Overview

The article titled '10 Key Trends in Flexible Packaging Manufacturing for Nutraceuticals' delves into the pivotal trends that are currently influencing the flexible packaging industry, particularly for nutraceutical products. It underscores the critical nature of:

- Sustainability

- Customization

- Smart packaging technologies

- Supply chain optimization

These trends are essential as they enable companies to effectively meet consumer demands and regulatory standards, all while enhancing operational efficiency and brand appeal. Understanding and adapting to these trends is not just beneficial; it is imperative for success in the evolving market landscape.

Introduction

The flexible packaging manufacturing landscape is rapidly evolving, driven by the increasing demand for innovative solutions that cater to the nutraceutical sector. As brands strive to meet consumer expectations for sustainability, customization, and efficiency, understanding the latest trends becomes crucial for maintaining a competitive edge.

What strategies can businesses adopt to not only keep pace with these changes but also leverage them for growth in an ever-changing market? This question is not merely rhetorical; it underscores the urgency for companies to adapt and thrive in this dynamic environment.

Western Packaging: Integrated Solutions for Flexible Packaging Manufacturing

Western Packaging distinguishes itself in the flexible packaging manufacturing industry through its comprehensive integrated offerings that seamlessly combine design, filling services, and third-party logistics (3PL). Our filling process is intricately woven into these end-to-end solutions, accommodating a diverse array of products ranging from powders to gummies and soft-gels. This unified approach empowers businesses to streamline their supply chains, substantially reducing lead times and enhancing product delivery.

By consolidating these services, Western Packaging simplifies complexities for clients, enabling them to focus on their core competencies while simultaneously elevating their market presence. The synergy of our filling and 3PL services not only enhances operational efficiency but also amplifies brand awareness and shelf appeal—crucial factors in the nutraceutical sector, where effective presentation is key to consumer engagement.

For instance, businesses that have adopted similar integrated strategies have reported significant improvements in their time-to-market; one tech company notably shortened its launch schedule by two weeks through coordinated production and manufacturing processes. This exemplifies the tangible benefits of a well-coordinated wrapping strategy, which can lead to heightened customer satisfaction and reduced costs associated with returns and damages.

Sustainability Initiatives: Adapting to Eco-Friendly Practices in Packaging

Sustainability initiatives are increasingly shaping the landscape of flexible packaging manufacturing, marked by a significant shift towards eco-friendly practices. Companies are prioritizing recyclable materials, minimizing plastic consumption, and embracing energy-efficient production methods.

Western Packaging exemplifies this commitment, incorporating recycled materials into their solutions and designing products that reduce waste. Notably, studies indicate that:

- 90% of shoppers are more inclined to purchase from companies that emphasize eco-friendly materials.

- 54% of shoppers reported intentionally acquiring items made from sustainable materials within the past six months.

This trend underscores the importance for businesses aiming to strengthen their market presence in 2025 and beyond. As consumer awareness grows, brands that align with these eco-friendly values are poised to gain a competitive edge in the nutraceuticals sector, particularly among younger demographics, with:

- 59% of Millennials actively seeking sustainable container alternatives.

- 56% of Gen Z actively seeking sustainable container alternatives.

Smart Packaging Technologies: Innovations Shaping the Future of Flexible Packaging

Intelligent container technologies are revolutionizing flexible materials through the integration of advanced features like QR codes, RFID tags, and temperature sensors. These innovations significantly enhance product safety and traceability, while also generating valuable insights into customer interactions.

Leading the charge in these advancements, Western Packaging offers customized solutions in flexible packaging manufacturing that amplify product attractiveness and identity. Our container designs not only engage consumers but also provide real-time information regarding product freshness and usage.

As the demand for interactive experiences escalates, intelligent containers are poised to become a crucial differentiator in the nutraceutical market, empowering brands to connect more effectively with their customers.

Regulatory Compliance: Navigating Standards in Flexible Packaging for Nutraceuticals

Regulatory compliance is essential for flexible packaging manufacturing, especially in the nutraceutical sector, where stringent guidelines dictate labeling and safety standards. Companies such as Western Packaging demonstrate a proactive stance, ensuring their packaging solutions meet all relevant regulations, including those set forth by the FDA. This commitment not only safeguards customers but also bolsters the company’s credibility in a competitive marketplace.

