Overview

This article delineates ten essential questions to consider when selecting a food supplement contract manufacturer, emphasizing critical factors such as production capacity, quality control, regulatory compliance, and client support. Each question is meticulously crafted to ascertain that potential manufacturers can fulfill specific business requirements, thereby safeguarding product quality, ensuring compliance, and fostering successful partnerships. These elements are vital for maintaining a competitive edge in the market, making informed decision-making imperative for industry professionals.

Introduction

Selecting the right food supplement contract manufacturer presents a significant challenge, particularly given the multitude of options in the marketplace. It is crucial to grasp the key factors that impact this decision, as they are vital for ensuring product quality, adhering to regulatory standards, and achieving overall business success.

To navigate this complex landscape effectively, businesses must ask essential questions that will help them identify a manufacturing partner who aligns with their specific requirements.

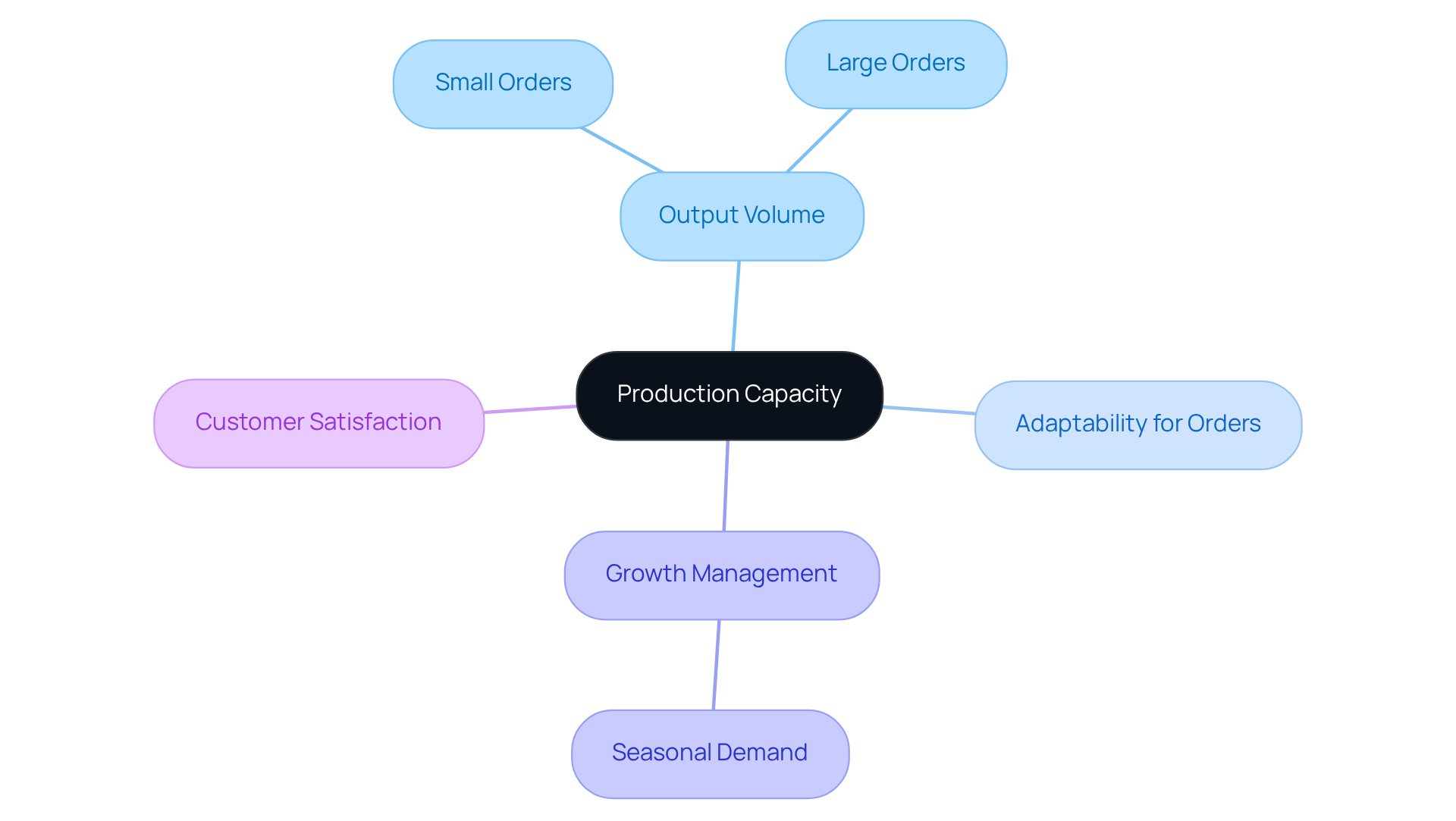

What Production Capacity Can You Provide?

