Overview

This article presents ten key strategies designed to optimize packaging workflows, underscoring the critical role of integrated services, technology, and continuous improvement practices. Among these strategies are:

- Effective project planning

- Quality assurance

- KPI tracking

Collectively, these approaches significantly enhance operational efficiency and product quality, empowering businesses to adapt to evolving market demands while ensuring compliance with industry standards. By implementing these strategies, organizations can not only streamline their processes but also position themselves as leaders in the packaging and logistics field.

Introduction

The packaging industry is experiencing a transformative shift, propelled by the demand for efficiency and innovation within a fiercely competitive market. Companies are increasingly pursuing strategies that not only streamline operations but also elevate product quality and compliance. This article explores ten pivotal strategies that can significantly optimize packaging workflows, ranging from the integration of advanced technology and automation to the implementation of rigorous quality assurance practices.

Yet, with a multitude of options at their disposal, how can businesses discern the most effective approaches to adopt? By examining these strategies, we will uncover the essential steps necessary to enhance packaging processes and sustain a competitive advantage.

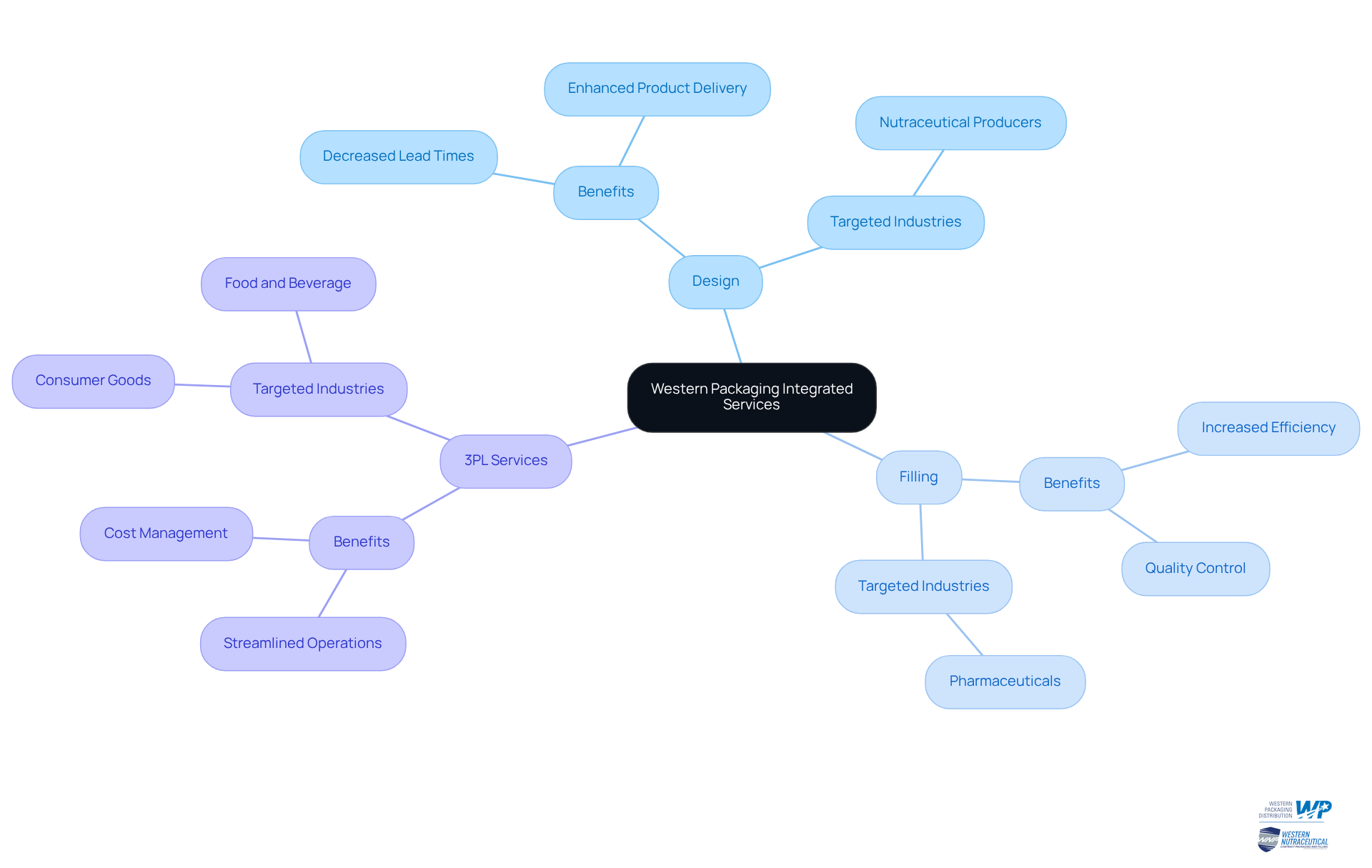

Western Packaging: Integrated Design, Filling, and 3PL Services for Streamlined Operations

Western Packaging stands as a leader in the seamless integration of design, filling, and third-party logistics (3PL) services, delivering a solution that significantly streamlines operations. This approach not only decreases lead times but also enhances product delivery, allowing companies to concentrate on their core competencies.