Engaging with local regulatory experts can further assist businesses in effectively navigating complex approval processes. Experts underscore the importance of remaining vigilant regarding evolving regulations, as this vigilance can help avoid potential pitfalls and transform compliance into a strategic advantage.

Notably, adherence to Good Manufacturing Practices (GMP) enhances buyer trust and facilitates access to international markets, making it a crucial component of regulatory compliance.

Customization Trends: Tailoring Flexible Packaging to Meet Market Demands

Customization trends in flexible packaging manufacturing are gaining significant momentum as companies strive to distinguish themselves in a competitive market. Western Packaging offers tailored solutions that address specific product needs and user preferences, including features like portion control and convenience. This level of customization not only enhances product appeal but also cultivates customer loyalty. Notably, in 2023, nearly 60% of shoppers expressed a preference for brands that utilize eco-friendly materials, indicating that aligning materials with consumer values can further strengthen loyalty. As consumers increasingly seek personalized experiences, companies must adapt their presentation strategies to meet these evolving expectations.

Advanced Materials: Enhancing Performance and Sustainability in Flexible Packaging

The adaptable materials sector is undergoing a significant transformation driven by innovative substances that enhance both performance and sustainability. Noteworthy advancements, such as biodegradable films and high-barrier materials, are gaining traction, demonstrating a robust commitment to eco-friendly practices.

Western Packaging leads this initiative by utilizing these materials to develop solutions that not only safeguard products but also reduce environmental impact. The transition towards biodegradable films is particularly significant, as they provide a sustainable alternative that caters to the needs of eco-conscious consumers. These films are designed to decompose naturally, minimizing waste and aligning with the increasing regulatory focus on sustainability in materials.

Moreover, high-barrier materials play a crucial role in extending product shelf life while reducing resource consumption, making them essential in modern wrapping strategies. By integrating these advanced materials, companies can substantially enhance their sustainability profiles, appealing to a market that increasingly prioritizes environmental responsibility.

E-Commerce Influence: Adapting Flexible Packaging for Online Retail Success

E-commerce is fundamentally transforming the flexible packaging manufacturing landscape, compelling brands to refine their container strategies in order to thrive in the online retail environment. Lightweight designs, tamper-evident seals, and easy-open closures have transitioned from optional to essential features for e-commerce success.

Studies reveal that:

- 72% of buyers believe the design of containers influences their purchasing decisions, underscoring the importance of attractive and practical wrapping.

- 56.8% of buyers consider sustainable materials significant or extremely significant when shopping online, highlighting the growing demand for environmentally friendly options.

Western Packaging stands at the forefront of this evolution, developing innovative solutions tailored to the specific needs of online retailers. By prioritizing wrapping that not only safeguards products but also enhances visual appeal, businesses can significantly improve customer satisfaction and reduce shipping costs.

As online shopping continues to expand, the integration of efficient wrapping methods will be vital for companies aiming to attract and retain customer loyalty in a competitive market. Notably, customer loyalty can increase by 40% when presentation is personalized, illustrating the tangible benefits of thoughtful design.

Moreover, the e-commerce flexible packaging manufacturing market is projected to grow from USD 41.52 billion in 2025 to USD 79.75 billion by 2034, emphasizing the necessity for brands to adapt their flexible packaging manufacturing strategies. With e-commerce activities contributing to over one billion kilograms of plastic waste globally in 2019, the importance of sustainable alternatives cannot be overstated.

Supply Chain Optimization: Streamlining Processes in Flexible Packaging Manufacturing

Supply chain optimization stands as a pivotal focus for flexible packaging manufacturing companies aiming to enhance efficiency and reduce costs. Western Packaging exemplifies this through its integrated filling processes, which seamlessly align with their extensive offerings, accommodating a diverse range of products from powders to gummies and soft-gels. Furthermore, their robust 3PL services—including warehousing, inventory management, and logistics—serve to streamline operations significantly.

These methodologies not only bolster responsiveness to market demands but also minimize waste and shorten lead times. It is evident that efficient supply chain management, supported by Western Packaging's tailored solutions, is essential for maintaining competitiveness in the rapidly evolving industry.

