Overview

The article titled "10 Essential Repackaging Services for Nutraceutical Manufacturers" centers on the critical repackaging services that nutraceutical manufacturers must consider. It details various service providers and their specialized offerings, underscoring how these services enhance product appeal, ensure compliance with regulations, and optimize supply chain management. This support enables manufacturers to effectively meet market demands. For those in the industry, understanding these essential services is not just beneficial; it is imperative for maintaining a competitive edge.

Introduction

The nutraceutical industry is experiencing rapid evolution, propelled by consumer demand for innovative packaging solutions that enhance product appeal and ensure safety. As manufacturers navigate this competitive landscape, the importance of effective repackaging services cannot be overstated. This article delves into ten essential repackaging services that not only streamline operations but also elevate brand presence. This prompts a critical question: how can nutraceutical producers leverage these services to tackle the challenges of an increasingly complex market?

Western Packaging: Integrated Packaging Solutions for Nutraceuticals

Western Packaging delivers a seamless integration of design, filling services, and third-party logistics specifically tailored for the nutraceutical sector. Their innovative container designs not only enhance product appeal but also streamline the supply chain, allowing producers to focus on their core competencies. By offering comprehensive services, Western Packaging ensures that clients can effectively meet their unique container requirements, ultimately boosting their market presence and operational efficiency. Trust in Western Packaging to provide the reliable solutions you need to elevate your business.

Safecor Health: Unit-Dose Repackaging Services for Compliance and Safety

Western Packaging stands at the forefront of customized flexible packaging solutions and integrated filling services, designed specifically to enhance product attractiveness for nutraceutical producers. Their filling process seamlessly integrates into comprehensive systems, adeptly accommodating a variety of forms, including powders and gummies. This holistic approach encompasses 3PL services for warehousing, inventory management, and logistics, ultimately optimizing supply chain management. By enabling producers to focus on their core competencies, Western Packaging ensures strict adherence to safety regulations and reliability in every aspect of the process.

Snapl: Scalable Repackaging Solutions for Supply Chain Optimization

Western Packaging offers adaptable repackaging services that empower nutraceutical producers to optimize their supply chains. Our comprehensive 3PL services—including warehousing, inventory management, logistics, and integrated filling options—enable producers to respond swiftly to evolving market demands.

As consumer preferences shift, the capacity to scale operations effectively is essential. Our tailored strategies ensure that producers maintain efficiency and meet client expectations without compromising quality, allowing them to focus on their core competencies.

Trust in our expertise to enhance your operational agility and drive success in a competitive landscape.

Lean Supply Solutions: Tailored Repackaging Management Services

Lean Supply Solutions stands as a leader in providing tailored repackaging services that are specifically designed to meet the unique needs of nutraceutical manufacturers. By focusing on customized wrapping options, they empower companies to enhance product appeal while ensuring that the packaging embodies brand identity. This personalized approach not only boosts customer satisfaction but also plays a pivotal role in cultivating brand loyalty.

Notably, effective container design significantly influences consumer perceptions; studies indicate that 72% of American consumers are swayed by container aesthetics. By investing in tailored solutions, nutraceutical brands can craft memorable unboxing experiences that reinforce brand identity and promote repeat purchases.

Ultimately, the impact of customized packaging transcends mere aesthetics; it fosters a deeper connection with consumers, solidifying brand loyalty in an increasingly competitive market.

Parcel Industry: Insights on Repackaging Services in Modern Supply Chains

The parcel industry provides critical insights into the transformation of repackaging services in modern supply chains. With the exponential growth of e-commerce, the demand for streamlined and effective repackaging services has surged. This shift compels manufacturers to remain vigilant about emerging trends, enabling them to refine their strategies and maintain a competitive edge in a dynamic market.

For instance, the rise of omni-commerce has redefined how nutraceuticals are packaged and distributed, emphasizing the need for flexibility and responsiveness to consumer preferences. Companies are increasingly adopting innovative container designs that not only enhance product visibility but also cater to the convenience sought by online shoppers.

