Overview

This article outlines four key strategies for effective CBD bottle design and compliance, focusing on:

- Understanding regulatory requirements

- Incorporating eye-catching design features

- Integrating filling services

- Implementing quality control measures

Each strategy is supported by specific guidelines and examples. For instance, the necessity for child-resistant packaging and clear labeling is crucial to meet legal standards. Furthermore, appealing design elements play a significant role in influencing consumer purchasing decisions while ensuring product safety and quality. By adhering to these strategies, businesses can enhance their product offerings and remain compliant in a competitive market.

Introduction

Navigating the complex world of CBD packaging demands a keen understanding of both design and compliance. As the market for CBD products continues to expand, brands confront the dual challenge of adhering to stringent regulatory requirements while capturing consumer attention through innovative design. This article explores four key strategies that not only ensure compliance with evolving laws but also enhance brand visibility and appeal.

How can companies effectively balance the need for regulatory adherence with the creative demands of impactful product presentation?

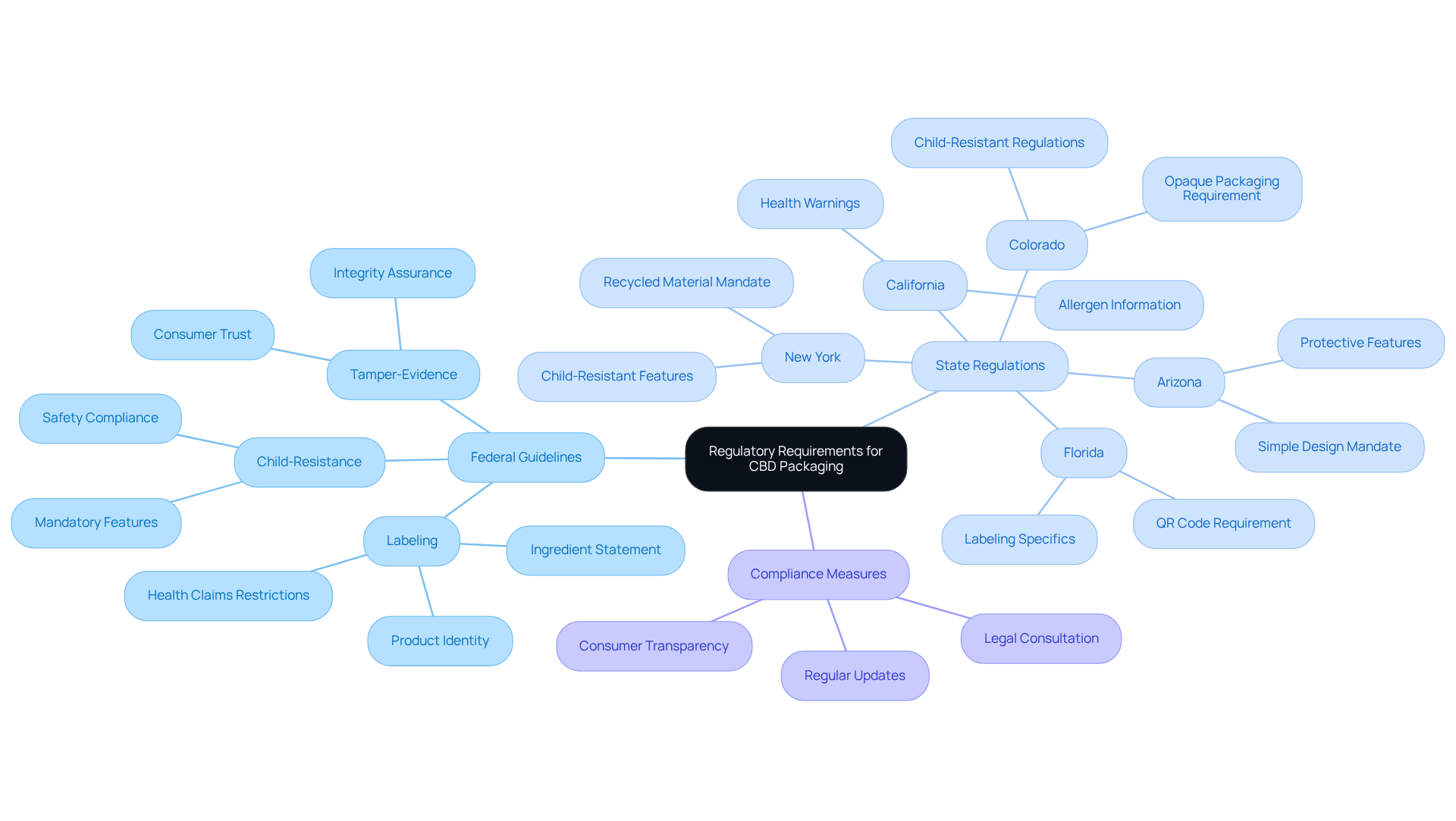

Understand Regulatory Requirements for CBD Packaging

To effectively design CBD bottles, it is imperative to understand the regulatory landscape. This encompasses federal guidelines from the FDA and state-specific regulations that dictate labeling, child-resistance, and tamper-evidence requirements. For instance, all CBD bottles must clearly indicate their contents, including the amounts of CBD and THC, and must not make unsubstantiated health claims.

Furthermore, CBD bottles must be child-resistant and tamper-evident to ensure consumer safety. It is vital to include the manufacturer's or distributor's name and contact details on the CBD bottles, along with a scannable barcode or QR code linked to a certificate of analysis (COA) for the hemp extract batch, particularly in states like Florida.

Familiarizing yourself with resources such as the FDA's CBD Labeling Guide and state-specific regulations can help ensure compliance and avoid costly penalties. Consistently examining updates from regulatory agencies is crucial, as laws can change often, affecting requirements for CBD bottles.

For example, states like New York and California impose stringent rules regarding labeling and containers for CBD bottles, including mandates for health warnings, allergen information, and the expiration date along with the number of milligrams of each marketed cannabinoid per serving. Staying informed about these evolving regulations is essential for avoiding costly penalties and ensuring that items meet legal standards.