By providing tailored solutions that address every facet of wrapping and distribution, Western Packaging empowers clients, particularly nutraceutical producers, to boost productivity and elevate market visibility.

Industry leaders emphasize that integrated solutions, including comprehensive 3PL services, are vital for improving efficiency and sustainability in today's competitive landscape. Thus, Western Packaging emerges as a pivotal partner for businesses aiming to optimize their workflows.

Esko: Comprehensive Packaging Workflow Management Software for Enhanced Efficiency

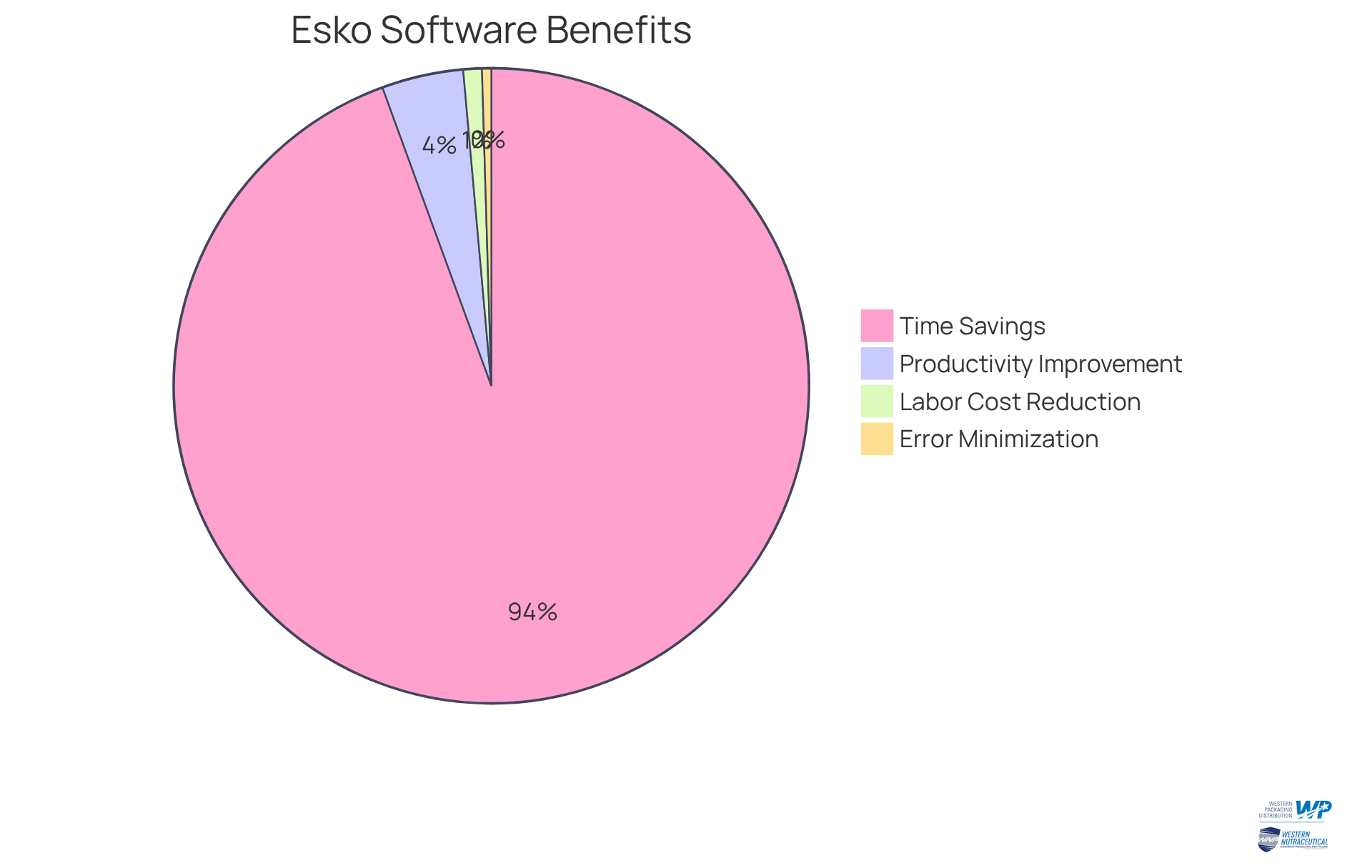

Esko's software for packaging workflow management revolutionizes the industry by automating tasks and facilitating real-time collaboration among teams. This comprehensive tool streamlines the packaging workflow from design to delivery, ensuring that all stakeholders remain aligned and informed throughout the process. By leveraging such technology, companies can significantly reduce time-to-market and enhance the quality of their containers.