When selecting a contract producer, it is crucial to inquire about their output capacity. This encompasses the volume of products they can produce within a designated timeframe. A producer with adaptable production capabilities can effectively manage both small and large orders, which is vital for businesses anticipating growth or seasonal demand fluctuations. By understanding their capacity, you can ensure that they will fulfill your orders without delays—an essential factor for maintaining customer satisfaction and a strong market presence.

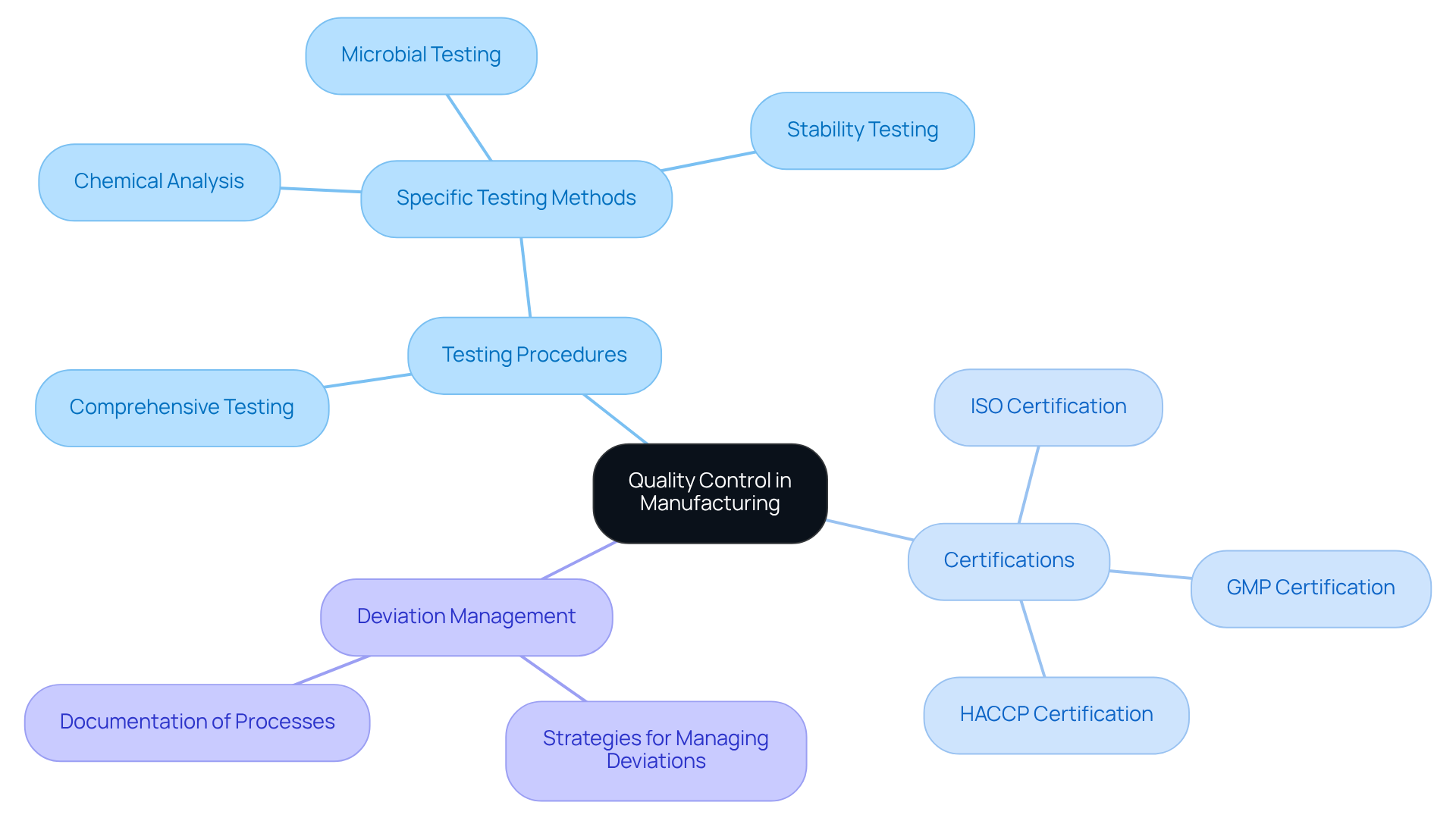

How Do You Ensure Quality Control Throughout the Manufacturing Process?

Quality control must be a foremost priority when selecting a contract manufacturer. It is essential to inquire about the assurance protocols of a food supplement contract manufacturer, which should include:

- Comprehensive testing procedures

- Relevant certifications such as GMP

- Strategies for managing deviations from established standards

A robust control system guarantees that every batch adheres to the required specifications, thereby safeguarding your brand's reputation and ensuring consumer safety. Furthermore, manufacturers should be prepared to provide documentation of their quality control processes, enhancing transparency and building trust with their partners.

