Overview

Partnering with a contract drug manufacturing organization presents a multitude of advantages that are crucial for pharmaceutical companies. These benefits include:

- Cost efficiency

- Scalability

- Regulatory compliance

- Access to specialized expertise

Such partnerships empower manufacturers to concentrate on their core competencies, adapt swiftly to market demands, and uphold stringent quality and compliance standards. This strategic focus not only enhances operational effectiveness but also drives innovation and fosters a competitive advantage in the industry. By leveraging these partnerships, companies can position themselves for sustained success in a dynamic marketplace.

Introduction

In the competitive landscape of pharmaceuticals, the selection of a manufacturing partner can profoundly impact a company's success. By collaborating with a contract drug manufacturing organization, businesses can unlock numerous advantages—ranging from cost savings and scalability to access to specialized expertise and regulatory compliance. Yet, the pivotal question persists: how can these partnerships not only streamline operations but also drive innovation and enhance market presence? Delving into the benefits of such collaborations unveils a strategic pathway that can redefine operational efficiency and foster growth in an ever-evolving industry.

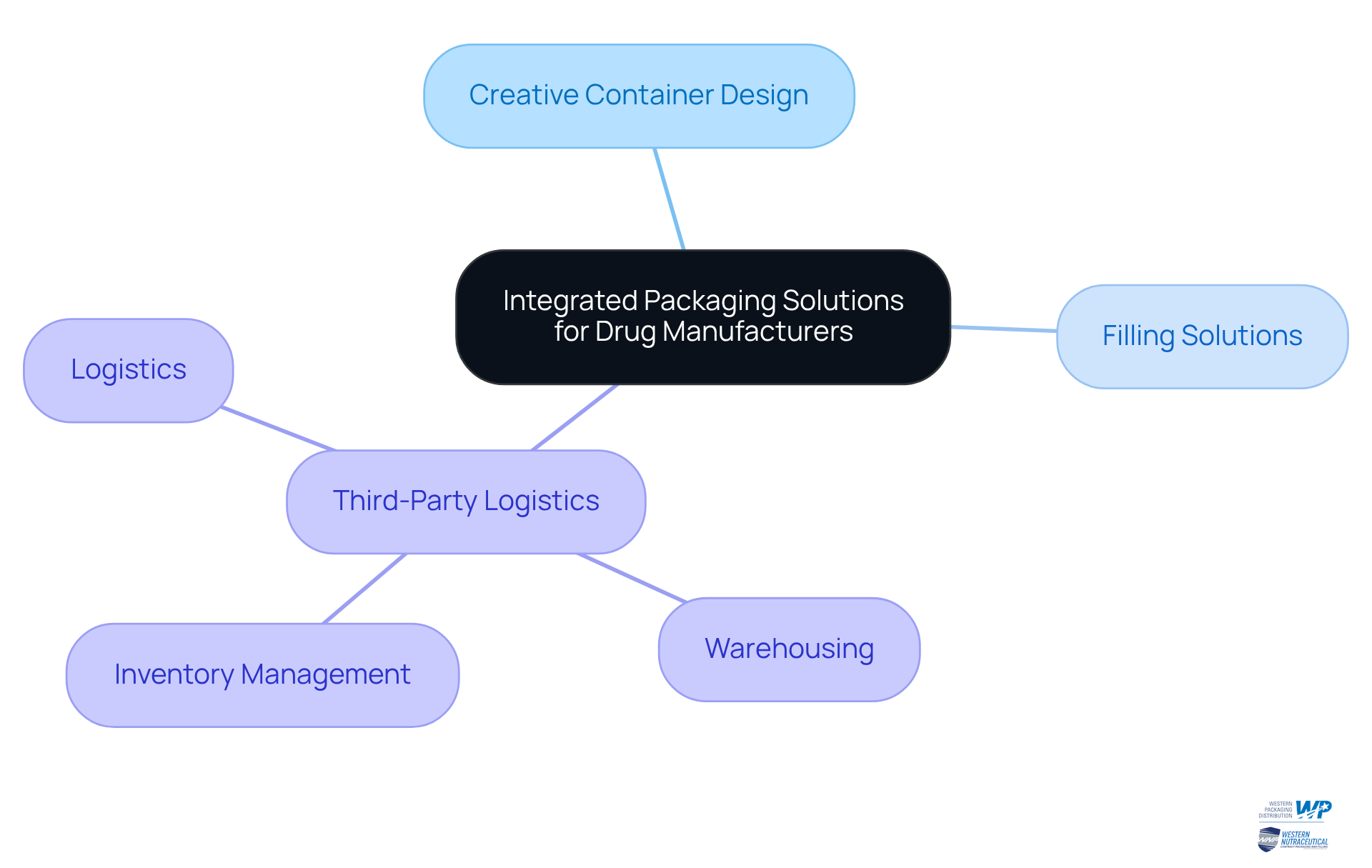

Western Packaging: Integrated Packaging Solutions for Drug Manufacturers

A company offers a comprehensive suite of services that seamlessly integrates creative container design, filling solutions, and extensive third-party logistics (3PL) tailored specifically for pharmaceutical manufacturers. Our 3PL services include:

- Warehousing

- Inventory management

- Logistics

All designed to streamline the supply chain. This allows manufacturers to concentrate on their core competencies. This integrated approach not only simplifies operations but also reduces lead times and enhances product delivery. By addressing the unique needs of the nutraceuticals sector, our company ensures that clients receive tailored solutions that boost brand visibility and operational efficiency.