Automation in wrapping not only minimizes errors but also results in substantial labor cost savings; businesses adopting these solutions can save an average of 2,000 hours annually, equivalent to the workload of one full-time employee. Furthermore, organizations that implement automation technologies often witness a 20% reduction in labor costs, with potential decreases reaching up to 40% in manufacturing sectors. This highlights the financial advantages of integrating advanced software like Esko into their operations.

As evidenced by case studies showcasing firms that have successfully streamlined their packaging workflows using Esko software, organizations have achieved improved productivity and reduced operational expenses. Notably, 88% of organizations cite enhanced productivity and decreased labor costs as significant benefits of automation. This positions Esko as an essential partner for companies aiming to refine their handling methods and overall efficiency.

To initiate the introduction of automation in your workflow, consider starting with small, repetitive tasks that can be automated to maximize efficiency gains.

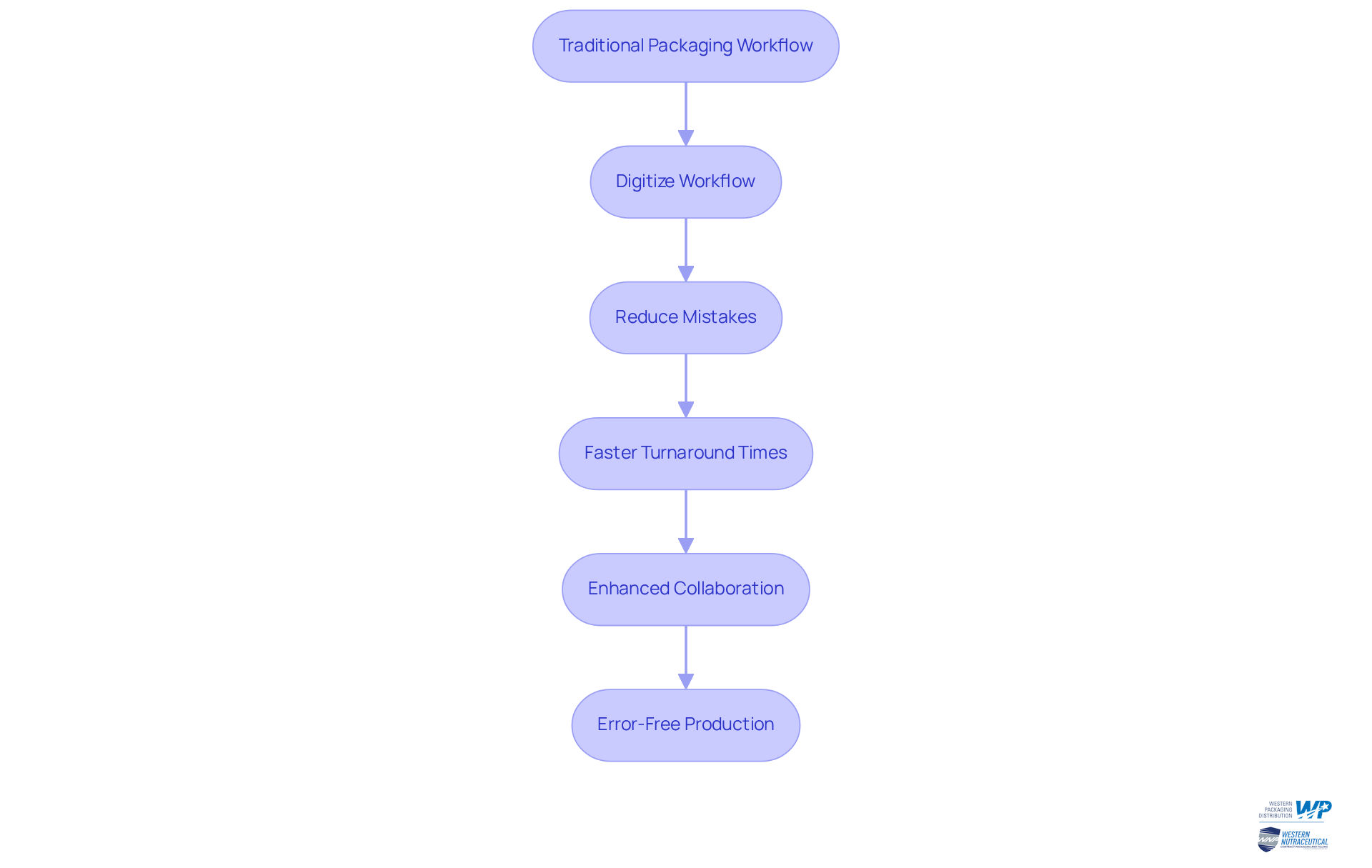

Millnet: Digital Workflows in Prepress for Error-Free Packaging Production

Millnet specializes in digital workflows that optimize the packaging workflow, ensuring error-free production. By digitizing the packaging workflow, businesses significantly reduce the likelihood of mistakes that are common in traditional methods. Digital printing offers turnaround times that can be completed days or even weeks earlier than conventional methods, saving time and enhancing the quality of the final product.