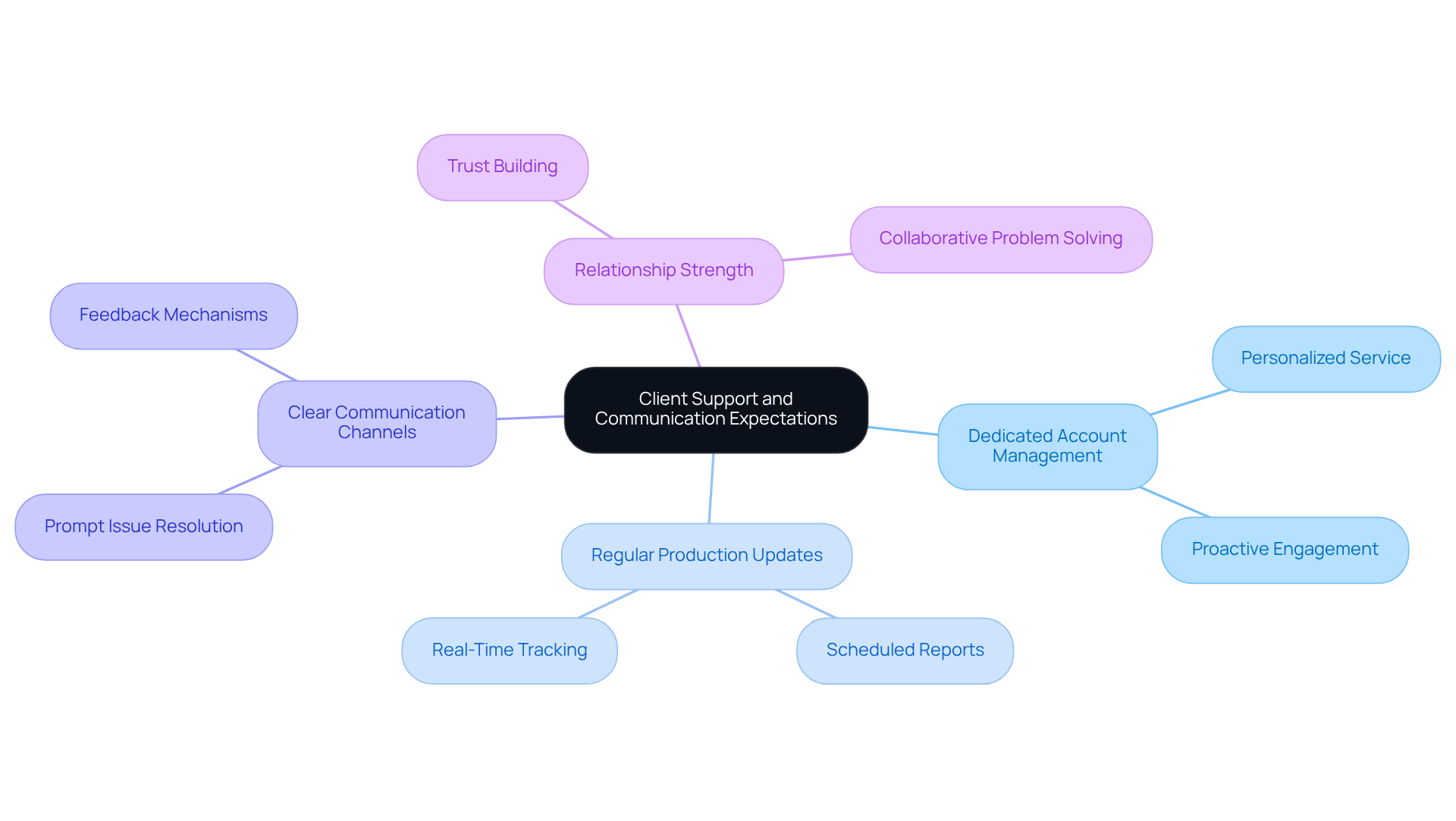

What Level of Client Support and Communication Can I Expect?

Inquire about the level of client assistance you can expect from the producer. A dependable partner should provide dedicated account management along with regular updates on production status. Establishing clear communication channels is vital; this approach allows for prompt issue resolution and ensures that your needs are consistently met throughout the manufacturing process. By fostering a strong relationship with your supplier, you can enhance collaboration and achieve more successful releases.

