Overview

This article delineates best practices for effective brand package design within the nutraceutical industry, underscoring the critical need to meet packaging requirements, ensure regulatory compliance, and optimize supply chain processes.

By integrating essential elements—such as the utilization of eco-friendly materials, collaboration with filling service providers, and strict adherence to health regulations—brands can significantly enhance product appeal, maintain compliance, and improve operational efficiency.

This strategic approach ultimately drives sales and fosters customer loyalty, compelling industry players to act decisively in refining their packaging strategies.

Introduction

In the rapidly evolving nutraceutical market, effective brand package design has become a pivotal element in capturing consumer attention and driving sales. This article explores best practices for developing packaging that not only adheres to stringent regulatory requirements but also resonates with environmentally conscious consumers. As brands seek to differentiate themselves in a competitive landscape, the challenge lies in seamlessly integrating design and functionality. How can companies ensure their packaging not only protects the product but also enhances its market appeal?

Understand Nutraceutical Packaging Requirements

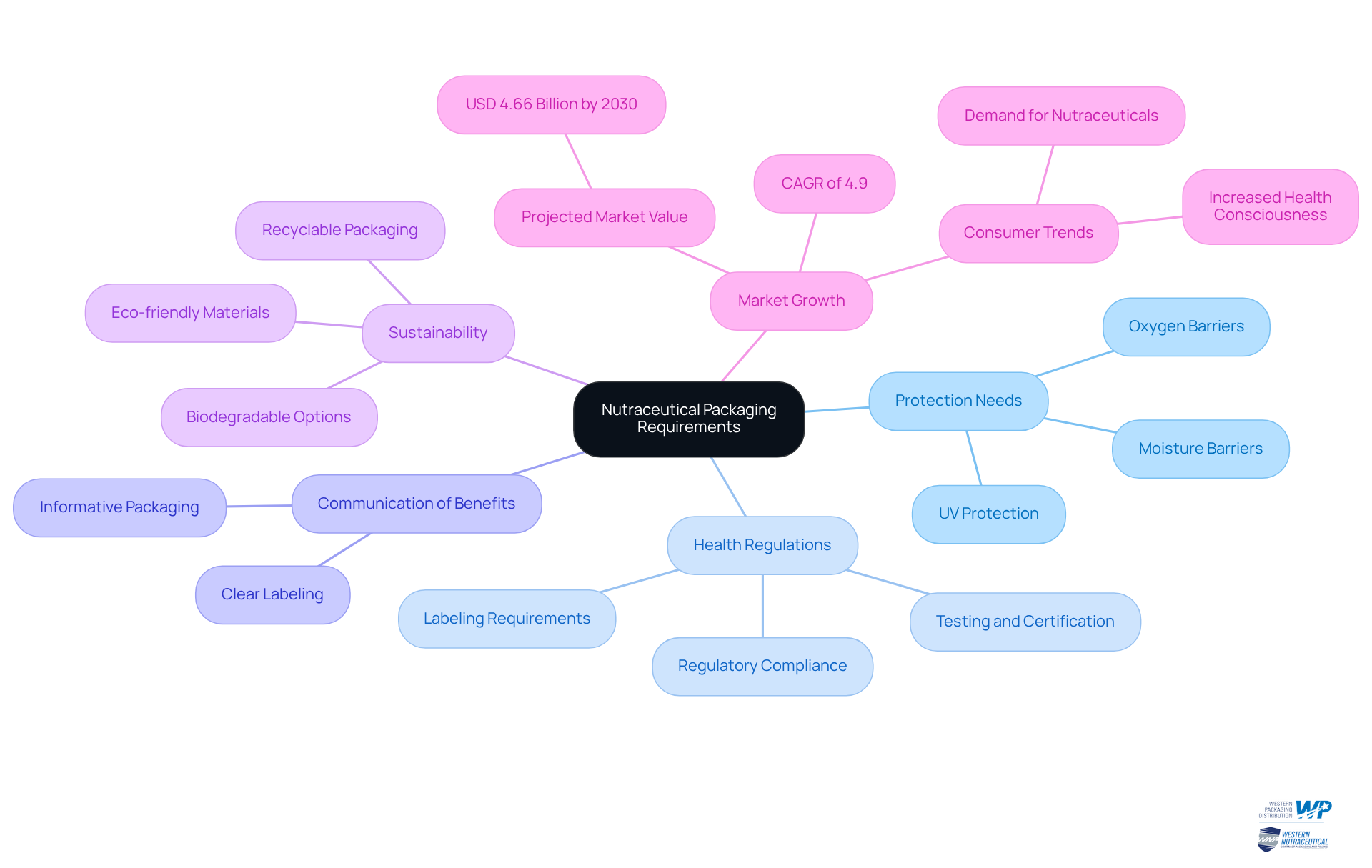

Nutraceutical containers must effectively meet several crucial requirements: protection from environmental factors, adherence to health regulations, and clear communication of benefits. Researching the specific needs of your product category is vital; for instance, powders require moisture barriers, while sensitive ingredients need UV protection.