Implementing digital prepress solutions as part of the packaging workflow fosters better collaboration among teams, ensuring that all design specifications are met accurately—an essential factor for maintaining brand integrity. Furthermore, automated workflows, such as those provided by Esko’s Automation Engine, improve the packaging workflow by enhancing production steps tailored for the industry, minimizing human error and boosting overall productivity.

In a competitive market that has evolved into a $5-billion industry, embracing these digital prepress solutions is crucial for companies aiming to elevate their production methods.

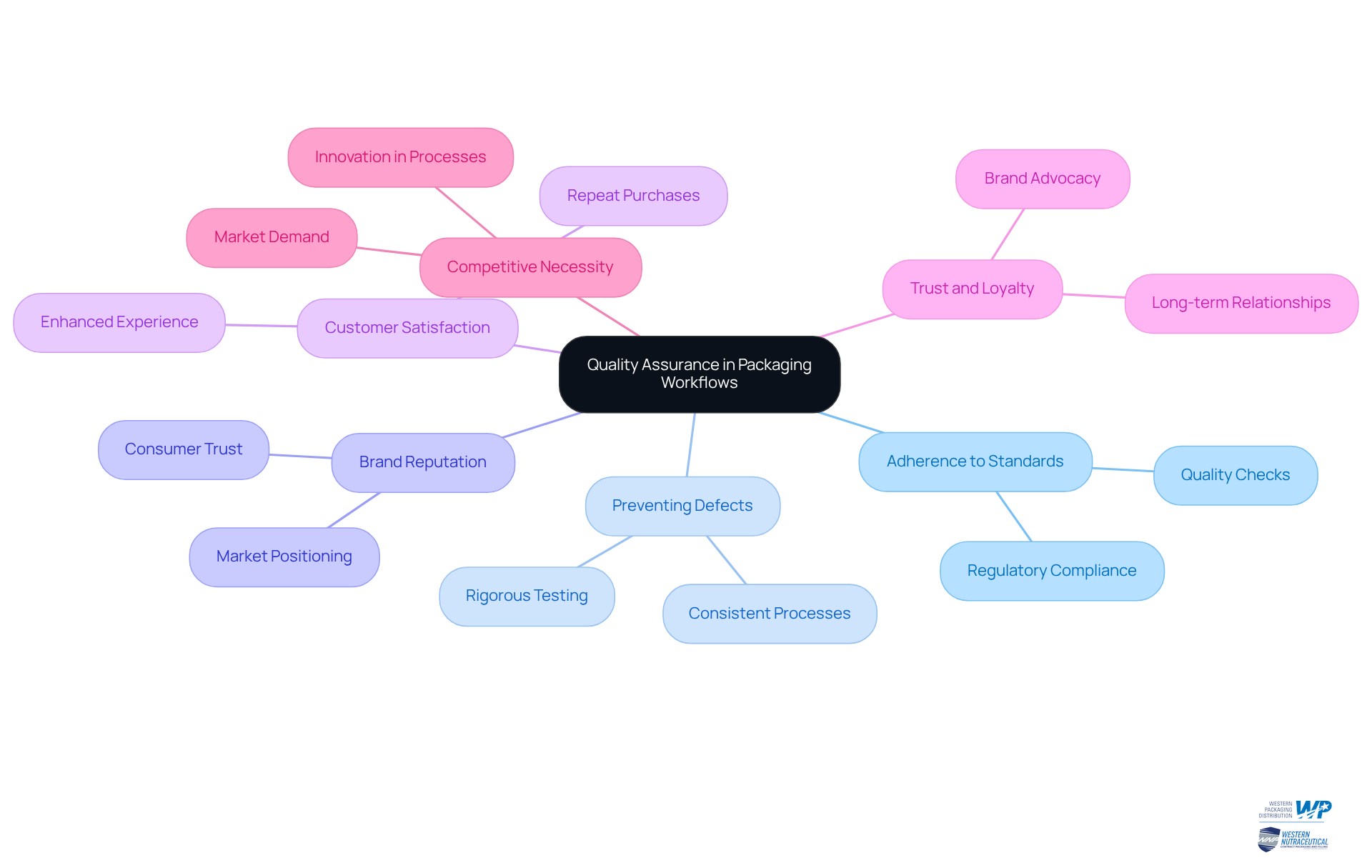

Quality Assurance: Key to Maintaining Standards in Packaging Workflows

Quality assurance stands as a cornerstone of the packaging workflow, guaranteeing that all products adhere to established standards and regulations. By implementing rigorous quality checks at every stage of the packaging workflow, businesses can effectively prevent defects and maintain consistency. This practice not only safeguards the brand's reputation but also significantly enhances customer satisfaction. Companies that prioritize quality assurance are more likely to cultivate trust with their consumers, resulting in increased loyalty and repeat purchases. In today's competitive market, ensuring quality is not just an option; it is a necessity for sustained success.

