Overview

The article delineates ten significant benefits of contract pharmaceutical manufacturing for nutraceuticals, highlighting key advantages such as:

- Cost efficiency

- Flexibility

- Access to advanced technologies

- Effective risk mitigation

These advantages empower nutraceutical companies to enhance product quality, swiftly respond to market demands, and concentrate on their core competencies. Ultimately, this strategic approach leads to improved operational efficiency and heightened competitiveness in a rapidly expanding market.

Introduction

The nutraceutical industry is witnessing remarkable growth, propelled by an increasing consumer appetite for health and wellness products. As companies endeavor to navigate this dynamic market, the strategic benefits of contract pharma manufacturing emerge as transformative. This article explores ten compelling advantages of outsourcing production, ranging from cost efficiency and regulatory compliance to enhanced flexibility and access to cutting-edge technologies. Yet, a critical question persists: can companies genuinely seize these opportunities without sacrificing quality or speed? A thorough examination of these benefits not only uncovers the potential for growth but also highlights the challenges that must be addressed in this competitive landscape.

Western Packaging: Integrated Packaging Solutions for Nutraceuticals

Western Packaging presents a distinctive integrated approach to packaging solutions, meticulously designed for the nutraceutical industry. By merging expert packaging design, advanced filling services, and robust third-party logistics (3PL), Western Packaging effectively simplifies the supply chain for its clients.

Our filling procedure seamlessly integrates into our comprehensive solutions, accommodating a diverse range of items from powders to gummies and soft-gels. This all-encompassing service not only enhances item appeal and shelf recognition but also streamlines distribution processes. Consequently, businesses can concentrate on their core competencies while relying on high-quality packaging and timely delivery.

Regulatory Compliance: Ensuring Safety and Quality Standards

Contract pharma manufacturing for nutraceuticals demands unwavering adherence to regulatory compliance. Manufacturers are required to meet rigorous safety and quality standards established by regulatory bodies, such as the FDA. By collaborating with experienced contract pharma manufacturing partners, health supplement brands can ensure that their products comply with all necessary regulations, thereby safeguarding consumer health and enhancing brand credibility. This commitment to compliance not only protects consumers but also reduces the risks associated with product recalls and legal liabilities.

Cost Efficiency: Reducing Production Expenses Through Outsourcing

One of the most significant benefits of contract pharma manufacturing is its cost efficiency. By outsourcing manufacturing, nutraceutical companies can avoid the substantial capital investment required for in-house facilities and equipment. Contract manufacturers frequently attain economies of scale, resulting in reduced expenses per unit. This cost reduction not only allows brands to allocate resources more effectively but also enables them to focus on marketing and product development rather than operational overhead. Ultimately, leveraging contract pharma manufacturing is a strategic move that enhances overall business performance.

