Overview

The article delineates ten significant benefits of kitting in pharmaceuticals specifically for nutraceutical manufacturers, asserting that this strategy not only enhances operational efficiency but also reduces costs and elevates customer satisfaction. It elaborates on various advantages, including:

- Expedited production times

- Enhanced inventory management

- Sustainability initiatives

All of these collectively contribute to a competitive edge in an ever-evolving market landscape.

Introduction

Kitting in the pharmaceutical sector is revolutionizing how nutraceutical manufacturers optimize their operations and enhance product delivery. By integrating various components into cohesive packages, companies can significantly reduce labor costs, improve inventory management, and ensure consistent quality—all while boosting customer satisfaction. Yet, as the industry evolves, the pressing question arises: how can businesses effectively leverage kitting to not only meet current demands but also anticipate future market shifts? This article delves into ten compelling benefits of kitting in pharmaceuticals, uncovering strategies that can provide manufacturers with a competitive edge in an ever-changing marketplace.

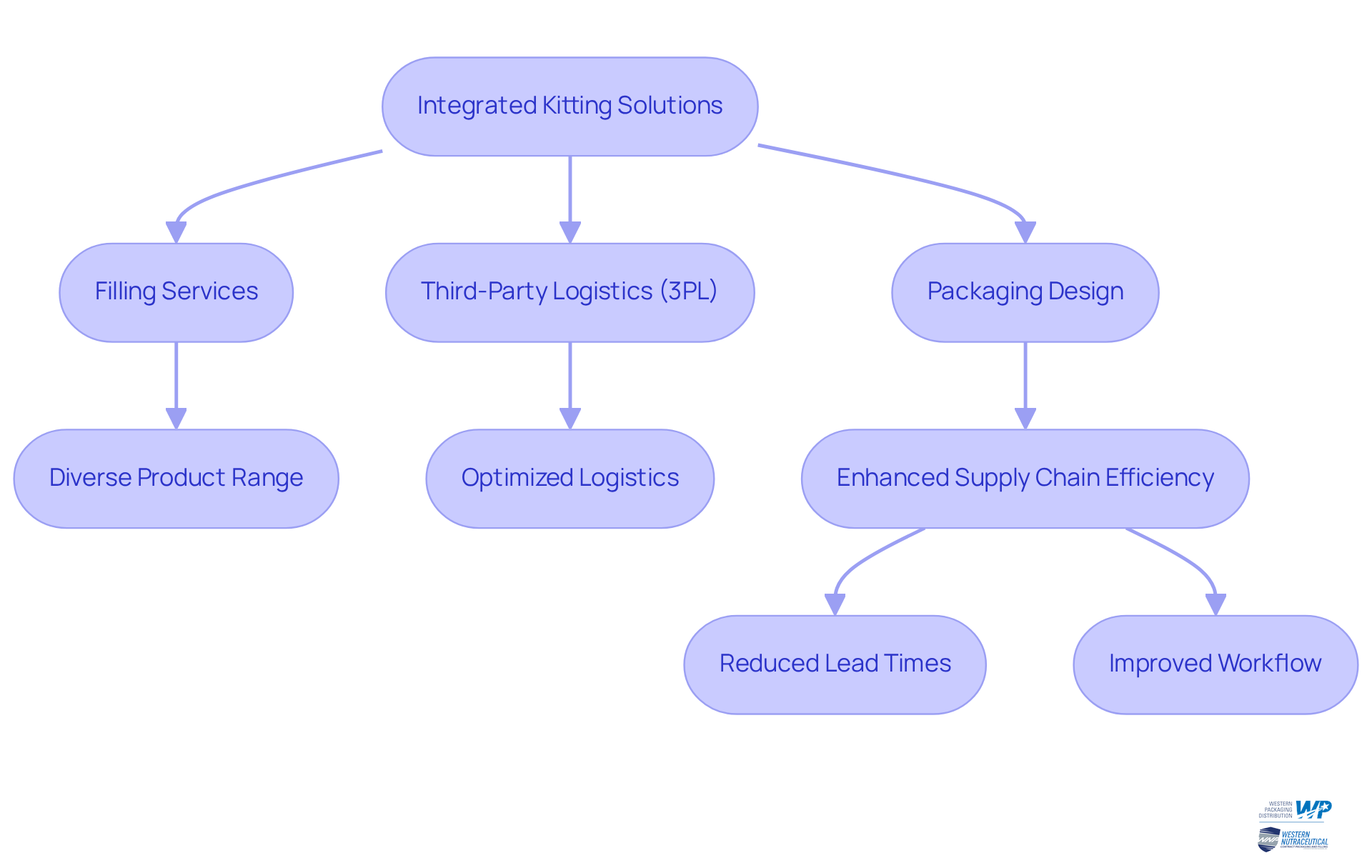

Western Packaging: Integrated Kitting Solutions for Enhanced Supply Chain Efficiency

Western Packaging delivers integrated solutions for kitting pharmaceuticals that seamlessly combine packaging design, filling services, and third-party logistics (3PL). Our innovative filling method accommodates a diverse range of products, from powders to gummies and soft-gels, ensuring meticulous preparation and packaging of all components. This comprehensive approach significantly enhances supply chain efficiency by streamlining production processes and optimizing logistics. Consequently, lead times are reduced, and overall workflow is improved.

For instance, companies employing automated packaging solutions have reported a remarkable decrease in assembly time from hours to mere minutes, while also cutting labor needs for picking by up to 50%. This allows dietary supplement producers to concentrate on their core competencies, leveraging an optimized supply chain process that not only elevates operational efficiency but also enhances product presentation and customer satisfaction.

By embracing kitting pharmaceuticals, businesses can secure a competitive advantage, as demonstrated by industry leaders who underscore the significance of cohesive packaging and logistics strategies in maximizing supply chain performance.