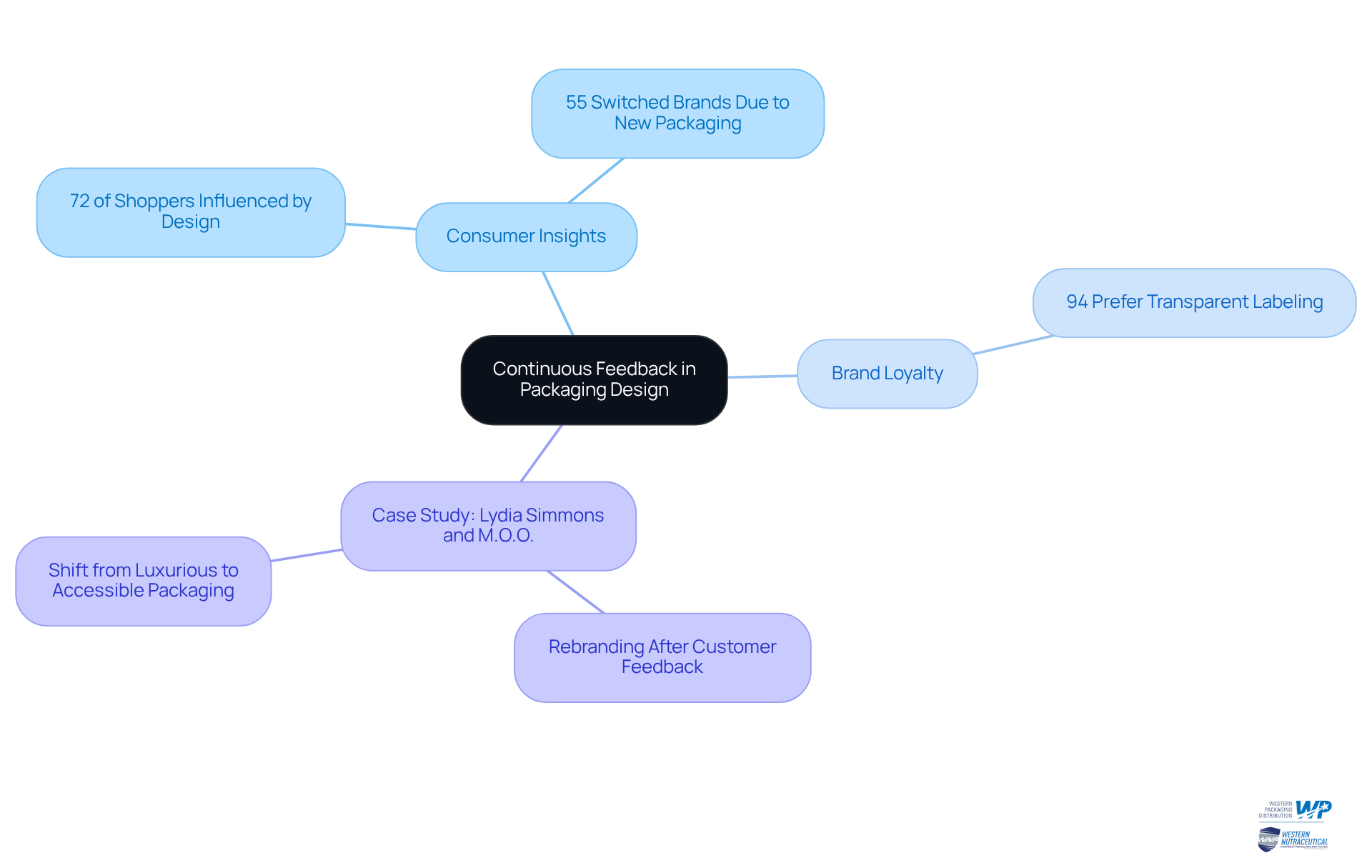

Continuous Feedback: Essential for Refining Packaging Design and Production

Implementing ongoing feedback systems is essential for improving the design and production of containers. By consistently seeking feedback from stakeholders, particularly customers, organizations can identify areas for enhancement and make necessary modifications. This iterative process not only enhances the quality of the containers but also ensures alignment with consumer preferences and market trends. Notably, 72% of American shoppers indicate that container design influences their buying choices, underscoring the necessity for companies to adapt based on consumer insights. Furthermore, 55% of consumers have switched brands due to new design innovations, highlighting the critical role of product presentation in consumer behavior. Companies that embrace stakeholder feedback often experience increased brand loyalty; 94% of consumers are more likely to remain loyal to a brand that demonstrates transparency in product labeling. By fostering a culture of innovation and responsiveness through feedback integration, businesses can effectively navigate the fast-paced market and maintain a competitive edge. A significant example is Lydia Simmons, creator of M.O.O., who revamped her business after recognizing that the initial presentation was perceived as overly lavish and costly, illustrating the tangible impact of customer input on presentation strategy.

Effective Project Planning: A Cornerstone of Successful Packaging Workflows

Effective project planning serves as a cornerstone of successful packaging workflow. By clearly defining project goals, timelines, and resource allocations, businesses can minimize delays and ensure alignment among all team members.