Current trends suggest a shift towards sustainable materials, reflecting consumer demand for environmentally friendly choices. Furthermore, the incorporation of technology in container processes, such as smart labels and QR codes, enables improved customer interaction and product traceability.

As e-commerce continues to influence the landscape, dietary supplement producers must adopt these changes in repackaging services to enhance their supply chains and satisfy the evolving demands of their clients. To remain competitive, producers should consider adopting adaptable packaging designs and investigating sustainable materials that align with consumer preferences. Moreover, as highlighted by industry experts, adapting to new technologies is crucial; failure to do so could result in significant challenges in the coming decade.

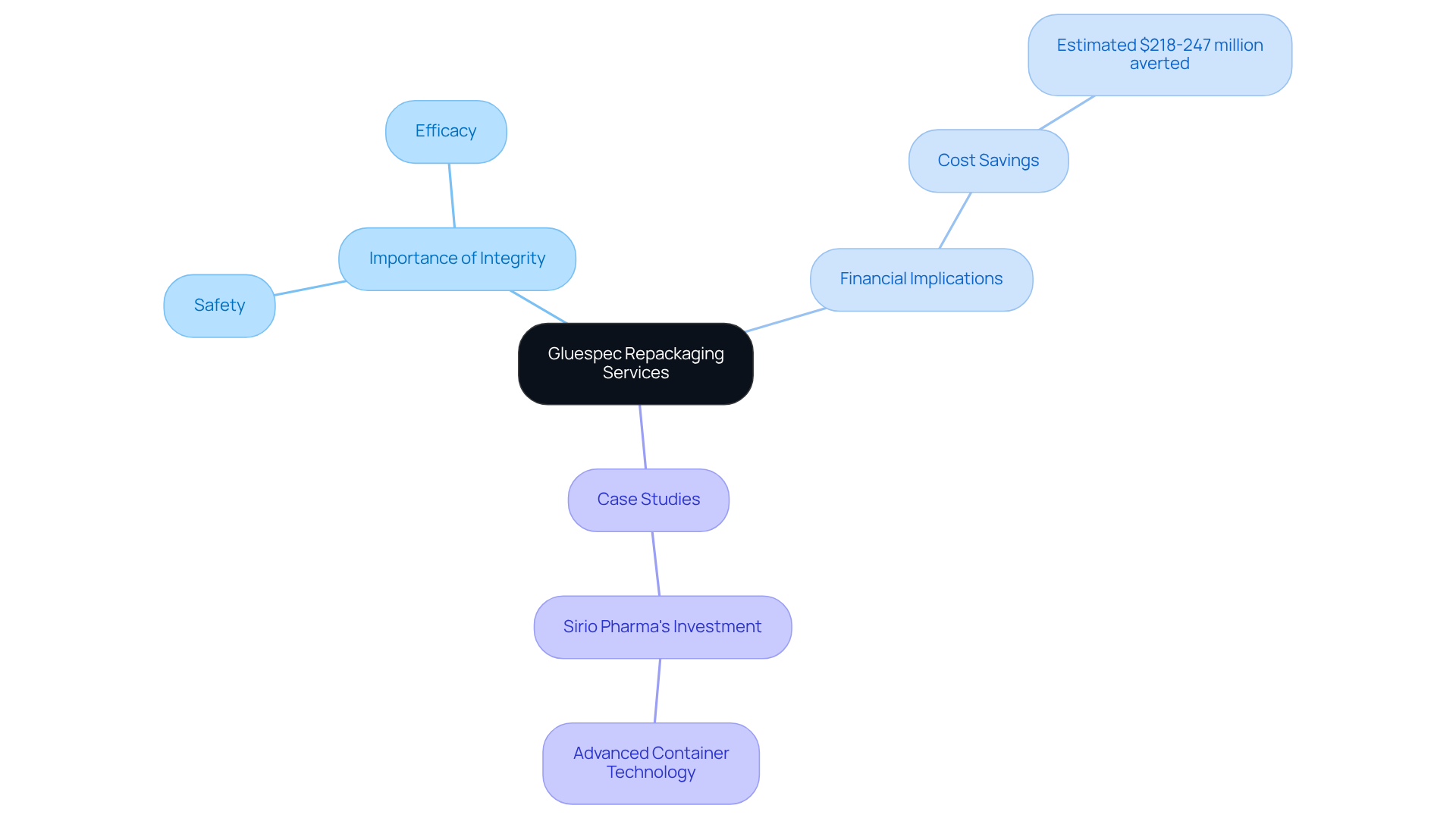

Gluespec: Chemical Repackaging Services for Diverse Formulations

Gluespec specializes in repackaging services for chemicals tailored to the diverse formulations found in health supplement products. This service is crucial for maintaining the integrity and efficacy of these formulations, ensuring that products remain safe and effective for consumers. By employing specialized repackaging services, Gluespec assists manufacturers in protecting their products while enhancing their shelf appeal.

The significance of maintaining product integrity is highlighted by the estimated $218-247 million in costs averted for the supplements industry due to tariff exemptions, underscoring the financial implications of effective repackaging. As Steve Brauer, President of Brenntag Specialties, Inc., emphasizes, a commitment to health product clients is vital for delivering high-quality wellness options.

Furthermore, case studies such as Sirio Pharma's investment in advanced container technology illustrate the practical benefits of preserving product integrity through specialized repackaging. As the dietary supplement industry advances, implementing effective repackaging services remains a top priority for producers striving to offer high-quality health products.