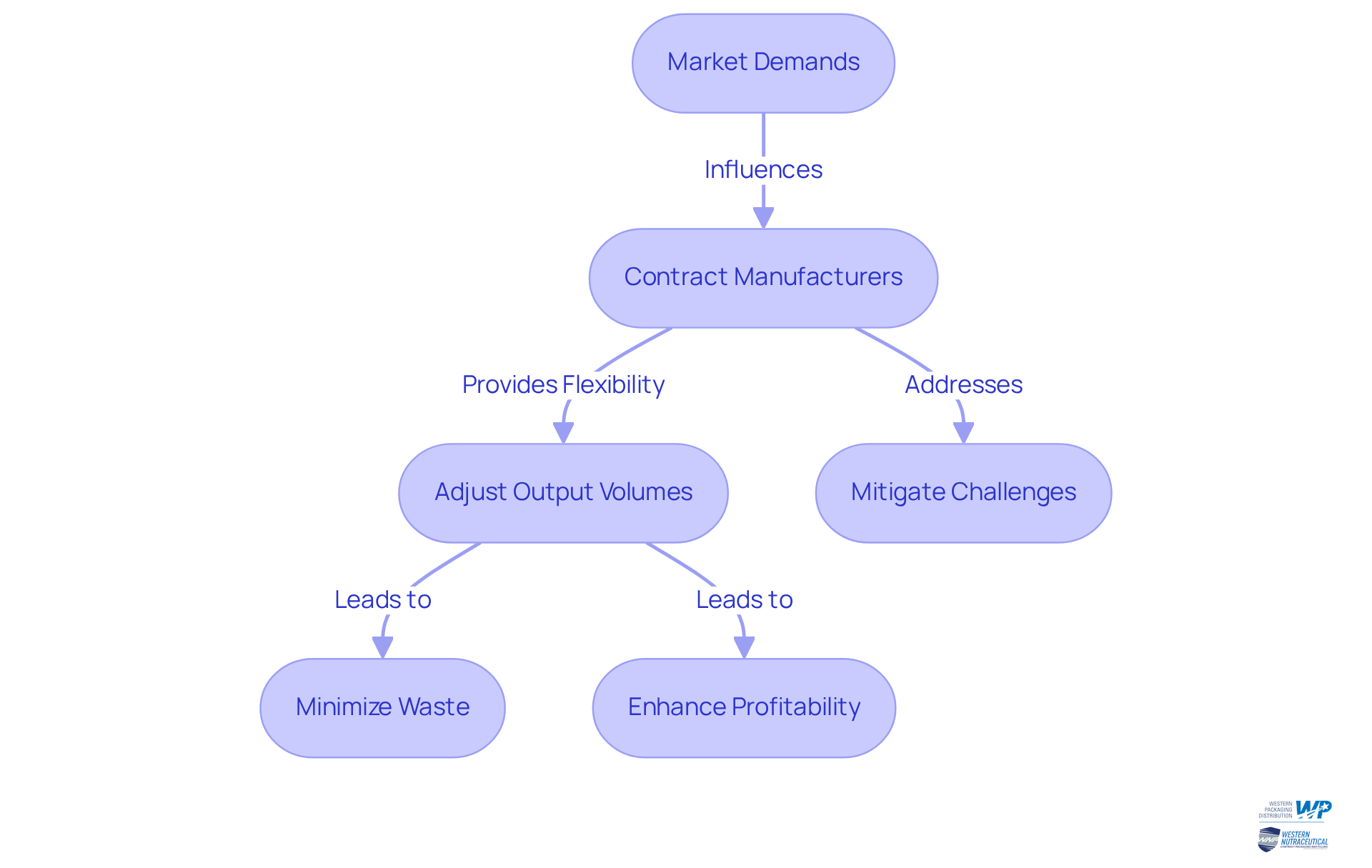

Flexibility: Adapting Production to Market Demands

Contract manufacturers play a pivotal role in providing the essential flexibility required to adjust output volumes in response to market demands. This adaptability is particularly vital in the dietary supplement industry, where consumer preferences can change rapidly. By harnessing the capabilities of contract manufacturers, brands can effectively modify output levels, mitigating the challenges associated with excess inventory or underutilized facilities. This responsiveness not only meets consumer needs but also significantly minimizes waste and enhances profitability.

Industry leaders underscore the significance of this flexibility. For example, Sabyasachi Ghosh points out that the nutraceutical contract manufacturing services market is projected to expand from USD 187.6 billion in 2025 to USD 585.2 billion by 2035, reflecting the surging demand for dietary supplements and functional foods. This growth highlights the necessity for manufacturers to swiftly adapt to fluctuating market conditions. Furthermore, Ghosh indicates that the dietary supplements segment is anticipated to account for 55.6% of total revenue by 2025, further illustrating the importance of this segment within the broader market context.

Numerous examples exist within the sector: companies such as NutraScience have enhanced their facilities to bolster manufacturing capabilities, ensuring they can meet the growing consumer interest in health and wellness products. In June 2024, NutraScience announced a 56,000 square foot expansion of its manufacturing facility, underscoring their commitment to responding to market demands. Similarly, collaborations like that between Nature’s Sunshine Products and Nutraceutical Sciences Institute exemplify how companies are leveraging contract manufacturing to innovate and effectively respond to market trends.

In a landscape where consumer emphasis on preventive healthcare is intensifying, the ability to modify manufacturing processes is not merely advantageous; it is essential for maintaining competitiveness and enhancing market presence.

Access to Advanced Technologies: Enhancing Product Quality

Partnering with contract pharma manufacturing allows nutraceutical brands to access advanced technologies that may not be feasible to implement in-house. These technologies include:

- Cutting-edge manufacturing equipment

- Quality control systems

- Innovative formulation techniques

Western Packaging's filling process seamlessly integrates into these solutions, delivering comprehensive services that streamline production from powders to gummies, soft-gels, and kitting. By leveraging these resources, brands can enhance quality, ensure consistency, and innovate more effectively. This technological advantage results in enhanced offerings that meet consumer expectations and set brands apart in a competitive market.