Incorporating Western Packaging's filling services and 3PL solutions into your project planning simplifies production processes and enhances supply chain performance. These services offer customized solutions tailored to specific container requirements, from powders to gummies, ensuring a seamless workflow.

Utilizing project management tools aids in tracking progress and facilitating communication among stakeholders. A well-structured plan not only boosts efficiency but also allows for improved risk management, proactively addressing potential issues.

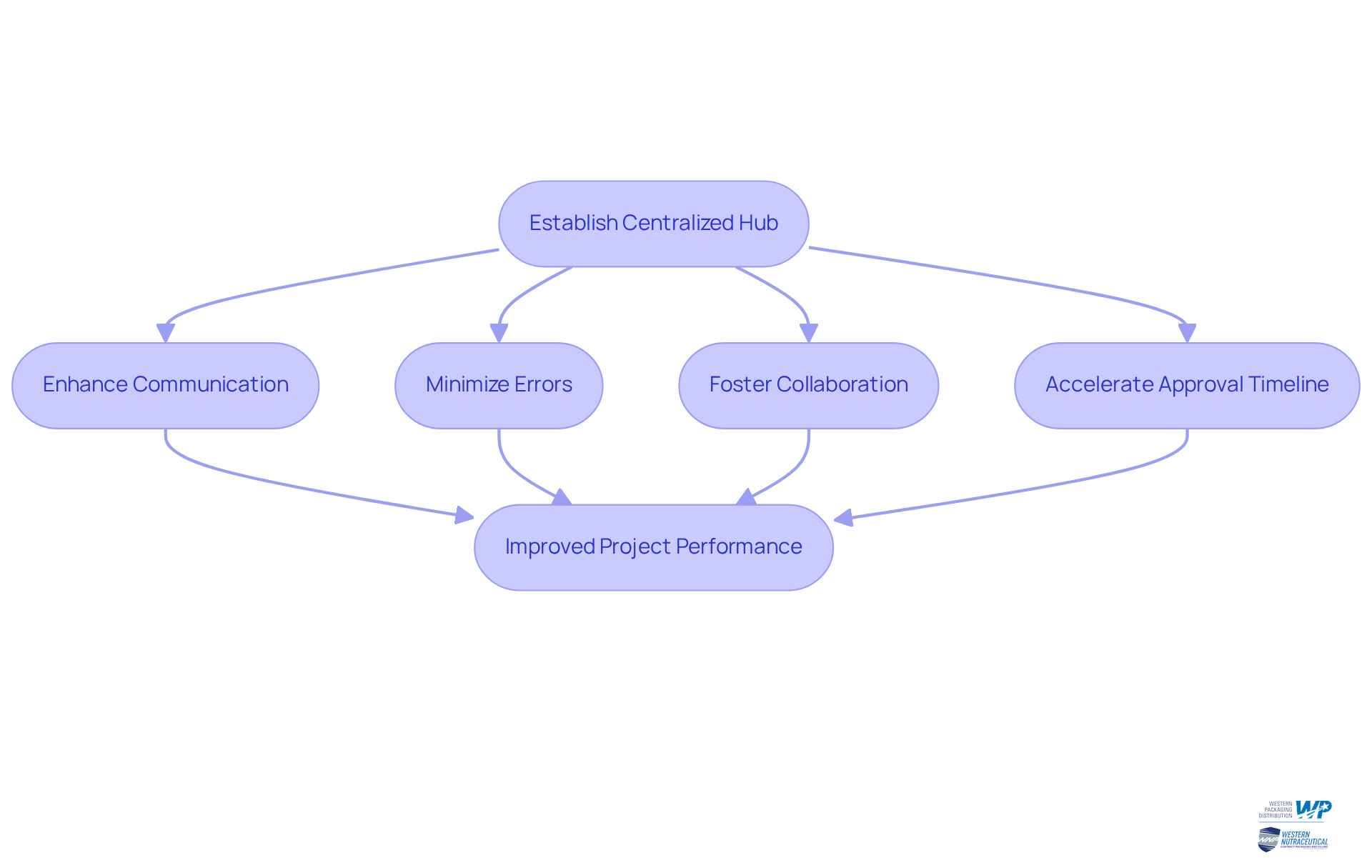

Centralized Hub: Streamlining File Management and Approval Processes

Establishing a centralized center for file management and approval activities significantly enhances communication and minimizes errors in workflows. By consolidating all project files in a single location, teams can easily access the most up-to-date versions and track changes. This streamlined approach not only fosters collaboration but also accelerates the approval timeline, enabling projects to advance without unnecessary delays. A well-organized file management system is crucial for sustaining consistency and quality in the packaging workflow, which ultimately leads to improved project performance.

Organizations that have adopted centralized hubs report notable boosts in productivity and reduced turnaround times, with 47% of enterprises that digitized document workflows experiencing enhancements in efficiency and customer experience. Mark Fairlie, a Senior Analyst, underscores that "your document management system is vital to your team’s productivity and directly affects the security and privacy of your business, customers, and vendors."

