Overview

The article identifies essential compostable packaging materials for nutraceuticals, emphasizing their critical role in promoting sustainability within the industry. It highlights various materials, including PLA, bagasse, and bamboo, demonstrating how these options not only fulfill consumer demand for eco-friendly solutions but also enhance brand reputation and ensure compliance with emerging regulations against single-use plastics.

By adopting these innovative materials, companies can position themselves as leaders in sustainability, appealing to environmentally conscious consumers and aligning with regulatory trends.

Introduction

As the demand for sustainable practices intensifies, nutraceutical companies are increasingly seeking innovative packaging solutions that align with eco-conscious consumer preferences. This article explores ten essential compostable packaging materials that not only meet environmental standards but also enhance brand appeal in a competitive market.

With numerous options available, how can companies effectively navigate the landscape of compostable materials to make informed choices that resonate with their target audience? By understanding the nuances of these materials, businesses can not only fulfill their environmental commitments but also strengthen their market position.

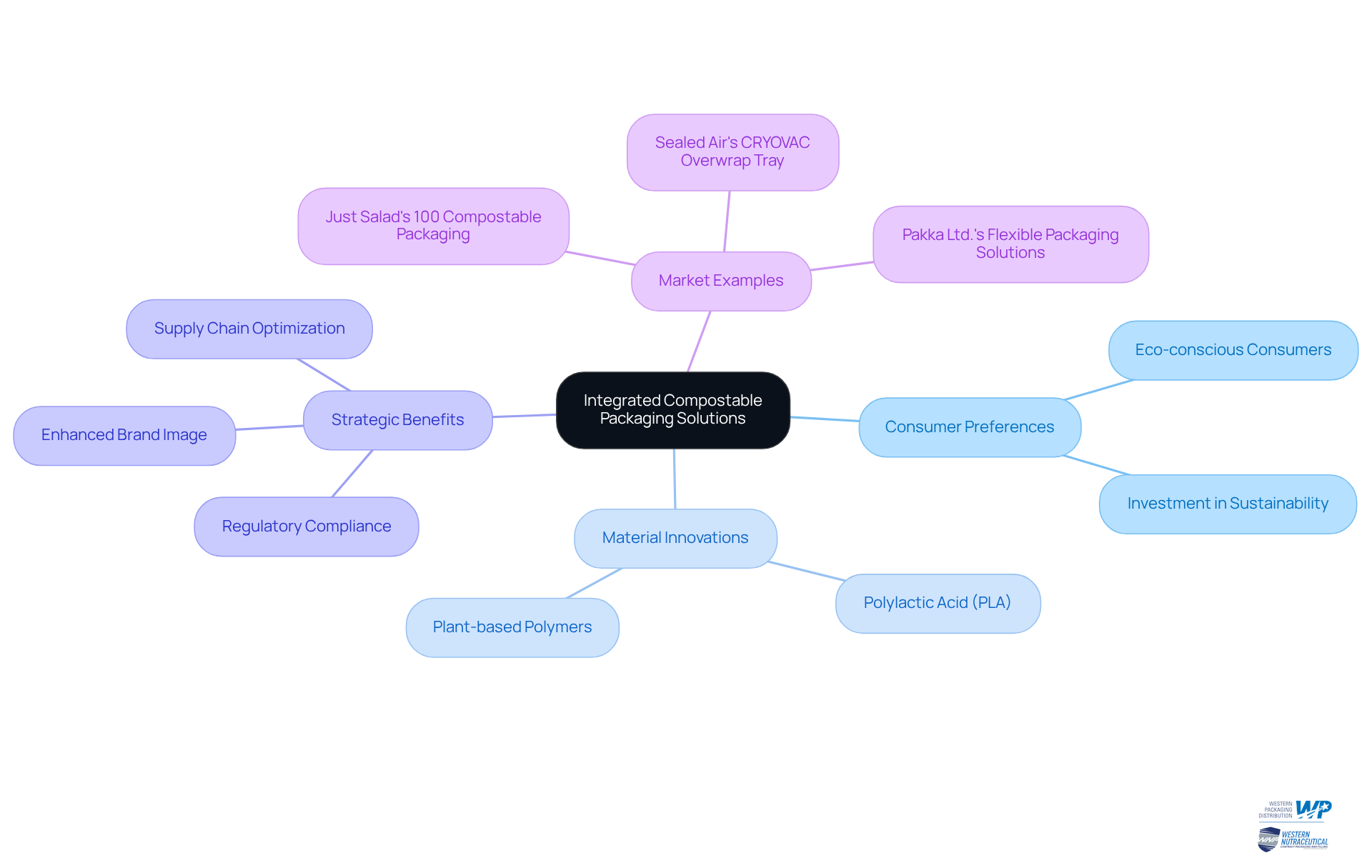

Western Packaging: Integrated Compostable Packaging Solutions for Sustainable Brands

Western Packaging offers a comprehensive suite of integrated compostable packaging materials solutions tailored specifically for nutraceutical companies, enhanced by our extensive 3PL services that encompass warehousing, inventory management, and distribution. By combining innovative design with sustainable materials, we enable businesses to meet regulatory standards while appealing to eco-conscious consumers. This strategic approach not only streamlines the supply chain but also elevates product visibility in a competitive market.

In 2025, consumer purchasing decisions are increasingly swayed by sustainability, with 63% of global consumers indicating a preference for eco-friendly brands and a readiness to invest more in sustainable products. Successful examples are plentiful; for instance, Just Salad has committed to using 100% compostable packaging materials for its food delivery services, illustrating the tangible benefits of sustainable practices.

Furthermore, advancements in compostable packaging materials, such as Polylactic Acid (PLA) and innovative plant-based polymers, are revolutionizing containers for nutraceuticals by offering enhanced durability and biodegradability, thus providing both environmental advantages and market differentiation. As sustainability becomes a core principle for shoppers, companies that prioritize environmentally friendly materials not only enhance their image but also position themselves for enduring success in the health supplement industry.