Cost Efficiency: Reducing Production Expenses with Contract Manufacturing

Partnering with a contract drug manufacturing organization provides significant cost savings, as seen with Western Packaging. By outsourcing production, companies can avoid the substantial overhead costs associated with running their own facilities. This strategy allows for a more effective allocation of resources, enabling businesses to invest further in marketing and product development. Moreover, a contract drug manufacturing organization typically possesses established supply chains and bulk purchasing power, which further drives down production costs. The benefits of such partnerships not only enhance operational efficiency but also position companies for greater market competitiveness.

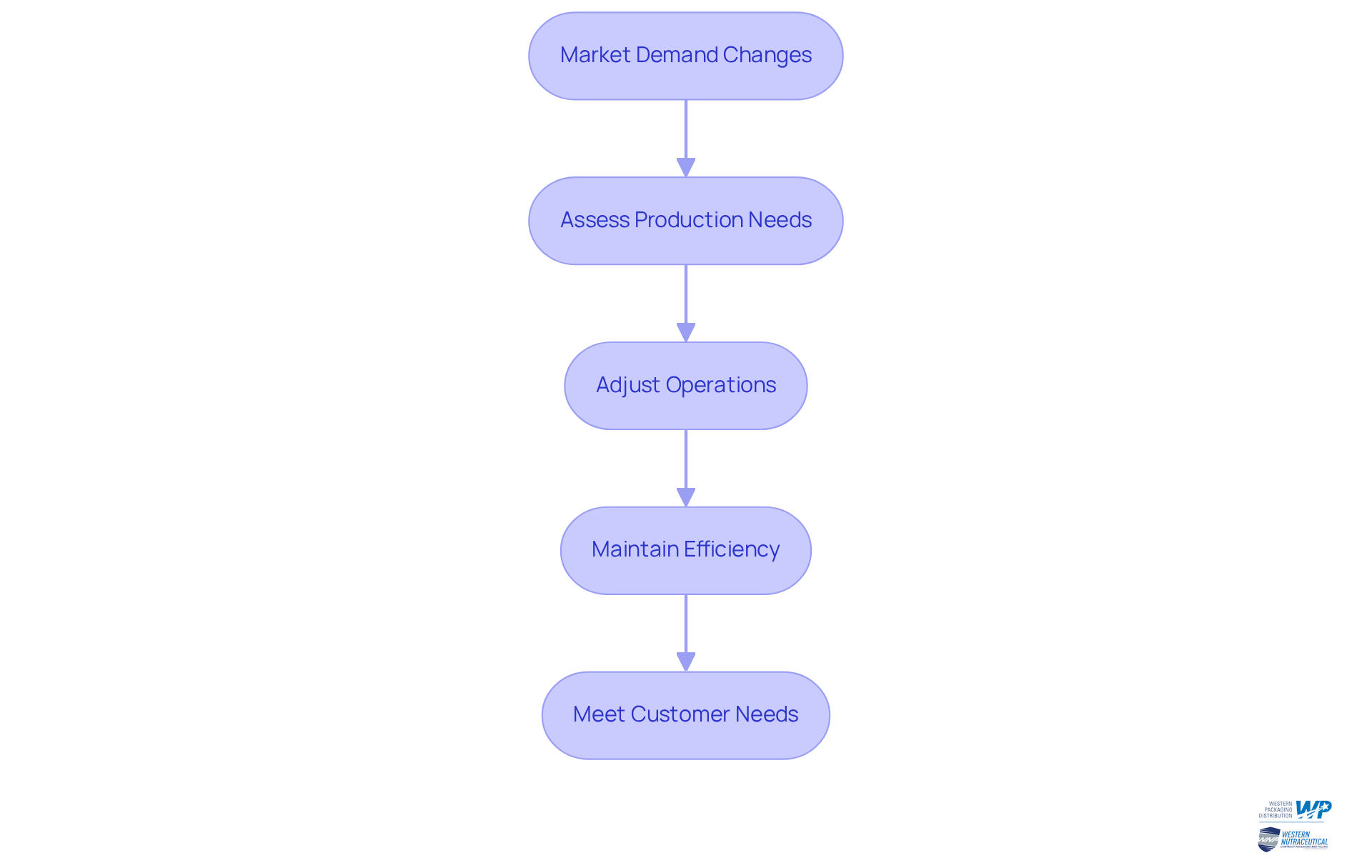

Scalability: Adapting Production Capacity to Market Needs

Contract drug manufacturing organizations provide the scalability essential for producers to respond to shifting market demands. In the face of a sudden surge in product demand or the necessity to reduce production, Western Packaging adeptly adjusts its operations. This remarkable flexibility empowers producers to maintain efficiency without the burden of surplus capacity or the risk of stockouts, guaranteeing they can meet customer needs promptly.