Moreover, given that employees dedicate 30% of their time searching for documents, implementing a centralized hub can drastically mitigate this inefficiency. Examples of firms successfully refining their approval systems through centralized hubs further illustrate the effectiveness of this strategy in optimizing the packaging workflow.

KPI Tracking: Measuring Success in Packaging Workflow Optimization

KPI monitoring is essential for evaluating success in refining workflow processes. By identifying and tracking key performance indicators (KPIs), businesses can effectively assess their processes and make informed decisions for continuous improvement. In 2025, critical KPIs for the packaging workflow will encompass metrics such as labor productivity, cost per package, and waste reduction rates. Regularly reviewing these indicators empowers teams to identify trends, address inefficiencies, and implement strategies that enhance overall performance and meet evolving market demands.

For instance, organizations are increasingly focusing on labor productivity metrics, such as Units per Labor Hour and Time per Package, to evaluate workforce performance. This data not only reveals areas for enhancement but also informs staffing and training decisions, ensuring that labor resources align with production needs. Additionally, monitoring Labor Cost per Package offers insights into labor efficiency, enabling organizations to pinpoint staffing and training efficiencies or inefficiencies.

Tracking the percentage of waste diverted from landfills stands as a vital KPI for sustainability initiatives, reflecting a company's commitment to environmental responsibility. The reduction of waste rates from containers allows companies to minimize their landfill contributions and decrease resource consumption in production.

Industry leaders underscore the importance of these metrics in driving operational success. By establishing a systematic packaging workflow for KPI tracking, businesses can optimize their processes, reduce costs, and ultimately enhance profitability. Companies that have effectively implemented KPI monitoring have reported improved cycle times and throughput rates, resulting in heightened customer satisfaction through timely deliveries. Furthermore, with 29% of global firms adopting digital twin applications in manufacturing, technology is playing a significant role in enhancing KPI monitoring and container performance. This comprehensive focus on performance metrics positions organizations to excel in a competitive landscape while fostering a culture of continuous improvement.

![]()

Technology Integration: Enhancing Efficiency in Packaging Workflows

Incorporating technology into container workflows significantly enhances efficiency while reducing manual errors. Automation tools, digital asset management systems, and collaborative platforms simplify various stages of the packaging workflow, from design to production.

Western Packaging's filling process includes comprehensive services for diverse products, such as powders, gummies, and soft-gels, which enhance production accuracy and speed. Companies utilizing automated filling systems report improved capabilities to meet market demands effectively.

Additionally, our 3PL services optimize the supply chain through tailored warehousing, inventory management, and logistics solutions. By embracing these technological advancements and integrated services, companies can enhance product quality and improve the packaging workflow to speed up time-to-market.