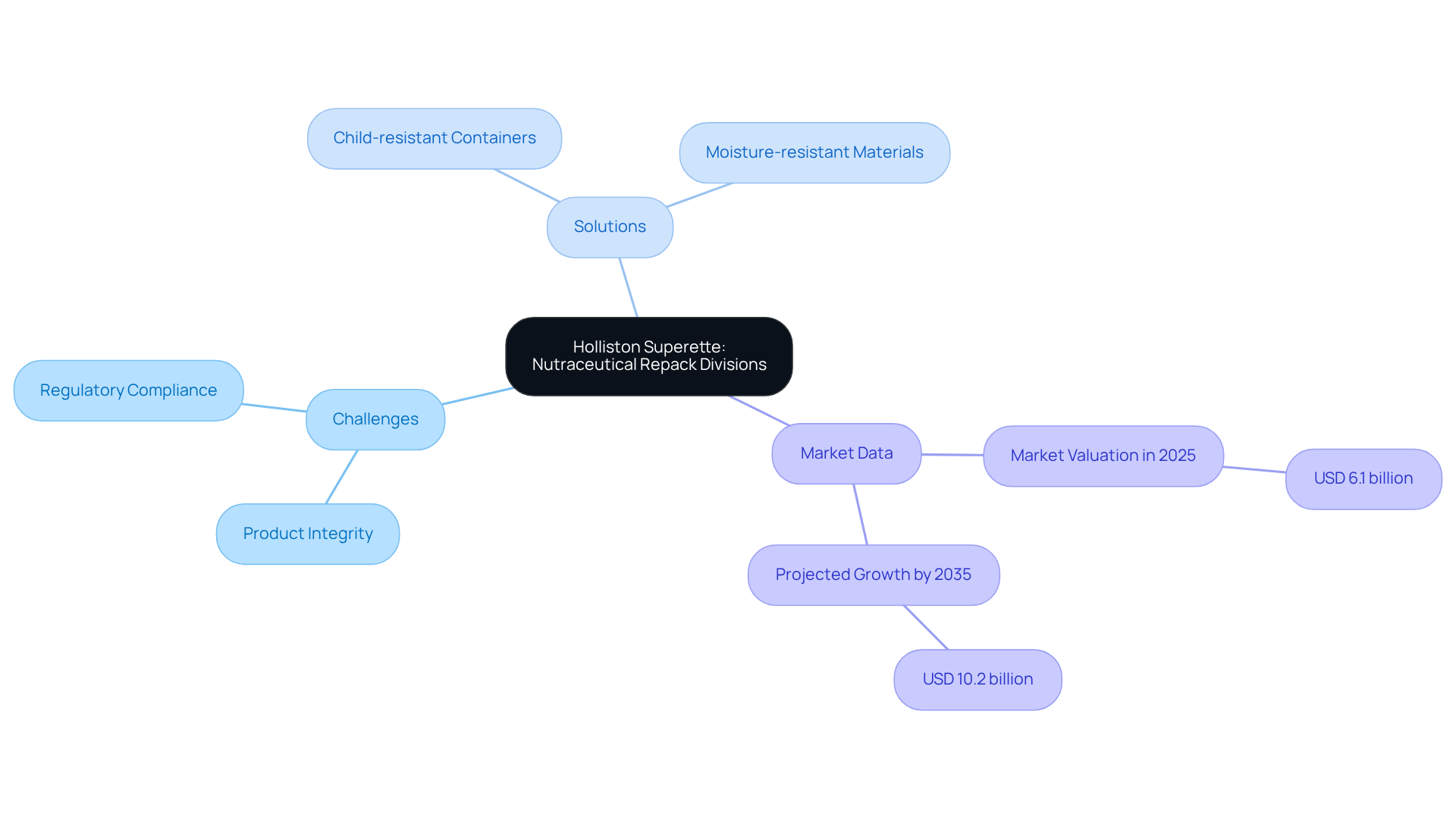

Holliston Superette: Specialized Repack Divisions for Nutraceuticals

Holliston Superette operates specialized repack divisions tailored specifically for the dietary supplement sector, adeptly addressing the unique challenges associated with dietary supplement containers. These divisions are meticulously designed to enhance product safety and ensure compliance with rigorous regulatory standards. The market for health-related product containers was valued at USD 6.1 billion in 2025 and is projected to reach USD 10.2 billion by 2035, expanding at a compound annual growth rate of 5.6% from 2025 to 2030. This growth underscores the increasing demand for efficient container solutions.

A primary challenge within this sector is maintaining product integrity while adhering to regulatory requirements. Compliance with guidelines from organizations such as the USFDA and EFSA is essential, as it guarantees consumer protection and product transparency. Industry experts assert, "Regulatory compliance poses a considerable obstacle to the nutraceutical sector, necessitating adherence to standards that regulate food safety and labeling." Holliston Superette's tailored offerings not only meet these compliance standards but also enhance operational efficiency, allowing manufacturers to focus on their core competencies.

The impact of these customized approaches is substantial; they facilitate smoother compliance processes and mitigate risks associated with labeling errors. Notable examples of tailored solutions include:

- Child-resistant containers

- Moisture-resistant materials

These solutions are vital for maintaining product stability and extending shelf life. As the dietary supplement market continues to expand—North America holding over 36% of the market share in 2024, with the tablets and capsules segment leading at over 42% market share—the necessity for specialized repackaging services becomes increasingly critical for producers striving to succeed in a competitive landscape. By prioritizing the distinct needs of health supplement manufacturers, Holliston Superette establishes itself as a pivotal partner in navigating the complexities of packaging compliance.