Studies show that companies utilizing contract pharma manufacturing often experience a significant increase in quality, with some reporting:

- Up to a 90% reduction in data entry errors

- Improved operational efficiencies

Furthermore, optimizing the supply chain with Western Packaging's 3PL services—encompassing warehousing, inventory management, and logistics—allows companies to focus on their core competencies. As the health supplement market evolves, projected to exceed $290 billion by 2033, companies that embrace these technological innovations are positioned for success and can better meet the rising demand for high-quality offerings. Additionally, a robust quality management plan is essential for contract pharma manufacturing to maintain quality standards.

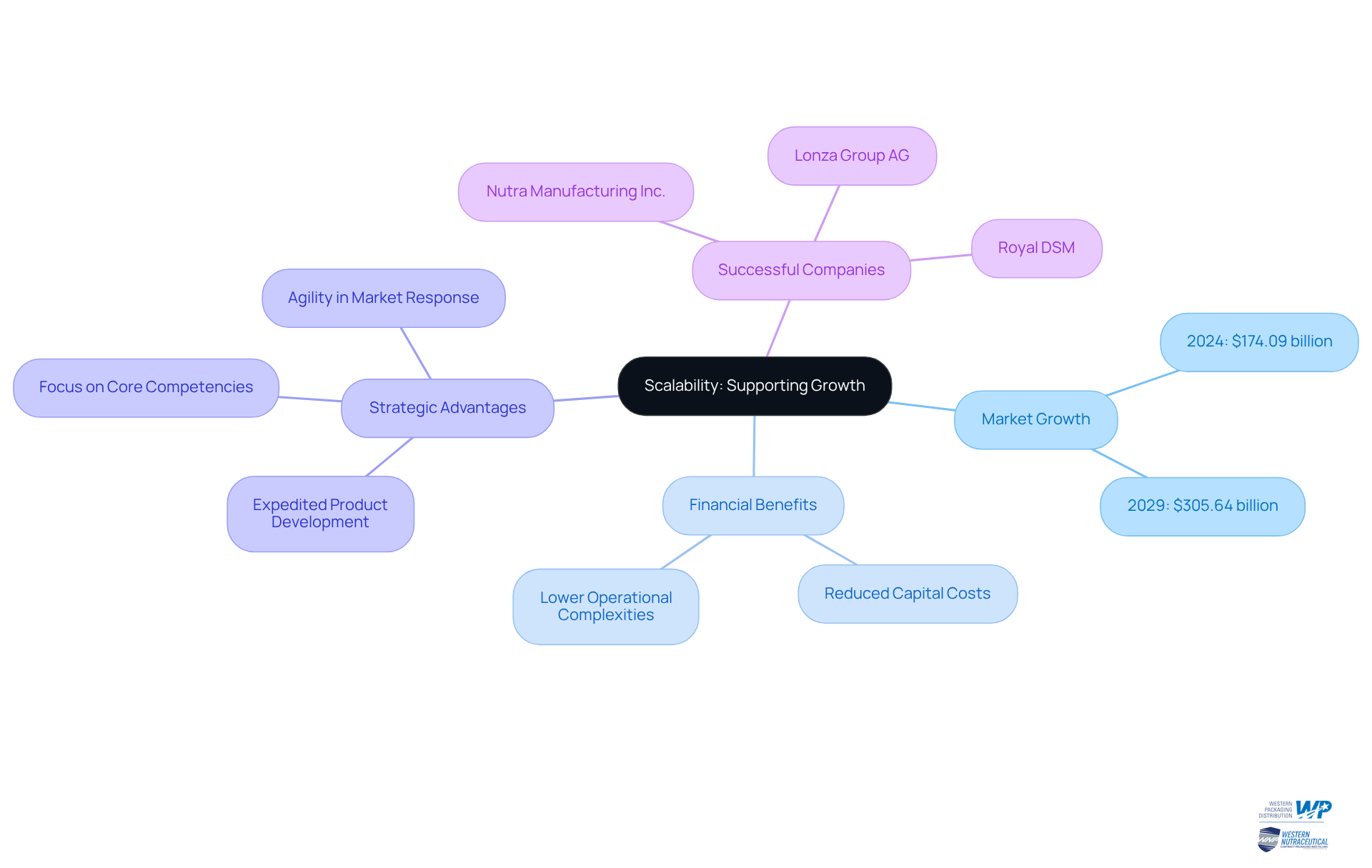

Scalability: Supporting Growth Without Infrastructure Investment

Contract pharma manufacturing offers a scalable solution that enables dietary supplement companies to grow without the burden of substantial infrastructure investments. With the increasing consumer demand for nutraceutical products, the market for contract pharma manufacturing services in the nutraceutical sector is anticipated to surge from $174.09 billion in 2024 to $305.64 billion by 2029, reflecting a compound annual growth rate (CAGR) of 11.9%. This growth indicates a robust opportunity for companies to effectively enhance their output by leveraging the established capabilities of contract pharma manufacturing.

