Overview

The article emphasizes essential strategies for effective packaging of gummies, highlighting critical factors such as material selection, regulatory compliance, and appealing design. By delving into these elements, it demonstrates how proper packaging not only enhances product quality but also aligns with consumer preferences, ultimately driving sales in the competitive gummy market.

Understanding the significance of these components is crucial for establishing a successful product presence. As we navigate the complexities of packaging, it becomes clear that these considerations are not just recommendations; they are essential for thriving in today's marketplace.

Introduction

The gummy market is witnessing a remarkable surge, with projections indicating it will reach an astounding USD 52.24 billion by 2030. In this competitive landscape, manufacturers are compelled to capture consumer attention, making effective packaging a critical factor for ensuring product quality and enhancing brand recognition.

This article explores ten essential tips that can elevate gummy packaging from mere containment to a formidable marketing tool, tackling challenges such as:

- Regulatory compliance

- Sustainability

- The rising demand for convenience

How can brands innovate their packaging strategies to not only meet consumer expectations but also distinguish themselves in a saturated marketplace?

Western Packaging: Tailored Flexible Packaging Solutions for Gummies

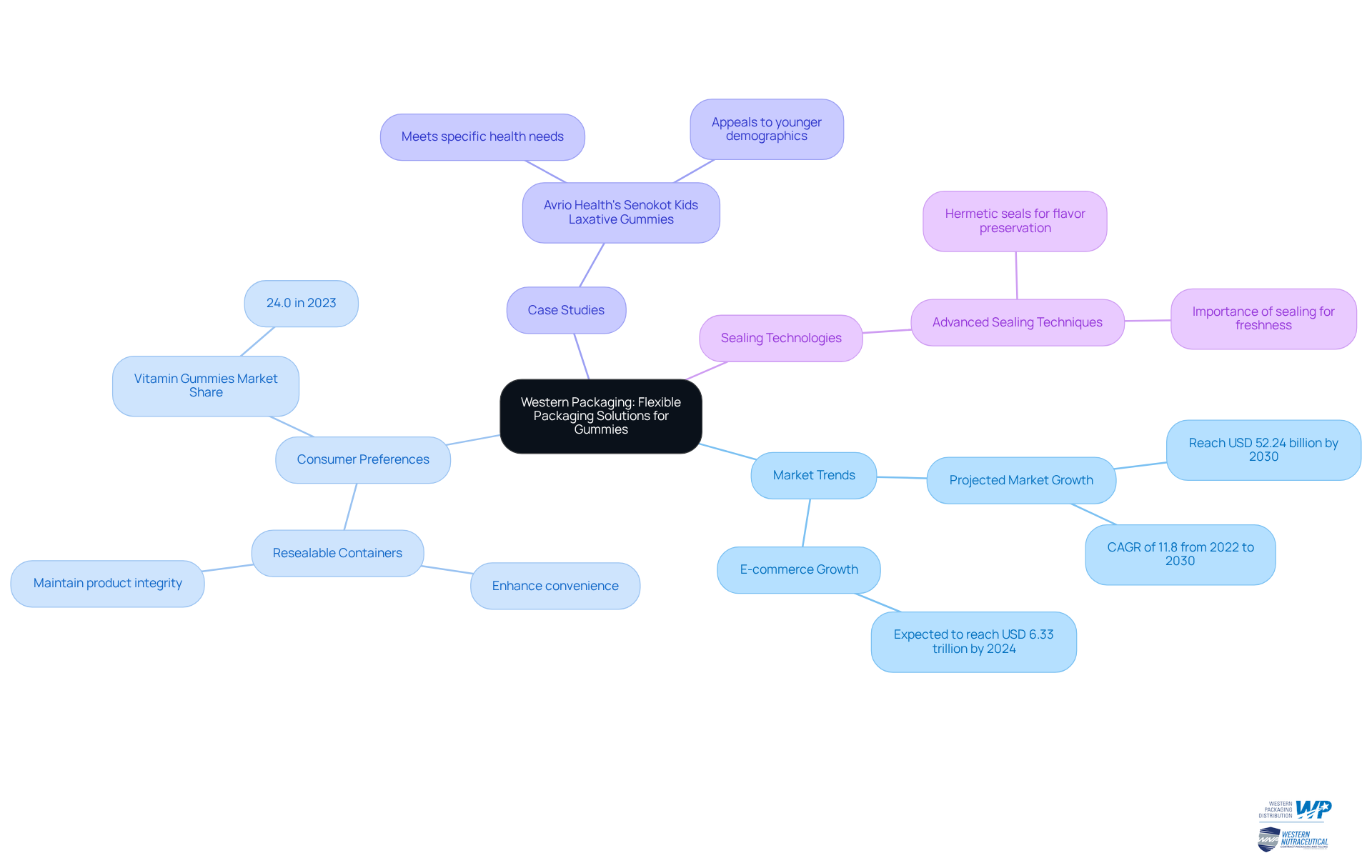

Western Packaging specializes in customized flexible wrappers designed specifically for packaging for gummies. Our approach seamlessly merges creativity with precision, ensuring that each package not only protects the product but also enhances its shelf appeal. With the chewy market projected to reach USD 52.24 billion by 2030, the demand for effective wrapping solutions is more critical than ever. By focusing on the unique requirements of gummy products, Western Packaging empowers manufacturers through effective packaging for gummies, allowing them to refine their wrapping techniques, resulting in improved freshness and heightened customer satisfaction.

Current industry trends indicate a growing preference for resealable containers, which enhance convenience and maintain product integrity. This trend aligns with consumer demands for user-friendly formats, as evidenced by the substantial market share of vitamin gummies, which represented 24.0% in 2023. Successful case studies, such as the launch of Avrio Health's Senokot Kids Laxative Gummies, demonstrate how effective packaging for gummies can meet specific health needs while appealing to younger demographics.