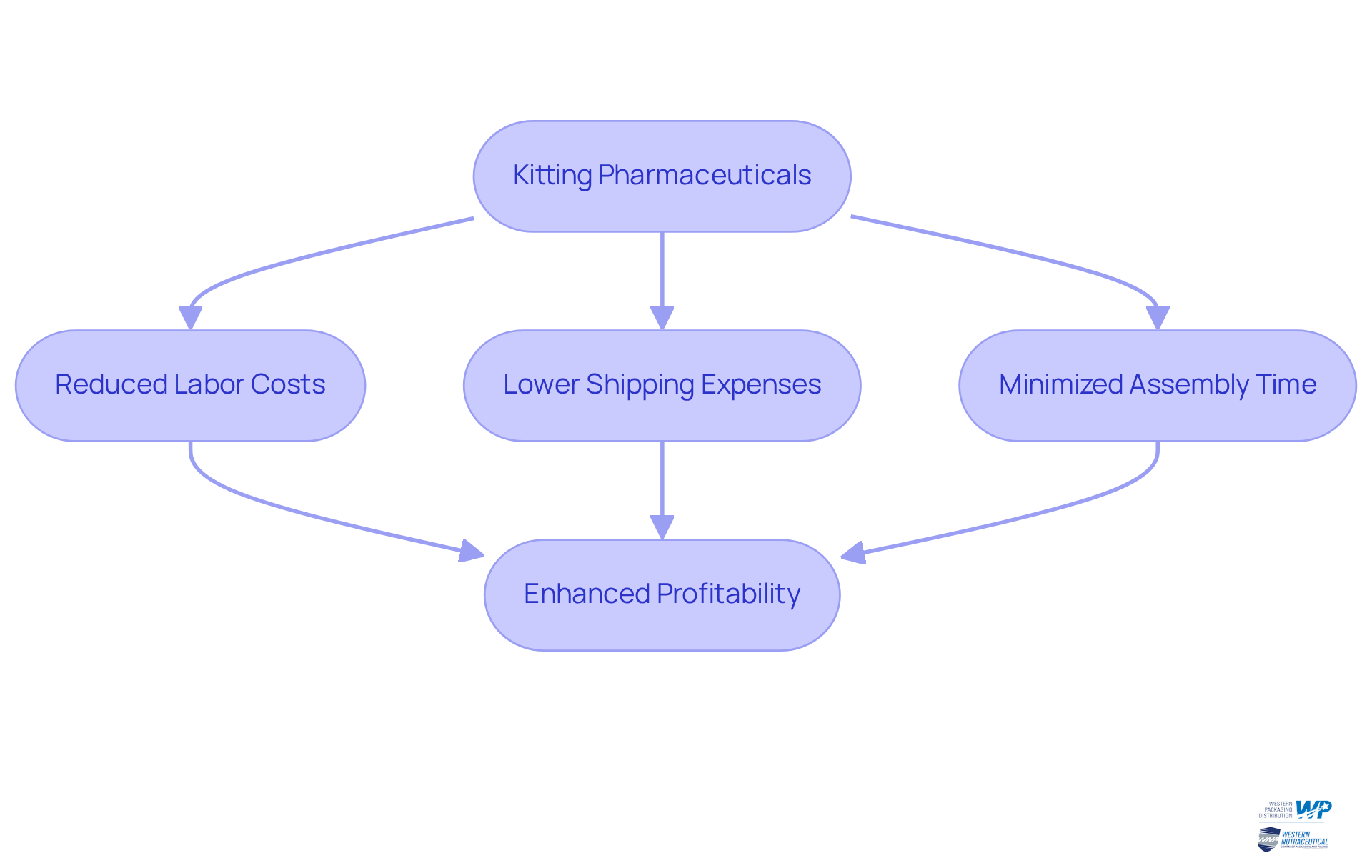

Cost Reduction: Lower Labor and Shipping Expenses Through Kitting

Kitting pharmaceuticals is a powerful strategy that significantly reduces labor and shipping expenses by consolidating multiple items into a single package. This approach not only minimizes assembly time but also lowers shipping costs by decreasing the number of packages dispatched. For producers of health-related products, efficiencies achieved through kitting pharmaceuticals translate into substantial savings, enabling them to allocate resources more effectively and enhance their profitability. By adopting kitting pharmaceuticals, businesses can streamline their operations and enhance overall logistics performance.