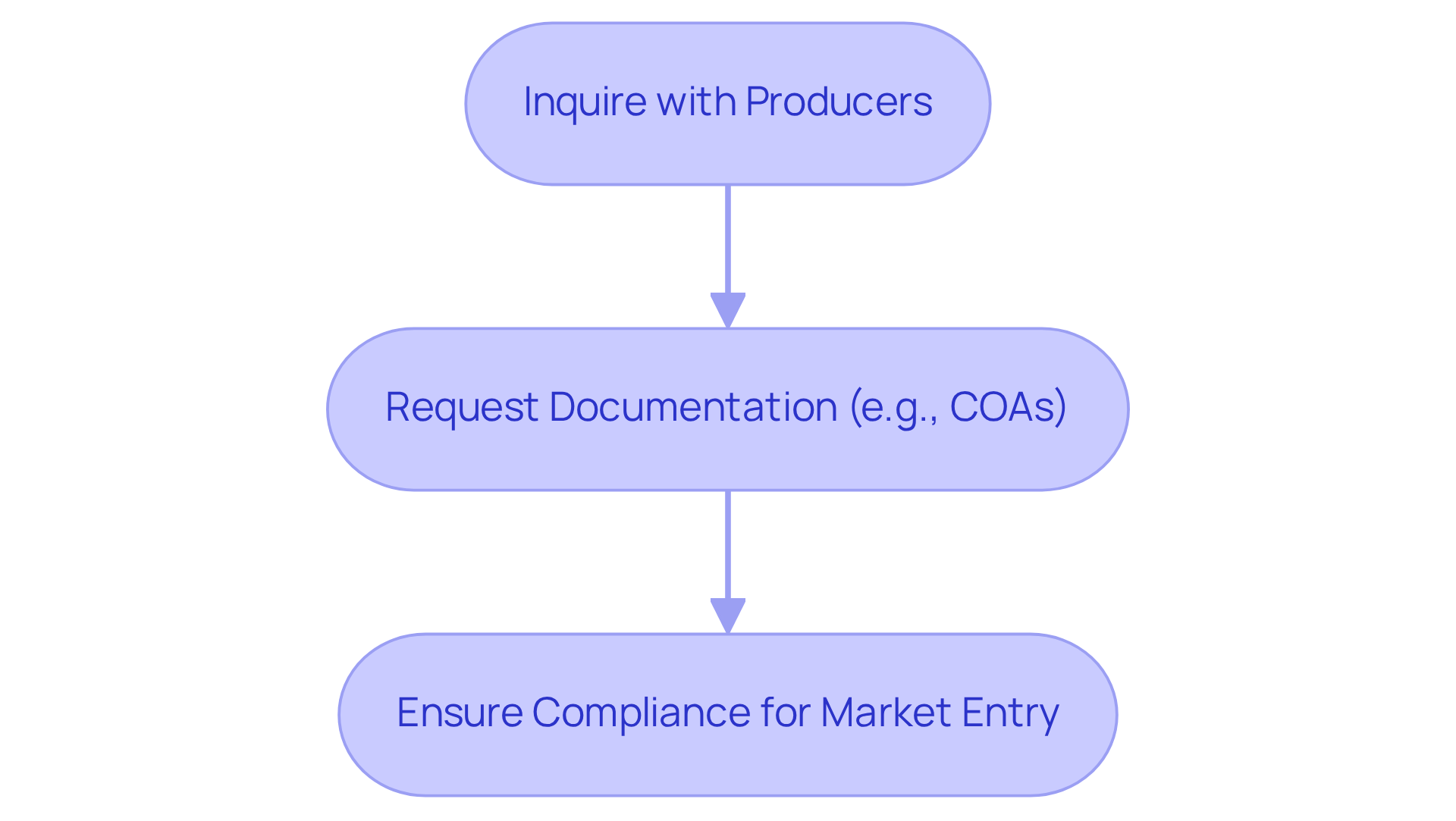

How Do You Handle Regulatory Compliance and Documentation?

Inquire with prospective producers about their management of regulatory compliance, specifically their adherence to FDA guidelines and other relevant regulations. They should provide documentation that substantiates their compliance with industry standards, including Certificates of Analysis (COAs) for both raw materials and finished products.

A producer knowledgeable in regulatory requirements can effectively guide you through the complexities of bringing a dietary supplement to market. This expertise is crucial for ensuring that your product meets all necessary compliance standards, ultimately facilitating a smoother market entry.

Can You Provide Custom Formulation Services Tailored to My Needs?

If you have specific specifications, inquire whether the producer offers tailored formulation services. This capability allows you to craft unique offerings that meet the needs of your target audience. A manufacturer with a robust R&D team can assist in developing formulations that align with current market trends and consumer preferences, thereby providing your brand with a competitive edge.

Additionally, consider how customized flexible packaging options from Western Packaging—such as large pouches for protein items and stick packs for nutraceuticals—can enhance your offering's shelf appeal and brand recognition. Creative packaging design not only elevates product appeal but also ensures a cohesive brand identity, enabling your offerings to stand out in the competitive nutraceutical market.

What Are Your Lead Times and Shipping Capabilities?

Lead times are a critical factor that can significantly impact your business operations. It is imperative to inquire with prospective suppliers about their usual lead times for creation and delivery. A manufacturer equipped with efficient logistics can play a pivotal role in helping you meet market demands swiftly, thereby minimizing the risk of stockouts or delays in product launches.