Furthermore, the adoption of advanced sealing technologies, including hermetic seals, is vital for preserving the flavor and texture of chewy candies. This commitment to quality not only fosters brand loyalty but also positions Western Packaging as a frontrunner in the competitive landscape of chewy product solutions. By prioritizing innovative designs and aligning with customer preferences, we guide clients through evolving market dynamics, ensuring their products stand out on retail shelves. Additionally, we provide a comprehensive suite of graphic assets, including labels and brochures, to cultivate a cohesive and captivating brand identity.

Choose the Right Material: Ensure Quality and Freshness

Selecting the appropriate packaging for gummies is essential to preserve product quality and freshness. High-barrier films, for instance, are a crucial type of packaging for gummies as they effectively protect them from moisture, light, and oxygen—critical factors in maintaining their texture and flavor. Furthermore, it is imperative that the materials used in packaging for gummies are food-safe and compliant with industry regulations to ensure consumer safety. Manufacturers should consider options such as Mylar or polyethylene for packaging for gummies, known for their excellent moisture barrier properties. By prioritizing the right materials, businesses can enhance product longevity and consumer satisfaction.

Understand Regulatory Compliance: Meet Industry Standards

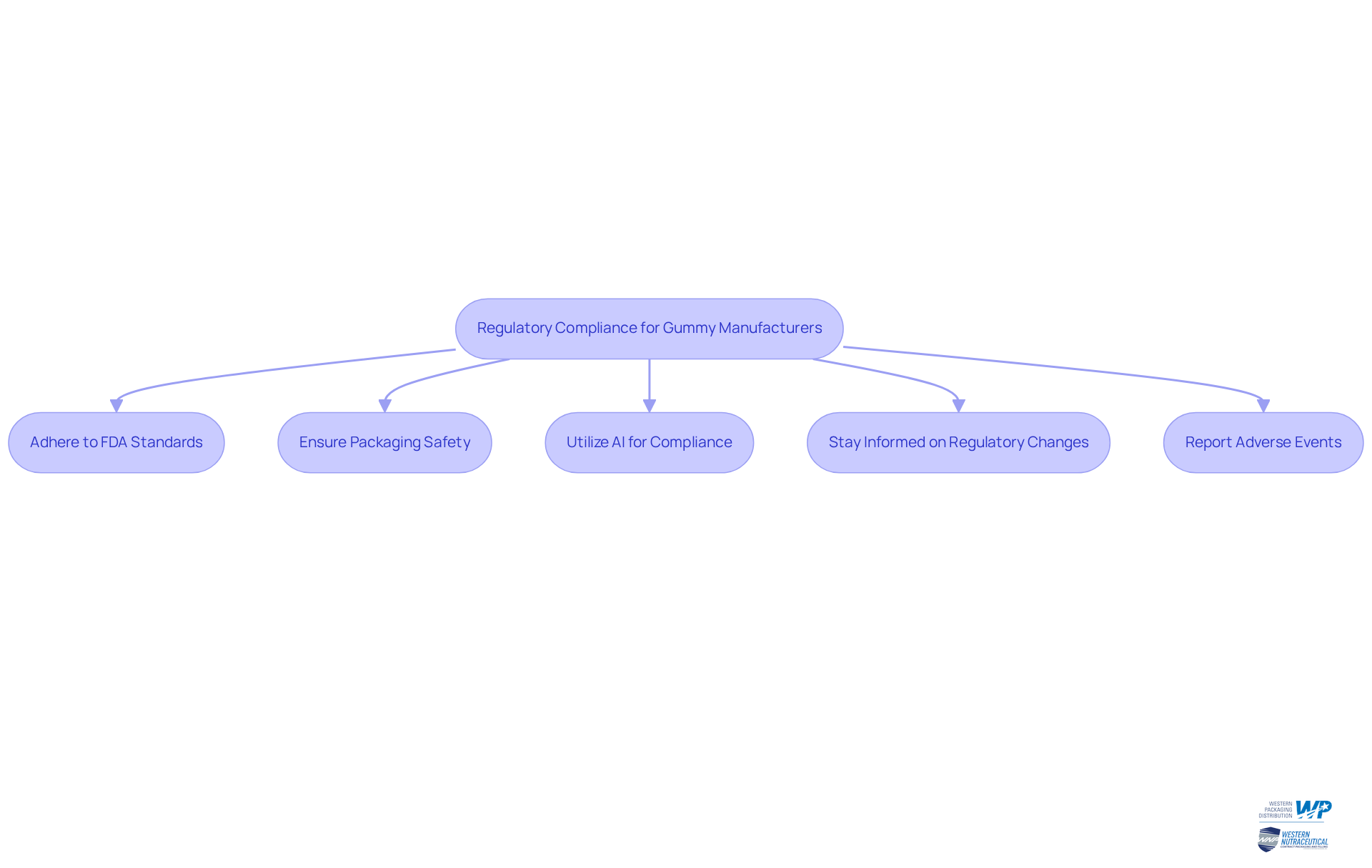

Regulatory compliance is paramount for gummy manufacturers. Packaging for gummies must adhere to stringent standards established by the FDA, which oversees food safety and labeling. This involves guaranteeing that all materials are safe for food contact and that labels precisely communicate the contents, including ingredients and nutritional information.

A significant statistic reveals that over 50% of compliance teams are actively utilizing AI applications to streamline adherence to these regulations, underscoring the evolving landscape of compliance management (Moody's report). Moreover, successful case studies show that manufacturers who prioritize compliance not only evade expensive penalties but also boost customer trust and brand reputation.