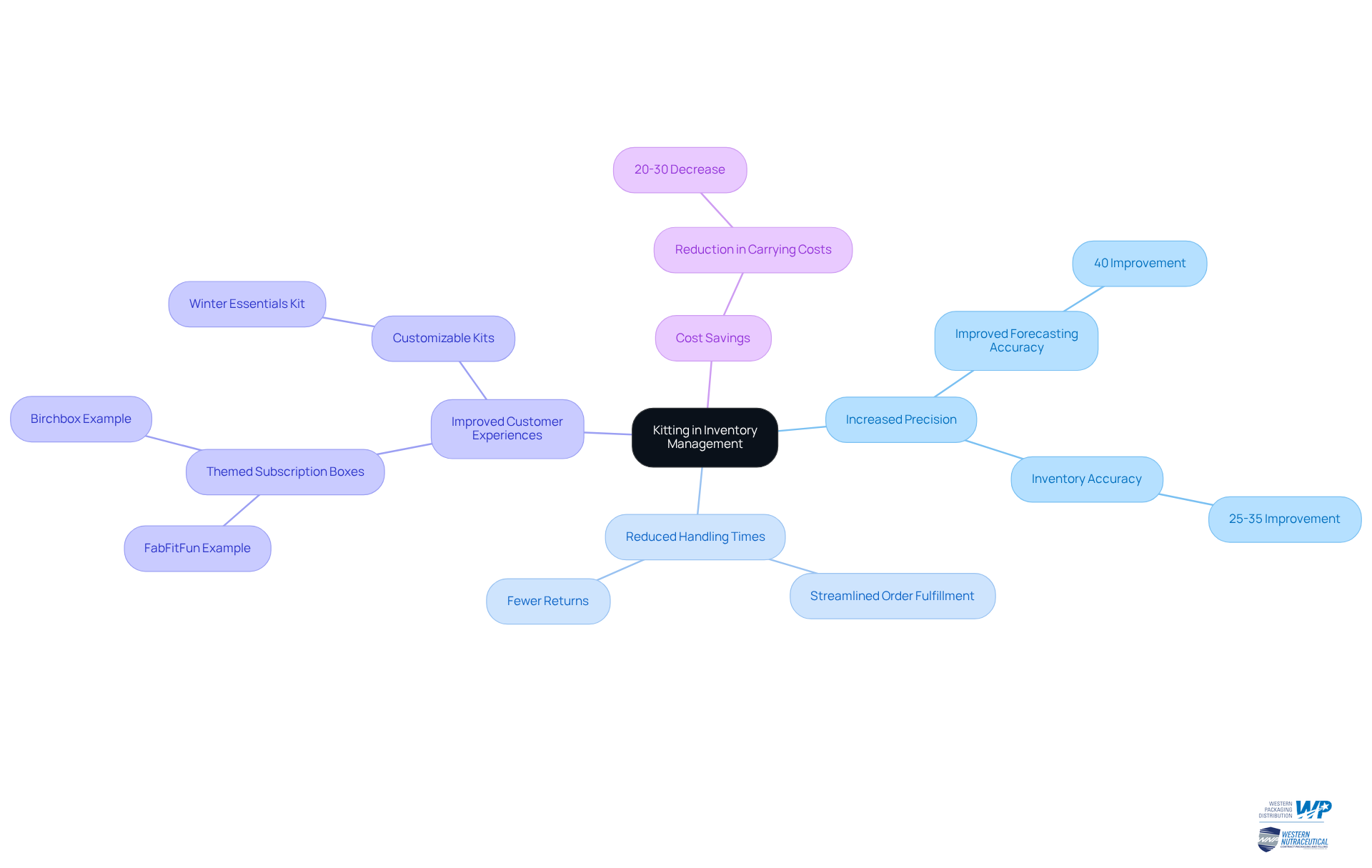

Improved Inventory Management: Streamlining Stock Control with Kitting

Kitting pharmaceuticals significantly enhances inventory management for nutraceutical producers by facilitating the grouping of related items into cohesive packages. This strategy simplifies stock control, reducing the complexity associated with managing multiple SKUs. By consolidating products, manufacturers can uphold more accurate inventory levels, which is vital for effective demand forecasting. The introduction of organized assembly has demonstrated an enhancement in forecasting precision by up to 40%, with average inventory accuracy improvements ranging from 25% to 35%, thereby mitigating the risks of overstocking and shortages.

For instance, companies such as FabFitFun and Birchbox have successfully streamlined their stock management processes through bundling, allowing them to offer themed subscription boxes that not only boost customer engagement but also elevate inventory turnover. Additionally, a skincare brand offering a 'winter essentials' kit exemplifies the versatility of kitting across diverse product categories. This method minimizes the number of individual SKUs that must be tracked, resulting in a more efficient inventory system.

Experts in supply chain management underscore the importance of bundling in achieving operational efficiency. As observed, "Kitting allows businesses to pre-assemble packages, improving order fulfillment efficiency," which directly enhances customer satisfaction and loyalty. Moreover, precise inventory records contribute to reducing the risk of stockouts, further improving customer satisfaction. Kitting pharmaceuticals can also lead to a decrease in carrying costs by 20% to 30%, thereby bolstering the financial health of health supplement companies.

In summary, integrating kitting pharmaceuticals into inventory management strategies presents significant benefits, including increased precision, reduced handling times, and improved customer experiences, establishing it as an essential practice for producers aiming to optimize their operations.

