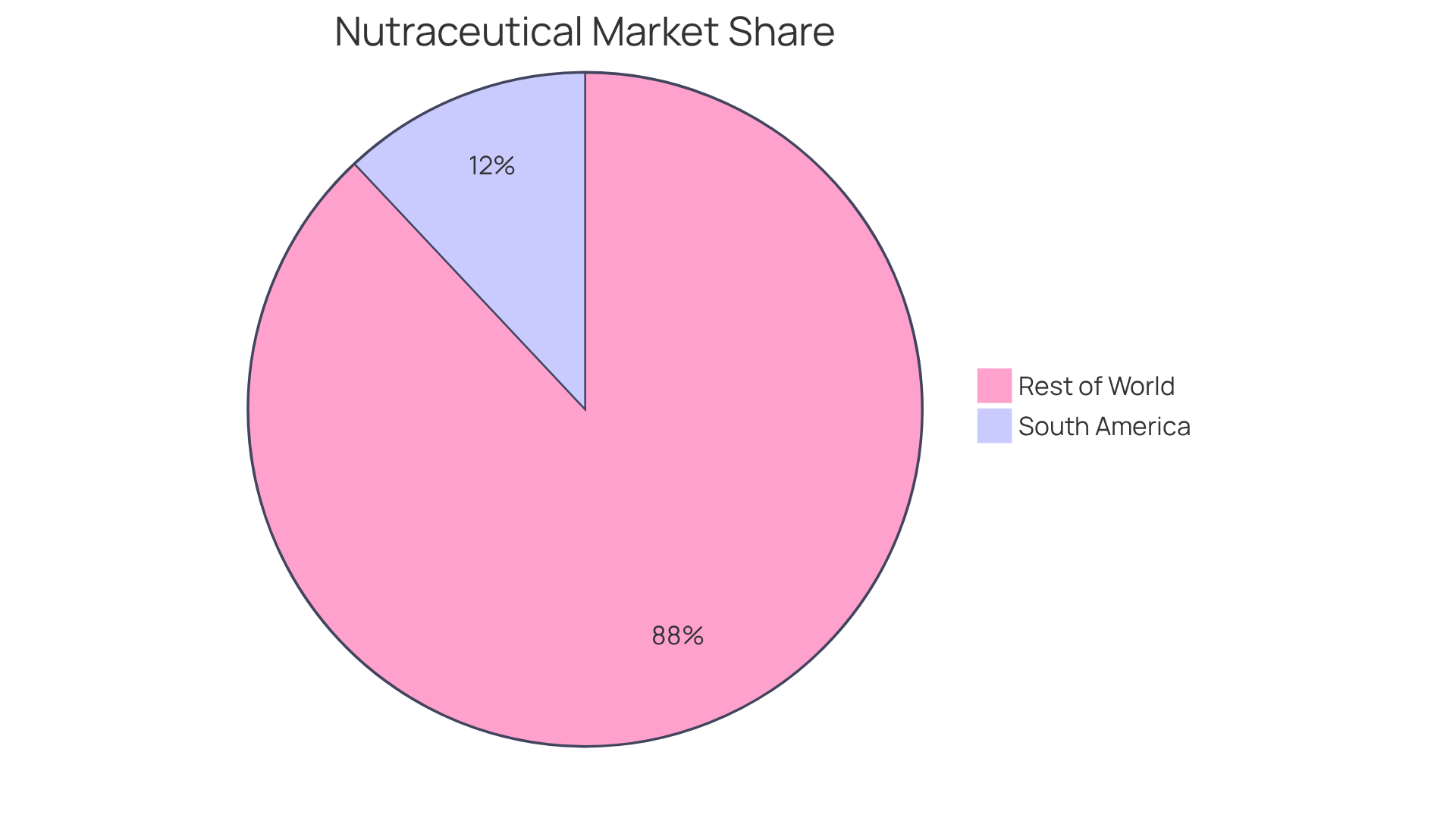

For instance, companies like Sabinsa Corporation have adeptly leveraged contract manufacturing to establish a foothold in developing areas, illustrating the effectiveness of this strategy. Notably, the South American region accounts for approximately 12% of the global turnover in the nutraceuticals sector, highlighting its growth potential.

Moreover, the global nutraceutical market, valued at around USD 458.55 billion in 2024, is anticipated to grow to USD 986.85 billion by 2032, reflecting a CAGR of 10.18%. According to industry analysts, "The rising demand for nutraceuticals to prevent lifestyle-related health issues is the key factor propelling the growth of the sector."

This expansion underscores the vital role that contract manufacturing pharma plays in enabling businesses to capitalize on evolving market demands. By utilizing established distribution channels, health supplement companies can more effectively navigate regulatory complexities and consumer preferences, ultimately driving sales and fostering brand loyalty.

Strategic Advantages: Maximizing the Value of Contract Manufacturing

Contract manufacturing pharma presents a multitude of strategic advantages for health supplement firms, including significant cost reductions, enhanced operational efficiencies, and superior product quality. By outsourcing production through contract manufacturing pharma, companies can concentrate on their core competencies—such as marketing and product innovation—while leveraging the specialized expertise of manufacturers. This collaboration not only adds value but also positions organizations for sustained success in the increasingly competitive health product landscape.