Staying informed about regulatory changes is essential. For instance, recent revisions to additive usage limits necessitate that manufacturers adapt their formulations to remain compliant, with the maximum allowable level for Acacia Gum Modified with octenyl succinic anhydride (OSA) in flavoring set at 500ppm. Additionally, manufacturers must report adverse events through the FDA's Safety Reporting Portal, a critical aspect of regulatory compliance.

By upholding strict standards and maintaining proactive communication with regulatory bodies, manufacturers of packaging for gummies can navigate the complexities of compliance effectively, ensuring both safety and market viability.

Prioritize Eye-Catching Design: Enhance Brand Recognition

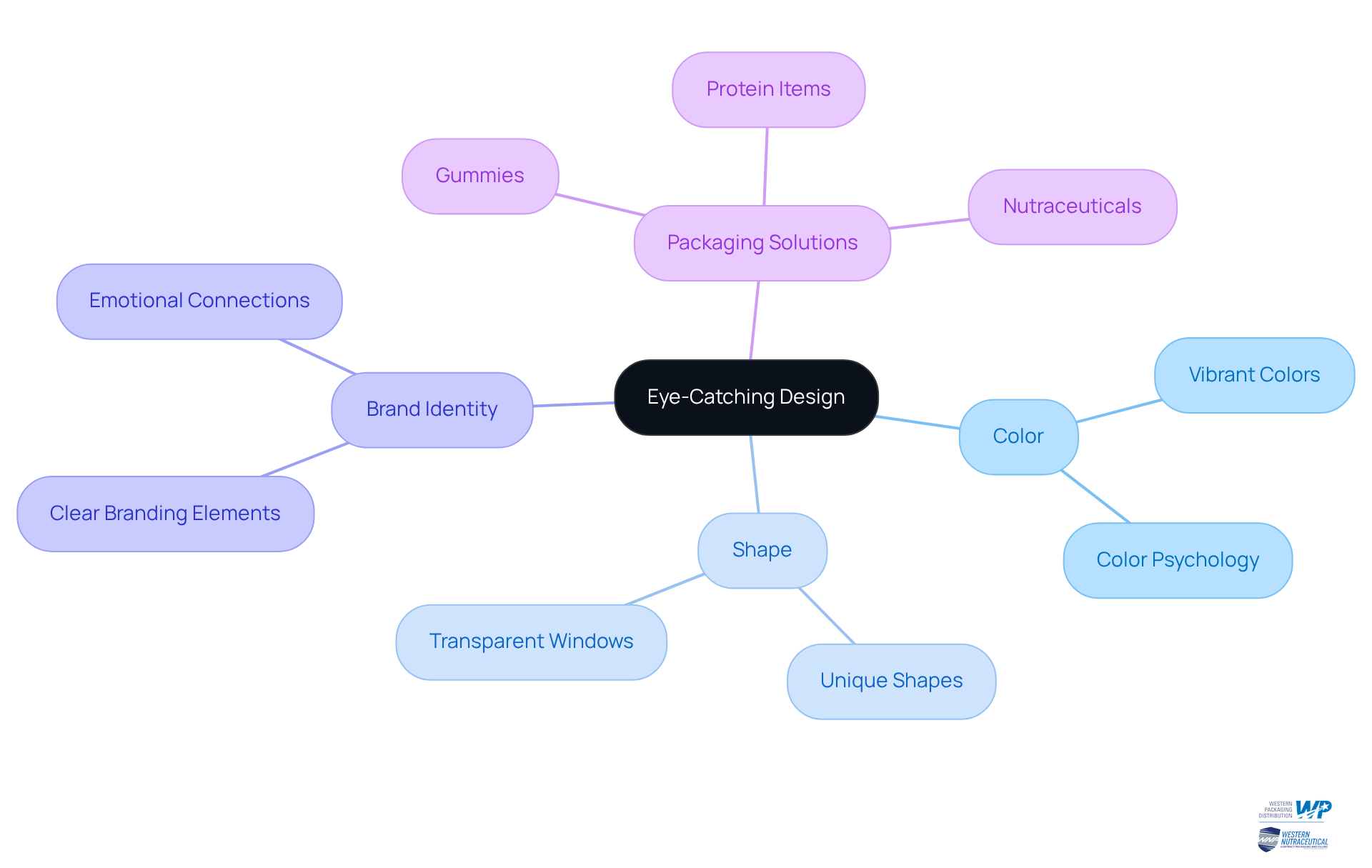

In a competitive market, prioritizing eye-catching design is crucial for enhancing brand recognition. Packaging must not only reflect the brand's identity but also resonate with the target demographic. Utilizing vibrant colors, unique shapes, and clear branding elements significantly attracts consumers' attention on the shelf. For instance, incorporating transparent windows allows potential buyers to view the item, further enticing them to make a purchase. Effective design serves a dual purpose: it captures attention and communicates the product's quality and value.

Research shows that 70% of consumers make buying choices based solely on presentation, highlighting its essential role in branding. Effective product design and appealing packaging for gummies can enhance brand awareness and customer loyalty, making it a crucial strategy for gummy producers.

Western Packaging focuses on customized flexible wrapping solutions, including:

- Packaging for gummies

- Large pouches for protein items

- Stick packs for nutraceuticals

These solutions enhance product appeal, ensuring that your presentation not only stands out but also aligns with your brand identity. Moreover, the emotional reactions prompted by containers' shapes and materials can greatly affect buyer behavior, emphasizing the necessity for deliberate design decisions.