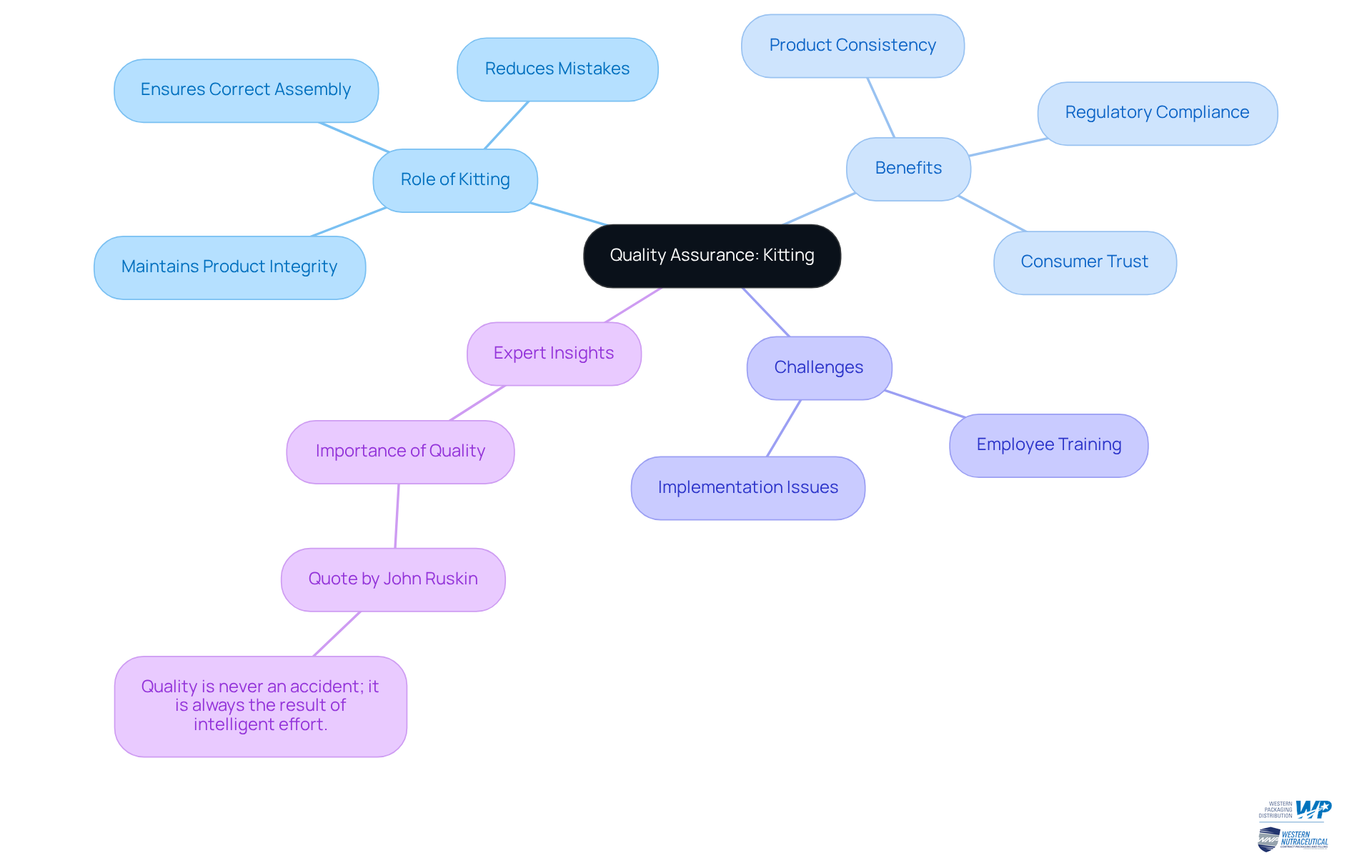

Quality Assurance: Enhancing Product Consistency with Kitting

Kitting plays a vital role in quality assurance by ensuring that all components of a product are assembled correctly and consistently. This meticulous procedure significantly reduces the chance of mistakes during assembly, which is essential for preserving product integrity in the health supplement industry. By applying rigorous quality assessments during the assembly phase, manufacturers can enhance product uniformity and comply with regulatory requirements.

Companies that adopt comprehensive quality assurance protocols—including regular audits and employee training—report substantial improvements in product reliability. Notably, the dietary supplement market is experiencing an annual growth rate of 14.2%, highlighting the increasing importance of quality in assembly methods.

Quality control experts emphasize that maintaining high standards in assembly not only enhances product consistency but also fosters consumer trust. As one expert aptly stated, 'Quality is never an accident; it is always the result of intelligent effort.' This commitment to excellence through assembly methods ultimately leads to improved market performance and customer satisfaction within the dietary supplement industry.

However, challenges such as inadequate employee training and inconsistent implementation of standard operating procedures can obstruct adherence to Good Manufacturing Practices (GMP), underscoring the necessity for a proactive approach to quality assurance.

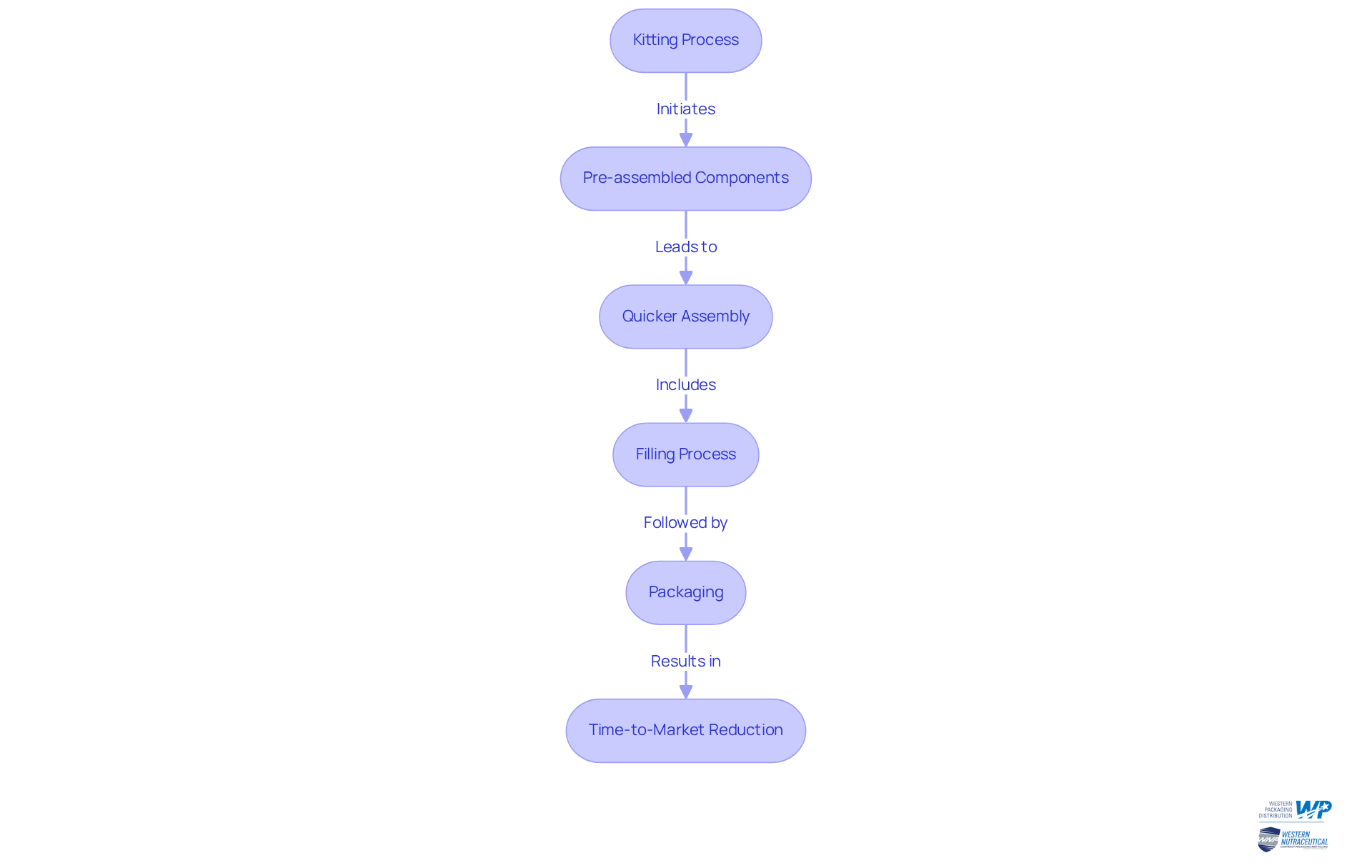

Faster Production: Accelerating Time-to-Market with Kitting

Kitting pharmaceuticals significantly accelerates production by delivering all necessary components in a pre-assembled format, which facilitates quicker assembly and packaging. This streamlined approach can reduce time-to-market by as much as 30%, enabling nutraceutical manufacturers to swiftly adapt to consumer demands and capitalize on emerging trends.