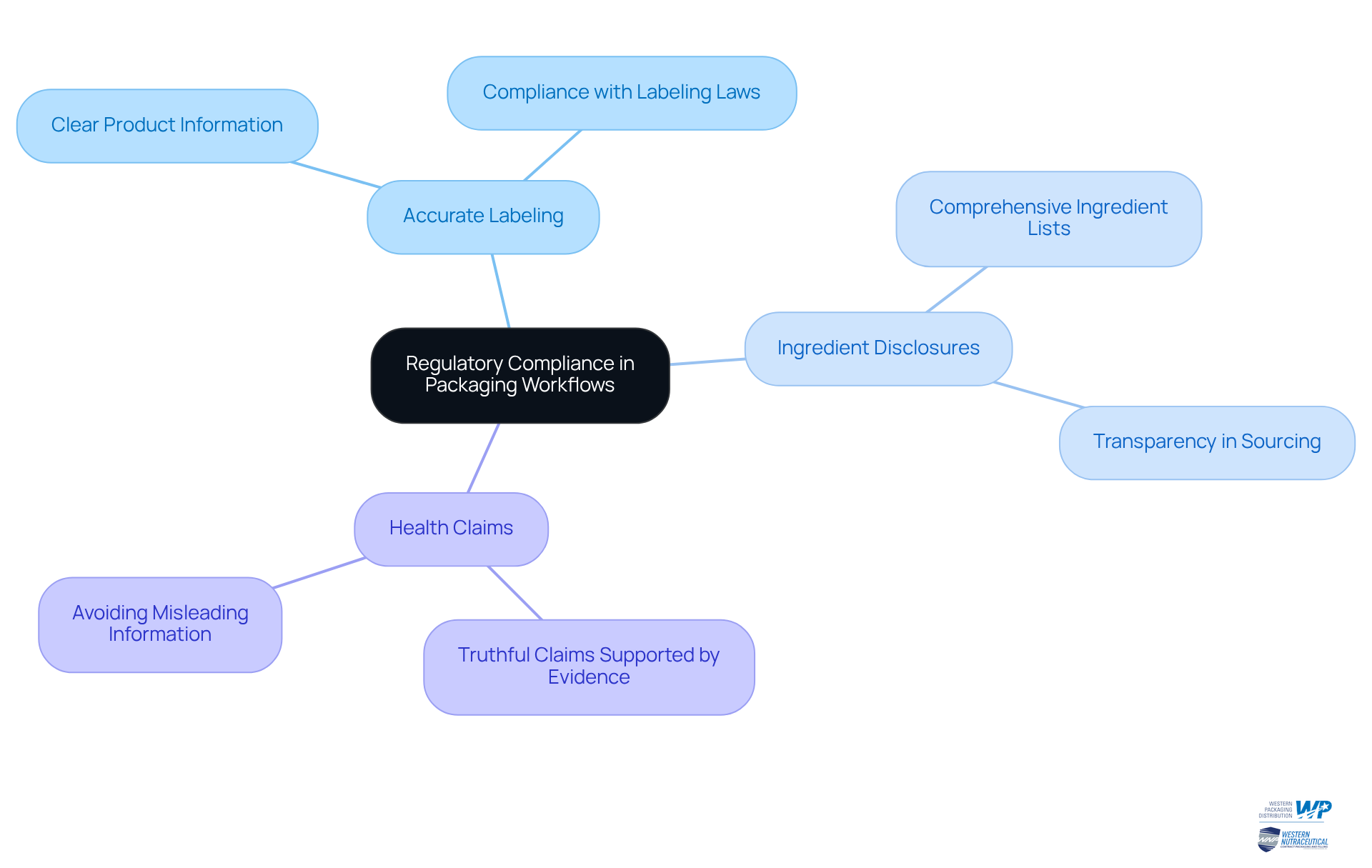

Regulatory Compliance: Ensuring Adherence in Packaging Workflows for Nutraceuticals

Ensuring regulatory compliance in the packaging workflow is critical for enterprises in the nutraceutical sector. Packaging must adhere to specific guidelines established by regulatory bodies to guarantee consumer safety and uphold product integrity. This encompasses:

- Accurate labeling

- Comprehensive ingredient disclosures

- Strict adherence to health claims

By prioritizing compliance, businesses can circumvent legal challenges and cultivate trust with consumers, thereby enhancing their brand reputation. It is essential to remain informed about regulatory changes and implement best practices to achieve success in this industry.

Conclusion

Optimizing packaging workflows is essential for businesses aiming to enhance efficiency, reduce costs, and improve overall product quality. The integration of advanced technologies, comprehensive project planning, and robust quality assurance practices serves as a foundation for achieving these goals. By adopting strategies such as centralized file management, continuous feedback loops, and KPI tracking, organizations can streamline operations and respond more effectively to market demands.

Throughout this article, key strategies have been explored, including the benefits of automated solutions like Esko's software, the importance of digital workflows from Millnet, and the role of third-party logistics provided by Western Packaging. Each of these elements contributes significantly to minimizing errors, enhancing collaboration, and ensuring compliance with industry standards. Furthermore, maintaining a focus on quality assurance and actively seeking stakeholder feedback can foster innovation and adaptability in packaging processes.

The significance of these strategies extends beyond mere operational improvements; they represent a commitment to excellence in product delivery and customer satisfaction. By prioritizing these practices, companies can not only optimize their packaging workflows but also position themselves as leaders in a competitive market. Embracing these insights will pave the way for sustained growth and success in the ever-evolving landscape of packaging.

Frequently Asked Questions

What services does Western Packaging offer?

Western Packaging provides integrated design, filling, and third-party logistics (3PL) services that streamline operations for businesses, particularly in the nutraceutical sector.

How does Western Packaging benefit its clients?

By offering tailored solutions that address all aspects of wrapping and distribution, Western Packaging helps clients boost productivity and enhance market visibility.

Why are integrated solutions important in today's market?

Integrated solutions, including comprehensive 3PL services, are essential for improving efficiency and sustainability, making Western Packaging a vital partner for businesses looking to optimize workflows.

What does Esko's software do for packaging workflow management?

Esko's software automates tasks and facilitates real-time collaboration among teams, streamlining the packaging workflow from design to delivery.

What are the benefits of automating packaging workflows with Esko?

Automation minimizes errors, saves substantial labor costs, reduces time-to-market, and enhances the quality of containers, with businesses saving an average of 2,000 hours annually.

How much can companies expect to reduce their labor costs by using Esko's automation technologies?

Organizations often see a 20% reduction in labor costs, with potential decreases reaching up to 40% in manufacturing sectors.

What are the advantages of implementing digital workflows in packaging production with Millnet?

Millnet's digital workflows reduce the likelihood of errors, improve turnaround times, and foster better collaboration among teams, ensuring design specifications are met accurately.

How does digital printing compare to traditional methods in terms of turnaround time?

Digital printing can achieve turnaround times that are completed days or even weeks earlier than conventional methods.

Why is embracing digital prepress solutions important for companies in the packaging industry?

In a competitive market, adopting digital prepress solutions is crucial for enhancing production methods and maintaining brand integrity.