Incorporate Resealability: Maintain Freshness and Convenience

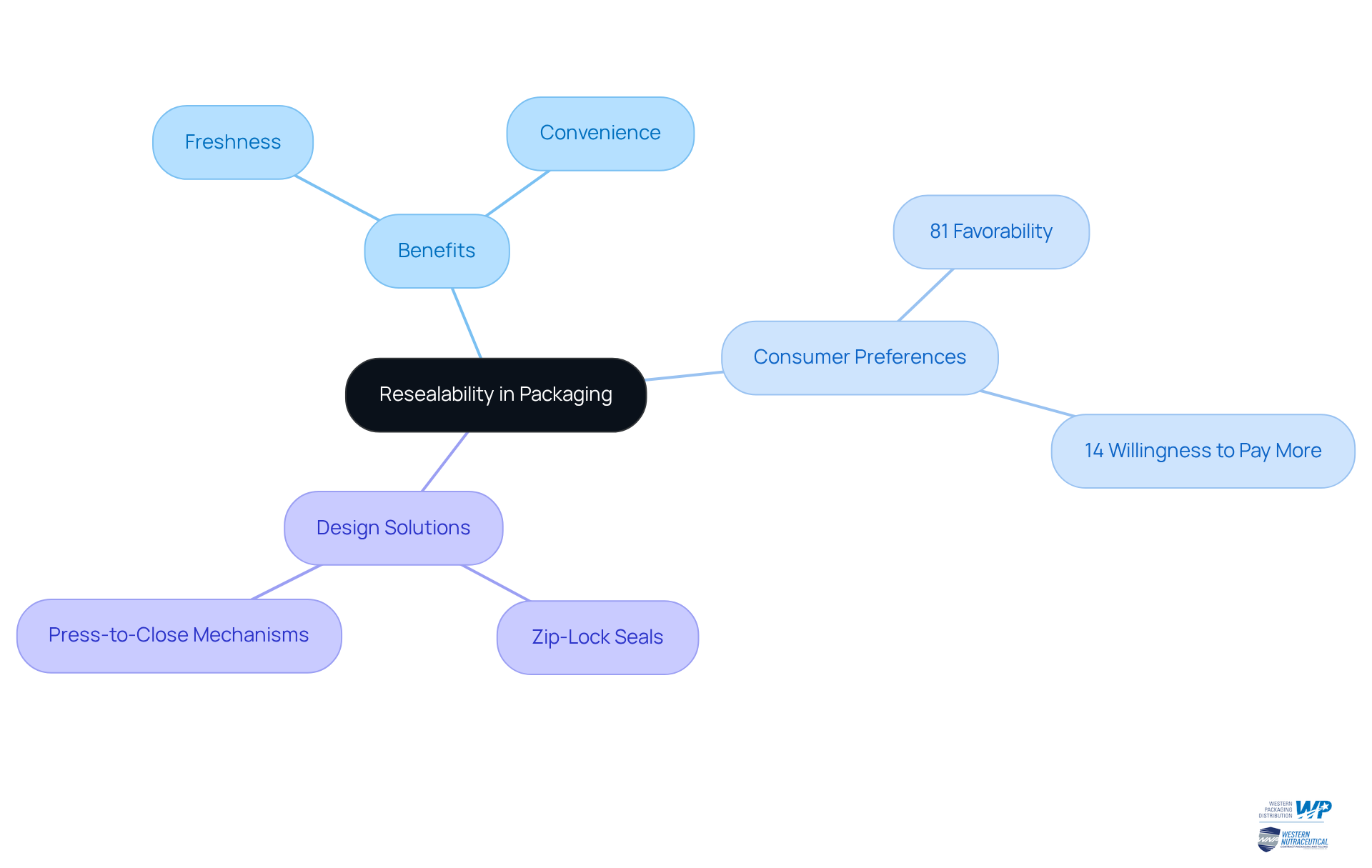

Incorporating resealability into the packaging for gummies is essential for enhancing both freshness and convenience. Resealable pouches or containers, equipped with features like zip-lock seals or press-to-close mechanisms, allow users to easily access the item while protecting it from air and moisture after opening. This is particularly beneficial for those who may not consume the entire package at once, as it helps maintain the gummies' texture and flavor over time. Packaging engineers emphasize that proper packaging for gummies, including airtight seals, is crucial for preserving their quality and preventing degradation caused by exposure to environmental factors.

Western Packaging's proficiency in creative design solutions guarantees that brands can efficiently incorporate resealable features that enhance item attractiveness and brand visibility. Case studies show that brands utilizing resealable containers have experienced notable enhancements in appeal and customer satisfaction. Research indicates that 81% of buyers favor resealable options, highlighting a robust desire for convenience and reassurance in their purchasing choices. Moreover, brands that invest in resealable containers can anticipate a favorable effect on their profits, with shoppers ready to pay up to 14% more for items that provide this feature. By prioritizing resealability in the packaging for gummies, manufacturers not only enhance the freshness of their products but also align with consumer preferences, ultimately driving sales and brand loyalty. As Leo Lee, a prominent authority in cannabis confectionery automation, states, "Effective wrapping serves as the first line of defense against environmental factors that can degrade cannabis treats," underscoring the critical role of efficient wrapping in maintaining product quality.