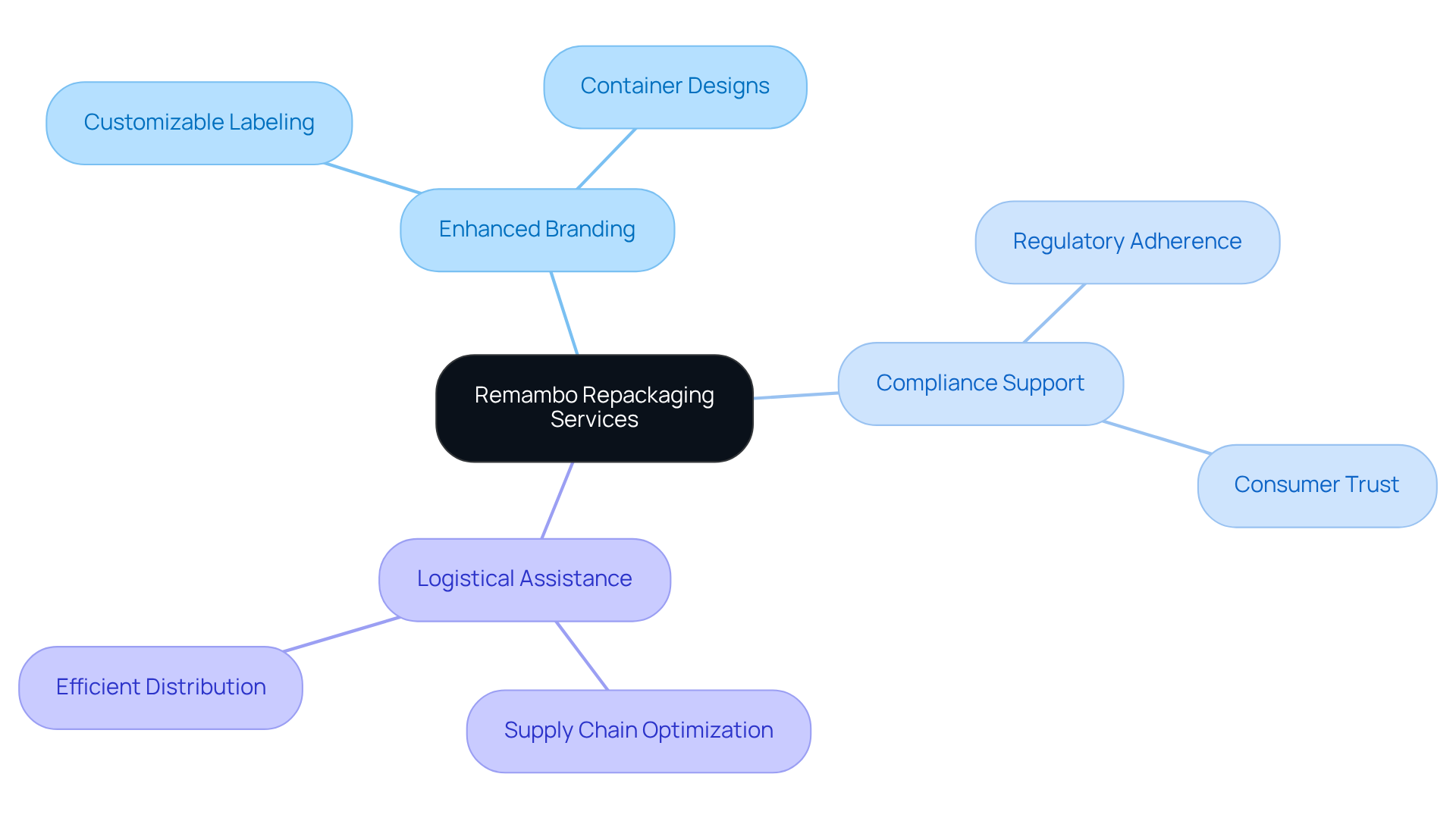

Remambo: Comprehensive Repackaging Services with Optional Features

Remambo provides a comprehensive suite of repackaging services that are specifically tailored for nutraceutical producers, including optional enhancements to address a variety of business needs. This flexibility empowers companies to select additional services that align with their strategic objectives, such as:

- Enhanced branding

- Compliance support

- Logistical assistance

By providing customizable options, Remambo enables manufacturers to optimize their repackaging services, ultimately maximizing value and enhancing brand recognition in a competitive market. For example, customizable labeling and container designs can significantly elevate product appeal, while compliance features ensure adherence to regulatory standards, fostering consumer trust. Such tailored approaches not only enhance operations but also contribute to a more robust market presence, establishing Remambo as an indispensable ally in the dietary supplement industry with its repackaging services.

