Overview

To calculate accurate packaging prices, businesses must adopt a systematic approach that encompasses:

- Gathering expense information

- Assessing resource costs

- Calculating labor and overhead

- Determining profit margins

This article delineates a comprehensive step-by-step process that underscores the significance of considering all expense components. By utilizing tools such as costing software and industry reports, companies can ensure competitive and precise pricing strategies. Embracing this methodology not only enhances pricing accuracy but also positions businesses for success in a competitive market.

Introduction

Understanding the intricacies of packaging pricing is essential for businesses aiming to maintain competitiveness in a rapidly evolving market. Factors such as material costs, labor expenses, and market trends play pivotal roles in this landscape. Companies must navigate these complexities to establish accurate pricing strategies. The question arises: how can organizations ensure they are not only covering costs but also maximizing profitability in an environment marked by fluctuating expenses and consumer demands? This guide delves into a systematic approach to calculating packaging prices, equipping businesses with the knowledge to optimize their pricing structures effectively.

Understand the Basics of Packaging Pricing

Packaging expenses encompass several essential elements, including resource expenses, labor, overhead, and profit margins. To establish precise packaging prices, it is vital to comprehend the various types of containers—such as plastic, glass, and cardboard—and their associated costs. In 2025, the expected average packaging prices for wrapping supplies will be significantly influenced by factors like tariffs, which have risen to 25% on imported materials, directly impacting total expenditures and pricing strategies.

Labor expenses play a crucial role in the packaging process, varying according to the complexity of the design and the filling services required. As companies increasingly adopt automation and digitalization, these labor costs may fluctuate, potentially leading to savings over time. Additionally, overhead expenses, which include utilities and equipment maintenance, must be factored into the financial equation.

To ensure a sustainable and competitive pricing strategy, it is essential to determine your desired profit margin. Typical firms allocate approximately 10-40% of a product's retail price to expenses related to its presentation, underscoring the importance of meticulous budgeting.

Real-world examples illustrate how companies calculate costs for wrapping based on different materials. For instance, businesses that have expanded their supplier networks have been able to mitigate risks associated with fluctuating raw material costs, ensuring more stable rates. Industry leaders emphasize that understanding these expense components, such as packaging prices, is critical for effectively managing the complexities of pricing. By grasping these fundamentals, businesses can make informed decisions that enhance their operational efficiency and market competitiveness.