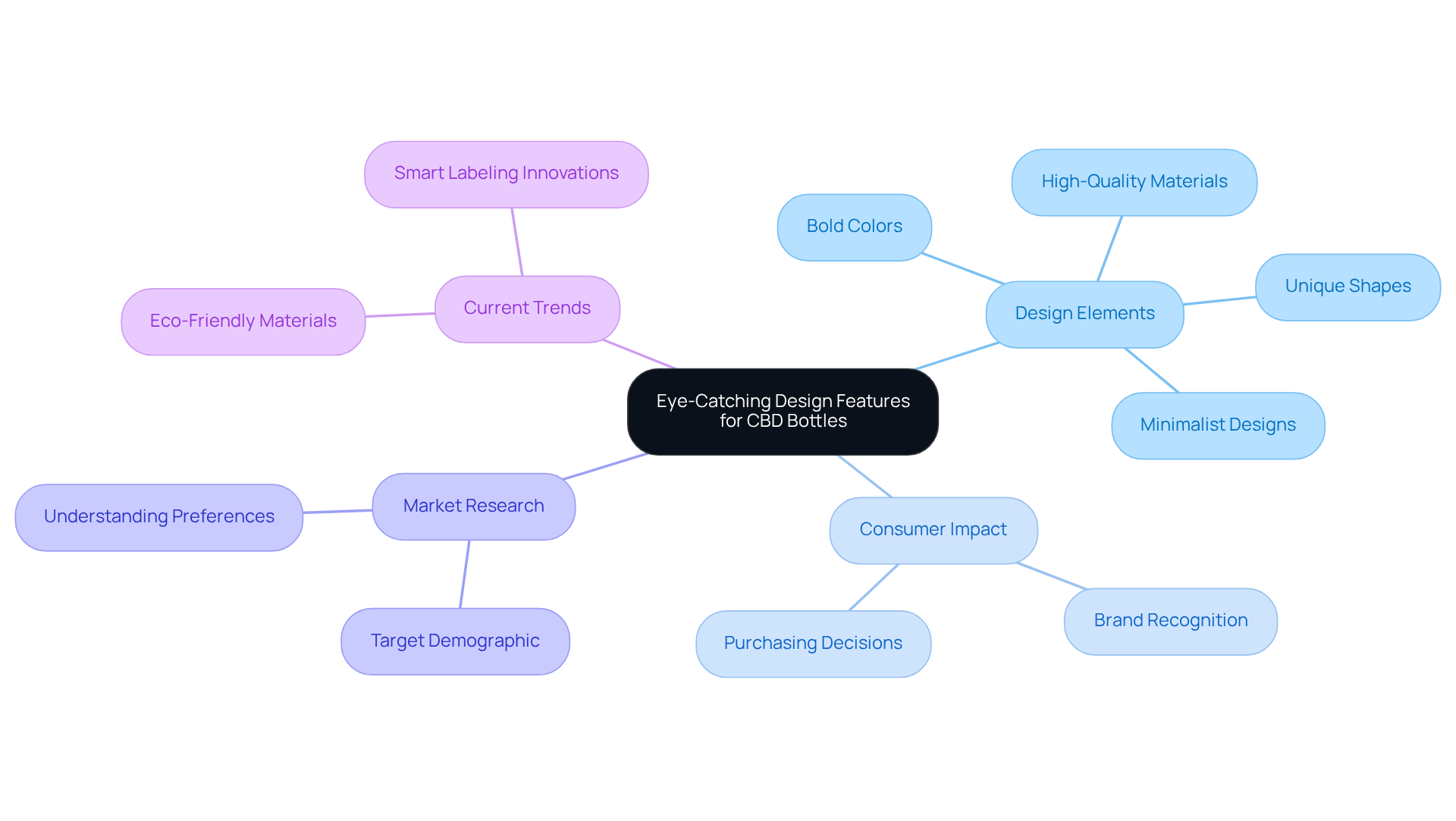

Incorporate Eye-Catching Design Features

Incorporating eye-catching design features into cbd bottles is crucial for enhancing brand recognition and consumer appeal. Utilizing bold colors and unique shapes creates a memorable first impression, while high-quality materials convey a sense of luxury and trustworthiness. At Western Packaging, we specialize in customized flexible containers, including large pouches for protein items and stick packs for nutraceuticals, which effectively appeal to consumers seeking premium offerings. Additionally, minimalist designs that emphasize clarity and sophistication play a significant role in this appeal. Furthermore, incorporating functional features like resealable closures or transparent windows not only improves usability but also highlights the items within, further attracting potential customers.

For instance, brands that employ vibrant colors and modern typography have successfully differentiated themselves on retail shelves, effectively capturing consumer interest. Research indicates that 72% of customers claim that design significantly influences their purchasing decisions, underscoring the importance of thoughtful design in driving sales. Moreover, 55% of consumers link luxury presentation with superior product quality, making it crucial for CBD brands to invest in appealing cbd bottles as part of their presentation solutions.

Conducting market research to understand design preferences within your target demographic can enhance your product strategy, ensuring it resonates with consumers. By remaining aware of current trends, such as the use of eco-friendly materials and intelligent labeling innovations like QR codes, brands can improve their market presence and cultivate customer loyalty.