Opt for Eco-Friendly Options: Appeal to Conscious Consumers

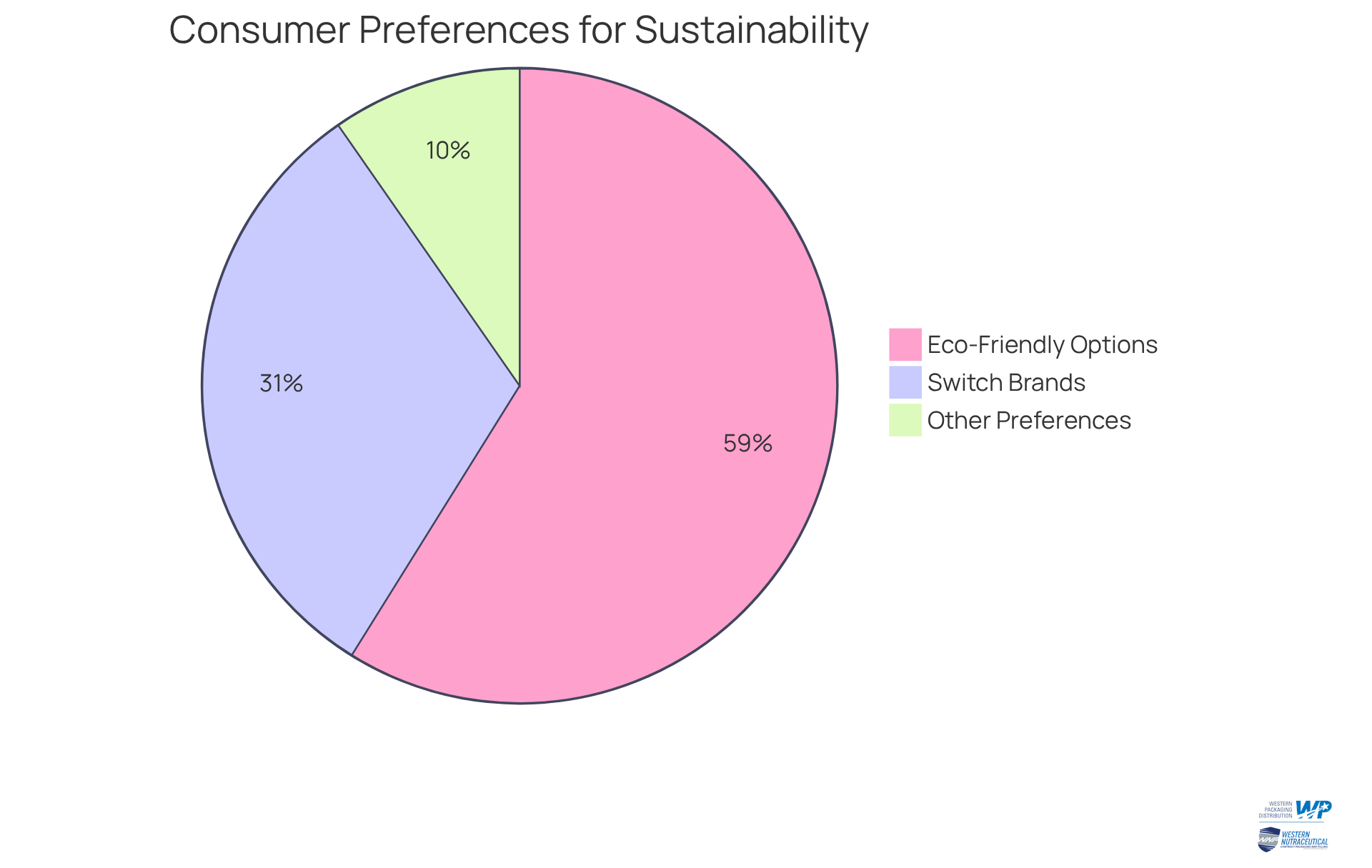

In today's environmentally aware market, it is crucial for gummy manufacturers to adopt eco-friendly packaging for gummies. By utilizing biodegradable materials and recyclable packaging for gummies while minimizing plastic use, brands can significantly enhance their appeal. This strategy not only aligns with customer values but also emphasizes the importance of packaging for gummies, setting a brand apart in a competitive landscape.

Producers are encouraged to explore eco-friendly materials such as compostable films and recycled paperboard in their packaging for gummies, which resonate with the choices of 73% of individuals actively seeking to reduce their environmental footprint. Furthermore, 39% of shoppers have indicated a willingness to switch to rival brands that offer sustainable packaging for gummies, underscoring the importance of sustainability in fostering customer loyalty.

The sustainable container market is projected to grow from USD 292.71 billion in 2024 to USD 423.56 billion by 2029, reflecting a compound annual growth rate (CAGR) of 7.67%. This growth highlights the necessity for confectionery producers to innovate with eco-friendly solutions. By committing to sustainable practices in packaging for gummies, candy producers can meet buyer expectations while contributing to a healthier planet.