Not only does this approach mitigate financial risks associated with in-house production—such as elevated capital costs and operational complexities—but it also allows companies to swiftly capitalize on emerging market opportunities through contract pharma manufacturing.

Industry analyst Abdul Wasay notes that "nutraceutical contract manufacturing provides nutraceutical companies with expedited product development and timelines for high-quality, customized nutraceutical products that can aid in managing and preventing chronic diseases."

By outsourcing production through contract pharma manufacturing, companies can focus on strengthening their market presence and fostering innovation, while their manufacturing partners handle the intricacies of production. This strategic collaboration is vital for companies striving to excel in a competitive environment, as it enables them to allocate resources more efficiently and respond to consumer trends with agility.

Noteworthy examples of dietary supplement companies that have successfully harnessed contract manufacturing to grow without substantial infrastructure expenditures further illustrate this trend.

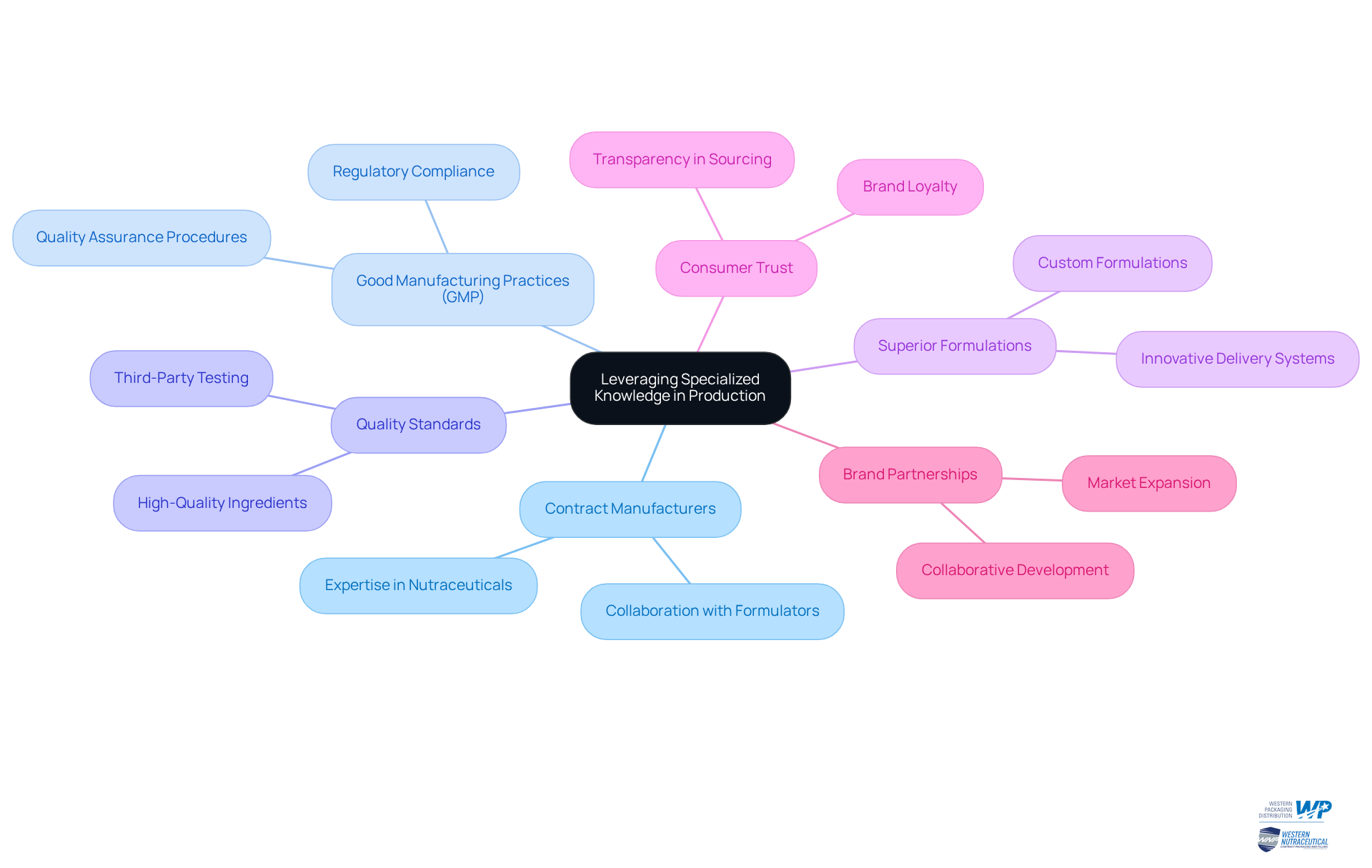

Expertise: Leveraging Specialized Knowledge in Production

Contract manufacturers offer invaluable specialized knowledge and expertise to the production process, particularly for nutraceutical companies. These manufacturers are typically well-versed in Good Manufacturing Practices (GMP) and possess extensive experience in formulating and producing dietary supplements. By leveraging this expertise, brands can ensure their offerings not only comply with regulations but also meet high-quality standards. Such specialized knowledge can lead to superior formulations, enhanced efficacy, and increased consumer trust. Therefore, partnering with a reputable contract pharma manufacturing company is essential for brands aiming to excel in the competitive nutraceutical market.