Furthermore, understanding their shipping capabilities, including international shipping options, is essential, particularly if you plan to expand your market reach. By prioritizing these inquiries, you position your business for success in a competitive landscape.

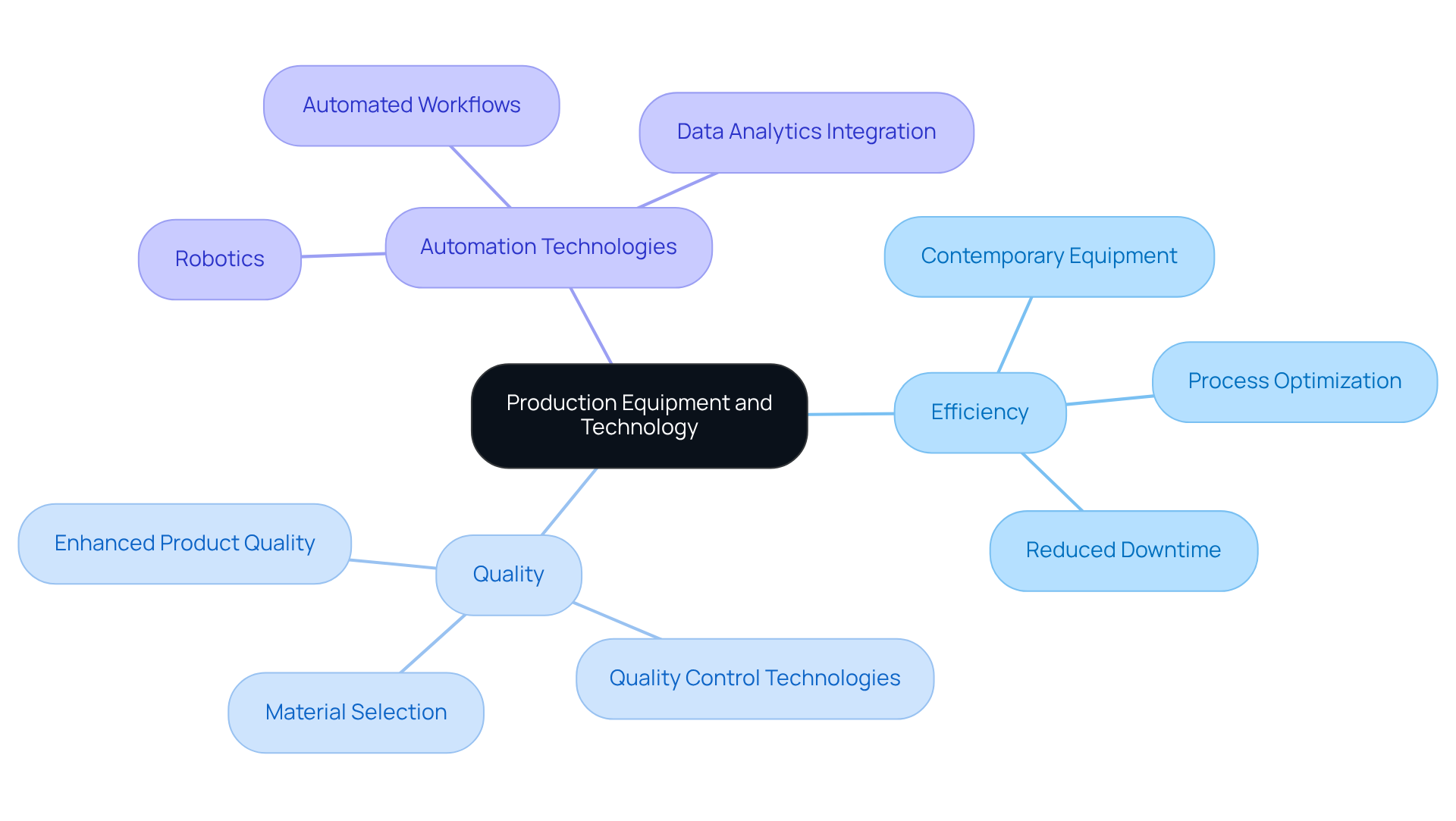

What Type of Equipment and Technology Do You Use in Production?

Inquire about the equipment and technology utilized in the manufacturing process. Contemporary, cutting-edge equipment significantly enhances manufacturing efficiency and product quality. Manufacturers should be prepared to disclose information regarding their equipment, including any automation technologies that optimize operations. Understanding their capabilities is crucial for assessing whether they can effectively meet your production needs.

What Packaging Options Do You Offer for Dietary Supplements?