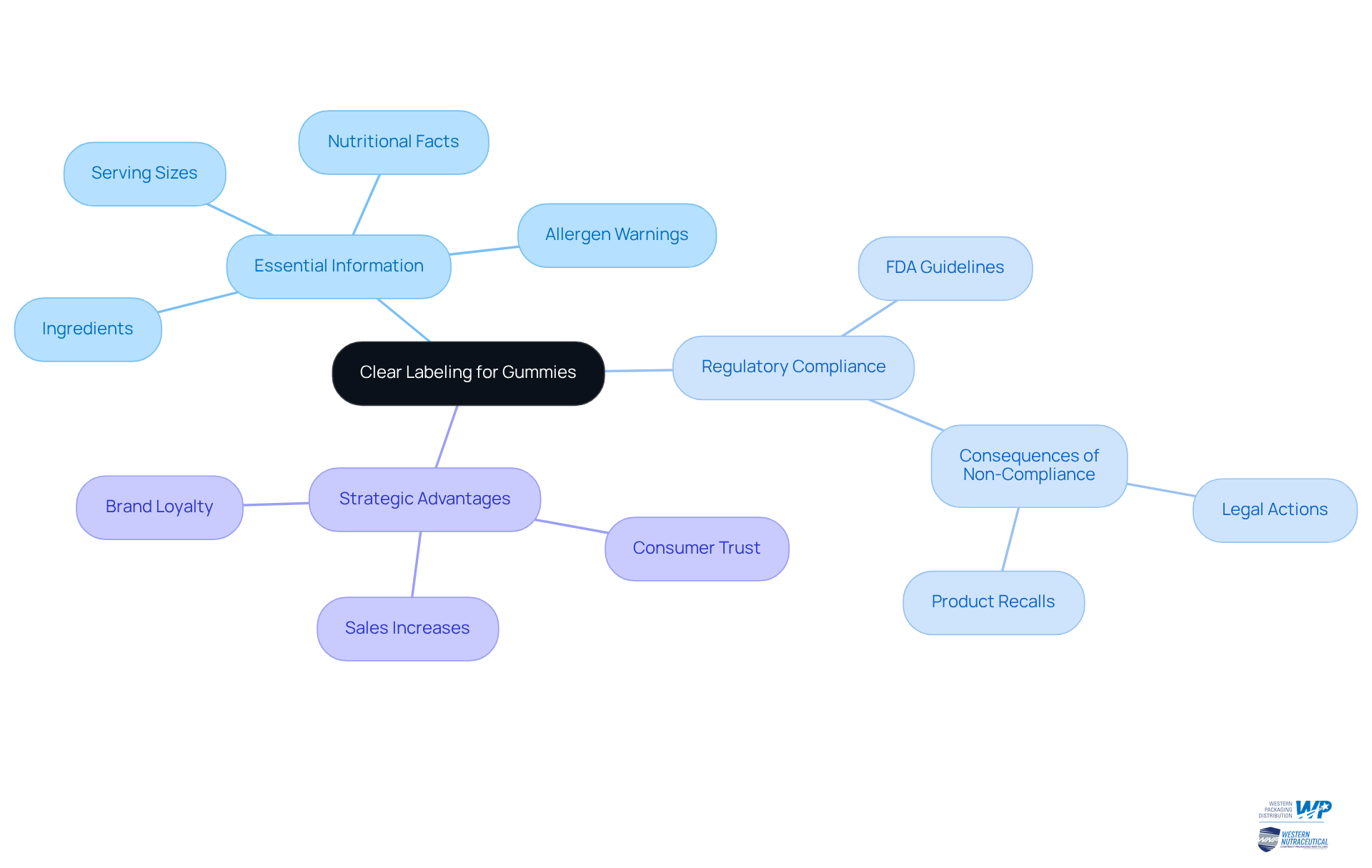

Ensure Clear Labeling: Provide Essential Product Information

Clear labeling on packaging for gummies is essential for providing consumers with vital information. Labels must prominently display:

- Ingredients

- Nutritional facts

- Allergen warnings

- Serving sizes

in a legible format to comply with FDA requirements. Adhering to these regulations not only helps avoid legal complications but also significantly enhances public trust. Studies indicate that 94% of shoppers prioritize clarity regarding item contents, making precise labeling a pivotal factor in purchasing decisions. Furthermore, well-designed labels can bolster brand reputation and foster customer loyalty by effectively communicating the item's benefits.

Effective labeling strategies, such as adhering to FDA guidelines on label clarity—including minimum font sizes and color contrast requirements—have proven to capture public attention and influence purchasing behavior. For instance, case studies reveal that brands employing structured label designs that comply with these guidelines experience increased sales, as consumers are more likely to choose products that provide thorough and easily accessible information. In an era where consumers are increasingly discerning about what they consume, investing in clear and compliant labeling is not merely a regulatory necessity but a strategic advantage.

Moreover, manufacturers must recognize that the FDA prohibits health claims on supplement labels, and non-compliance can lead to serious repercussions, including recalls and legal actions. Therefore, prioritizing clear labeling is not just a best practice; it is a critical component of successful packaging for gummies.