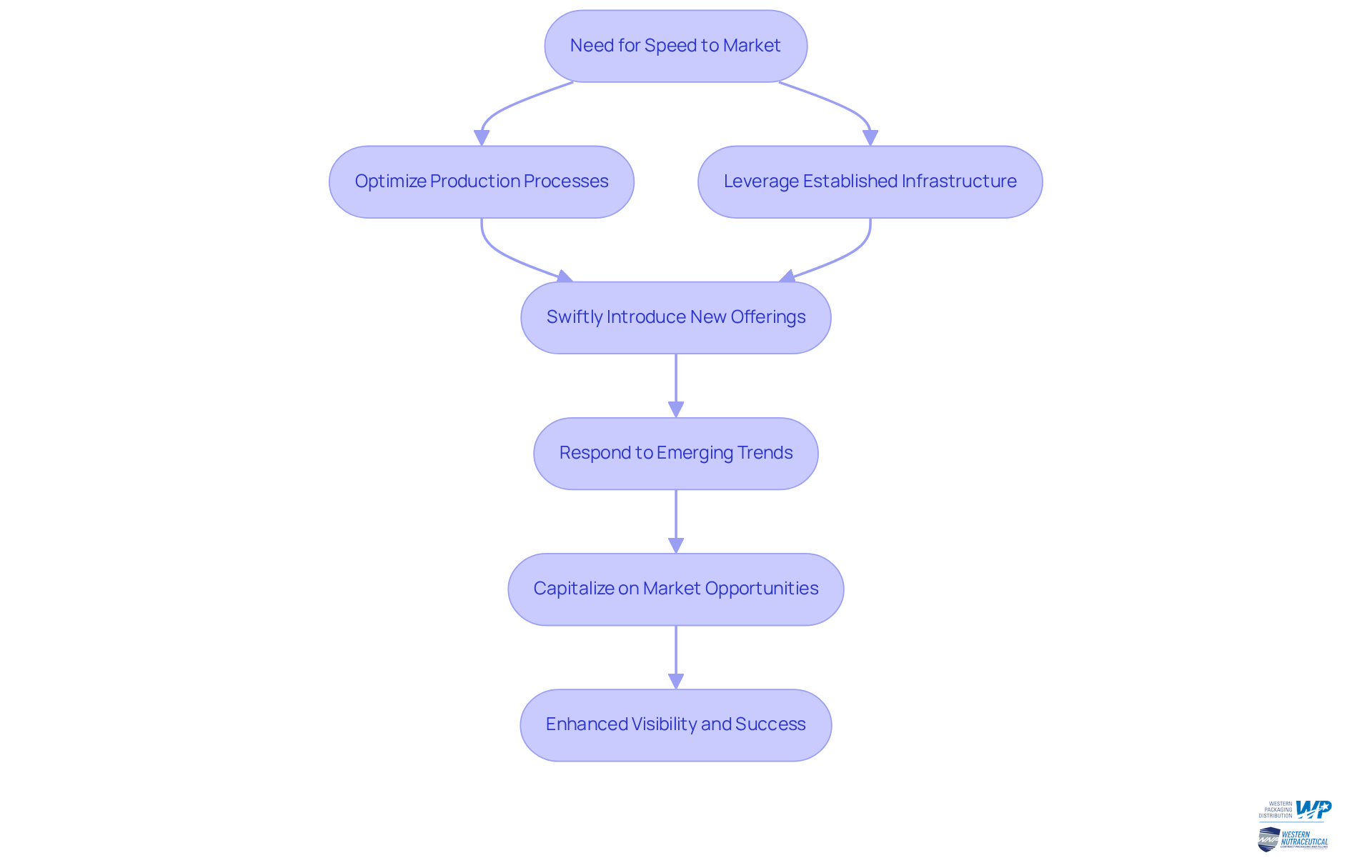

Speed to Market: Accelerating Product Launches

In the fast-paced nutraceutical market, speed to market is essential for maintaining a competitive edge. Contract pharma manufacturing plays a crucial role in accelerating product launches by optimizing production processes and leveraging established infrastructure. This efficiency empowers brands to swiftly introduce new offerings, respond to emerging trends, and capitalize on market opportunities. By minimizing the time required to bring products to market, companies not only enhance their visibility but also significantly increase their chances of success.