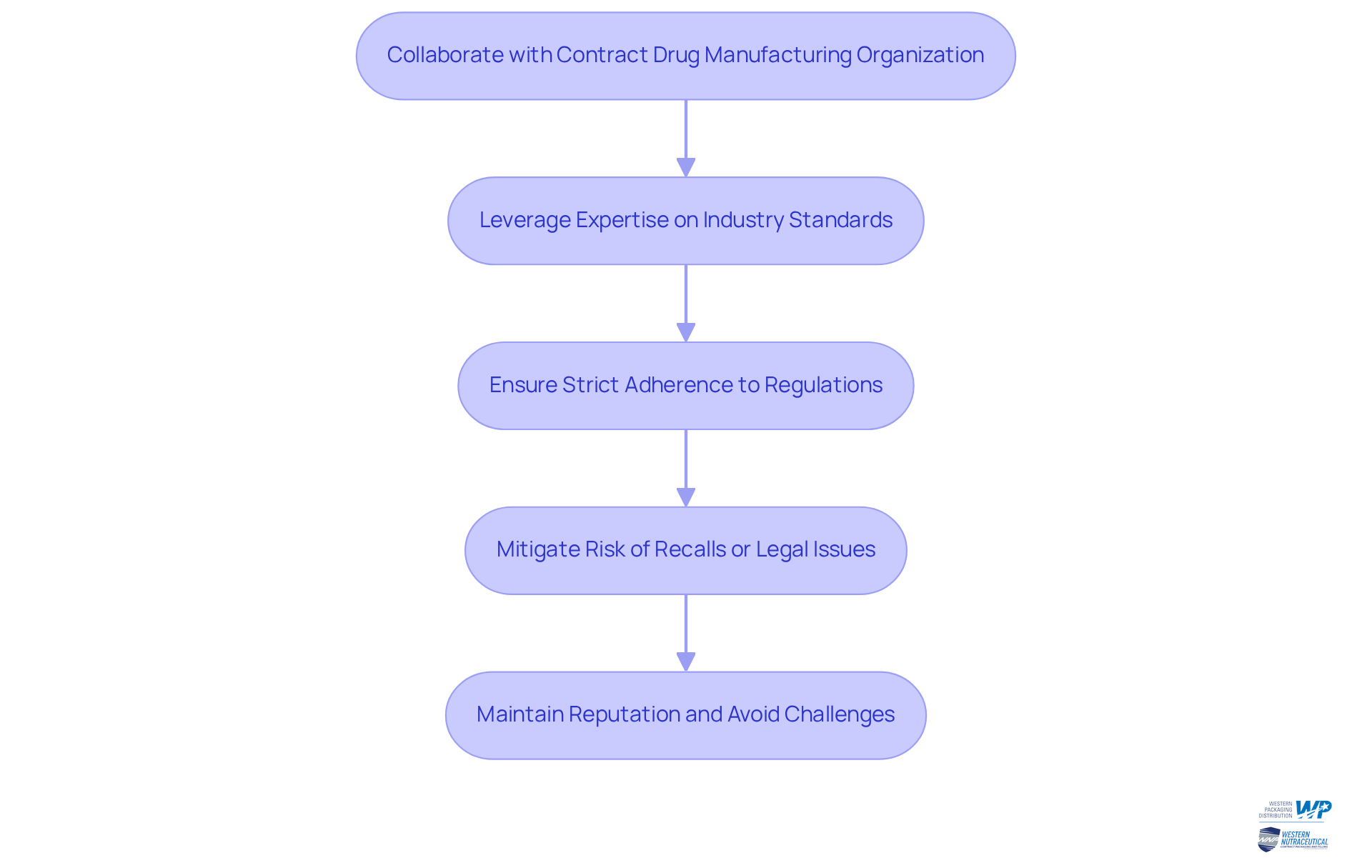

Regulatory Compliance: Ensuring Adherence to Industry Standards

Navigating the complex landscape of regulatory compliance is a formidable challenge for pharmaceutical manufacturers. By collaborating with a contract drug manufacturing organization, companies can leverage the expertise of professionals well-versed in industry standards. This strategic partnership guarantees that all products are manufactured in strict adherence to regulations, significantly mitigating the risk of costly recalls or legal complications. The unwavering commitment of these firms to quality and compliance not only aids clients in maintaining their reputations but also equips them to avoid potential challenges effectively.