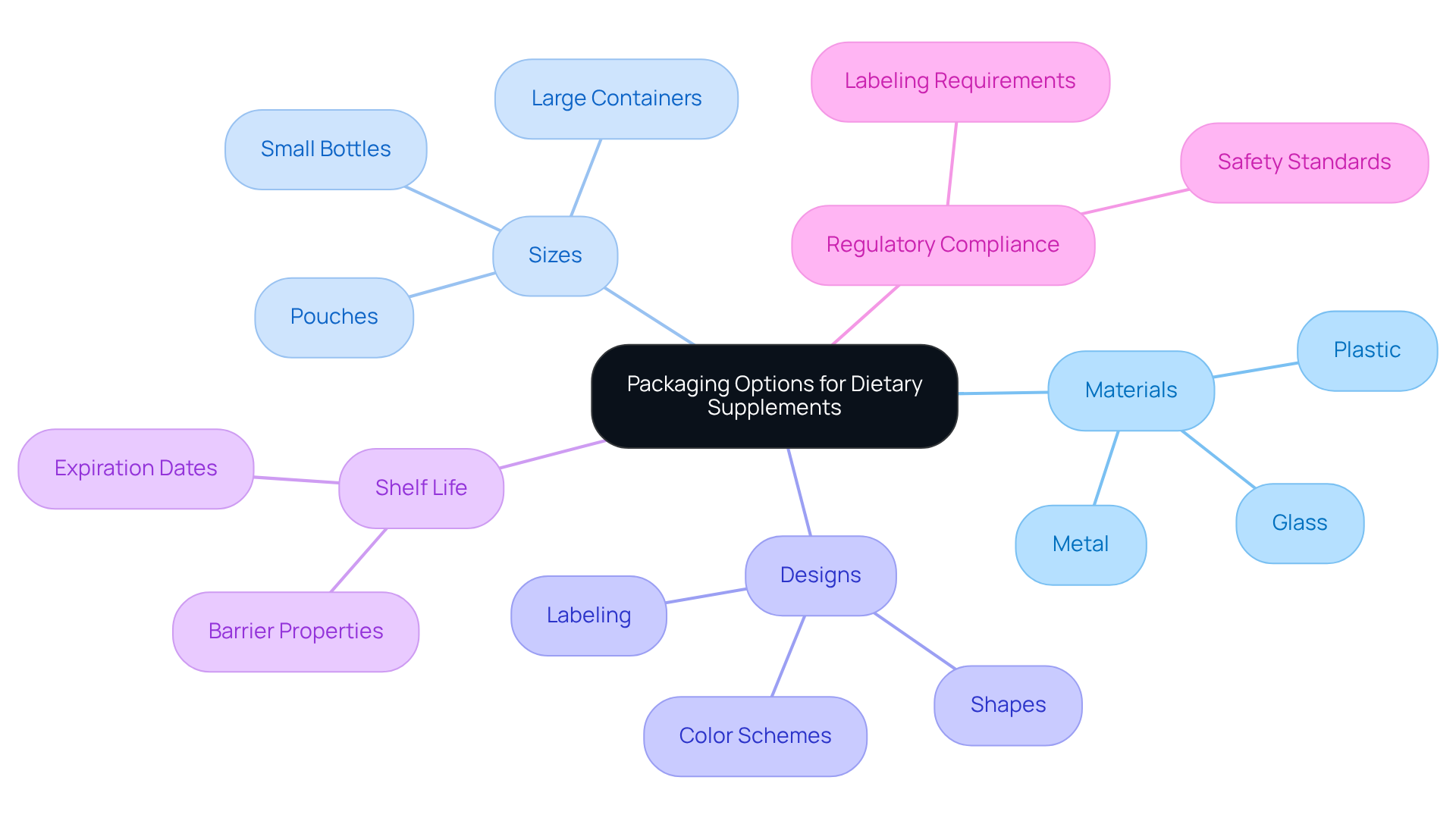

Packaging plays a crucial role in attracting consumers and maintaining the integrity of products. It is essential to consult with a food supplement contract manufacturer about the available packaging options for dietary supplements, including materials, sizes, and designs. A food supplement contract manufacturer that offers a diverse range of packaging solutions can help you create a product that stands out on the shelf and meets consumer expectations. Moreover, it is important to consider how packaging influences shelf life and adherence to regulations. By prioritizing quality packaging, you not only enhance product appeal but also ensure compliance and longevity in the market.