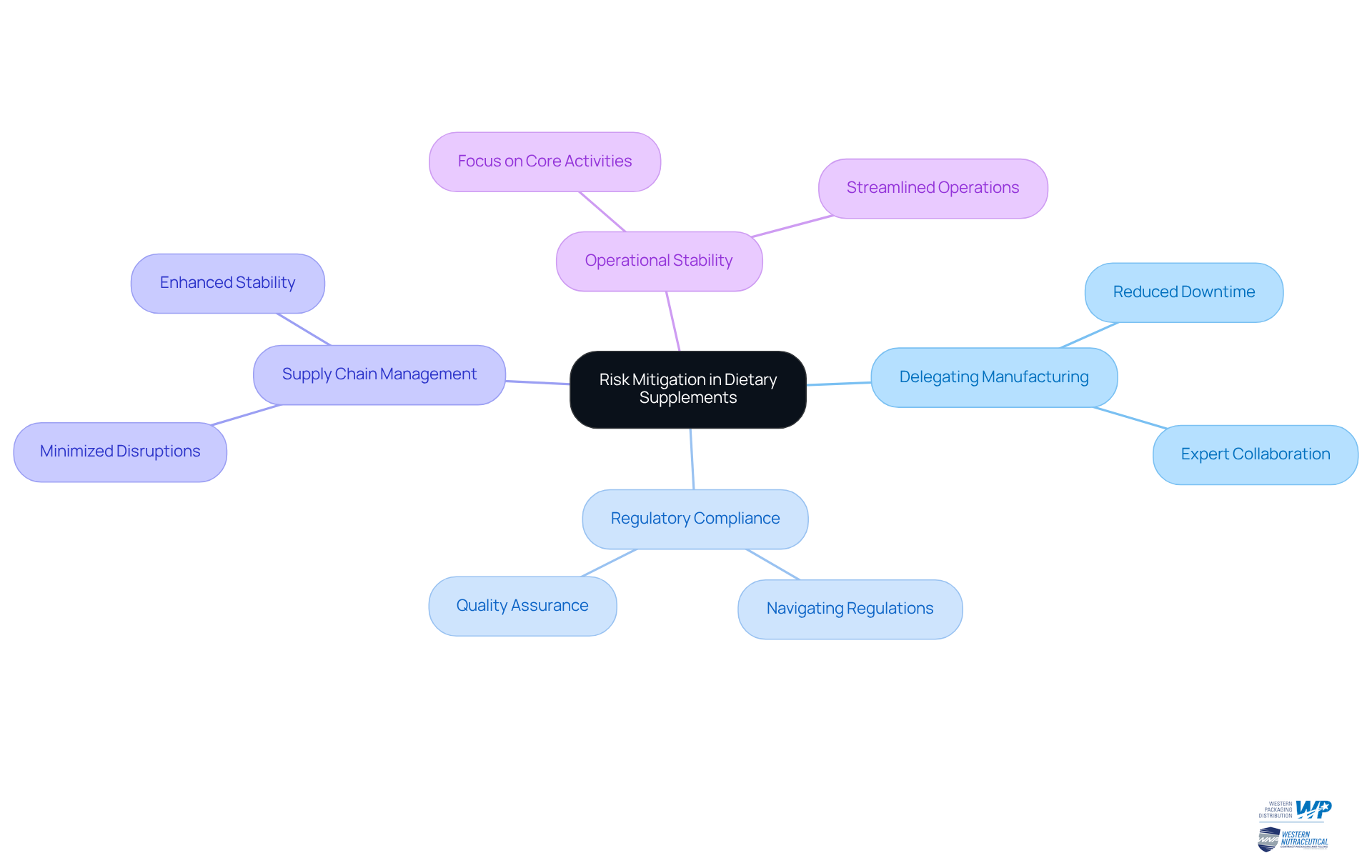

Risk Mitigation: Reducing Production Uncertainties

Delegating manufacturing to expert collaborators significantly mitigates various risks associated with operations in the dietary supplement industry. By leveraging the expertise of established contract pharma manufacturing partners, companies can effectively navigate regulatory compliance, minimize manufacturing downtime, and alleviate supply chain disruptions. This strategic partnership not only reduces uncertainties but also enhances operational stability, allowing health supplement companies to concentrate on their core business activities.