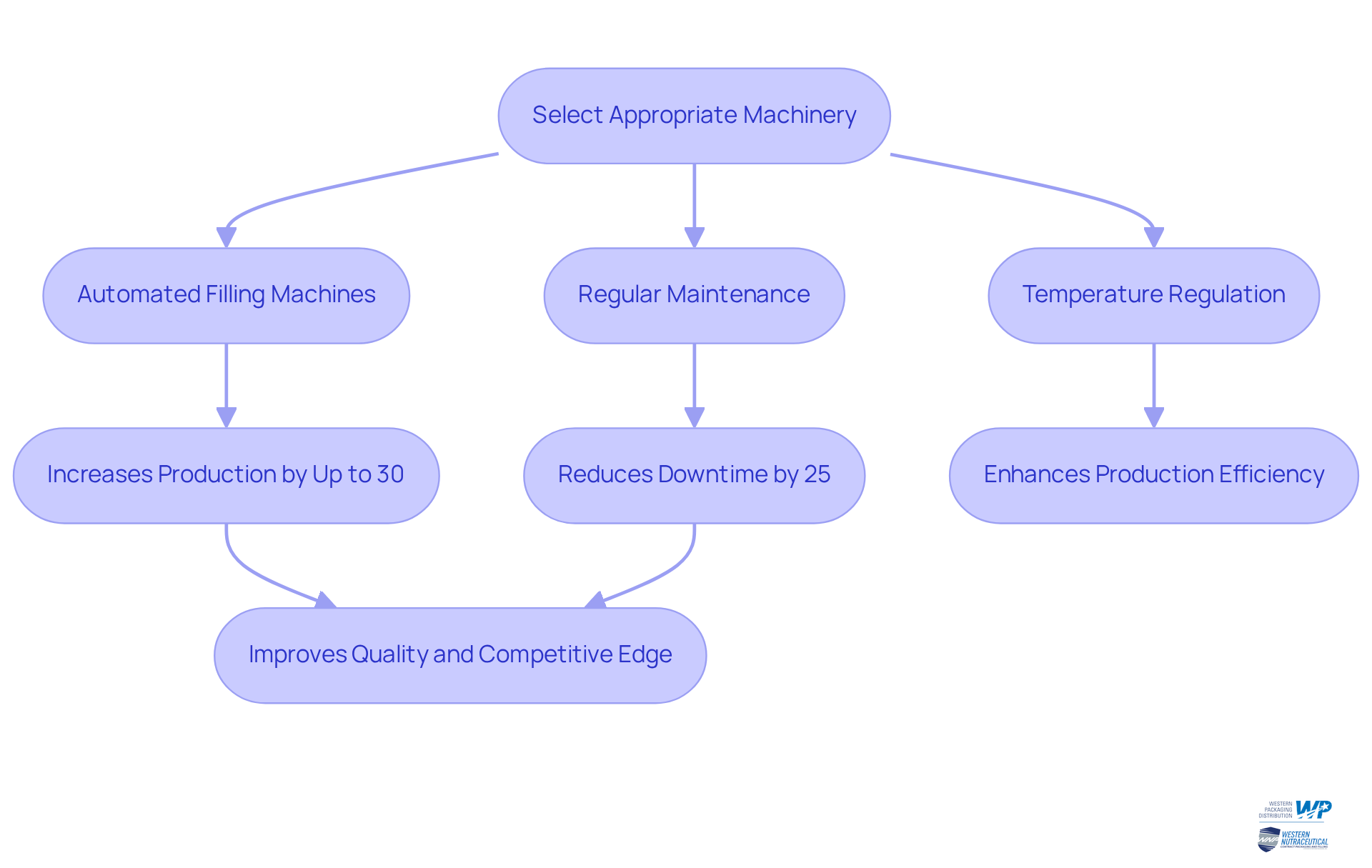

Select Appropriate Machinery: Optimize Production Efficiency

Selecting the appropriate equipment for candy wrapping is essential for enhancing production efficiency. Producers must prioritize machinery that meets the specific requirements of chewy items, including precise temperature regulation and careful handling to prevent damage.

Automated filling machines, such as the Automated Universal Candy Depositor, significantly enhance throughput, with the potential to increase production rates by up to 30%, according to industry experts. Regular maintenance and timely updates to machinery are crucial to avoid downtime; studies indicate that proactive maintenance can reduce operational disruptions by 25%.

As industry author Leo Lee states, 'Investing in automation—like having an extra pair of hands that never get tired—can dramatically streamline workflow.' By investing in advanced automation, manufacturers can refine their processes, improve quality, and sustain a competitive edge in the rapidly expanding market for packaging for gummies.

However, it is vital to consider the substantial initial capital investment required for advanced production equipment, which can pose a barrier for small and medium-sized enterprises.