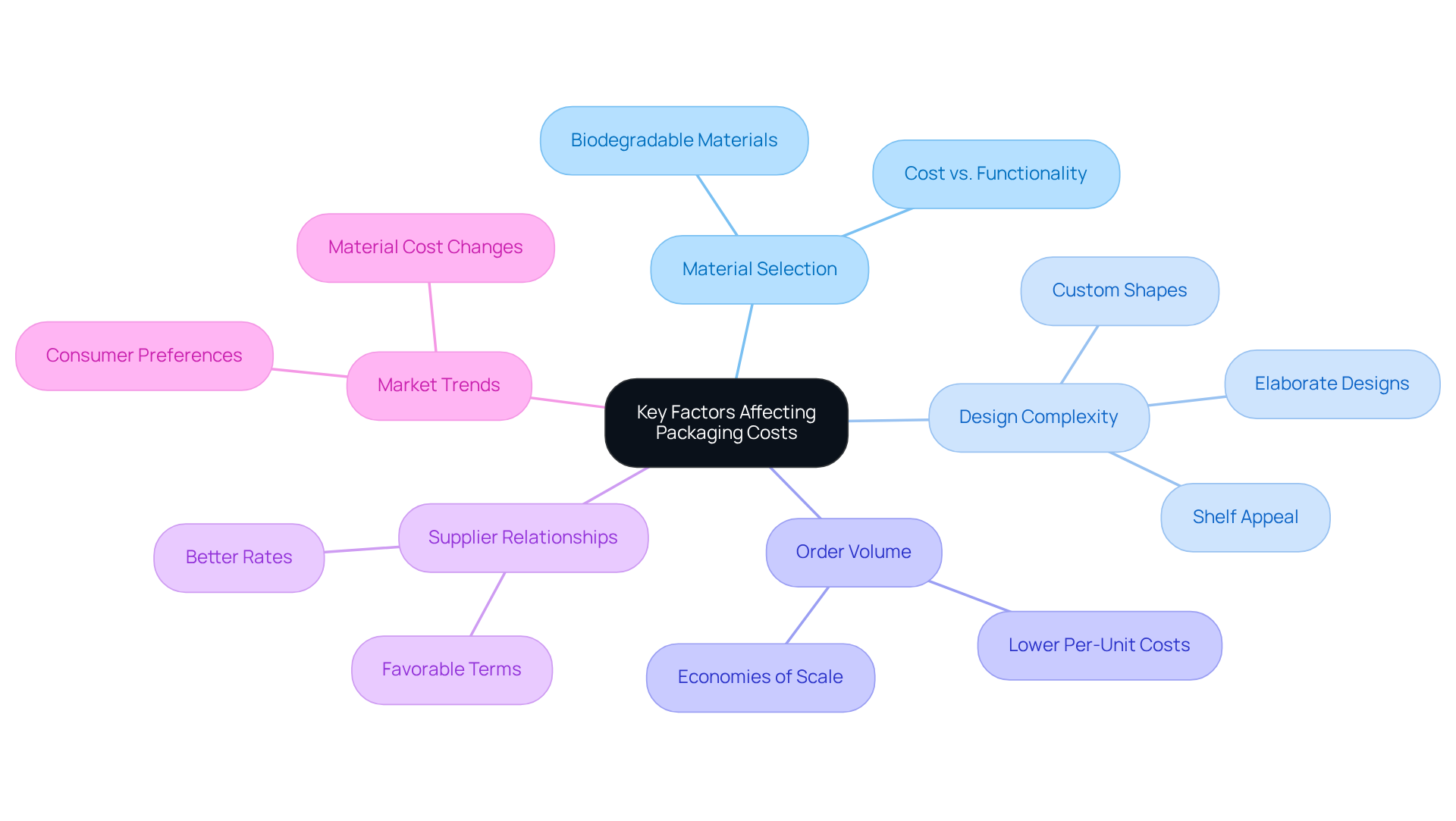

Identify Key Factors Affecting Packaging Costs

Several essential elements significantly influence packaging prices:

-

Material Selection: The choice of materials directly impacts both cost and functionality. For example, while biodegradable materials may lead to higher packaging prices, they can greatly enhance a brand's image and attract environmentally conscious consumers.

-

Design Complexity: The intricacy of container design is crucial in determining production costs. Custom shapes or elaborate designs often require more resources and time, which results in increased packaging prices. At Western Packaging, we offer tailored flexible solutions, such as large pouches for protein products and stick packs for nutraceuticals, which not only boost your product's shelf appeal but also strengthen brand recognition.

-

Order Volume: Economies of scale are vital; larger order quantities typically result in lower per-unit costs, which helps businesses optimize their packaging prices.

-

Establishing strong relationships with suppliers can lead to better rates and favorable terms, ultimately impacting overall packaging prices.

-

Market Trends: Staying informed about industry trends is crucial for anticipating changes in material costs and consumer preferences, enabling businesses to adjust their strategies effectively.

By thoroughly examining these factors, companies can make informed decisions regarding their packaging prices that align with their pricing strategies and enhance their competitive advantage.