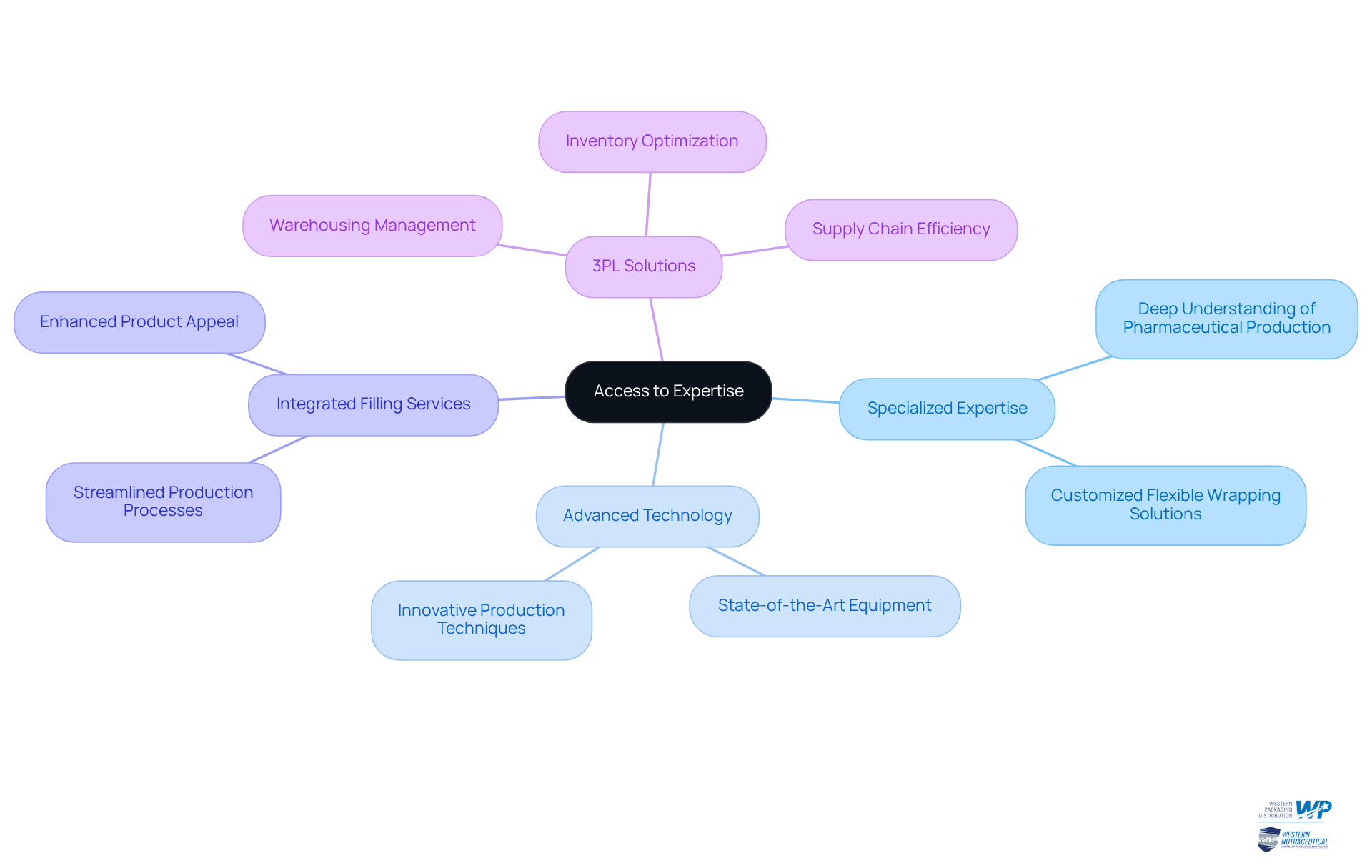

Access to Expertise: Leveraging Advanced Technology and Knowledge

Collaborating with a contract drug manufacturing organization offers a significant advantage: access to specialized expertise and advanced technology. Our skilled experts possess a deep understanding of the complexities inherent in pharmaceutical production and packaging, particularly when it comes to delivering customized flexible wrapping solutions. Furthermore, our integrated filling services streamline production processes, allowing producers to enhance both product appeal and operational efficiency. By leveraging our comprehensive 3PL solutions—encompassing warehousing and inventory management—companies can optimize their supply chain and stay ahead of industry trends, effectively meeting evolving consumer demands.