As sustainability emerges as a significant consumer preference, container designs should reflect eco-friendly materials and practices. Engaging with focus groups or conducting surveys can yield valuable insights into what your target audience values in product presentation.

By aligning your container design with these critical requirements, you enhance both functionality and marketability, ultimately driving increased sales and fostering brand loyalty.

Western Packaging specializes in customized flexible solutions, including large pouches for protein items and stick packs for nutraceuticals, that enhance product appeal and brand recognition.

The nutraceutical container market is anticipated to expand considerably, achieving USD 4.66 billion by 2030, with a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2025 to 2030. This growth underscores the significance of incorporating environmental factors into product strategies to satisfy changing consumer expectations.

Integrate Design and Filling Services for Cohesion

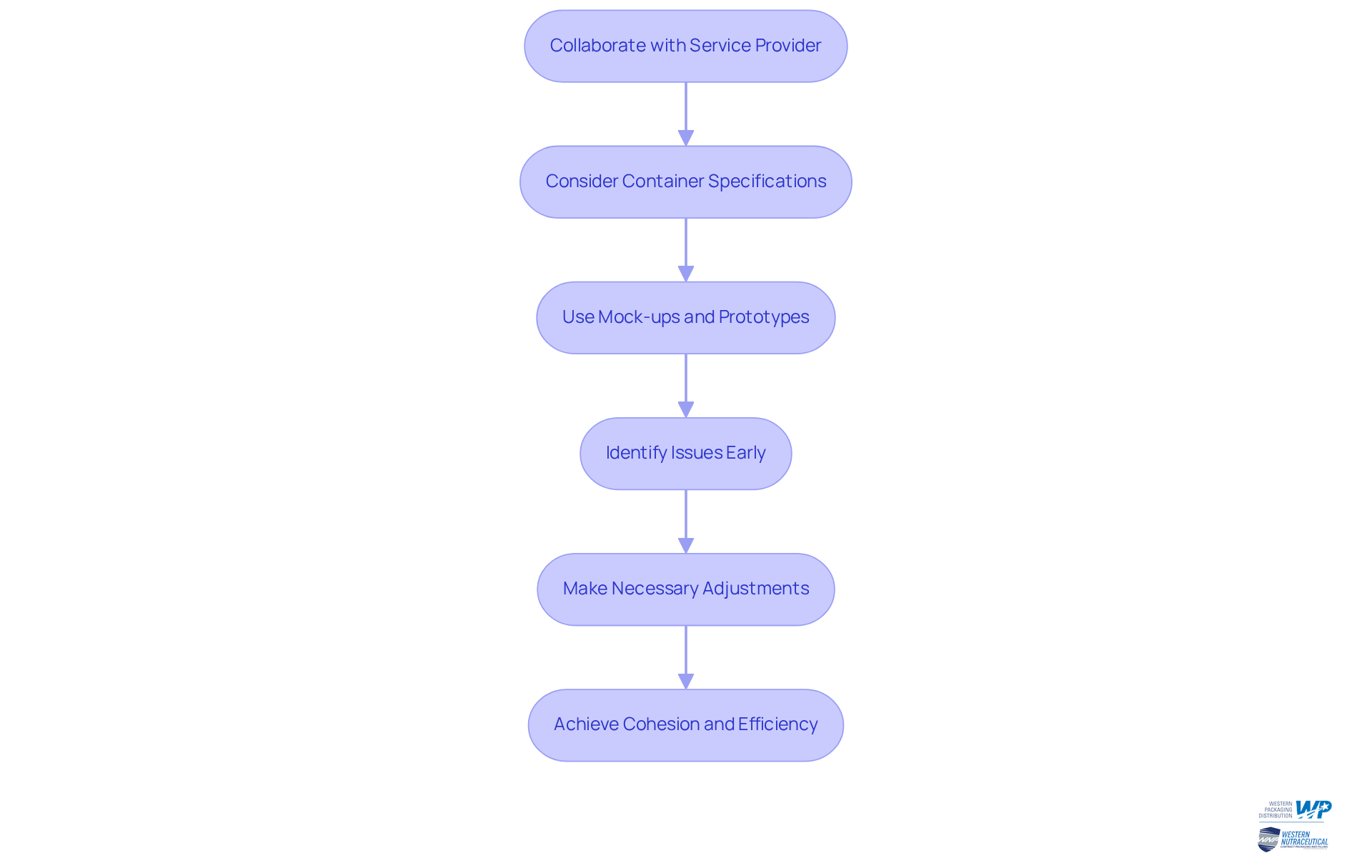

Collaborating with your service provider during the design stage is essential for achieving a cohesive solution. This partnership ensures that the containers are not only visually appealing but also compatible with the loading equipment and procedures.

For example, when designing a bottle for a liquid supplement, it is imperative to consider the neck size and cap type to facilitate smooth pouring and sealing.

Employing mock-ups and prototypes can help identify potential issues early in the process, enabling necessary adjustments prior to full-scale production. This integrated approach minimizes downtime and mitigates the risk of costly errors, ultimately enhancing the overall efficiency of your operations.

Effective collaboration between design creators and filling service providers can lead to a significant reduction in production delays and improved quality, establishing it as a best practice in the nutraceutical industry.

At Western Packaging, we manage a diverse array of product types, including powders, gummies, and soft-gels, ensuring that our comprehensive services, such as kitting and inventory management, are tailored to meet your specific needs.