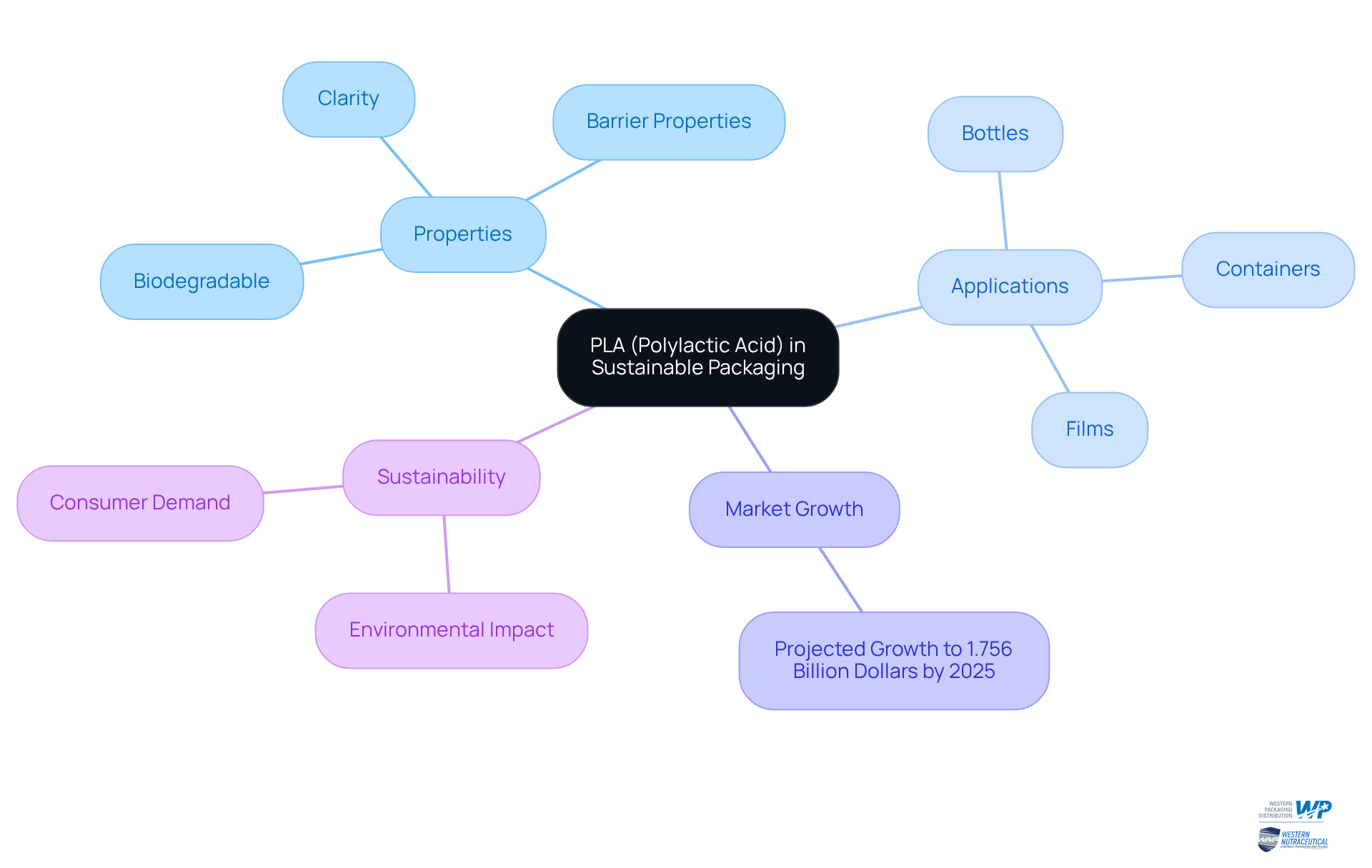

PLA (Polylactic Acid): A Versatile Compostable Material for Packaging

Polylactic Acid (PLA) represents a significant advancement in sustainable packaging solutions, as it is a type of compostable packaging materials derived from renewable resources such as corn starch. This biodegradable polymer serves as an environmentally friendly alternative for compostable packaging materials. Renowned for its exceptional barrier properties and clarity, PLA is versatile, suitable for applications ranging from bottles to containers and films.

As one of the compostable packaging materials, PLA decomposes into natural elements, aligning seamlessly with the sustainability goals of health product companies. By 2025, the global market for PLA is projected to reach approximately 1.756 billion dollars, reflecting its growing acceptance within the industry. Leading nutraceutical companies are increasingly adopting compostable packaging materials such as PLA for their packaging needs, recognizing its potential to enhance their sustainability image while preserving product integrity.

Industry experts emphasize that utilizing PLA and compostable packaging materials not only mitigates environmental impact but also meets consumer demand for eco-friendly products, highlighting the critical importance of sustainable solutions in today’s marketplace.

At Western Packaging, we specialize in delivering customized flexible solutions designed to elevate brand recognition and shelf appeal. Our innovative design capabilities ensure that your products stand out while adhering to eco-friendly practices. For instance, we have effectively integrated compostable packaging materials, such as PLA, into various applications, including custom-designed pouches for nutraceuticals that not only maintain product integrity but also enhance visual appeal on the shelf. This positions us as the ideal partner for nutraceutical producers seeking to refine their presentation strategy.