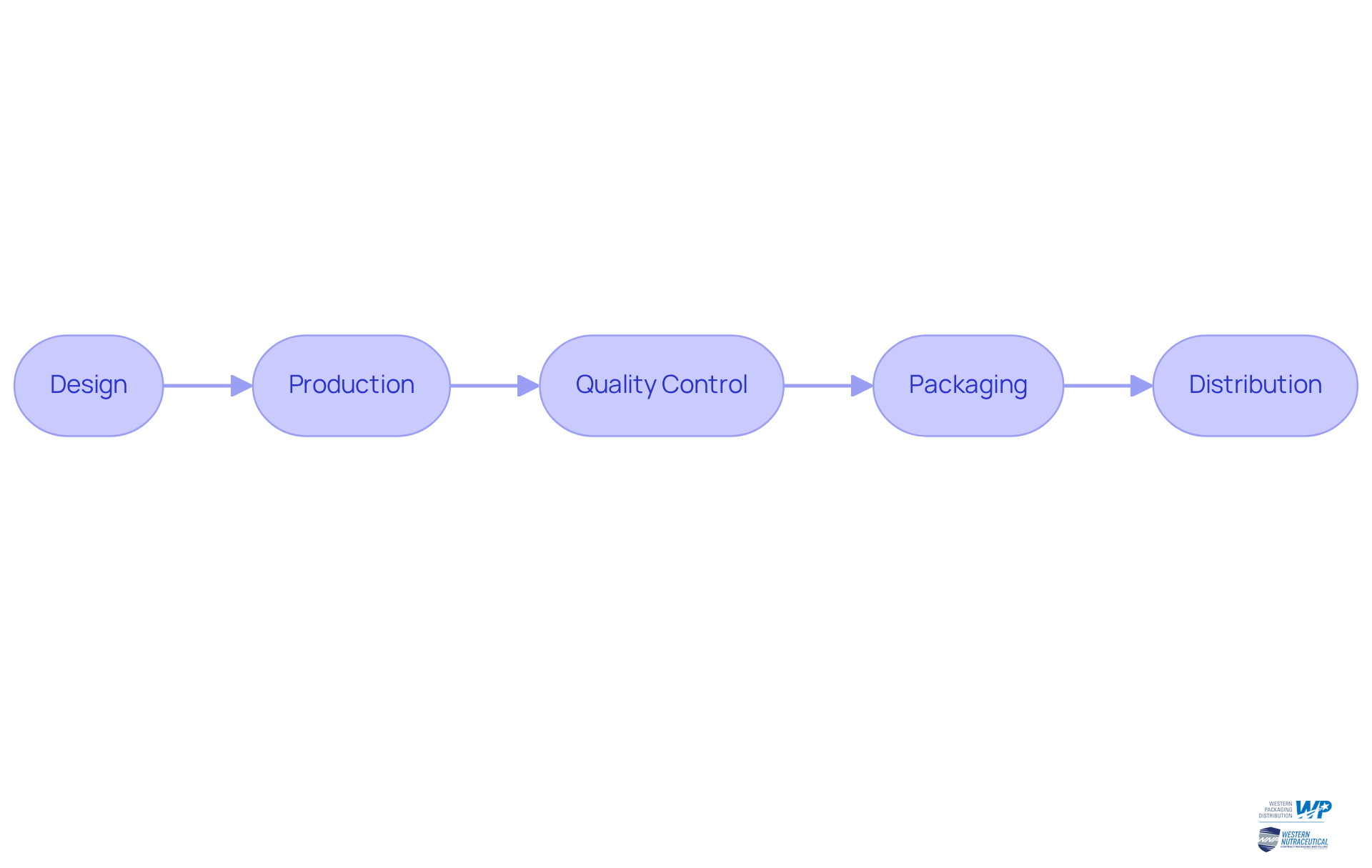

Speed to Market: Accelerating Product Launches with Contract Manufacturing

In today's fast-paced market, speed to market stands as a critical factor for success. Contract drug manufacturing organizations, such as Western Packaging, play a pivotal role in significantly accelerating product launches. By streamlining production processes and reducing lead times, they empower producers to bring their products to market swiftly. This integrated approach encompasses everything from design to distribution, enabling companies to seize emerging trends and respond to consumer demands ahead of their competitors. Embracing these capabilities not only enhances operational efficiency but also positions businesses as leaders in their field.

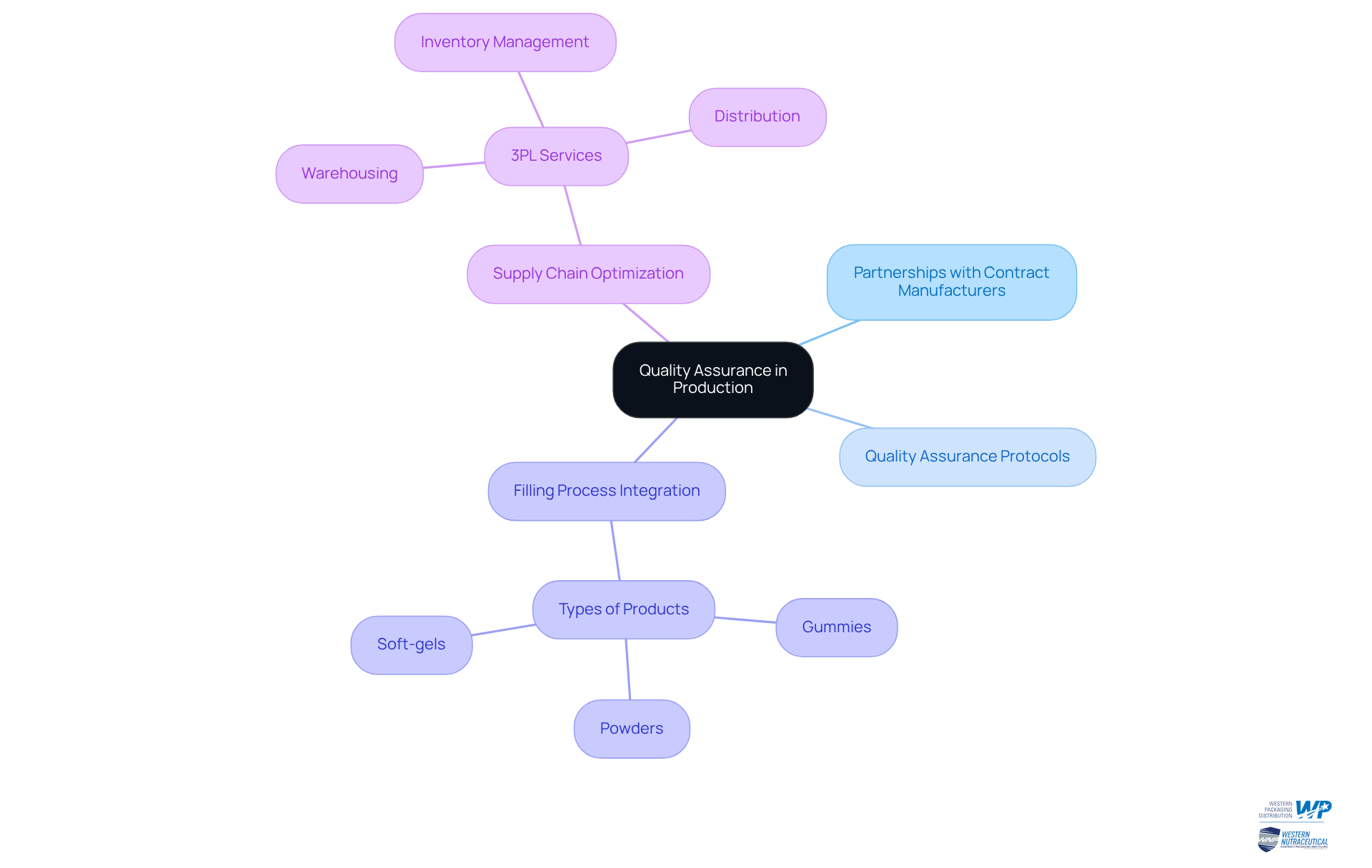

Quality Assurance: Maintaining High Standards in Production

Upholding high standards in production is paramount for pharmaceutical producers, and partnering with a contract drug manufacturing organization is essential in achieving this goal. Western Packaging enforces stringent quality assurance protocols to guarantee that all products not only meet but exceed industry standards.