By incorporating our filling process into the assembly solutions, Western Packaging enhances this efficiency, providing extensive services that encompass everything from powders to gummies and soft-gels. Businesses that have adopted these packaging solutions report a notable rise in productivity, allowing teams to accomplish more tasks within a single day.

Industry leaders emphasize that kitting pharmaceuticals not only enhances operational efficiency but also provides a competitive edge by reducing production costs and assembly times. Furthermore, our 3PL services enhance the supply chain, including warehousing, inventory management, and logistics, enabling producers to concentrate on their core competencies.

As the nutraceutical market continues to grow, with projections exceeding $700 billion by 2025, the ability to bring products to market rapidly becomes increasingly vital for success. By utilizing assembly solutions alongside integrated filling and 3PL services, manufacturers can ensure they remain agile and responsive in a fast-paced environment.

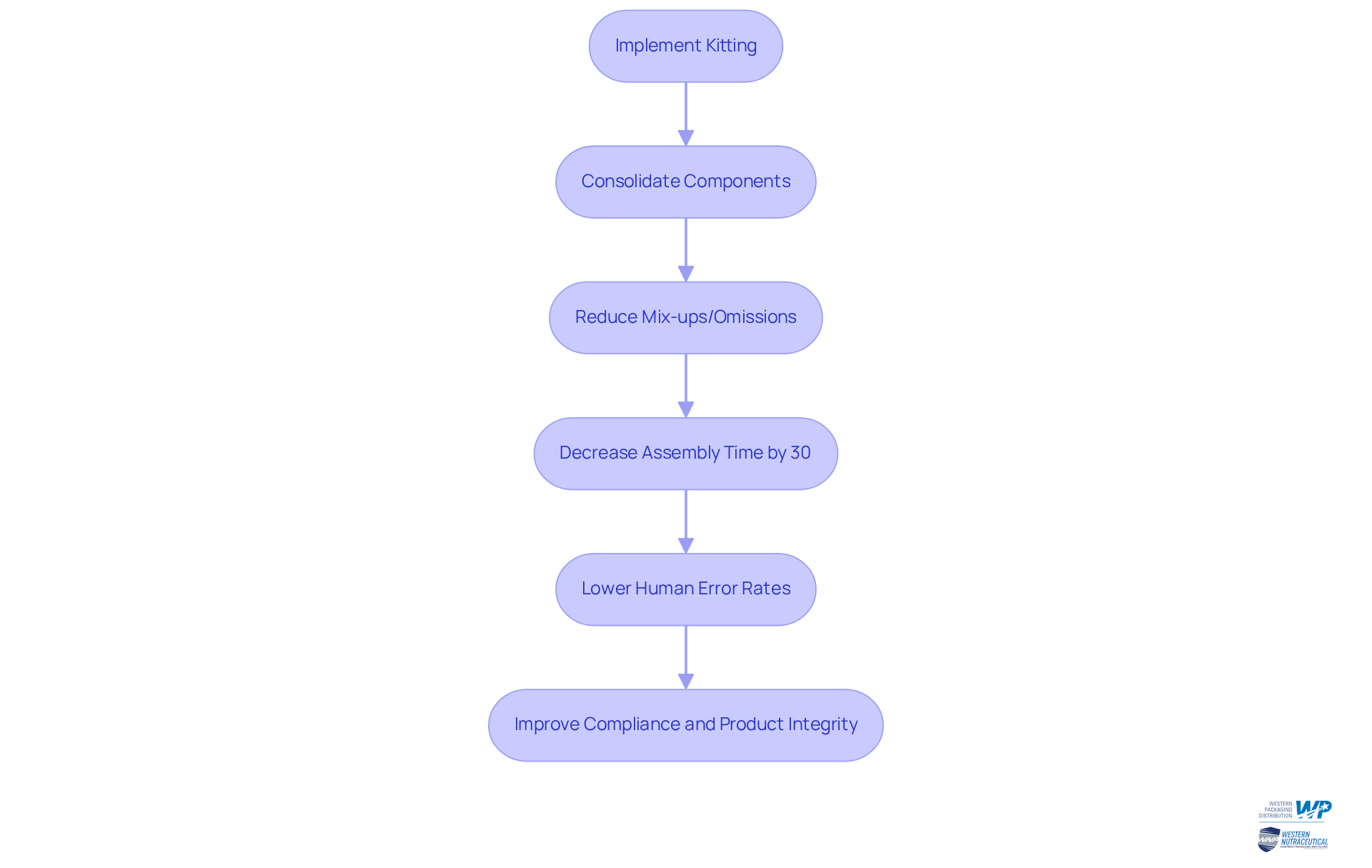

Error Reduction: Minimizing Mistakes in Pharmaceutical Assembly with Kitting

Kitting is essential in minimizing errors during assembly by consolidating all necessary components into a single, organized kit. This method significantly reduces the chances of mix-ups or omissions in kitting pharmaceuticals, which is vital in the pharmaceutical industry where precision is paramount for compliance and consumer safety.

Companies utilizing assembly kits have reported reductions in assembly time by up to 30%, leading to enhanced productivity and faster time-to-market. Furthermore, kitting pharmaceuticals with organized assembly solutions has been shown to reduce human error rates, with approximately 36% of filling mistakes in pharmaceutical production attributed to human error.

Compliance specialists emphasize that maintaining precision in kitting pharmaceuticals operations is crucial for ensuring both product integrity and regulatory compliance. Notably, a global CDMO that implemented RoSS® shells for its fluid management reported a product loss rate of under 0.001%, demonstrating the effectiveness of structured assembly in preventing mistakes.