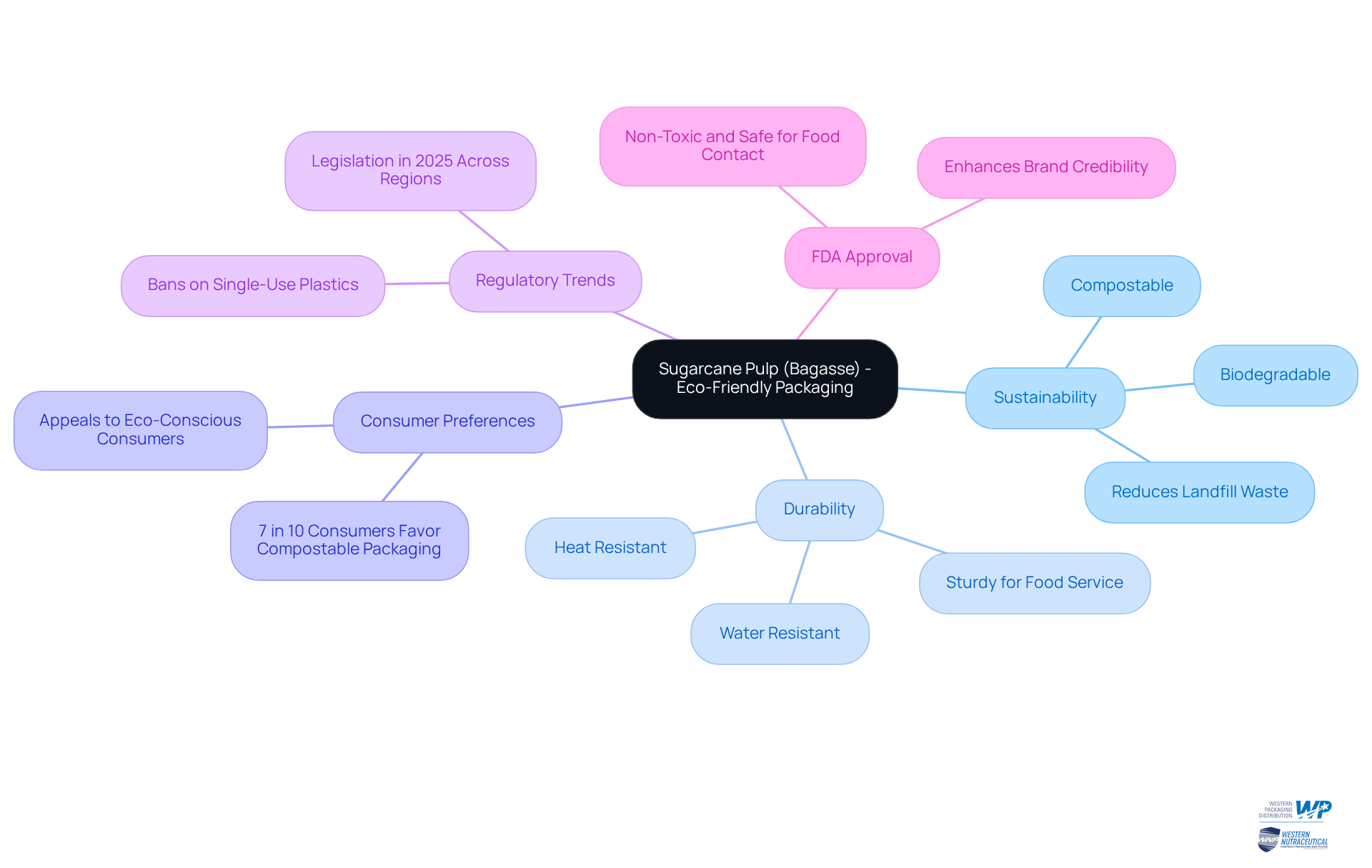

Sugarcane Pulp or Bagasse: Eco-Friendly Packaging Alternative

Sugarcane pulp, commonly referred to as bagasse, serves as a sustainable alternative derived from the fibrous residue left after sugar extraction. This material is not only compostable but also remarkably durable, making it ideal for a range of delivery formats, including trays and containers. By opting for bagasse, health supplement brands can markedly diminish their environmental impact, as it decomposes naturally within months—unlike conventional plastics, which linger in landfills for centuries.

Moreover, the transition to bagasse aligns seamlessly with contemporary consumer preferences, as surveys reveal that:

- 7 in 10 consumers favor restaurants that utilize compostable packaging materials, even if it incurs a slightly higher cost.

As regulatory pressures mount globally, with many regions instituting bans on single-use plastics—including new legislation in 2025 across Europe, Asia, and the Middle East that will prohibit single-use plastic containers in foodservice—the adoption of compostable packaging materials positions nutraceutical companies as pioneers in sustainability.

Additionally, all bagasse packaging is FDA-approved for direct food contact, thereby enhancing credibility and nurturing customer loyalty among environmentally conscious consumers.

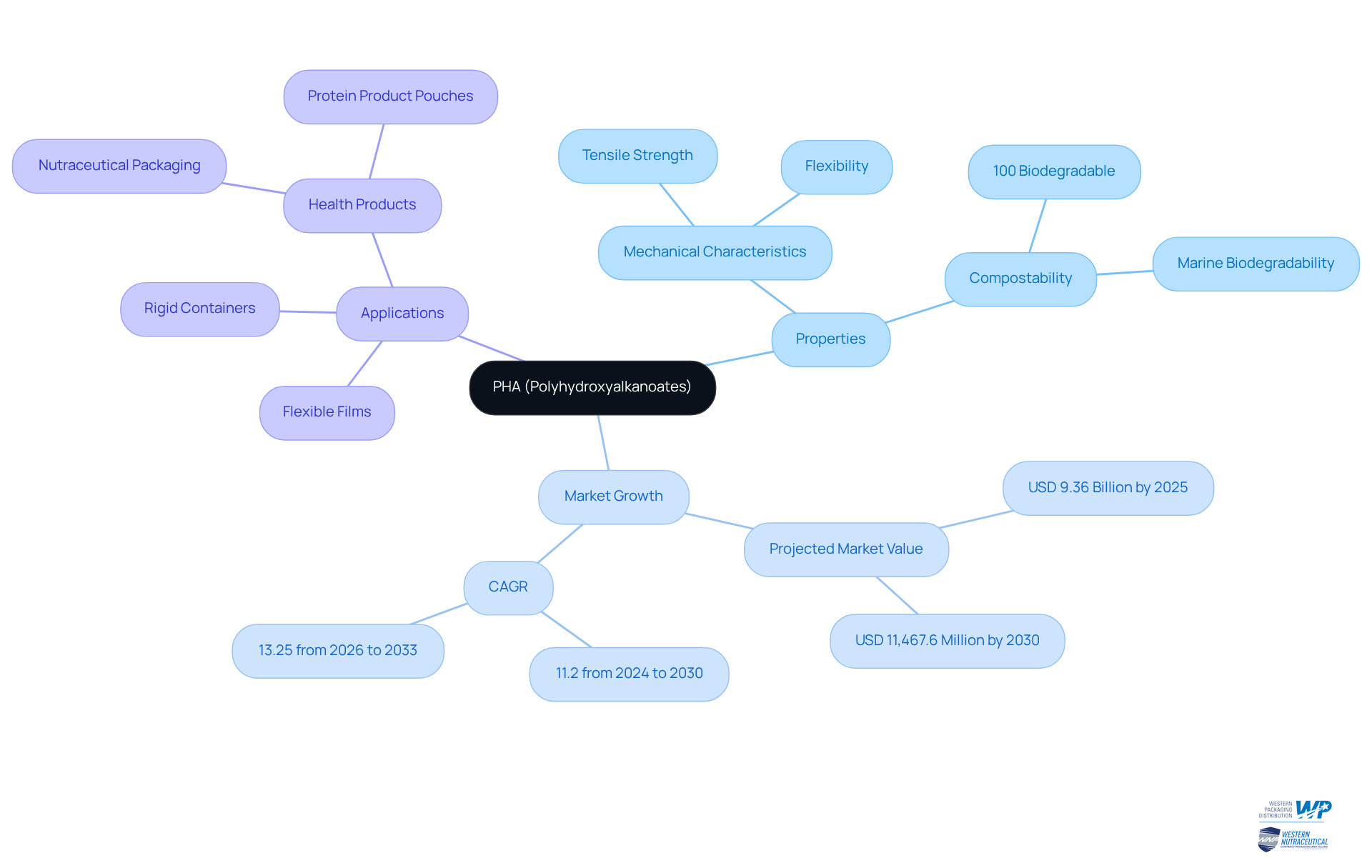

PHA (Polyhydroxyalkanoates): Innovative Compostable Material for Packaging Solutions