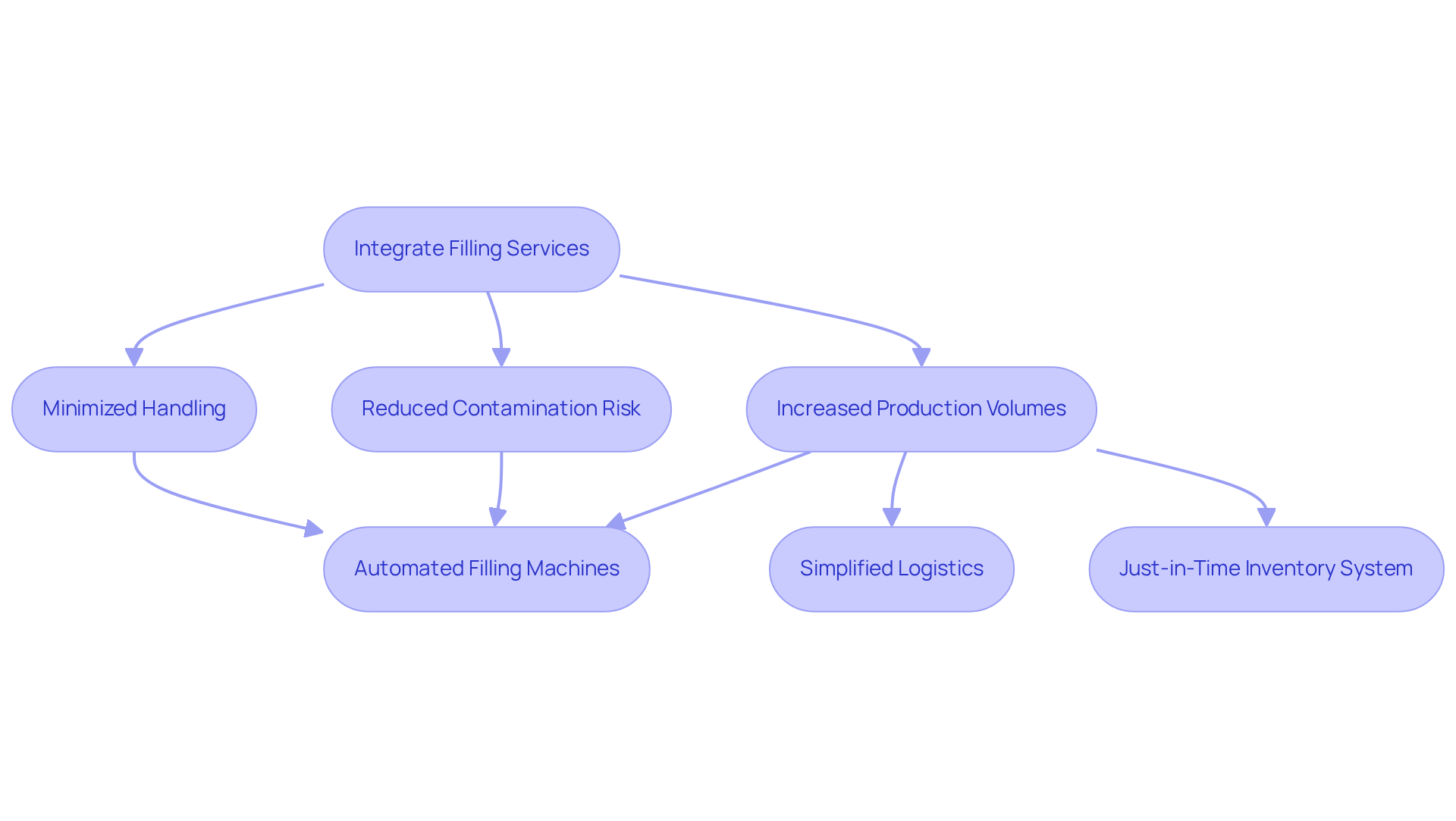

Integrate Filling Services for Streamlined Production

Integrating filling services directly into your packaging process is essential for streamlining production. This method minimizes handling and significantly reduces the risk of contamination, ensuring that products are filled with precision and efficiency. Automated filling machines improve consistency and speed, allowing for greater production volumes without sacrificing standards.