By streamlining the assembly process, kitting not only enhances operational efficiency but also fosters a culture of continuous improvement, ultimately benefiting producers in their pursuit of quality and reliability.

Flexibility: Adapting to Market Changes with Kitting Solutions

Kitting solutions empower supplement producers to swiftly adapt to evolving market demands. By facilitating rapid reconfiguration of kits, businesses can effectively respond to emerging trends and shifting customer preferences, ensuring they remain competitive in a dynamic landscape. This flexibility is crucial, as the nutraceutical sector is characterized by fast-paced changes in consumer behavior and preferences.

Notably, firms that have adopted bundling strategies report considerable enhancements in their capacity to introduce new products and modify existing offerings based on market feedback. Market analysts emphasize that the adaptability of this method not only streamlines production processes but also enhances overall operational efficiency. Consequently, manufacturers can minimize lead times and reduce the risk of stockouts, ultimately leading to improved customer satisfaction and loyalty.

Significant instances include brands that have effectively incorporated product bundling into their operations, enabling them to combine complementary items and react to seasonal demands effortlessly. This strategic approach not only meets consumer expectations but also positions companies for sustained growth in a competitive marketplace.

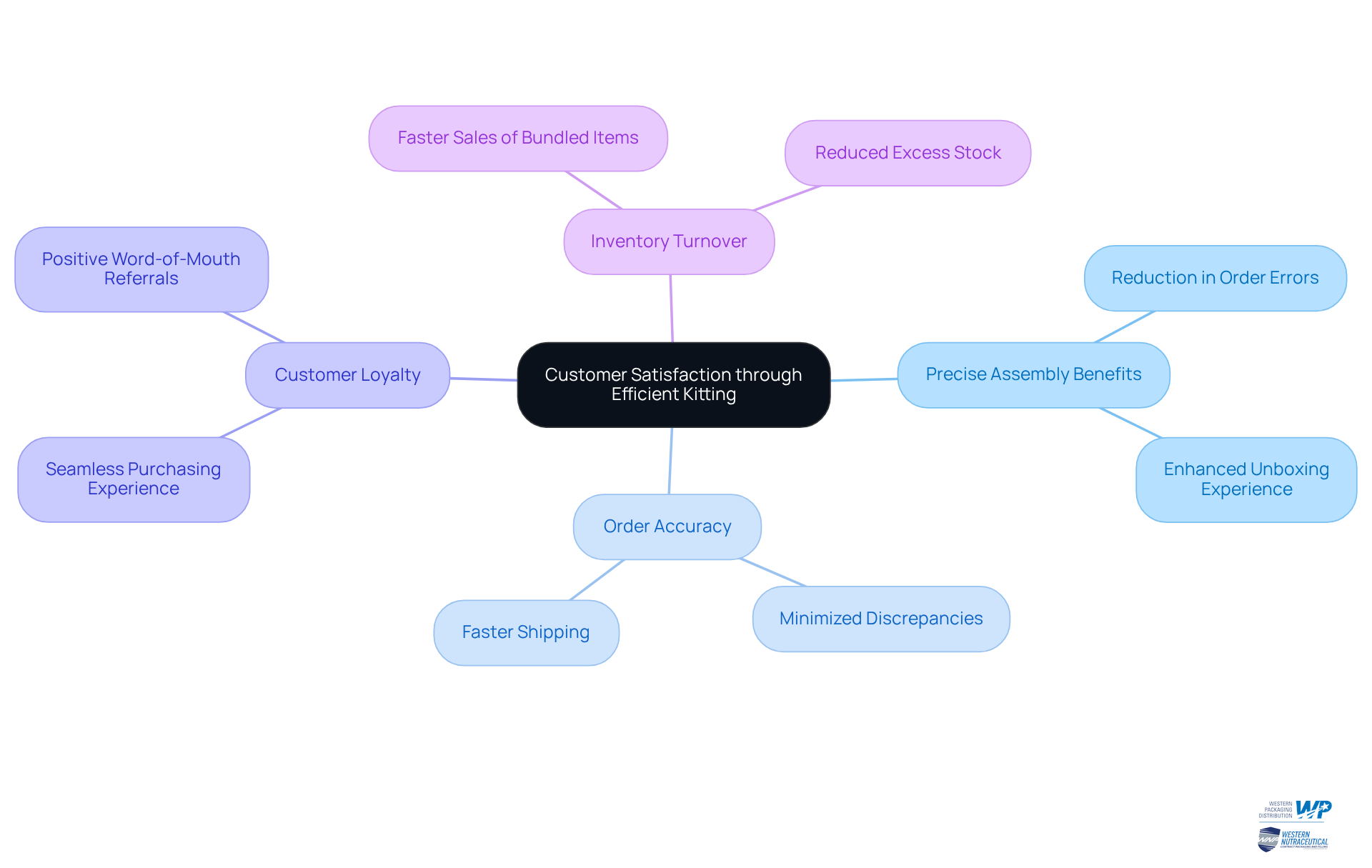

Customer Satisfaction: Boosting Client Experience with Efficient Kitting

Effective assembly methods significantly enhance customer satisfaction by ensuring precise and prompt order delivery. When supplement producers implement efficient packaging, clients receive their products accurately and on time, directly improving their overall experience. This results in heightened satisfaction and loyalty, leading to repeat business and positive word-of-mouth referrals.

Notably, firms within the nutraceutical industry that have adopted efficient packaging strategies report a substantial reduction in order errors. Precise assembly processes minimize discrepancies and elevate the unboxing experience. As a customer experience specialist noted, 'Precise assembly not only guarantees that customers receive exactly what they ordered but also fosters brand loyalty through a seamless purchasing experience.'

Moreover, companies that leverage innovative packaging solutions can boost their inventory turnover, as bundled items tend to sell more rapidly, reducing excess stock and enhancing operational efficiency. This comprehensive kitting pharmaceuticals strategy not only fulfills customer expectations but also positions nutraceutical producers for sustained growth in a competitive market.