Our filling process is seamlessly integrated into our comprehensive end-to-end solutions for flexible packaging needs, encompassing everything from powders to gummies and soft-gels. This unwavering commitment to quality not only protects consumers but also enhances the brand's reputation.

By optimizing your supply chain through our extensive 3PL services—including warehousing, inventory management, and distribution—producers can ensure consistent quality, foster trust with their customers, and stand out in a competitive market.

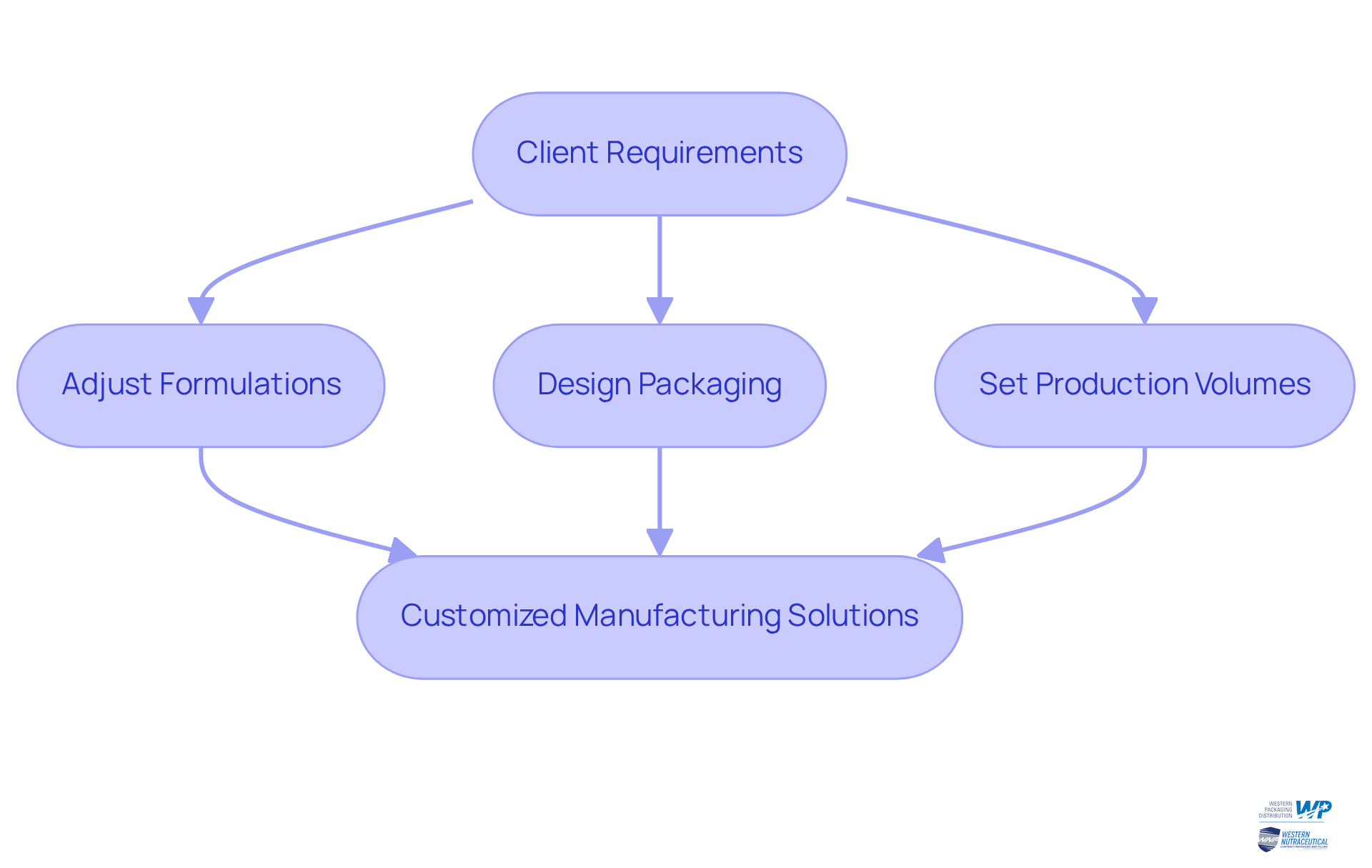

Flexibility: Customizing Production Processes to Fit Unique Requirements

Each producer possesses unique requirements, and a contract drug manufacturing organization, such as Western Packaging, delivers the adaptability essential for customizing manufacturing methods. By adjusting formulations, packaging designs, and production volumes, we collaborate closely with clients to ensure their specific needs are met. This level of customization not only amplifies product appeal but also empowers manufacturers to respond effectively to market demands. Trust in our expertise to provide tailored solutions that enhance your competitive edge.