PHA (Polyhydroxyalkanoates): Innovative Compostable Material for Packaging Solutions

Polyhydroxyalkanoates (PHA) signify a groundbreaking advancement in biodegradable polymers, synthesized through microbial fermentation of renewable resources such as sugars and lipids. This innovative substance possesses exceptional mechanical properties, rendering it suitable for a diverse array of applications, including flexible films and rigid containers. As a completely compostable packaging materials option, PHA naturally breaks down, which aligns seamlessly with the sustainability objectives of nutraceutical companies.

Recent studies indicate that the global PHA market for container materials is projected to reach USD 9.36 billion by 2025, highlighting an increasing demand for eco-friendly solutions. Notably, companies such as Danimer Scientific and RWDC Industries are leading the charge in utilizing PHA for their container needs, showcasing its adaptability and efficiency in enhancing product appeal while minimizing ecological impact.

The mechanical characteristics of PHA, which include its tensile strength and flexibility, establish it as an ideal choice for health product containment, ensuring product integrity throughout transport and storage. Researchers emphasize that PHA's performance traits not only match but often exceed those of conventional plastics, presenting a compelling case for its widespread use in the health supplement industry.

At Western Packaging, we specialize in tailored flexible solutions that incorporate PHA, such as large pouches for protein products and stick packs for nutraceuticals. By leveraging PHA and adopting compostable packaging materials, health supplement brands can significantly diminish their carbon footprint and contribute to a circular economy, positioning themselves as leaders in sustainability.

Cornstarch Packaging: Biodegradable Option for Sustainable Packaging

Cornstarch containers, composed of corn starch, represent a fully biodegradable option that is gaining traction in the health supplement industry. This versatile material, specifically compostable packaging materials, finds application in various products, including bags, containers, and food service items, effectively mitigating plastic waste while offering a sustainable alternative that resonates with environmentally conscious consumers.

As awareness of sustainability rises, nutraceutical companies can capitalize on the increasing demand for compostable packaging materials, with projections indicating that the market for cornstarch containers will reach USD 1,581.0 million by 2035. Notably, the food sector is expected to capture a 52.3% share of the cornstarch container market by 2025, underscoring its significance within the industry.

This transition not only enhances brand reputation but also aligns with consumer expectations for responsible product packaging practices, including the use of compostable packaging materials. Brands such as Alter Eco and Driftaway Coffee have effectively adopted cornstarch materials, demonstrating their potential to strengthen sustainability narratives in the sector.

Moreover, effective container design should encompass disposal information for compostable packaging materials and recycling methods, guiding consumers toward responsible choices. As Michael Dillon notes, businesses are increasingly integrating sustainable materials into their operations, recognizing their importance in meeting the expectations of environmentally conscious stakeholders.

By embracing compostable packaging materials such as cornstarch containers, health supplement firms can significantly reduce their ecological footprint while appealing to a growing market segment that prioritizes sustainability.