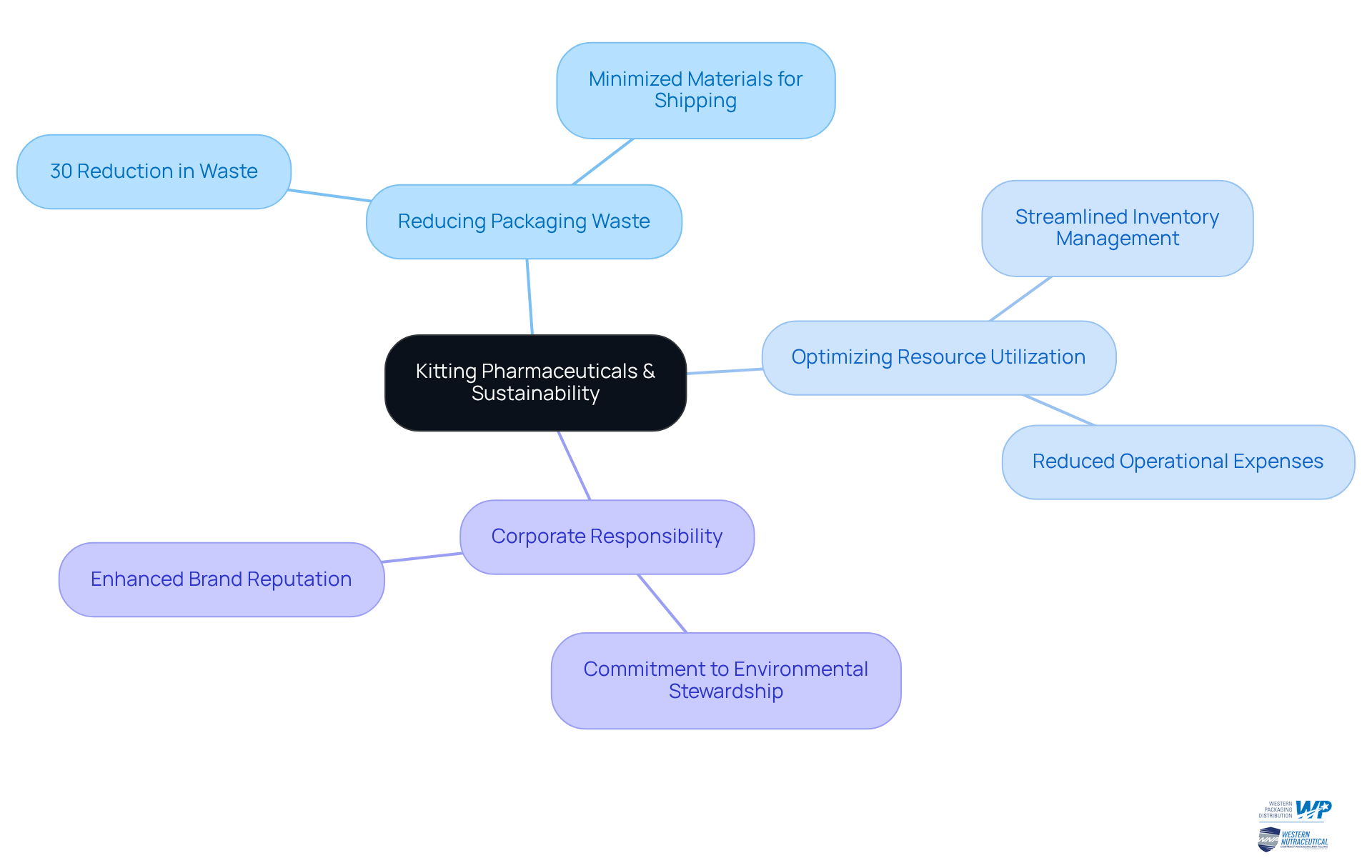

Sustainability: Reducing Waste and Environmental Impact with Kitting

Kitting pharmaceuticals plays a pivotal role in advancing sustainability initiatives by significantly reducing packaging waste and optimizing resource utilization. By consolidating multiple items into a single package through kitting pharmaceuticals, manufacturers can minimize the materials required for shipping and packaging. This method not only reduces operational expenses but also lessens the environmental impact of production methods, aligning with the growing consumer demand for eco-friendly practices in kitting pharmaceuticals.

Western Packaging's integrated solutions enhance the kitting pharmaceuticals process by offering expertise in packaging design and filling various products, including powders, gummies, and soft gels, which can streamline inventory management and reduce the number of individual SKUs. For instance, a skincare brand that implemented a 'winter essentials' kit, which included moisturizer, serum, and lip balm, reported substantial reductions in waste as it streamlined inventory management.

Environmental analysts emphasize that kitting pharmaceuticals can lead to a more efficient use of materials, thereby supporting broader sustainability goals within the nutraceutical industry. As businesses adopt these practices, including kitting pharmaceuticals, they not only enhance their operational efficiency but also contribute positively to their brand reputation by demonstrating a commitment to environmental stewardship.

According to a recent study, companies that utilize kitting pharmaceuticals can achieve up to a 30% reduction in packaging waste, further solidifying their position as responsible corporate citizens. By leveraging Western Packaging's comprehensive 3PL services, including kitting pharmaceuticals, producers can optimize their supply chain while reinforcing their sustainability initiatives.