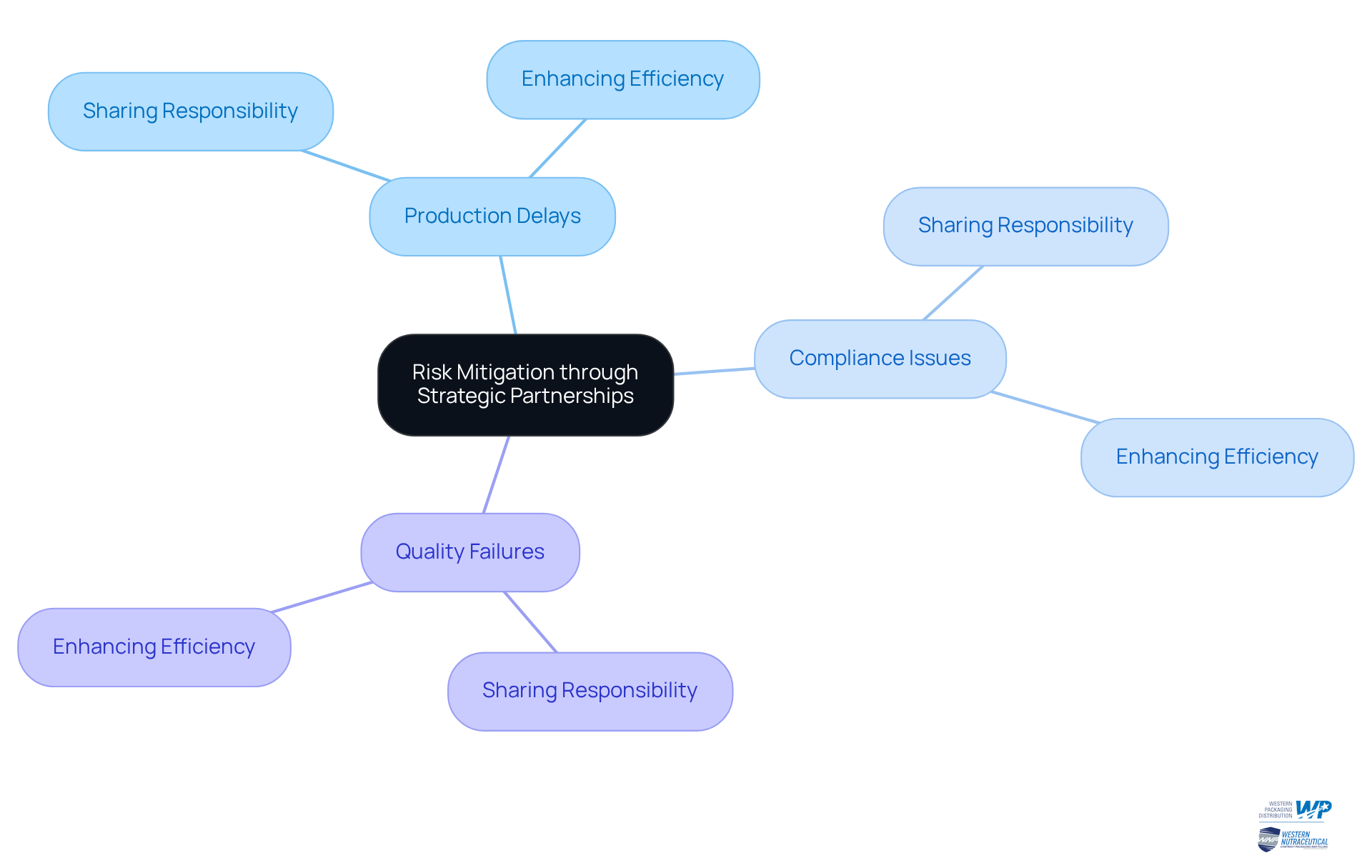

Risk Mitigation: Reducing Operational Risks through Strategic Partnerships

Operational risks are inherent in the manufacturing process. However, collaborating with a contract drug manufacturing organization can effectively mitigate these risks.

Western Packaging's established processes and experienced team significantly reduce the likelihood of:

- Production delays

- Compliance issues

- Quality failures

By sharing the responsibility of production, manufacturers can concentrate on their core competencies while minimizing the potential risks associated with in-house manufacturing. This strategic collaboration not only enhances operational efficiency but also fosters a reliable production environment.