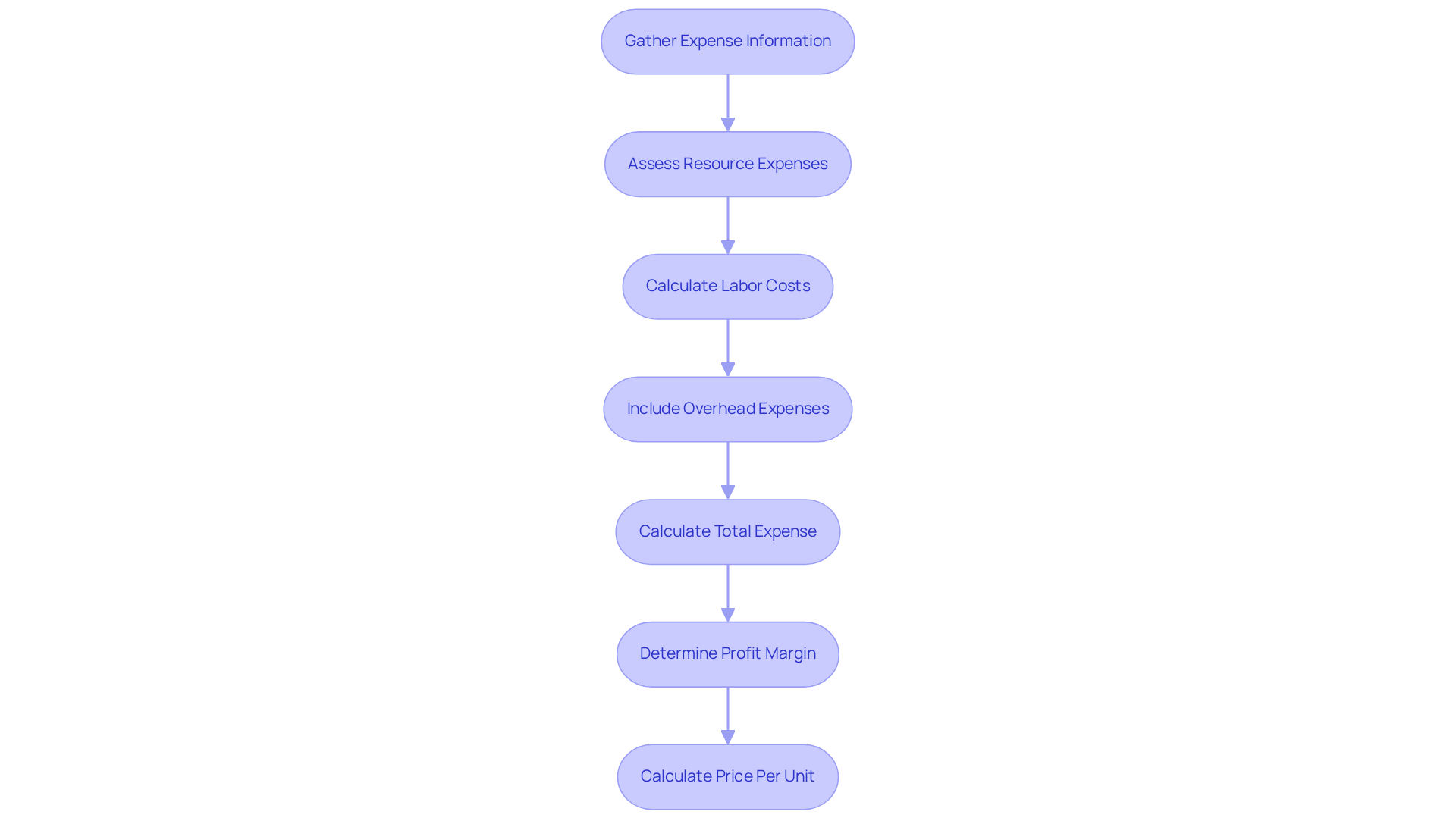

Calculate Your Packaging Prices Step-by-Step

To determine your shipping costs, follow these essential steps:

- Gather Expense Information: Collect comprehensive data on substance expenses, labor, overhead, and desired profit margins.

- Assess resource expenses by computing the overall expense of supplies required for your packaging prices. For instance, if you require 1000 boxes at $0.50 each, your material expense totals $500.

- Calculate Labor Costs: Estimate the labor necessary for wrapping. If it takes 10 hours at $15/hour, your labor expense amounts to $150.

- Include Overhead Expenses: Allocate a portion of your overhead expenses to the packaging process. If your monthly expenses are $2000 and you produce 1000 units, the packaging prices result in an overhead cost per unit of $2.