For instance, organizations that have embraced contract pharma manufacturing, such as those partnering with Akums Drugs and Pharmaceuticals Ltd., have reported a marked decrease in manufacturing uncertainties, leading to more streamlined operations and improved quality. Industry insights reveal that approximately 85% of failures to meet customer expectations arise from deficiencies in systems and processes, emphasizing the vital importance of effective risk management.

As supply chain expert Martin Christopher aptly stated, 'The real competition is between supply chains, not companies,' highlighting the necessity for health supplement companies to adopt innovative strategies that prioritize outsourcing as a means to optimize production and ensure compliance. Furthermore, Yossi Sheffi noted, 'Products can be easily copied. But a supply chain can provide a true competitive advantage.'

By pursuing these strategies, companies can not only boost their operational efficiency but also position themselves advantageously in a competitive market.

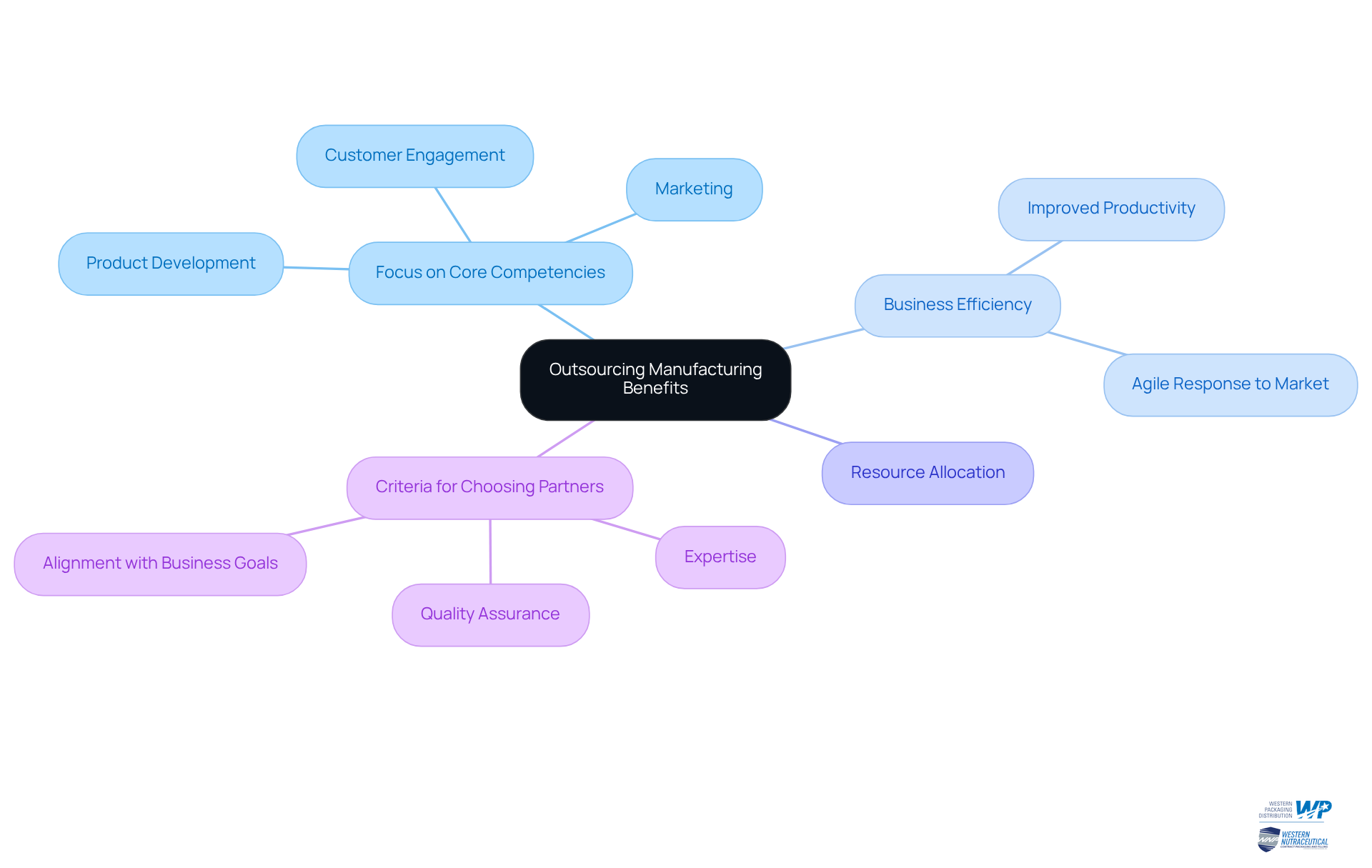

Focus on Core Competencies: Enhancing Business Efficiency

Outsourcing manufacturing to contract pharma manufacturing empowers nutraceutical companies to concentrate on their core strengths, such as product development, marketing, and customer engagement. This strategic emphasis not only enhances overall business efficiency but also enables companies to allocate resources more effectively, thereby fostering innovation.

Industry insights reveal that the global outsourcing market was valued at approximately US$620.381 billion in 2020 and is projected to reach US$904.948 billion by 2027, growing at a CAGR of 5.54%. By choosing to contract pharma manufacturing to specialized partners, brands can focus their efforts on strengthening their market presence and delivering exceptional value to customers.

As Jagdev Singh articulates, "A primary benefit of manufacturing outsourcing production is that it enables businesses to focus on their core skills." Companies that embrace this approach frequently report improved productivity and a more agile response to market demands, ultimately leading to a stronger competitive edge in the nutraceutical sector.

To initiate the outsourcing process, brands should assess potential partners based on their:

- Expertise

- Quality assurance processes

- Alignment with business goals

Conclusion

The advantages of contract pharmaceutical manufacturing for nutraceuticals are numerous and impactful, offering businesses a strategic pathway to enhance their operations and market presence. By leveraging expert manufacturing partners, nutraceutical companies can effectively navigate the complexities of production, compliance, and market demands, ultimately allowing them to focus on their core competencies and innovation.