Recycled Materials: Incorporating Sustainability into Flexible Packaging Solutions

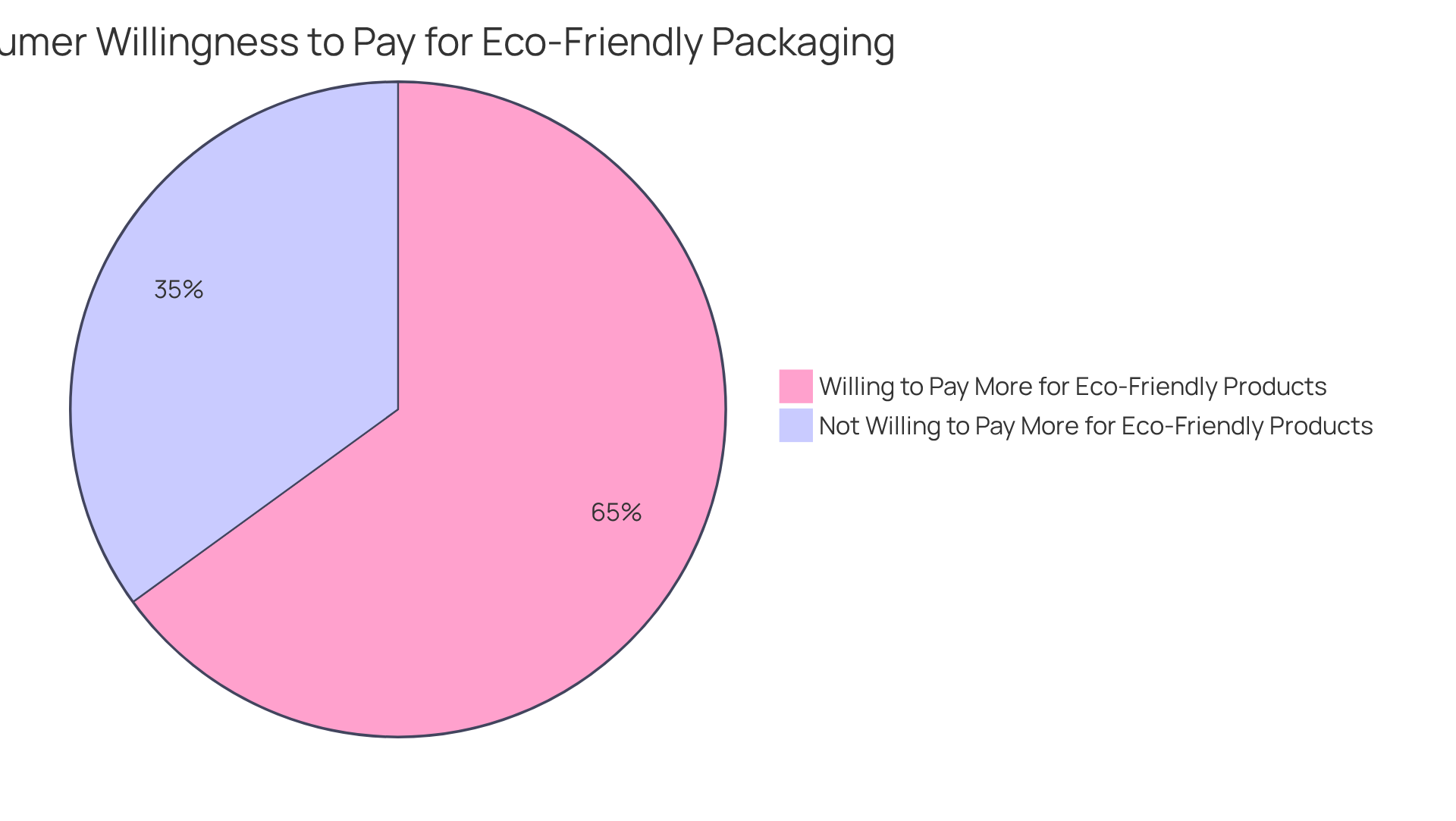

The incorporation of recycled materials into flexible packaging manufacturing solutions is increasingly essential as brands pursue their sustainability goals. Western Packaging prioritizes the use of post-consumer recycled materials in its designs, effectively minimizing environmental impact while resonating with eco-aware individuals. Research indicates that 60-70% of buyers are willing to pay a premium for eco-friendly materials, showcasing a growing preference for products aligned with their values.