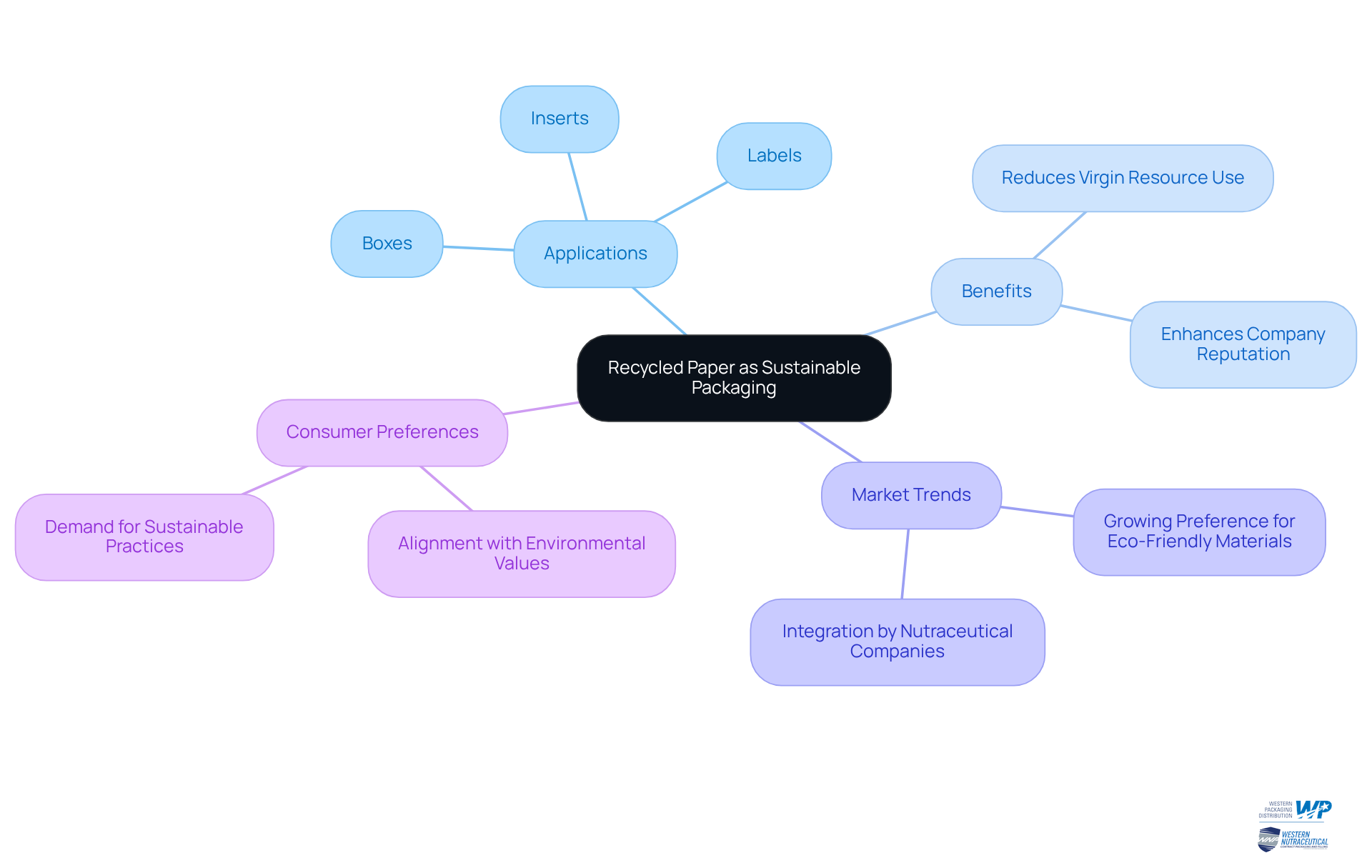

Recycled Paper: Sustainable and Compostable Packaging Material

Recycled paper emerges as a leading option among compostable packaging materials, significantly diminishing the reliance on virgin resources. Its remarkable adaptability allows for a wide range of applications, including boxes, labels, and inserts, positioning it as an ideal choice for health supplement companies. By selecting recycled paper, these companies not only affirm their commitment to sustainability but also align with the values of environmentally conscious consumers. This strategic choice enhances their reputation, as consumers increasingly favor products that exemplify eco-friendly practices.

Notably, numerous nutraceutical companies have effectively integrated recycled paper into their packaging strategies, demonstrating their dedication to sustainability while responding to market demands. Current trends reveal a growing preference for eco-friendly resources, with compostable packaging materials leading the way in expressing a company's environmental accountability and commitment to waste reduction.

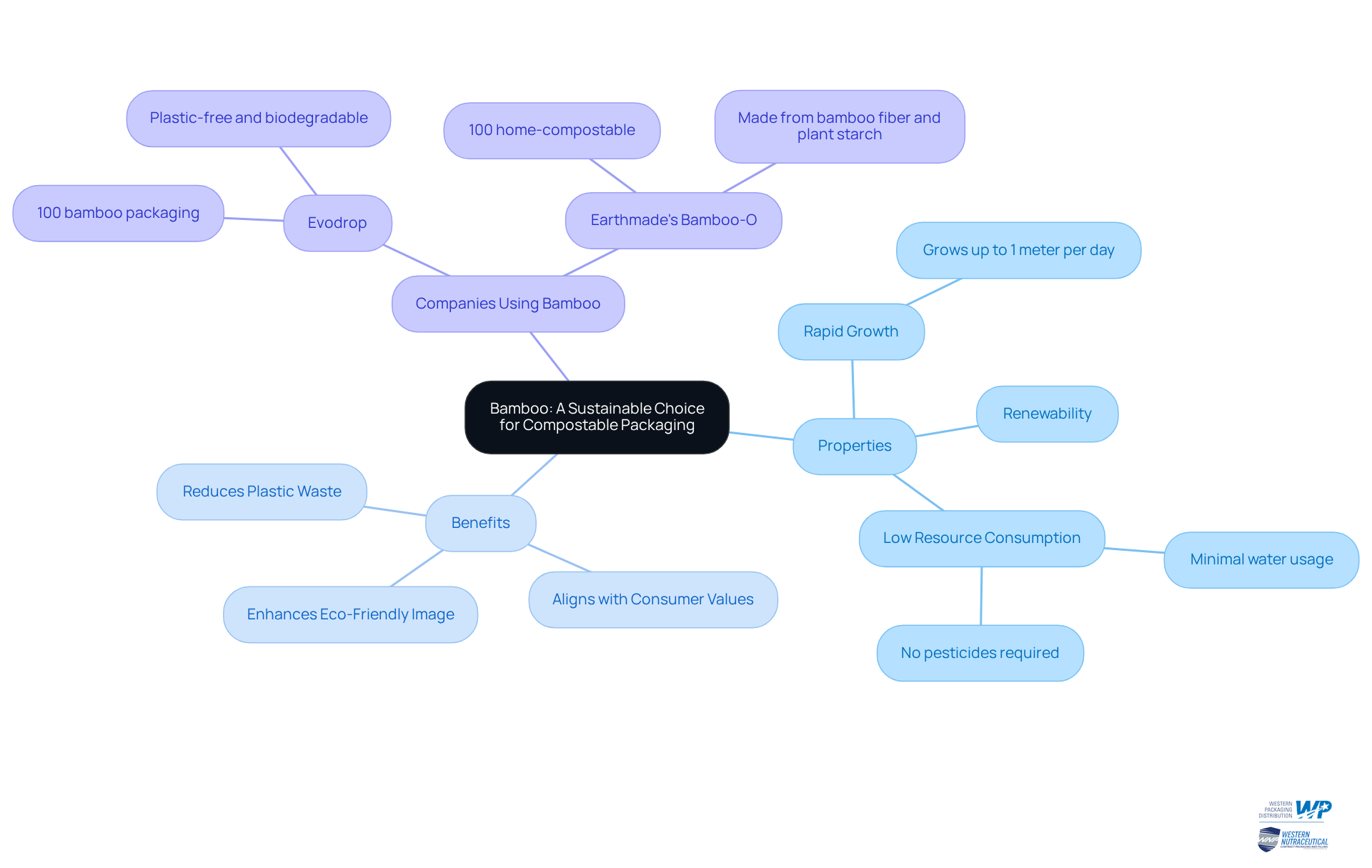

Bamboo: A Sustainable Choice for Compostable Packaging

Bamboo stands out as a remarkably sustainable material, characterized by its rapid growth—up to one meter per day—and renewability. This adaptable resource can be converted into various container formats, including vessels and tools, making it an ideal option for nutraceutical companies. As a compostable alternative, bamboo serves as one of the compostable packaging materials that significantly lessen plastic waste while enhancing a brand's eco-friendly image. In 2025, consumer perspectives increasingly support sustainable products, with many prioritizing environmentally friendly materials in their purchasing choices. Brands that adopt bamboo containers not only contribute to environmental preservation but also align with the values of a growing segment of environmentally conscious consumers.