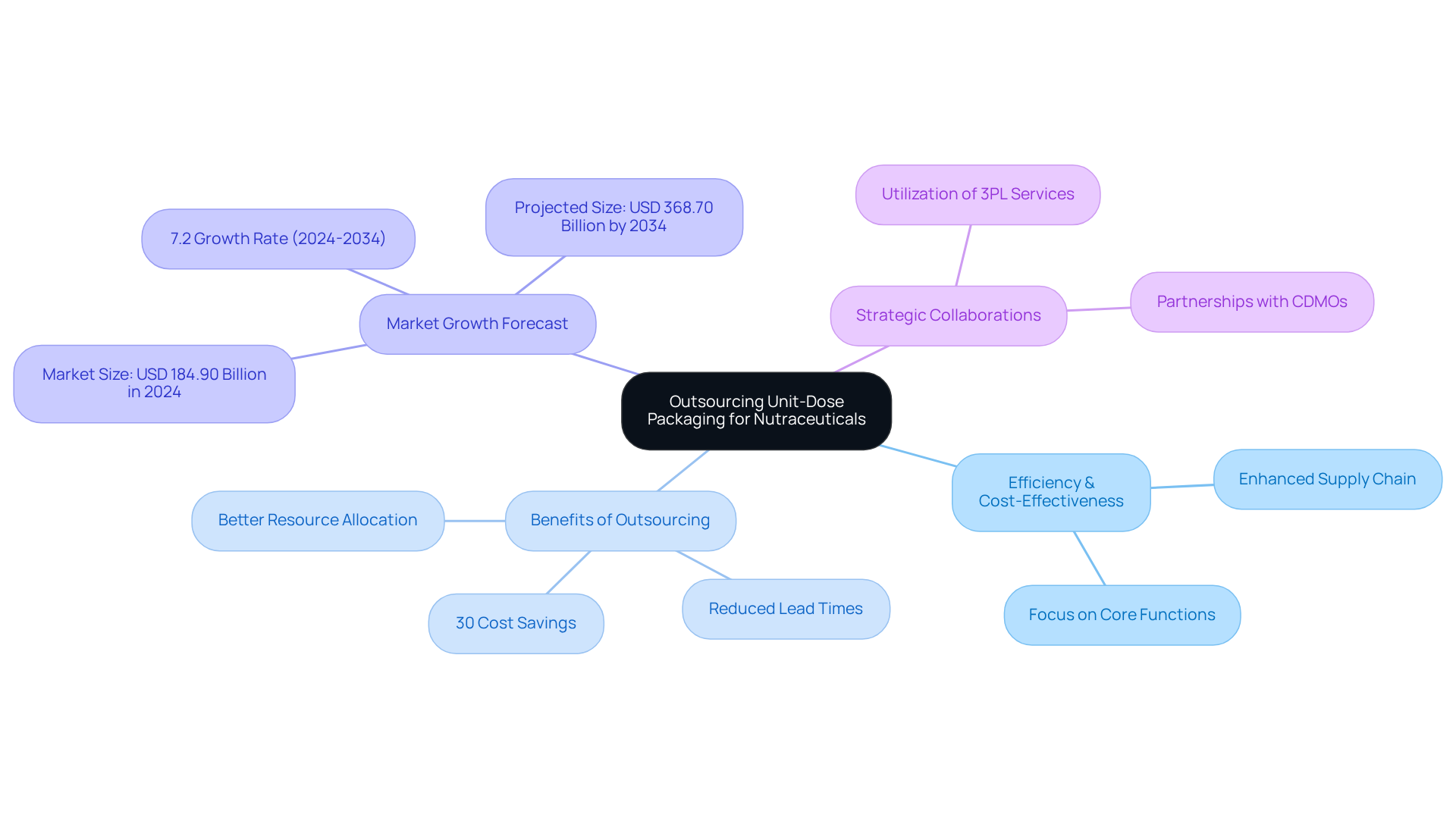

Rx Insider: Trends in Outsourcing Unit-Dose Packaging for Nutraceuticals

The trend of outsourcing unit-dose wrapping is gaining momentum among nutraceutical producers, driven by the necessity for enhanced efficiency and cost-effectiveness. By leveraging specialized wrapping services, such as those offered by Western Packaging, companies can significantly enhance their supply chain through comprehensive 3PL solutions that encompass warehousing, inventory management, and logistics. This strategic move allows producers to concentrate on their core business functions while experts manage the complexities of wrapping.