The global nutraceutical manufacturing services sector is projected to grow from USD 182.47 billion in 2024 to USD 414.4 billion by 2034, reflecting a robust CAGR of 10.4%. This growth underscores the rising trend among businesses to engage in contract manufacturing pharma agreements to fulfill consumer demand for dietary supplements and functional foods.

Industry leaders are acutely aware of the significance of this strategy. As the sector evolves, companies that adeptly engage in contract manufacturing pharma can enhance operational efficiencies, streamline supply chains, and ensure compliance with stringent regulations. For instance, NutraLab, a prominent player in the dietary supplement market, has successfully utilized manufacturing agreements to maintain high quality standards while expanding its product offerings, demonstrating both adherence and cost-effectiveness.

Moreover, the integration of advanced technologies, such as manufacturing execution systems (MES) and enterprise resource planning (ERP) systems, into contract manufacturing pharma processes fosters greater flexibility and responsiveness to shifts in demand, further boosting operational efficiencies. By adopting these outsourcing strategies, nutraceutical companies can not only elevate their market presence but also respond adeptly to the evolving needs of health-conscious consumers. However, they must remain vigilant regarding potential challenges, including capacity constraints stemming from outdated technology and rigorous quality assurance protocols that may impede production speeds.

Conclusion

Contract manufacturing in the pharmaceutical sector represents a transformative strategy for nutraceutical companies, enabling them to streamline operations while enhancing product quality and market responsiveness. By outsourcing production, firms can concentrate on their core strengths, such as innovation and marketing, while leveraging the specialized capabilities of experienced manufacturers. This strategic collaboration not only reduces operational costs but also empowers businesses to adapt swiftly to market demands, ensuring they remain competitive in a rapidly evolving landscape.

Key benefits of contract manufacturing are evident, including:

- Reduced capital expenditures

- Lower operational costs

- Access to advanced technology and compliance expertise

The ability to quickly adapt to market changes, mitigate risks, and accelerate time-to-market for new products further underscores the strategic advantages of this approach. As the demand for nutraceuticals continues to rise, the importance of leveraging contract manufacturing becomes increasingly clear, positioning firms for sustained growth and success.

Embracing contract manufacturing is not merely a business decision; it is a strategic imperative for nutraceutical companies aiming to thrive in a competitive market. By capitalizing on the benefits of outsourcing, businesses can enhance operational efficiencies, ensure regulatory compliance, and expand their reach into new markets. As the industry evolves, those who strategically engage in contract manufacturing will be better equipped to meet consumer demands and drive innovation, solidifying their place in the future of health products.

Frequently Asked Questions

What services does Western Packaging provide to enhance supply chain efficiency?

Western Packaging integrates packaging design, filling services, and third-party logistics (3PL) to significantly enhance supply chain efficiency, particularly for nutraceuticals.

How does the integrated approach of Western Packaging benefit businesses?

The integrated approach allows businesses to reduce lead times, improve product delivery, and swiftly adapt to market demands, while simplifying operations and providing tailored solutions.

What printing technology is mentioned as beneficial for quicker turnarounds?

Hybrid flexo printing is mentioned as a technology that reduces setup times and allows for faster job switching, contributing to quicker turnarounds without compromising quality.

Why should dietary supplement warehouses implement warehouse management software?

Implementing warehouse management software enables real-time inventory traceability, ensures compliance with FDA regulations, and optimizes fulfillment processes.

What is the impact of rising online orders in North America on integrated packaging solutions?

The rise of online orders by 80% in North America increases the urgency for integrated packaging and logistics solutions to meet consumer demands effectively.

How does contract manufacturing help dietary supplement firms reduce capital expenditure?

Contract manufacturing allows firms to outsource production processes, avoiding the substantial costs of establishing and maintaining manufacturing facilities, thus enabling them to focus on marketing and product development.

What financial benefits do businesses gain from outsourcing production through contract manufacturing?

Outsourcing reduces expenses, boosts productivity, and allows firms to invest in innovation and growth, enhancing competitiveness in the dietary supplement sector.

What operational advantages do nutraceutical firms achieve by utilizing contract manufacturing?

Contract manufacturing helps streamline production processes, leading to lower operational costs, reduced labor expenses, minimized waste, and optimized resource allocation.

What are some potential downsides of contract manufacturing for businesses?

Businesses may experience a loss of complete control over the production process, impacting their ability to influence decisions regarding raw materials and manufacturing techniques.

How do manufacturing agreements impact customer acquisition costs and profitability?

Manufacturing agreements can lead to low customer acquisition costs, such as $70, alongside a lifetime value of $400, indicating potential profitability through improved production workflows and customer satisfaction.

What factors should businesses consider when managing relationships with manufacturers?

Businesses should consider the overhead costs associated with managing these relationships and the geographical location of manufacturers, which can influence lead times and shipping costs.