Successful examples include Evodrop, which announced on May 22, 2025, that it has switched to 100% bamboo materials, showcasing a commitment to reducing plastic waste and promoting a cleaner environment. This shift not only satisfies consumer demand for sustainable options but also positions brands as leaders in the movement towards responsible packaging solutions. Sustainability leaders emphasize that "Bamboo is a raw material that is especially fitting for containers because it grows rapidly and returns to the natural cycle by itself after use," further solidifying its status as an eco-friendly material.

Additionally, Earthmade's Bamboo-O demonstrates the versatility and benefits of compostable packaging materials, as it is made from bamboo fiber and plant starch, and is 100% home-compostable. Highlighting bamboo's low resource consumption, which requires minimal water and no pesticides, further emphasizes its advantages, making it a compelling option for companies aiming to enhance their market presence while supporting a sustainable future.

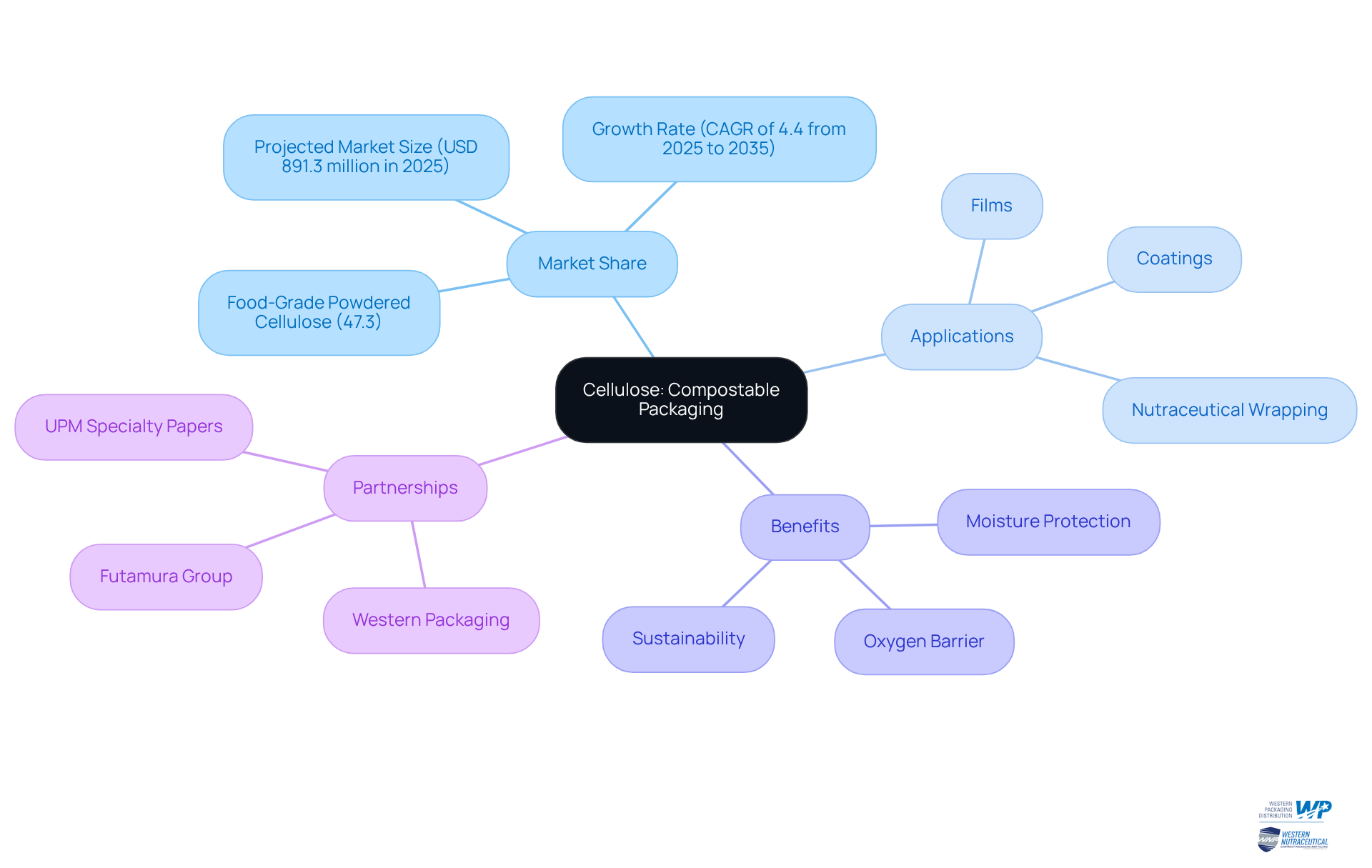

Cellulose: Natural Compostable Material for Packaging Solutions

Cellulose, derived from plant fibers, is one of the highly regarded compostable packaging materials known for its exceptional barrier properties. This versatile material, specifically compostable packaging materials, is increasingly utilized in films and coatings for food containers, making it an ideal choice for health product companies aiming to enhance product freshness while promoting sustainability.

By 2025, the cellulose market is projected to capture a significant share, with food-grade powdered cellulose leading at 47.3%. This growth reflects the rising consumer preference for compostable packaging materials, as companies recognize the importance of aligning with clean-label trends. Notably, prominent dietary supplement firms are already integrating cellulose into their wrapping strategies, showcasing its effectiveness in preserving product integrity.

The barrier properties of cellulose provide protection against moisture and oxygen, thereby extending shelf life, which positions it as a compelling option for manufacturers dedicated to sustainability and quality, particularly those utilizing compostable packaging materials.

By partnering with Western Packaging, nutraceutical producers can access customized flexible containers, such as large pouches and stick packs, that utilize cellulose, enhancing product appeal and identity. Consider Western Packaging for your wrapping needs to ensure a cohesive and captivating brand identity.