Key insights from the article highlight how contract manufacturing not only ensures regulatory compliance and cost efficiency but also provides flexibility, access to advanced technologies, and scalability. This model empowers companies to adapt swiftly to changing market conditions, accelerate product launches, and mitigate risks associated with in-house production. Furthermore, the emphasis on specialized knowledge and expertise enhances product quality and consumer trust, positioning brands for success in a competitive landscape.

As the nutraceutical market continues to evolve, embracing contract manufacturing emerges as a vital strategy for companies aiming to thrive. By prioritizing partnerships that enhance operational efficiency and innovation, businesses can better meet consumer demands and capitalize on emerging opportunities. The time to explore the transformative potential of contract pharma manufacturing is now, as it holds the key to unlocking growth and ensuring long-term success in the nutraceutical industry.

Frequently Asked Questions

What is Western Packaging's approach to packaging solutions for nutraceuticals?

Western Packaging offers an integrated approach that combines expert packaging design, advanced filling services, and robust third-party logistics (3PL) to simplify the supply chain for clients in the nutraceutical industry.

What types of products can Western Packaging accommodate in its filling services?

Western Packaging's filling services can accommodate a diverse range of items, including powders, gummies, and soft-gels.

How does Western Packaging enhance product appeal and distribution?

The comprehensive services provided by Western Packaging enhance item appeal and shelf recognition while streamlining distribution processes, allowing businesses to focus on their core competencies.

Why is regulatory compliance important in contract pharma manufacturing for nutraceuticals?

Regulatory compliance is crucial as it ensures that manufacturers meet safety and quality standards set by regulatory bodies like the FDA, protecting consumer health and enhancing brand credibility.

How can health supplement brands ensure compliance with regulations?

By collaborating with experienced contract pharma manufacturing partners, health supplement brands can ensure that their products comply with necessary regulations, reducing risks associated with product recalls and legal liabilities.

What are the cost benefits of contract pharma manufacturing for nutraceutical companies?

Contract pharma manufacturing offers cost efficiency by allowing nutraceutical companies to avoid significant capital investments in in-house facilities and equipment, while also benefiting from economies of scale that reduce expenses per unit.

How does outsourcing manufacturing affect resource allocation for nutraceutical brands?

By outsourcing manufacturing, nutraceutical brands can allocate resources more effectively, focusing on marketing and product development instead of operational overhead, which enhances overall business performance.