Ensure Regulatory Compliance in Packaging

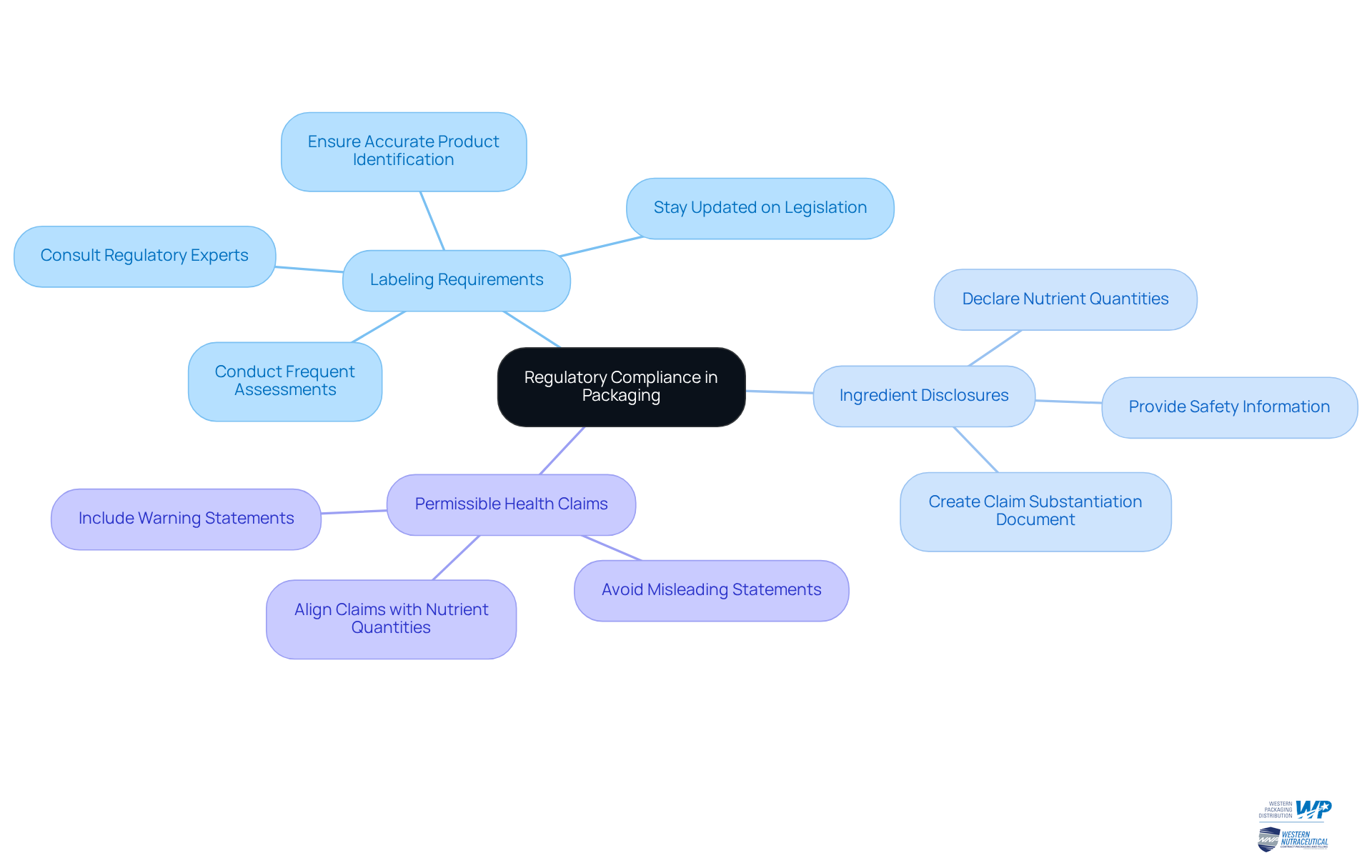

To ensure your containers comply with all regulatory requirements, it is essential to familiarize yourself with the guidelines established by authorities such as the FDA and EFSA. This encompasses a thorough understanding of:

- Labeling requirements

- Ingredient disclosures

- Permissible health claims

Frequent assessments of your materials and designs are vital for maintaining compliance. Consulting with regulatory experts or legal advisors can provide valuable insights into navigating complex regulations, including the creation of a claim substantiation document to support your assertions.

Furthermore, staying updated on legislative changes enables you to proactively modify your container strategies, assisting in preventing potential issues like insufficient product identification on labels. Statistics indicate that frequent labeling mistakes in health product packaging often stem from inadequate adherence to these guidelines, underscoring the necessity for diligence in this field.

As the health supplement market in India is projected to reach USD 18 billion by 2025, ensuring compliance is not only a regulatory requirement but also a strategic advantage in a competitive environment.