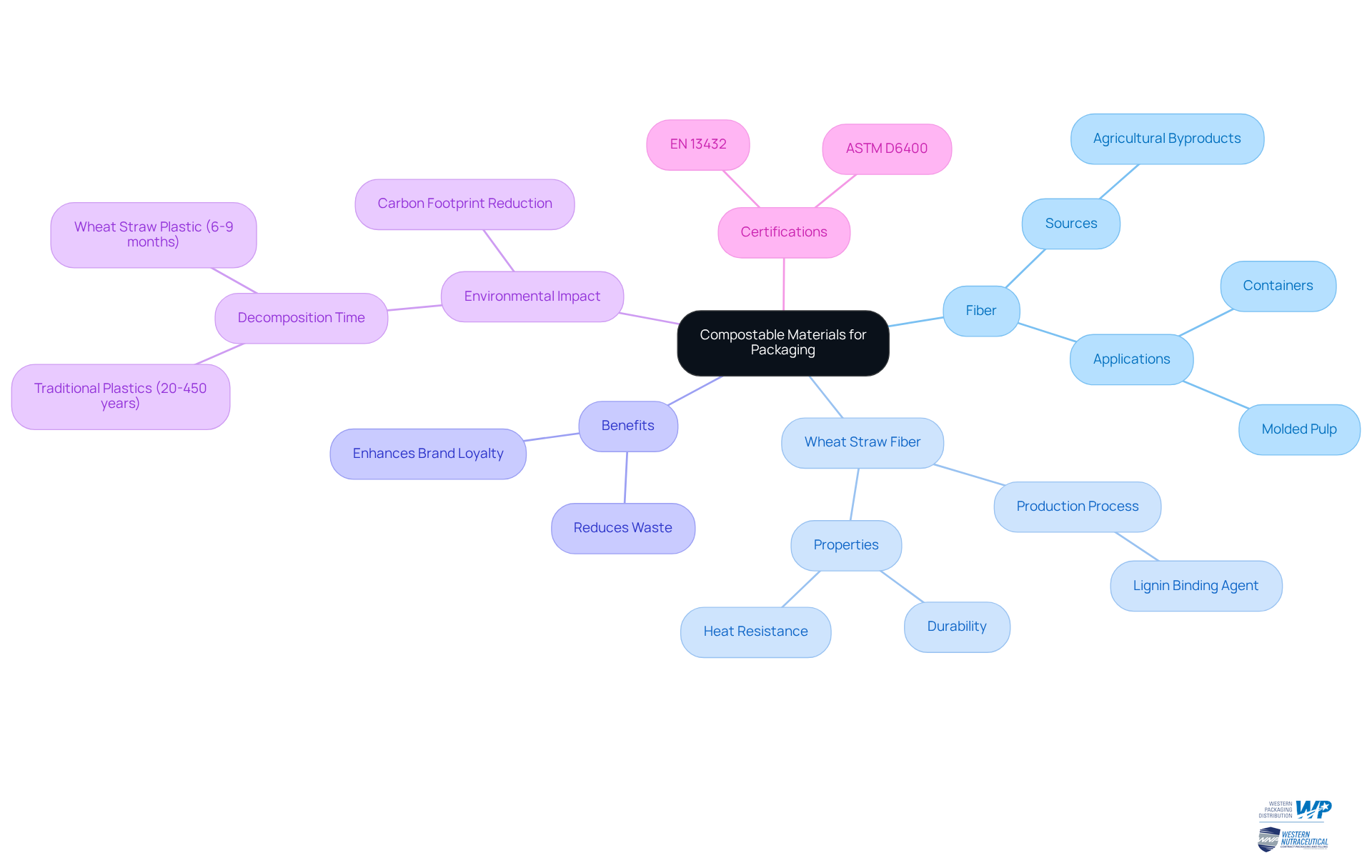

Fiber and Wheat Straw Fiber: Compostable Materials for Eco-Conscious Packaging

Fiber and wheat straw fiber, both derived from agricultural byproducts, serve as innovative compostable options for packaging solutions. These materials can be transformed into various products, including containers and molded pulp, significantly reducing waste and promoting sustainability within the health supplement industry. By embracing these eco-friendly alternatives, nutraceutical brands not only contribute to environmental conservation but also connect with eco-conscious consumers, thereby enhancing brand recognition and loyalty.

Recent studies underscore the benefits of utilizing agricultural byproducts, showcasing their capacity to mitigate environmental impacts while providing efficient alternatives. Notably, traditional plastic packaging can take between 20 to 450 years to decompose, highlighting the urgent need to adopt eco-friendly options. Additionally, certifications such as ASTM D6400 and EN 13432 validate the compostability of these materials, ensuring compliance with industry standards.

As the sector evolves towards more sustainable practices, integrating these resources is vital for brands aiming to thrive in a competitive market focused on sustainability.