Outsourcing repackaging services offers significant advantages, such as reduced lead times and better resource allocation. Companies that have adopted this approach report impressive cost savings, with some achieving reductions of up to 30% in packaging expenses. This financial relief empowers producers to reinvest in research and development, thereby strengthening their competitive edge in the marketplace.

Furthermore, the pharmaceutical Contract Development and Manufacturing Organization (CDMO) market is anticipated to expand at a rate of 7.2% from 2024 to 2034, underscoring the growing demand for efficient outsourcing solutions. As this market evolves, health product producers increasingly recognize the importance of collaborating with CDMOs and utilizing tailored 3PL services from Western Packaging to enhance their packing processes.

In conclusion, outsourcing unit-dose wrapping not only fosters operational efficiency but also enables producers to adeptly respond to the shifting demands of the market, ultimately leading to improved product offerings and heightened customer satisfaction.

All In Aviation: Maintenance and Support Services for Packaging Equipment

All In Aviation offers expert maintenance and support services for wrapping machinery, which are crucial for ensuring the reliability and efficiency of repackaging services. Regular maintenance not only prevents downtime but also guarantees that equipment operates at peak performance. For nutraceutical manufacturers, investing in repackaging services is vital for maintaining high-quality packaging standards and meeting production demands. By prioritizing maintenance, manufacturers can achieve consistent operational excellence and enhance their competitive edge in the market.

Conclusion

The exploration of essential repackaging services for nutraceutical manufacturers underscores the critical role that effective packaging plays in enhancing product appeal, ensuring compliance, and optimizing supply chains. By leveraging specialized services, manufacturers can streamline their operations and strengthen their market presence in a competitive landscape.

Key insights discussed throughout the article highlight the importance of tailored solutions, such as those offered by Western Packaging, Safecor Health, and Lean Supply Solutions. These companies provide a comprehensive range of services that address unique industry challenges, from unit-dose compliance to scalable packaging strategies. The emphasis on customization and flexibility enables nutraceutical producers to respond adeptly to changing consumer preferences while maintaining high standards of safety and quality.

In a rapidly evolving market, the significance of adopting innovative repackaging strategies cannot be overstated. As manufacturers navigate the complexities of compliance and consumer expectations, investing in comprehensive repackaging services emerges as a strategic imperative. By prioritizing these solutions, nutraceutical companies can enhance their operational efficiency, foster brand loyalty, and ultimately deliver superior products that resonate with health-conscious consumers. Embracing these advancements will prepare businesses for future challenges and position them for sustained success in the thriving nutraceutical sector.

Frequently Asked Questions

What services does Western Packaging provide for the nutraceutical sector?

Western Packaging offers integrated packaging solutions that include design, filling services, and third-party logistics (3PL) tailored specifically for nutraceutical producers.

How does Western Packaging enhance product appeal for nutraceutical producers?

They provide innovative container designs that not only enhance product attractiveness but also streamline the supply chain, allowing producers to focus on their core competencies.

What types of products can Western Packaging accommodate in their filling process?

Western Packaging's filling process can accommodate a variety of forms, including powders and gummies.

What are the benefits of Western Packaging's 3PL services?

Their 3PL services include warehousing, inventory management, and logistics, which optimize supply chain management and enable producers to respond quickly to market demands.

How does Western Packaging ensure compliance and safety in their services?

They adhere strictly to safety regulations and reliability in every aspect of the process, ensuring that their clients meet compliance requirements.

What is the significance of scalable repackaging solutions offered by Western Packaging?

Scalable repackaging solutions allow nutraceutical producers to optimize their supply chains and adapt to shifting consumer preferences without compromising quality, thus maintaining operational efficiency.

How does Western Packaging help clients focus on their core competencies?

By providing comprehensive services and support in packaging and logistics, Western Packaging enables clients to concentrate on their primary business activities rather than the complexities of packaging and supply chain management.