Companies that utilize both filling and wrapping services for CBD bottles often experience simplified logistics and shortened lead times—critical factors in the fast-paced market. Furthermore, implementing a just-in-time inventory system effectively manages stock levels, allowing businesses to meet consumer demand without overproduction.

Case studies reveal that organizations adopting this integrated approach frequently achieve substantial improvements in operational efficiency and cost savings, reinforcing the undeniable value of automation in producing CBD bottles.

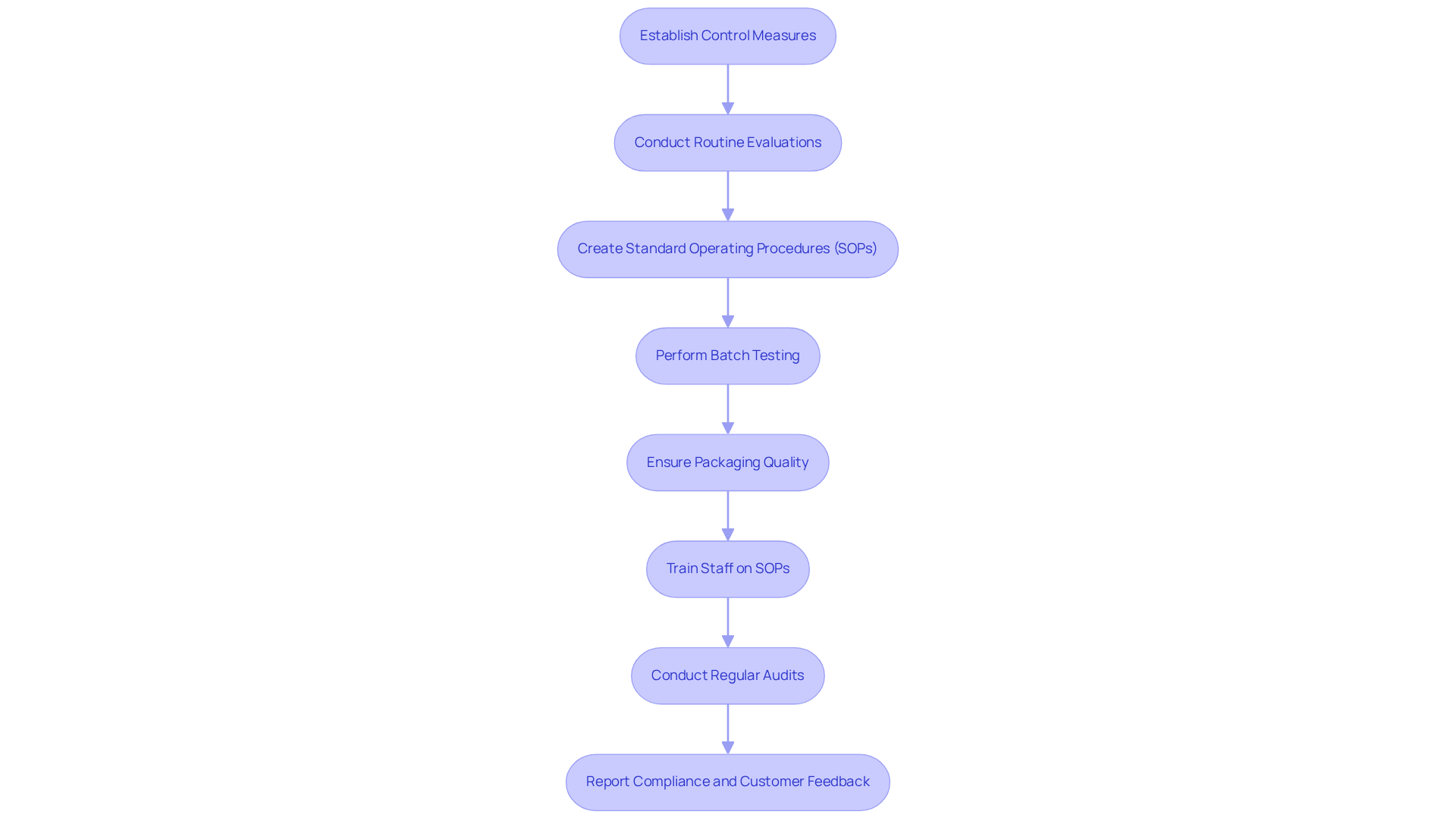

Implement Quality Control Measures in Packaging

Establishing strong control measures in the wrapping process of CBD bottles is crucial for guaranteeing safety and regulatory adherence in the CBD sector. This necessitates routine evaluations of container materials, strict compliance with Good Manufacturing Practices (GMP), and thorough testing of filled items.

Creating standard operating procedures (SOPs) for each phase of the wrapping process is essential for ensuring consistency and excellence. For instance, performing batch testing to confirm that items meet specified potency levels and ensuring that packaging is free from defects can significantly diminish the risk of expensive recalls.

Statistics indicate that over 80% of CBD products examined contained either more or less CBD than claimed, underscoring the necessity for strict control protocols. Furthermore, instructing staff on SOPs and conducting regular audits are crucial for ensuring compliance with control measures.

Organizations that enforce strict control procedures frequently report fewer compliance problems and greater customer satisfaction levels, illustrating the direct connection between assurance and consumer trust. Investing in quality control not only enhances corporate profitability but also provides substantial benefits in a federally regulated environment.

Conclusion

Understanding the intricacies of CBD bottle design and compliance is essential for any brand aiming to thrive in this competitive market. By grasping the regulatory requirements, incorporating appealing design features, integrating efficient filling services, and implementing stringent quality control measures, businesses can not only meet legal standards but also enhance their market presence and consumer trust.

The article highlights four pivotal strategies:

- Staying informed about evolving regulatory landscapes to avoid penalties.

- Utilizing eye-catching designs that resonate with consumers and elevate brand recognition.

- Streamlining production through integrated filling services to boost efficiency.

- Enforcing robust quality control measures to ensure product safety and compliance.

Each of these elements plays a critical role in establishing a reputable and successful CBD brand.

Ultimately, the significance of these strategies cannot be overstated. As the CBD industry continues to evolve, brands must adapt to regulatory changes and consumer preferences. By prioritizing compliance, design, efficiency, and quality, businesses can not only safeguard their operations but also foster loyalty and trust among their customers. Embracing these best practices will pave the way for sustained success in the dynamic landscape of CBD products.

Frequently Asked Questions

What are the key regulatory requirements for CBD packaging?

CBD packaging must comply with federal guidelines from the FDA and state-specific regulations, which include clear labeling of contents, child-resistance, and tamper-evidence requirements.

What information must be included on CBD bottles?

CBD bottles must clearly indicate the amounts of CBD and THC, include the manufacturer's or distributor's name and contact details, and feature a scannable barcode or QR code linked to a certificate of analysis (COA) for the hemp extract batch.

Why is child-resistance and tamper-evidence important for CBD packaging?

Child-resistance and tamper-evidence are crucial for ensuring consumer safety by preventing accidental ingestion by children and ensuring the product has not been altered or compromised.

How can businesses ensure compliance with CBD packaging regulations?

Businesses can ensure compliance by familiarizing themselves with the FDA's CBD Labeling Guide, state-specific regulations, and regularly examining updates from regulatory agencies to stay informed about any changes in the law.

What specific labeling requirements exist in states like New York and California?

In states like New York and California, CBD bottles must include health warnings, allergen information, an expiration date, and the number of milligrams of each marketed cannabinoid per serving.

What are the consequences of not complying with CBD packaging regulations?

Failure to comply with CBD packaging regulations can result in costly penalties and legal issues for businesses.