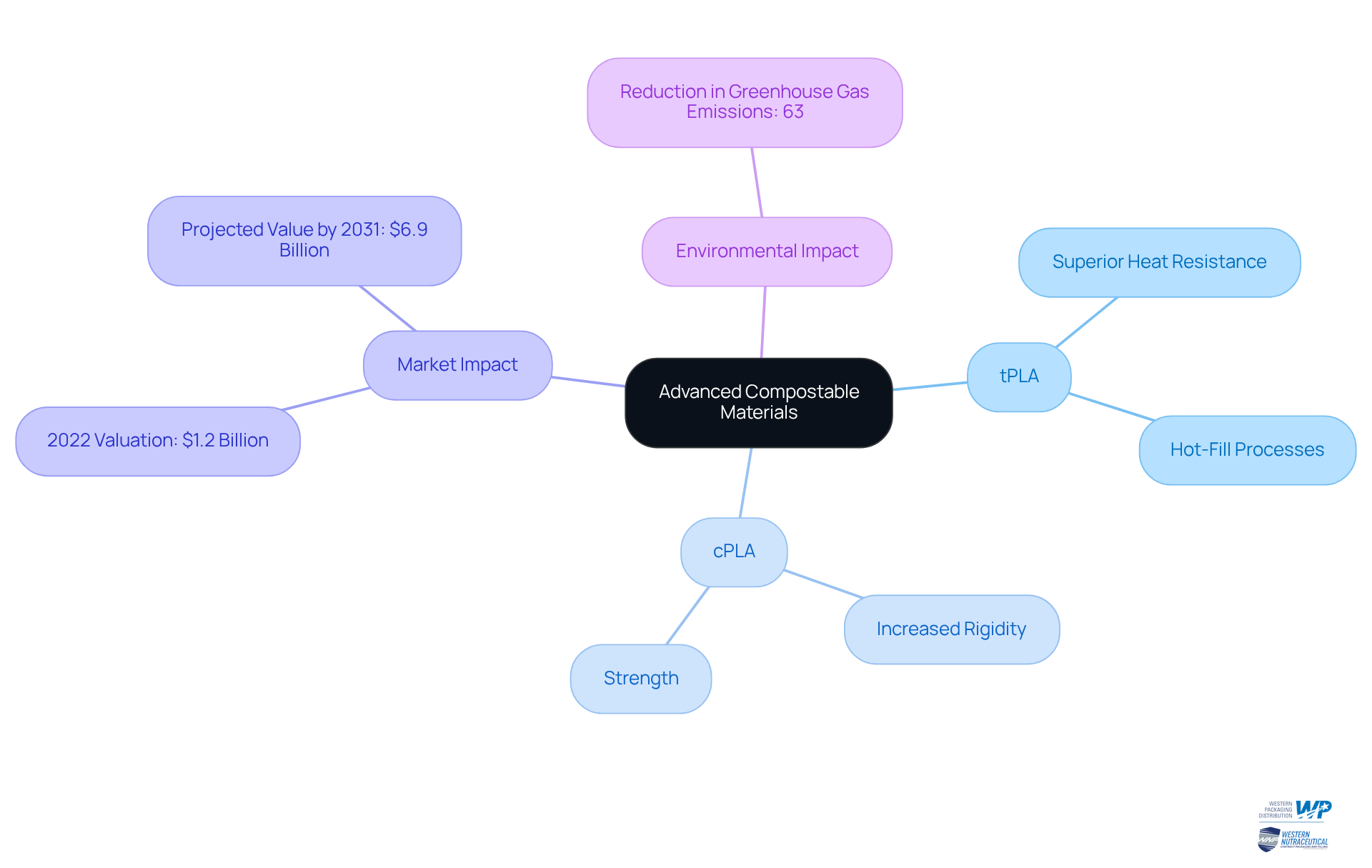

tPLA and cPLA: Advanced Compostable Materials for Packaging Innovation

tPLA (thermoplastic PLA) and cPLA (crystalized PLA) represent significant advancements in Polylactic Acid technology, offering enhanced characteristics tailored for container solutions. tPLA is particularly recognized for its superior heat resistance, making it optimal for hot-fill processes, whereas cPLA is distinguished by its increased rigidity and strength. Both compostable packaging materials are fully compostable, aligning perfectly with the growing demand for eco-friendly solutions in the nutraceutical sector.

The global market for PLA products was valued at $1.2 billion in 2022, with projections indicating an increase to $6.9 billion by 2031, underscoring the rising interest in sustainable resources. By incorporating tPLA and cPLA into their packaging strategies, brands not only enhance their product offerings but also reinforce their commitment to environmental stewardship.

However, it is essential to acknowledge that the production costs of PLA are higher than those of conventional plastics, which may present challenges for some manufacturers. This shift towards advanced compostable packaging materials is increasingly recognized as a competitive advantage in the nutraceutical market, where sustainability is becoming a crucial differentiator.

Industry leaders assert that the adoption of these innovative materials can significantly reduce greenhouse gas emissions by up to 63%, further strengthening the case for their implementation.

Conclusion

Embracing compostable packaging materials is not merely a trend; it is a pivotal strategy for nutraceutical companies striving to align with consumer values and environmental sustainability. The exploration of various compostable options, such as PLA, bagasse, PHA, and cornstarch, illustrates how these materials can effectively reduce ecological footprints while enhancing brand reputation. As demand for eco-friendly packaging solutions continues to rise, adopting these innovative materials positions companies as leaders in the sustainable marketplace.

Throughout this discussion, key insights illuminate the advantages of different compostable materials, including their biodegradability, consumer preferences for sustainable options, and the regulatory landscape advocating for greener practices. Case studies of successful brands exemplify the tangible benefits of integrating compostable packaging into their operations, reinforcing the notion that sustainability is not only a responsibility but also a competitive advantage in the nutraceutical sector.

In a world where consumer choices are increasingly influenced by environmental considerations, the shift towards compostable packaging is crucial. Companies that prioritize sustainable materials not only contribute to a healthier planet but also resonate with a growing base of eco-conscious consumers. The time has come for nutraceutical brands to embrace these innovative solutions, setting a standard for sustainability that will drive success and foster loyalty in an evolving marketplace.

Frequently Asked Questions

What integrated solutions does Western Packaging offer for sustainable brands?

Western Packaging provides a comprehensive suite of integrated compostable packaging materials solutions specifically tailored for nutraceutical companies, along with extensive 3PL services that include warehousing, inventory management, and distribution.

How does Western Packaging help businesses meet sustainability goals?

By combining innovative design with sustainable materials, Western Packaging enables businesses to meet regulatory standards while appealing to eco-conscious consumers, streamlining the supply chain, and enhancing product visibility in a competitive market.

What are the trends in consumer purchasing decisions regarding sustainability?

By 2025, 63% of global consumers are expected to prefer eco-friendly brands and are willing to invest more in sustainable products, indicating a significant shift towards sustainability in purchasing decisions.

What is Polylactic Acid (PLA) and its significance in packaging?

PLA is a biodegradable polymer derived from renewable resources like corn starch, recognized for its exceptional barrier properties and clarity. It serves as an environmentally friendly alternative for compostable packaging materials, suitable for various applications.

What is the projected market growth for PLA by 2025?

The global market for PLA is projected to reach approximately 1.756 billion dollars by 2025, reflecting its growing acceptance and use in the industry.

How does using PLA benefit nutraceutical companies?

Utilizing PLA and other compostable packaging materials helps nutraceutical companies enhance their sustainability image while preserving product integrity, meeting consumer demand for eco-friendly products.

What is sugarcane pulp (bagasse) and how is it used in packaging?

Sugarcane pulp, or bagasse, is a sustainable alternative derived from the fibrous residue left after sugar extraction. It is compostable and durable, making it suitable for various delivery formats like trays and containers.

What consumer preferences are influencing the adoption of compostable packaging?

Surveys indicate that 7 in 10 consumers prefer restaurants that use compostable packaging materials, even at a slightly higher cost, reflecting a growing preference for sustainability.

What regulatory changes are affecting the use of single-use plastics?

By 2025, new legislation in Europe, Asia, and the Middle East will prohibit single-use plastic containers in foodservice, prompting nutraceutical companies to adopt compostable packaging materials to stay ahead of regulatory pressures.

Is bagasse packaging safe for food contact?

Yes, all bagasse packaging is FDA-approved for direct food contact, enhancing credibility and fostering customer loyalty among environmentally conscious consumers.