Optimize Supply Chain with Effective 3PL Solutions

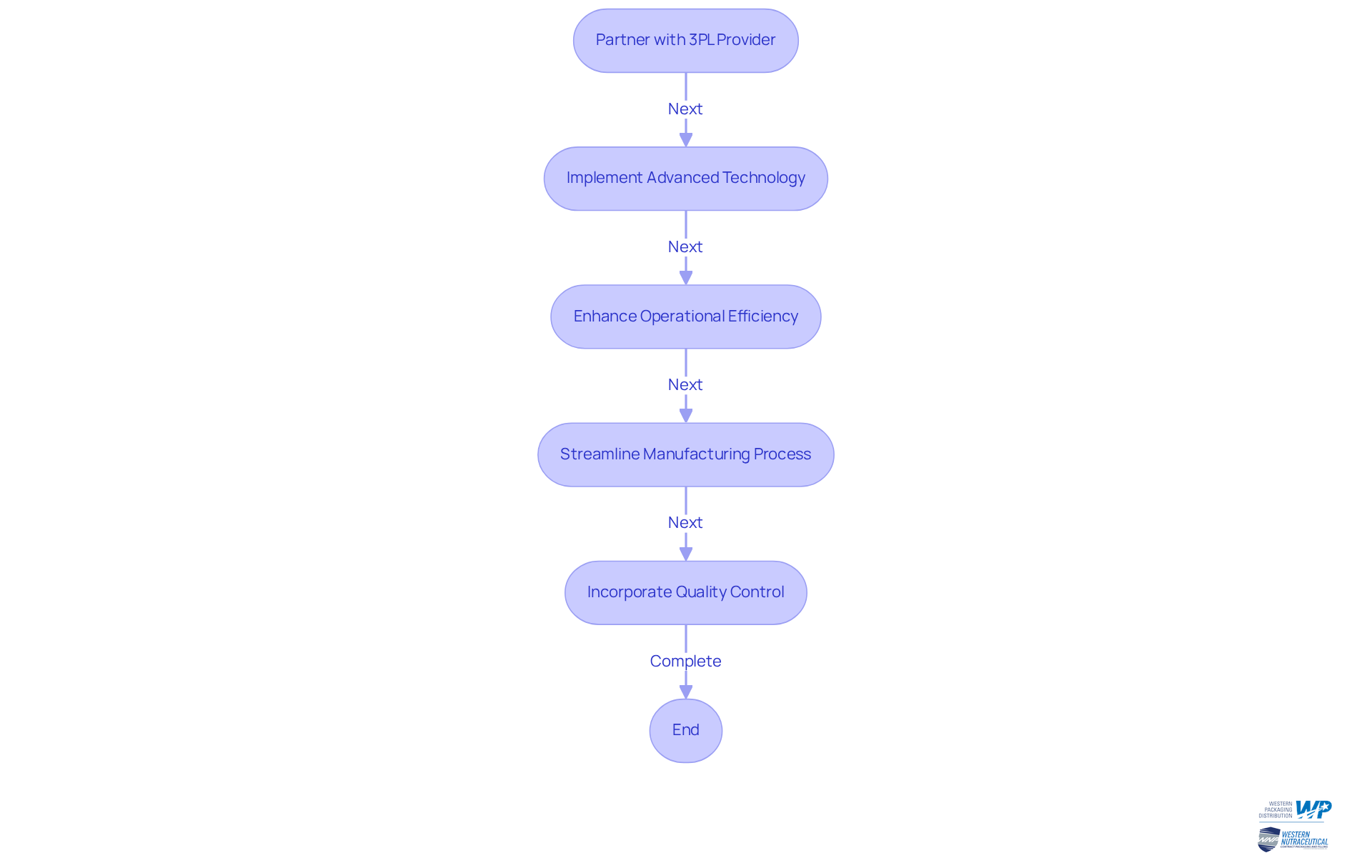

To enhance your supply chain, consider a partnership with Western Packaging, a reliable 3PL provider adept in navigating the unique challenges of the health product industry. Our comprehensive suite of services—warehousing, inventory management, and distribution—is meticulously tailored to optimize your supply chain efficiency. By leveraging our expertise, you can significantly elevate operational efficiency and focus on your core business functions. Moreover, our integrated filling services seamlessly align with our 3PL solutions, streamlining your manufacturing process for a diverse range of products, from powders to gummies and soft-gels.

Implementing advanced technology, such as IoT devices coupled with RFID tracking and predictive analytics, can provide real-time insights into stock levels and order statuses, enabling swift responses to demand fluctuations. This proactive strategy not only enhances customer satisfaction but also reinforces your brand's reputation as a trustworthy choice in a competitive landscape. With the nutraceutical market projected to expand from $591.1 billion in 2024 to $919.1 billion by 2030, optimizing your supply chain has never been more critical. As Tom Ullrich, Chief Supply Chain Officer at Vitaquest, underscores, effective supply chain strategies are vital for success in this evolving market. Additionally, incorporating robust quality control measures throughout your supply chain can ensure product safety and compliance, further solidifying your brand's reliability.

Conclusion

Effective brand package design in the nutraceutical sector hinges on understanding the unique requirements of the industry. By prioritizing functionality, compliance, and sustainability, brands can create packaging that not only protects their products but also resonates with consumers. This strategic approach enhances marketability and establishes a strong foundation for brand loyalty.

Key practices highlighted in this discussion emphasize the importance of integrating design and filling services to ensure cohesion throughout the production process. Collaborating closely with service providers can prevent costly errors and streamline operations, ultimately leading to better quality and efficiency. Moreover, staying informed about regulatory compliance is crucial for maintaining product integrity and avoiding pitfalls that can arise from labeling mistakes or insufficient disclosures.