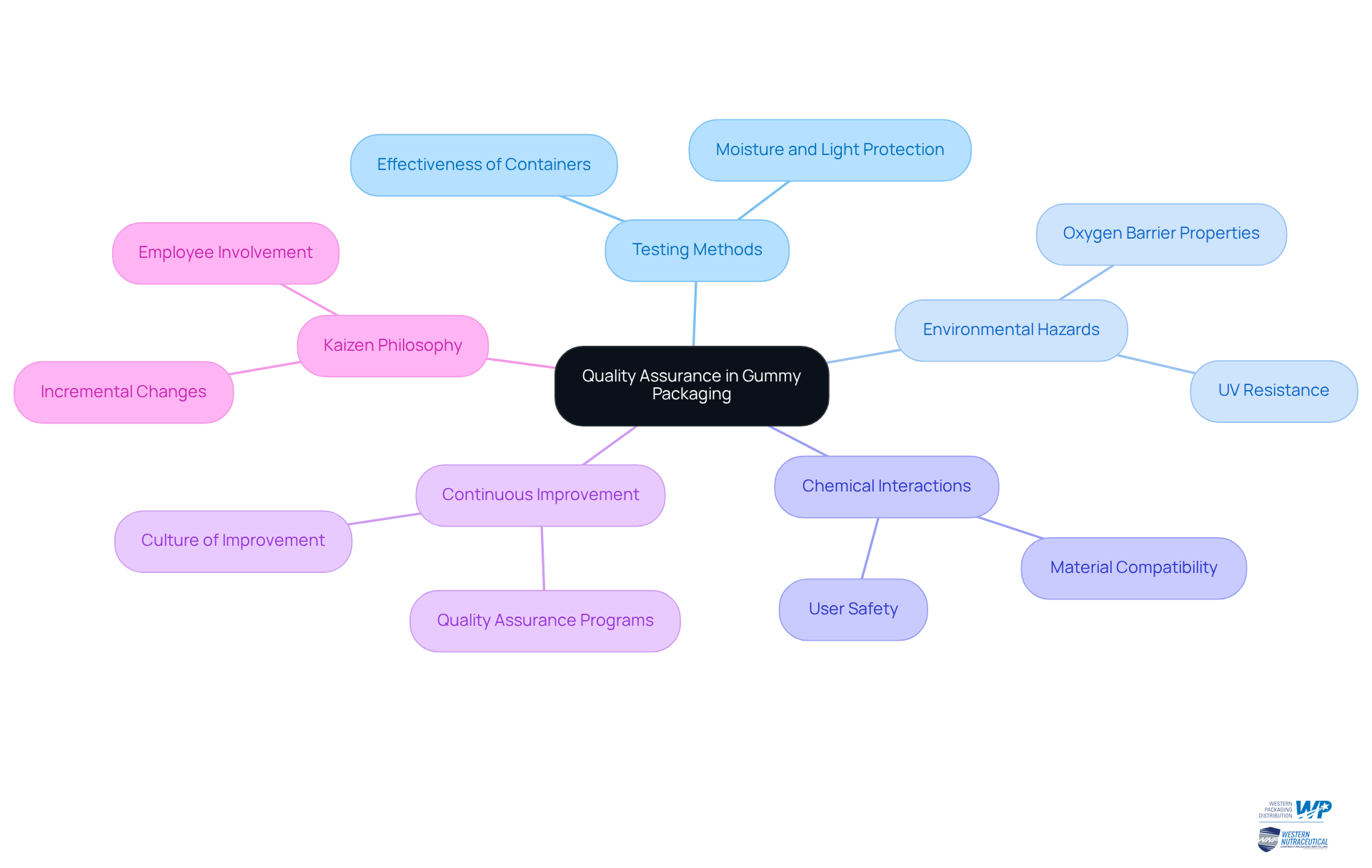

Test Packaging Solutions: Validate Quality and Safety

Ensuring the quality and safety of packaging for gummies is paramount for manufacturers. Thorough testing is essential to evaluate the effectiveness of containers in safeguarding products against environmental hazards such as moisture and light. Advanced packaging for gummies that features oxygen barrier properties plays a critical role in minimizing oxygen ingress, which can jeopardize freshness.

As Peter Drucker aptly stated, "There is nothing so useless as doing efficiently that which should not be done at all," underscoring the importance of implementing meaningful quality assurance practices in gummy wrapping. Furthermore, assessing potential chemical interactions between the materials and the gummies is vital to ensure user safety and maintain product integrity.

Establishing a robust quality assurance program not only helps identify potential issues before products reach the market but also fosters a culture of continuous improvement. Effective quality assurance initiatives in chewy products demonstrate that a proactive approach can significantly enhance product quality and build customer trust. By adopting the Kaizen philosophy of continuous enhancement, manufacturers can ensure their quality assurance processes evolve in tandem with industry standards and customer expectations.

Conduct Market Research: Align Packaging with Consumer Preferences

Conducting thorough market research is essential for aligning candy containers with changing buyer preferences. Insights into trends such as the rising demand for healthier choices and distinctive flavor combinations can greatly influence design and messaging strategies.

Employing techniques such as surveys, focus groups, and competitor analysis enables manufacturers to collect valuable information on consumer expectations for gelatin products. For instance, the gummy market is anticipated to attain USD 74.4 billion by 2033 and is predicted to increase at a CAGR of 11.8% from 2022 to 2030. This data emphasizes the need for brands to modify their packaging for gummies to capture this expanding segment.

By staying in tune with market dynamics, manufacturers can develop containers that resonate with their target audience and drive sales effectively. Successful case studies, such as Cargill's texture correspondence analysis, demonstrate the impact of innovative packaging on audience engagement, illustrating the importance of aligning packaging with preferences.

This strategic approach not only enhances brand visibility but also fosters loyalty among health-conscious consumers seeking functional and enjoyable gummy experiences.

Conclusion

Effective packaging for gummies transcends mere aesthetics; it is pivotal in preserving product quality, ensuring compliance, and enhancing brand recognition. The insights provided underscore the multifaceted approach required to create packaging that not only protects but also captivates consumers. By grasping the essential elements of packaging—from selecting optimal materials and ensuring regulatory compliance to prioritizing visually appealing designs and eco-friendly options—manufacturers can markedly enhance their market positioning.

Key strategies highlighted include:

- The significance of resealability for maintaining freshness

- The necessity of clear labeling to foster consumer trust

- The impact of market research in aligning packaging with consumer preferences

These factors are crucial in driving sales and cultivating brand loyalty within a competitive landscape. Furthermore, investing in advanced machinery and testing solutions further bolsters production efficiency and product safety, enabling manufacturers to meet the demands of an evolving market.

In a world where consumer expectations are perpetually rising, the importance of effective packaging cannot be overstated. By embracing these best practices and innovative solutions, gummy manufacturers can not only meet current consumer demands but also lay the groundwork for future growth. Adopting these strategies will ultimately lead to a more sustainable and successful approach in the gummy industry, making it imperative for brands to regard packaging as a cornerstone of their overall business strategy.

Frequently Asked Questions

What does Western Packaging specialize in?

Western Packaging specializes in customized flexible wrappers designed specifically for packaging gummies, merging creativity with precision to enhance product protection and shelf appeal.

What is the projected market growth for the gummy market by 2030?

The gummy market is projected to reach USD 52.24 billion by 2030.

What are the current trends in gummy packaging?

Current trends indicate a growing preference for resealable containers, which enhance convenience and maintain product integrity, particularly in the vitamin gummy segment.

Can you provide an example of successful gummy packaging?

An example includes the launch of Avrio Health's Senokot Kids Laxative Gummies, which effectively met specific health needs while appealing to younger demographics.

What types of sealing technologies are important for gummy packaging?

Advanced sealing technologies, such as hermetic seals, are vital for preserving the flavor and texture of chewy candies.

What materials are recommended for packaging gummies?

High-barrier films like Mylar or polyethylene are recommended, as they effectively protect gummies from moisture, light, and oxygen, ensuring quality and freshness.

Why is regulatory compliance important for gummy manufacturers?

Regulatory compliance is crucial as packaging must adhere to FDA standards for food safety and labeling, ensuring materials are safe for food contact and that labels accurately communicate product contents.

How are manufacturers using technology to meet compliance standards?

Over 50% of compliance teams are using AI applications to streamline adherence to regulatory standards, helping manufacturers avoid penalties and build customer trust.

What recent changes should manufacturers be aware of regarding compliance?

Manufacturers should be aware of recent revisions to additive usage limits, such as the maximum allowable level for Acacia Gum Modified with octenyl succinic anhydride (OSA) in flavoring set at 500ppm.

How can manufacturers effectively navigate regulatory compliance?

By upholding strict standards, staying informed about regulatory changes, and maintaining proactive communication with regulatory bodies, manufacturers can ensure safety and market viability.