As regulations surrounding recycled content tighten, including the minimum PCR requirement for plastic beverage containers effective January 1, 2026, companies in flexible packaging manufacturing must proactively adapt their container strategies to integrate sustainable materials and practices. Noteworthy examples include:

- Berry Global

- Mars

These companies have transitioned their pantry jars to 100% recycled plastic, eliminating over 1,300 metric tons of virgin plastic annually. This shift not only promotes a circular economy but also enhances brand loyalty among consumers who prioritize flexible packaging manufacturing for sustainability.

Furthermore, utilizing PCR can reduce greenhouse gas emissions by at least 67%, significantly influencing consumer choices and contributing to a more sustainable future within the industry. Many companies are also striving to ensure that all their materials are recyclable, reusable, or compostable by 2025, underscoring the industry's commitment to sustainability.

Consumer Preferences: Understanding Market Trends in Flexible Packaging

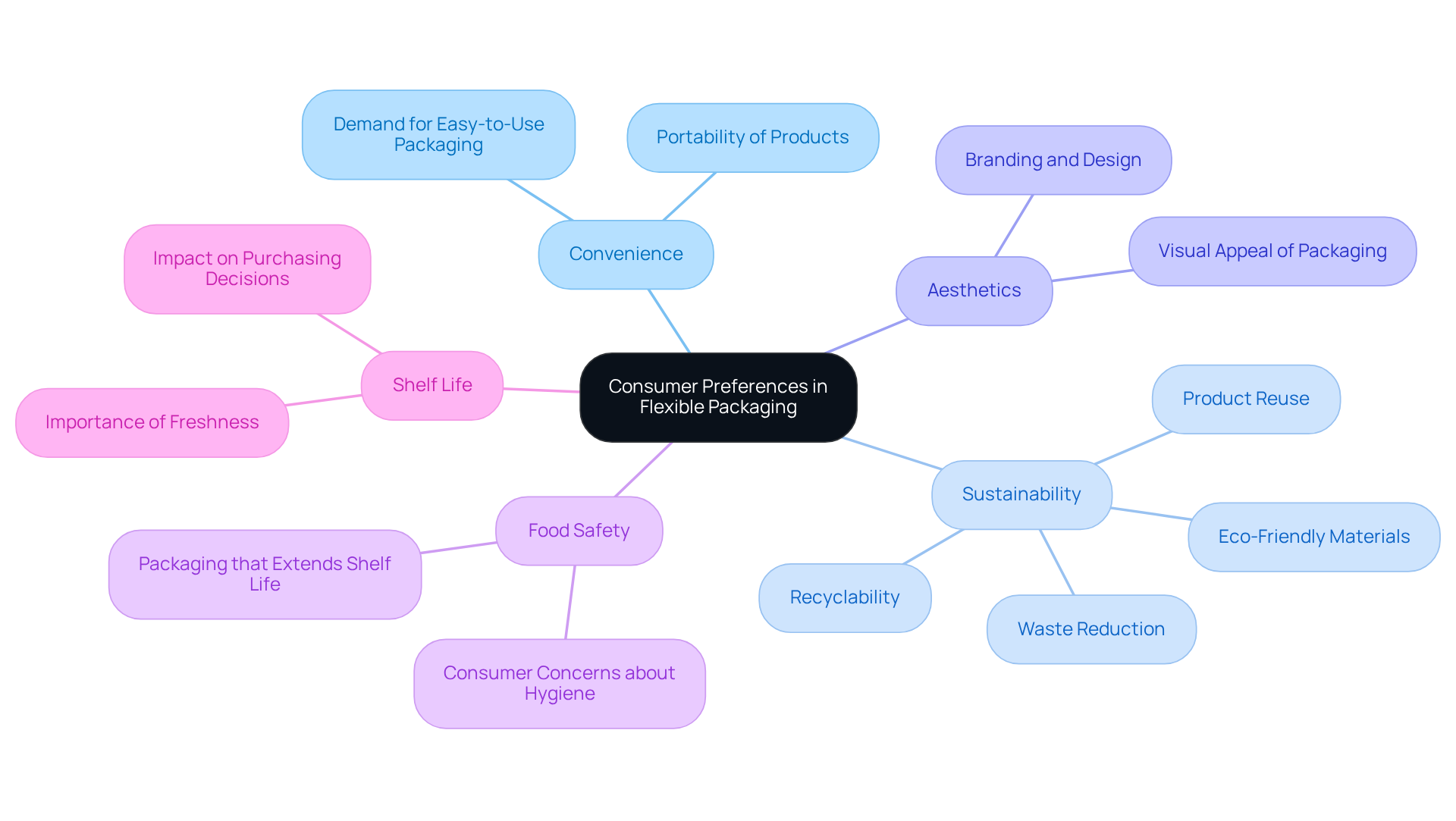

Consumer preferences are evolving at an unprecedented pace, underscoring the necessity for adaptable producers to remain vigilant to these changes. Convenience, sustainability, and aesthetics are increasingly shaping buying decisions. Notably, food safety and shelf life are paramount characteristics influencing purchasing choices, highlighting a growing demand for convenience within the nutraceutical sector.

Western Packaging actively engages in market research to ensure its products resonate with these buyer expectations. As Mark Conrad from McKinsey aptly states, "Those that can offer a compelling sustainability narrative without sacrificing on price or quality will be well positioned to grow their market share and capture value."

Furthermore, with 50% of buyers focusing on product reuse and waste reduction as defining aspects of sustainability, the integration of eco-friendly materials is becoming essential. As the market landscape transforms, brands can bolster their market presence by implementing strategies that prioritize these consumer trends, ensuring their packaging solutions effectively meet the needs of today's environmentally conscious consumers.

Conclusion

The landscape of flexible packaging manufacturing for nutraceuticals is evolving rapidly, driven by trends prioritizing sustainability, innovation, and consumer preferences. As businesses aim to enhance their market presence and operational efficiency, adopting integrated solutions, eco-friendly practices, and advanced technologies becomes essential. The focus on customization and regulatory compliance underscores the need for brands to align their strategies with market demands and consumer expectations.