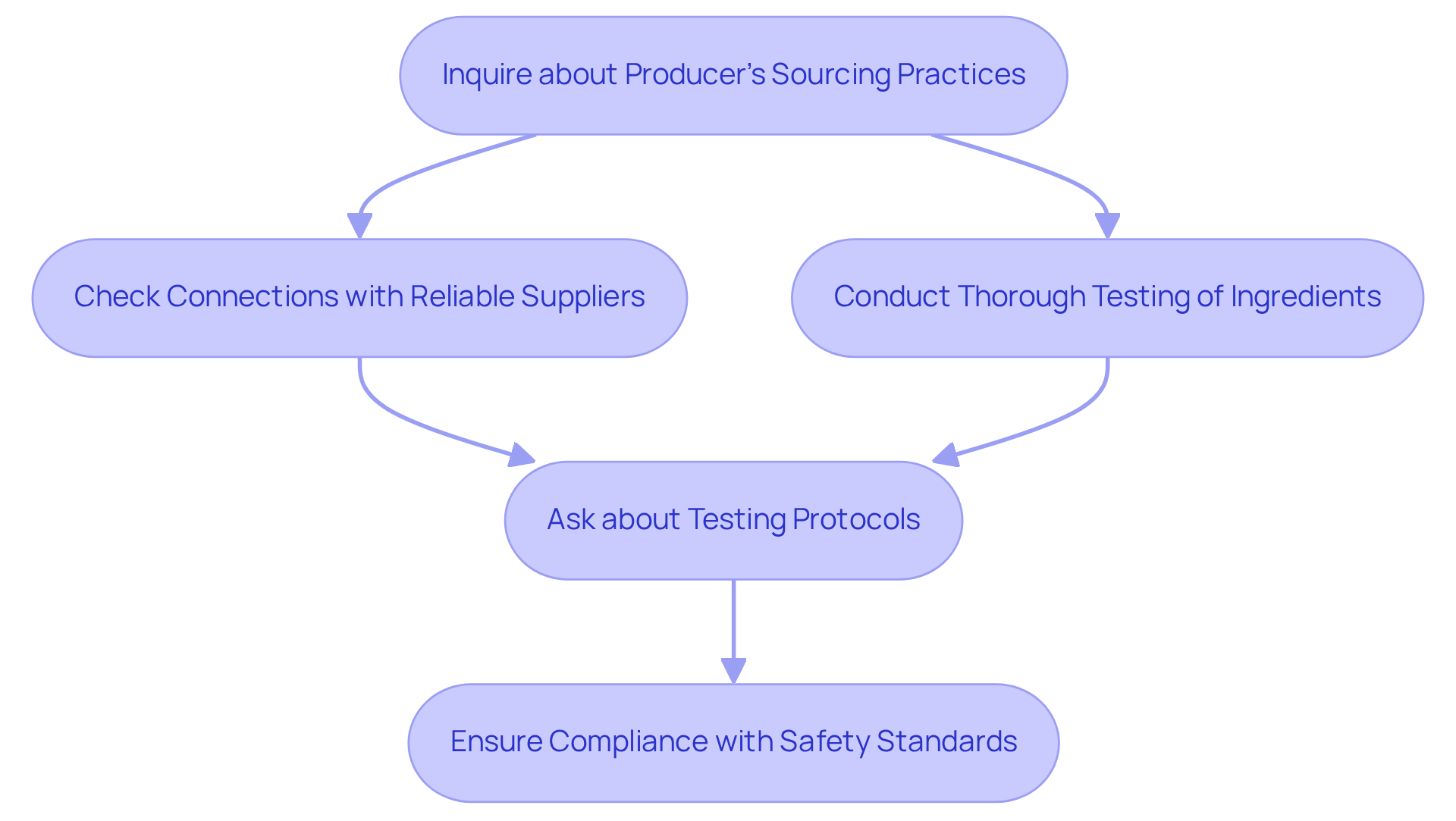

How Do You Source and Test Ingredients for Quality Assurance?

Inquire about the producer's sourcing practices for raw materials. It is imperative that they have established connections with reliable suppliers and conduct thorough testing of ingredients to ensure compliance with safety standards.

Ask about their testing protocols, including any third-party testing they may employ. A food supplement contract manufacturer that is committed to quality assurance will prioritize sourcing premium ingredients, which is crucial for the production of effective dietary supplements.