Ultimately, the growth potential of the nutraceutical market underscores the necessity for brands to adopt these best practices. As the industry continues to evolve, leveraging effective supply chain solutions and innovative technologies will be vital for staying competitive. Embracing these strategies positions brands for success and fosters trust and satisfaction among consumers in a rapidly changing landscape.

Frequently Asked Questions

What are the key requirements for nutraceutical packaging?

Nutraceutical packaging must provide protection from environmental factors, comply with health regulations, and clearly communicate the product's benefits.

How do different product categories affect packaging needs?

Different product categories have specific requirements; for example, powders need moisture barriers, while sensitive ingredients require UV protection.

Why is sustainability important in nutraceutical packaging?

Sustainability is important because it reflects consumer preferences for eco-friendly materials and practices, which can enhance product appeal.

How can companies understand consumer preferences for packaging?

Companies can gain insights into consumer preferences by engaging with focus groups or conducting surveys to learn what their target audience values in product presentation.

What advantages does aligning container design with packaging requirements offer?

Aligning container design with packaging requirements enhances both functionality and marketability, which can lead to increased sales and brand loyalty.

What types of packaging solutions does Western Packaging offer for nutraceuticals?

Western Packaging specializes in customized flexible solutions, including large pouches for protein items and stick packs for nutraceuticals.

What is the projected growth of the nutraceutical container market?

The nutraceutical container market is expected to grow to USD 4.66 billion by 2030, with a compound annual growth rate (CAGR) of 4.9% from 2025 to 2030.

Why is it important to consider environmental factors in product strategies?

Considering environmental factors in product strategies is crucial to meet changing consumer expectations and preferences, which can significantly influence purchasing decisions.