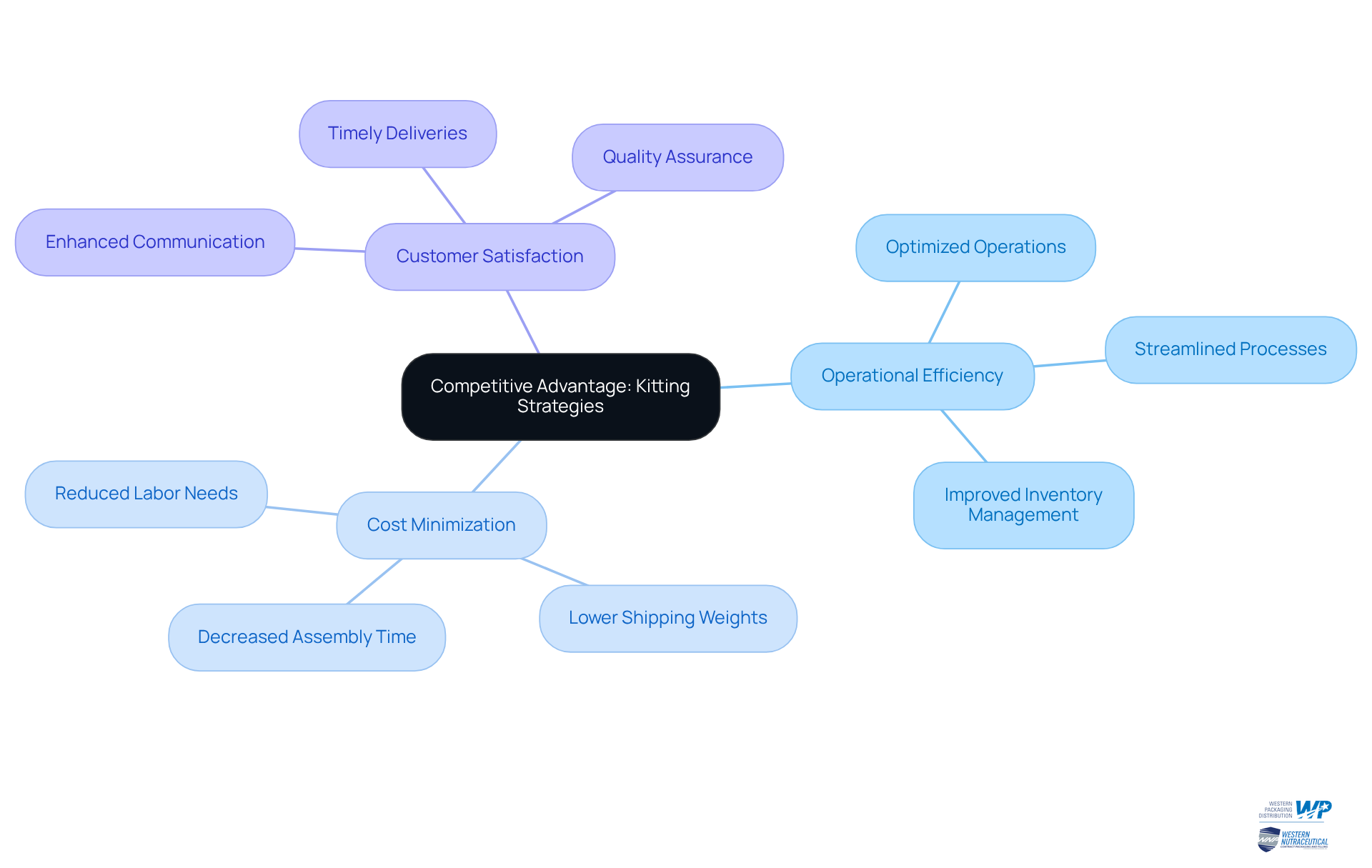

Competitive Advantage: Gaining Market Edge Through Effective Kitting Strategies

Implementing efficient kitting pharmaceuticals strategies provides health supplement producers with a significant competitive advantage. By optimizing operations, minimizing costs, and enhancing customer satisfaction, companies can effectively distinguish themselves in a saturated market. This strategic method not only boosts operational efficiency but also establishes manufacturers as frontrunners in kitting pharmaceuticals within the nutraceutical industry. Such an approach is essential for those aiming to lead and innovate in this dynamic field.

Conclusion

Kitting in pharmaceuticals presents a transformative strategy for nutraceutical manufacturers, merging efficiency with cost-effectiveness and enhanced customer satisfaction. By integrating kitting solutions into their operations, businesses can streamline processes, reduce labor and shipping expenses, and improve inventory management. This ultimately results in a significant competitive advantage in a crowded marketplace.

The discussion highlights numerous benefits of kitting, including:

- Improved quality assurance

- Faster production times

- The agility to adapt quickly to market changes

Furthermore, the emphasis on sustainability and reduced environmental impact underscores the critical role of kitting in modern manufacturing practices. By consolidating products into cohesive packages, companies not only enhance operational efficiency but also positively contribute to their brand reputation.

As the nutraceutical industry evolves, embracing kitting solutions becomes essential for producers aiming to meet consumer demands while upholding high standards of quality and sustainability. The strategic implementation of kitting can drive growth, foster customer loyalty, and position businesses for long-term success in an increasingly competitive landscape.

Frequently Asked Questions

What are integrated kitting solutions in pharmaceuticals?

Integrated kitting solutions in pharmaceuticals combine packaging design, filling services, and third-party logistics (3PL) to streamline production processes and optimize logistics, enhancing supply chain efficiency.

How does kitting pharmaceuticals improve supply chain efficiency?

Kitting pharmaceuticals improves supply chain efficiency by reducing lead times, improving workflow, and minimizing assembly time, which can decrease from hours to minutes, while also cutting labor needs for picking by up to 50%.

What are the cost benefits of kitting pharmaceuticals?

Kitting pharmaceuticals significantly reduces labor and shipping expenses by consolidating multiple items into a single package, which minimizes assembly time and lowers shipping costs, leading to greater profitability for health-related product producers.

How does kitting pharmaceuticals affect inventory management?

Kitting pharmaceuticals enhances inventory management by grouping related items into cohesive packages, simplifying stock control, improving inventory accuracy by 25% to 35%, and enhancing forecasting precision by up to 40%.

Can you provide examples of companies using kitting effectively?

Companies like FabFitFun and Birchbox have successfully used kitting to streamline stock management processes through bundling, allowing them to offer themed subscription boxes that increase customer engagement and inventory turnover.

What are the overall operational benefits of kitting pharmaceuticals?

The operational benefits of kitting pharmaceuticals include increased precision in inventory management, reduced handling times, improved customer experiences, and a decrease in carrying costs by 20% to 30%, contributing to better financial health for health supplement companies.