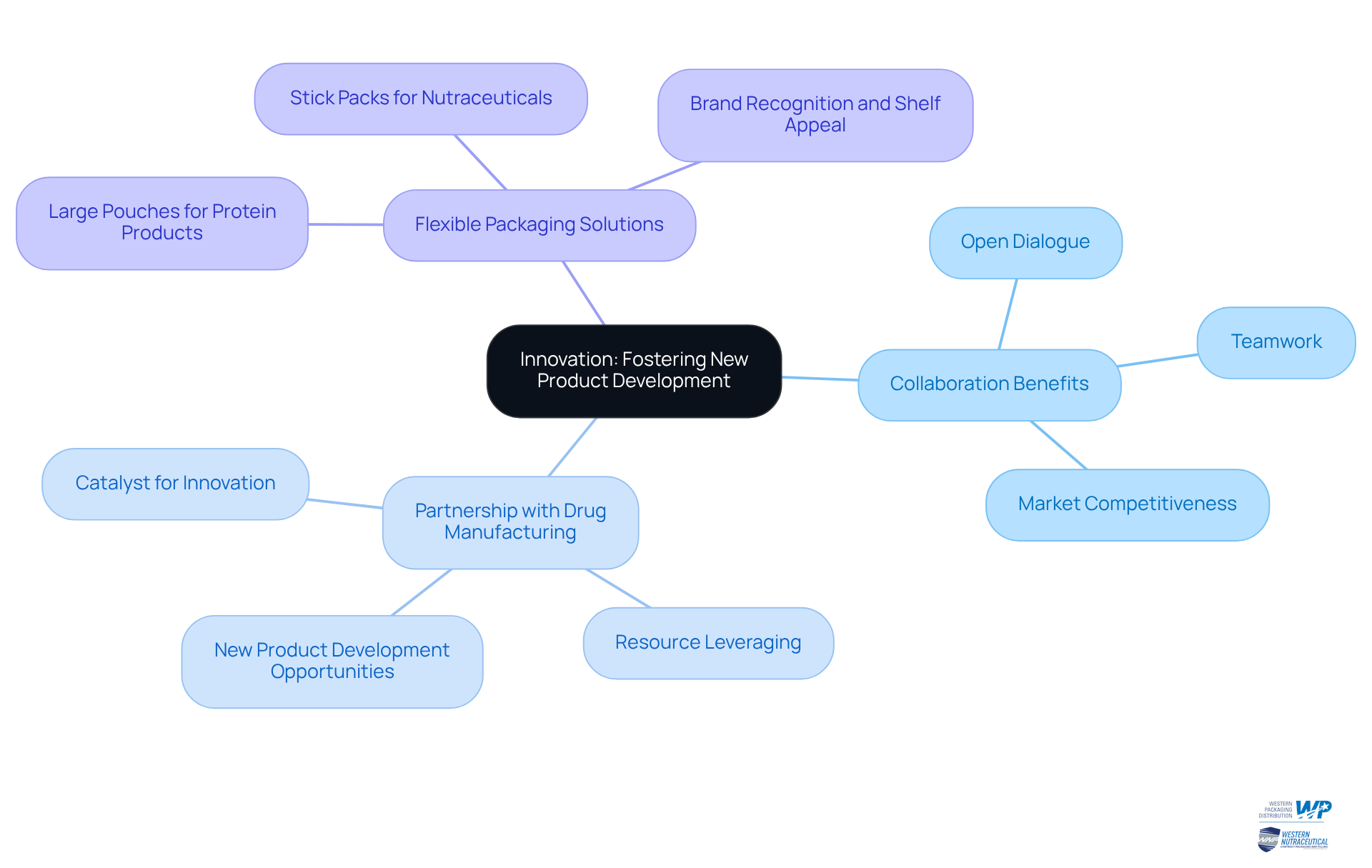

Innovation: Fostering New Product Development through Collaboration

Collaborating with a contract drug manufacturing organization acts as a catalyst for innovation. This partnership encourages open dialogue and teamwork with clients, creating an environment conducive to new ideas. By leveraging the expertise and resources of a contract drug manufacturing organization, companies can uncover new product development opportunities, ensuring they remain competitive in an ever-evolving market. Such a collaborative approach not only enhances product offerings but also propels growth and strengthens market presence.

With customized flexible packaging solutions—including large pouches for protein products and stick packs for nutraceuticals—Western Packaging significantly elevates brand recognition and shelf appeal. This equips nutraceutical manufacturers with the essential tools to distinguish themselves in the marketplace.

Conclusion

Partnering with a contract drug manufacturing organization offers a strategic advantage for pharmaceutical companies, significantly enhancing operational efficiency and competitiveness in the market. By outsourcing production, businesses can concentrate on their core competencies while leveraging the specialized expertise, advanced technology, and integrated solutions provided by these organizations, such as Western Packaging.

Key benefits of such partnerships include:

- Cost efficiency

- Scalability

- Regulatory compliance

- Quality assurance

The ability to swiftly adapt to market demands, uphold high production standards, and mitigate operational risks are crucial elements that empower manufacturers to thrive. Furthermore, fostering innovation and accelerating product launches are significant advantages that enable companies to maintain a competitive edge.

Ultimately, embracing collaboration with contract drug manufacturing organizations transcends a mere tactical decision; it represents a transformative strategy that can drive growth and success. Companies are urged to explore these partnerships to unlock new opportunities, enhance brand visibility, and ensure agility in a rapidly evolving industry landscape. The benefits are evident, and the time to act is now.

Frequently Asked Questions

What services does Western Packaging offer for drug manufacturers?

Western Packaging offers a comprehensive suite of services, including creative container design, filling solutions, and extensive third-party logistics (3PL) tailored specifically for pharmaceutical manufacturers. Their 3PL services include warehousing, inventory management, and logistics.

How does Western Packaging's integrated approach benefit pharmaceutical manufacturers?

The integrated approach simplifies operations, reduces lead times, and enhances product delivery, allowing manufacturers to focus on their core competencies while addressing the unique needs of the nutraceuticals sector.

What are the cost benefits of partnering with a contract drug manufacturing organization like Western Packaging?

Partnering with a contract drug manufacturing organization can lead to significant cost savings by avoiding overhead costs associated with running in-house facilities. This strategy allows for better resource allocation towards marketing and product development.

How does contract manufacturing enhance operational efficiency?

Contract drug manufacturing organizations typically have established supply chains and bulk purchasing power, which drive down production costs and enhance operational efficiency, positioning companies for greater market competitiveness.

What scalability benefits does Western Packaging provide to its clients?

Western Packaging offers essential scalability that allows producers to adapt their production capacity to shifting market demands. They can quickly adjust operations in response to sudden surges in demand or the need to reduce production, maintaining efficiency without surplus capacity or stockouts.