- Calculate Total Expense: Combine supplies, labor, and overhead expenses. For our example: $500 (materials) + $150 (labor) + $2000 (overhead) = $2650 total expense.

- Determine Profit Margin: Decide on a profit margin (e.g., 20%). Multiply the total expense by 1.20 to find the final price: $2650 x 1.20 = $3180.

- Calculate Price Per Unit: Divide the final price by the number of units: $3180 / 1000 = $3.18 per unit.

This systematic approach ensures that all expenses are accounted for, resulting in accurate cost assessments.

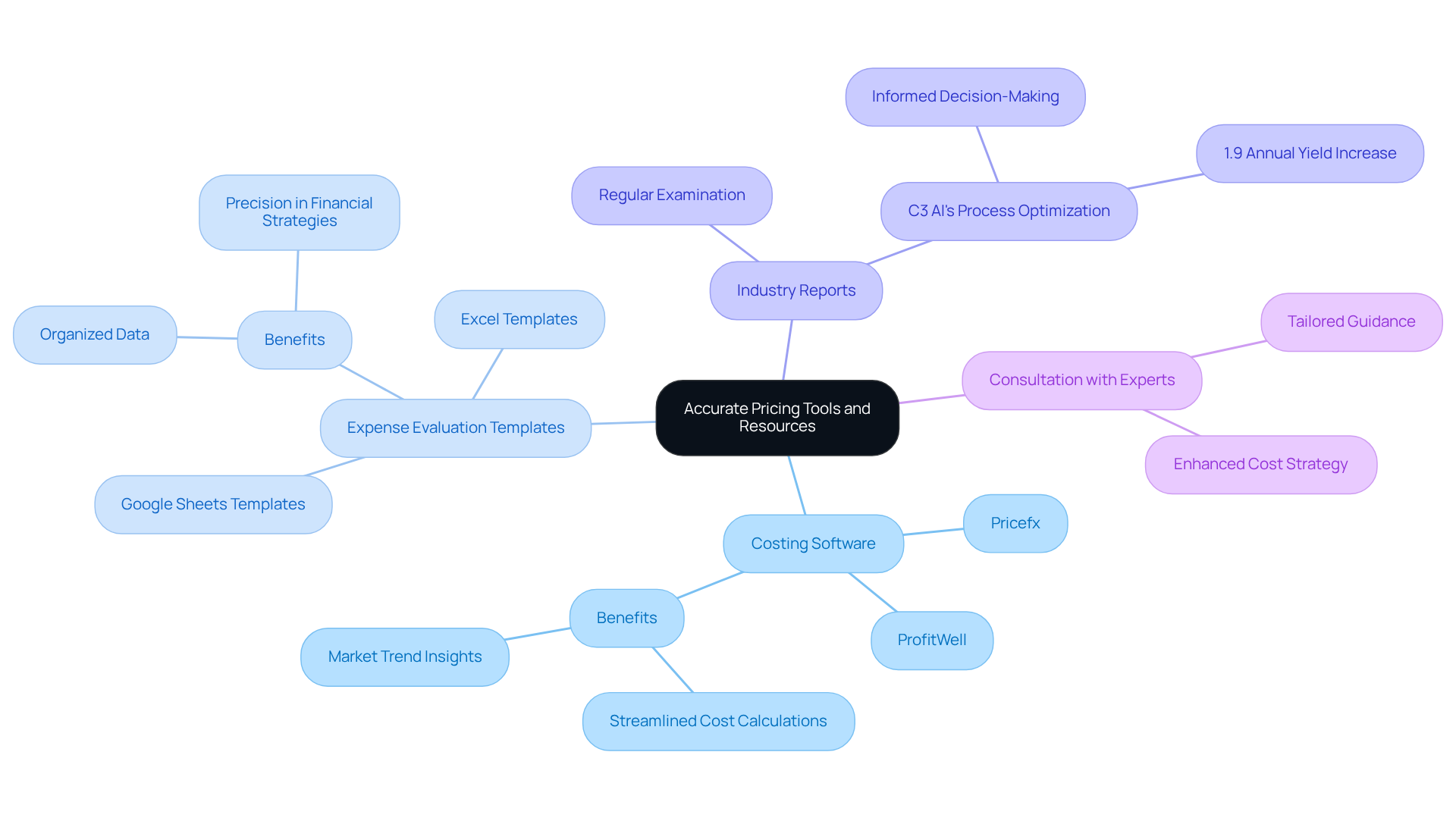

Utilize Tools and Resources for Accurate Pricing

To achieve accurate packaging prices, it is essential to utilize the appropriate tools and resources. Consider the following key options:

-

Costing Software: Implementing solutions such as Pricefx or ProfitWell can streamline cost calculations and provide valuable insights into market trends. This enables businesses to make informed financial decisions. As noted by eProductivity Software, this signifies a transformative shift in the industry, poised to reshape the framework of cost strategies.

-

Expense Evaluation Templates: Utilizing templates in Excel or Google Sheets specifically designed for expense analysis can effectively organize data and calculations, ensuring precision in financial strategies. Companies like LetsGetChecked have successfully adopted such templates to enhance their operational efficiency.

-

Industry Reports: Regular examination of industry reports is vital for staying updated on material costs and market dynamics, which can significantly influence pricing strategies. For example, C3 AI's Process Optimization has delivered an estimated 1.9% annual yield increase for clients, highlighting the potential advantages of informed decision-making.

-

Consultation with Experts: Engaging with consultants or industry specialists can offer tailored guidance and strategies that align with your unique business needs, thereby enhancing your cost strategy.

By integrating these resources into your pricing strategy, you can ensure that your packaging prices remain competitive and accurately reflect current market conditions.

Conclusion

Understanding how to calculate accurate packaging prices is essential for businesses aiming to remain competitive and efficient in today’s market. By grasping the various components that contribute to packaging costs, companies can create pricing strategies that not only cover expenses but also drive profitability.

Several key factors influence packaging prices, including:

- Material selection

- Design complexity

- Order volume

- Supplier relationships