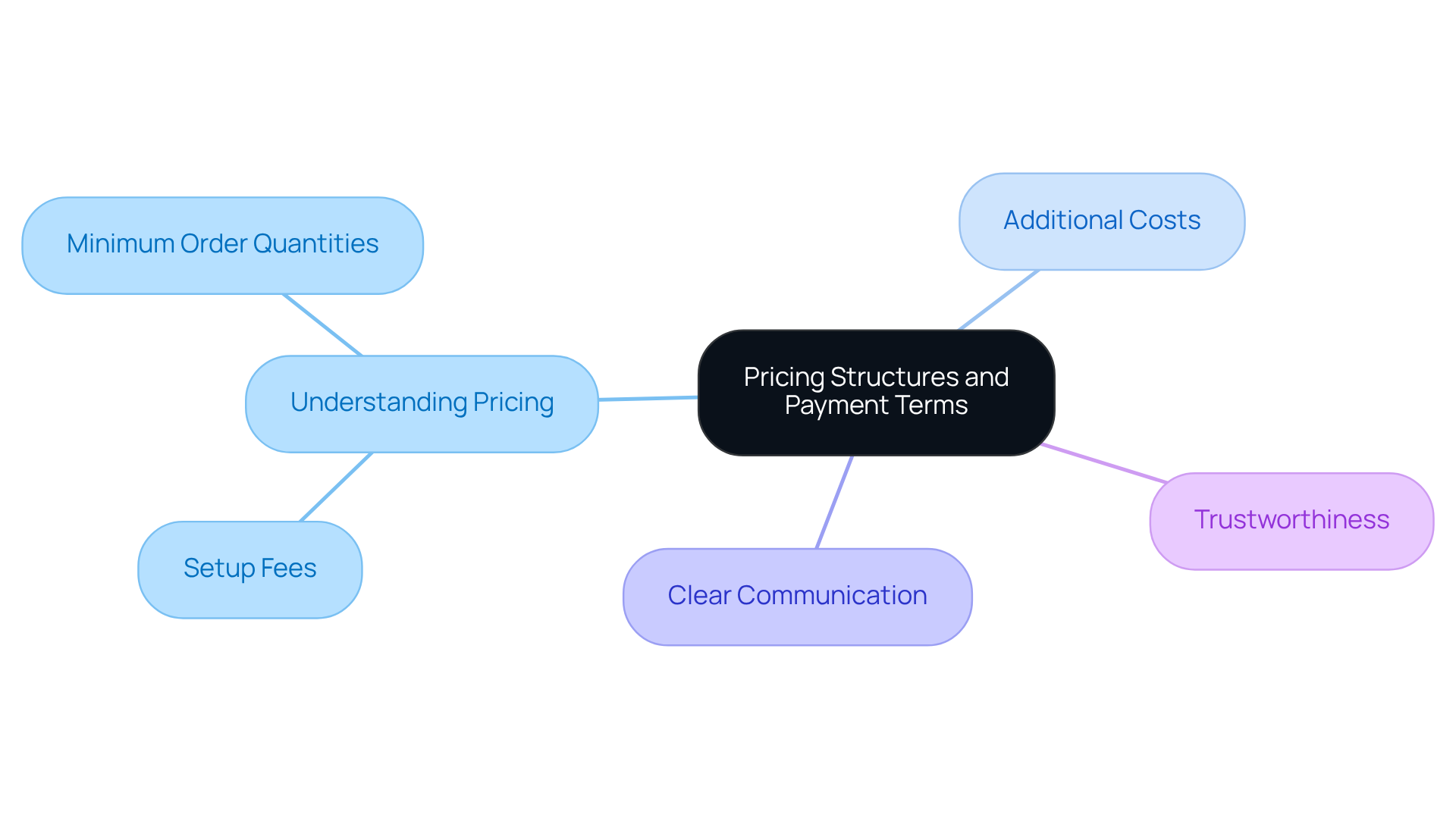

What Are Your Pricing Structures and Payment Terms?

Before concluding a contract, it is essential to fully understand the producer's pricing structures and payment terms. Inquire about any additional costs that may arise during production, such as setup fees or minimum order quantities. Clear communication regarding pricing not only helps prevent misunderstandings but also ensures effective budgeting for your manufacturing needs. A transparent pricing model is indicative of a trustworthy manufacturer, reinforcing the reliability that is crucial in the packaging and logistics industry.

Conclusion

Selecting the right food supplement contract manufacturer is a critical decision that can significantly influence the success of a product in the marketplace. By carefully evaluating factors such as production capacity, quality control measures, and client support, businesses can ensure they partner with a manufacturer that aligns with their goals and standards. This selection process not only impacts the efficiency of production but also the overall reputation and reliability of the brand.

Key considerations include:

- Understanding the manufacturer's ability to meet regulatory compliance

- Their approach to custom formulation

- The technology they employ in production

Additionally, aspects like:

- Lead times

- Shipping capabilities

- Transparent pricing structures

play vital roles in facilitating smooth operations and fostering strong supplier relationships. Each of these elements contributes to a comprehensive strategy for successful product launches and sustained market presence.

Ultimately, taking the time to ask the right questions and thoroughly assess potential manufacturers can lead to fruitful partnerships that enhance product quality and consumer satisfaction. By prioritizing these inquiries, businesses can navigate the complexities of the supplement industry more effectively, ensuring that they not only meet consumer demands but also position themselves for long-term success.

Frequently Asked Questions

What should I consider regarding production capacity when selecting a contract producer?

It is crucial to inquire about the producer's output capacity, which includes the volume of products they can produce within a designated timeframe. A producer with adaptable production capabilities can manage both small and large orders, ensuring they can fulfill your orders without delays.

How can I ensure quality control in the manufacturing process?

When selecting a contract manufacturer, inquire about their quality control protocols, which should include comprehensive testing procedures, relevant certifications such as GMP, and strategies for managing deviations from established standards. A robust control system ensures that every batch meets required specifications.

What level of client support and communication can I expect from a contract producer?

You should expect dedicated account management and regular updates on production status from a reliable partner. Establishing clear communication channels is essential for prompt issue resolution and ensuring that your needs are consistently met throughout the manufacturing process.