Key insights reveal that sustainability initiatives are not merely beneficial for the environment; they resonate with consumers, significantly influencing their purchasing decisions. The incorporation of smart packaging technologies and advanced materials can enhance product safety, traceability, and overall appeal. Moreover, understanding consumer preferences—particularly the demand for convenience and sustainability—provides a competitive edge in a crowded marketplace.

As the nutraceutical sector continues to grow, brands must commit to innovative and sustainable packaging solutions that meet regulatory standards and cater to the evolving needs of consumers. By embracing these trends, companies can position themselves at the forefront of the industry, ensuring they not only survive but thrive in the dynamic landscape of flexible packaging manufacturing.

Frequently Asked Questions

What integrated solutions does Western Packaging offer in flexible packaging manufacturing?

Western Packaging provides comprehensive integrated offerings that combine design, filling services, and third-party logistics (3PL) to streamline supply chains and enhance product delivery.

What types of products can Western Packaging accommodate in its filling process?

The filling process at Western Packaging accommodates a diverse array of products, including powders, gummies, and soft-gels.

How does Western Packaging's approach benefit businesses?

By consolidating services, Western Packaging simplifies complexities for clients, allowing them to focus on their core competencies while improving operational efficiency and brand awareness.

Can you provide an example of the benefits of an integrated strategy in packaging?

Yes, one tech company reported shortening its launch schedule by two weeks through coordinated production and manufacturing processes, highlighting the benefits of a well-coordinated wrapping strategy.

What sustainability initiatives is Western Packaging implementing?

Western Packaging prioritizes recyclable materials, minimizes plastic consumption, and incorporates recycled materials into their solutions, demonstrating a commitment to eco-friendly practices.

How do consumers respond to eco-friendly packaging?

Studies indicate that 90% of shoppers are more inclined to purchase from companies that emphasize eco-friendly materials, and 54% have intentionally acquired sustainable items in the past six months.

What demographic trends are emerging in relation to sustainable packaging?

Among younger demographics, 59% of Millennials and 56% of Gen Z actively seek sustainable container alternatives, indicating a growing consumer preference for eco-friendly products.

What innovations are shaping the future of flexible packaging?

Innovations such as QR codes, RFID tags, and temperature sensors are enhancing product safety and traceability, while also providing valuable insights into customer interactions.

How does Western Packaging utilize smart packaging technologies?

Western Packaging offers customized solutions that integrate intelligent container technologies to improve product attractiveness, identity, and provide real-time information about product freshness and usage.