- Market trends

Each of these elements plays a critical role in shaping the final cost of packaging, emphasizing the importance of a comprehensive approach to pricing. Moreover, a systematic step-by-step guide provides a clear framework for calculating shipping costs, ensuring that businesses can account for all necessary expenses.

Ultimately, leveraging the right tools and resources—such as costing software, expense evaluation templates, and industry reports—can significantly enhance the accuracy of packaging price calculations. By staying informed and utilizing these strategies, businesses can not only optimize their packaging pricing but also improve their overall operational effectiveness. Embracing these practices will lead to better financial decisions and a stronger position in the marketplace, making accurate packaging pricing a vital aspect of any successful business strategy.

Frequently Asked Questions

What are the main components of packaging expenses?

Packaging expenses include resource expenses, labor, overhead, and profit margins.

How do different types of containers affect packaging pricing?

The costs of different types of containers, such as plastic, glass, and cardboard, play a significant role in establishing precise packaging prices.

What external factors are expected to influence packaging prices in 2025?

In 2025, packaging prices will be significantly influenced by factors like tariffs, which have risen to 25% on imported materials, impacting total expenditures and pricing strategies.

How do labor expenses vary in the packaging process?

Labor expenses vary according to the complexity of the design and the filling services required, and they may fluctuate as companies adopt automation and digitalization.

What are overhead expenses in packaging?

Overhead expenses include utilities and equipment maintenance, which must be factored into the overall financial equation of packaging.

How is a desired profit margin determined in packaging pricing?

Companies typically allocate approximately 10-40% of a product's retail price to expenses related to its presentation, which helps determine the desired profit margin.

How can companies mitigate risks associated with fluctuating raw material costs?

Businesses that expand their supplier networks can mitigate risks associated with fluctuating raw material costs, ensuring more stable rates.

Why is understanding packaging pricing components important for businesses?

Understanding the components of packaging pricing is critical for effectively managing pricing complexities, enhancing operational efficiency, and maintaining market competitiveness.