Overview

Choosing a reliable nutraceutical contract manufacturer involves four essential steps:

- Define your specific manufacturing needs.

- Research potential manufacturers.

- Assess their capabilities and certifications.

- Establish clear communication and support expectations.

Understanding product requirements is crucial, as it lays the foundation for evaluating production capacity and quality standards. Moreover, fostering effective communication is vital to ensure a successful partnership. By following these steps, you can enhance operational efficiency and product quality, ultimately leading to a more reliable manufacturing process.

Introduction

Navigating the world of nutraceuticals presents a significant challenge, particularly when it comes to selecting the right contract manufacturer. As the industry is on the brink of substantial growth, it is imperative to understand how to choose a reliable partner. This decision is crucial for ensuring product quality and achieving market success.

Prioritizing the right factors in this selection process is essential. Businesses must ensure they are making informed decisions that align with their specific needs, thereby securing their position in a competitive landscape.

Define Your Nutraceutical Manufacturing Needs

Begin by detailing your specific requirements for working with a nutraceutical contract manufacturer. Consider the following aspects:

- Product Type: Identify whether you require capsules, powders, gummies, or liquids. Each format necessitates unique manufacturing processes, which can significantly influence quality and consumer appeal. As indicated by industry specialists, comprehending the type of offering is essential for aligning with market needs.

- Volume Requirements: Determine the quantity of products you plan to manufacture. This will affect your selection of producer based on their production capacity and ability to scale operations effectively. The market for nutraceutical contract manufacturer services is projected to grow from $174.09 billion in 2024 to $195.76 billion in 2025 at a compound annual growth rate (CAGR) of 12.4%, underscoring the importance of capacity planning.

- Target Market: Understand the demographics and preferences of your target audience. This understanding will assist you in choosing a manufacturer that can accommodate specific market trends, such as the increasing demand for clean label items and plant-based formulations. Significant trends in the industry emphasize immune health and e-commerce integration, which are crucial factors for your strategy.

- Regulatory Compliance: Ensure that your needs align with industry regulations, such as Good Manufacturing Practices (GMP), to guarantee safety and quality. Adhering to these standards is crucial, especially as consumer awareness around ingredient transparency continues to rise.

By clearly defining these needs, you will streamline the subsequent steps in your search for a dependable nutraceutical contract manufacturer, ultimately enhancing your product's market presence and operational efficiency.

Research Potential Contract Manufacturers

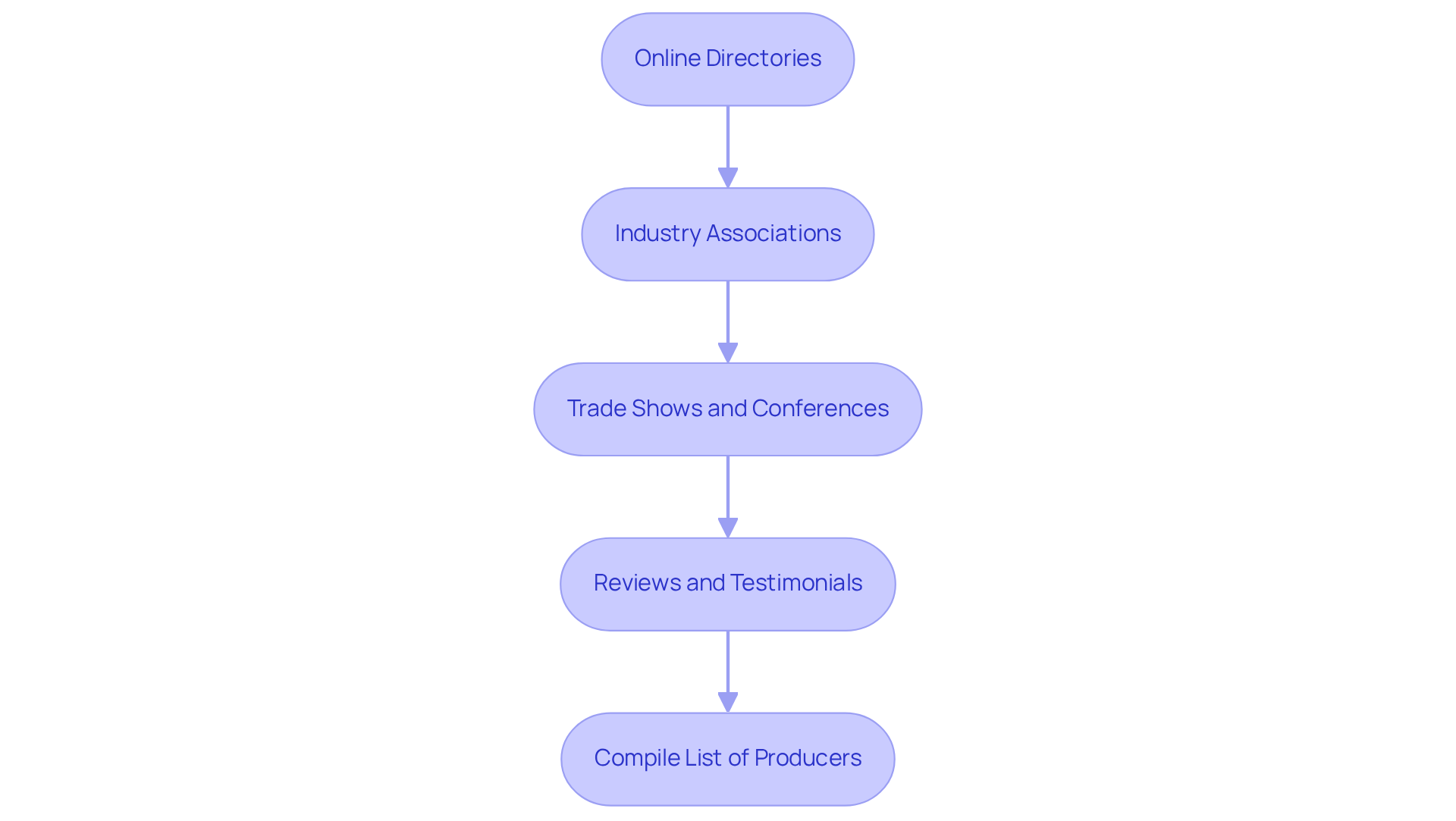

To effectively research potential contract manufacturers, follow these essential steps:

- Online Directories: Leverage industry-specific directories and platforms that list contract manufacturers specializing in nutraceuticals to identify potential partners.

- Industry Associations: Consult organizations like the Council for Responsible Nutrition (CRN) or the Natural Products Association (NPA) for recommendations on reputable producers.

- Trade Shows and Conferences: Engage with producers at industry events to gather insights into their capabilities and services, fostering valuable connections.

- Reviews and Testimonials: Investigate reviews and testimonials from businesses that have previously collaborated with potential producers, offering insights into their reliability and quality of service.

By compiling a list of possible producers, you will be better equipped for the subsequent stages in the assessment process, ensuring a thorough evaluation of your options.

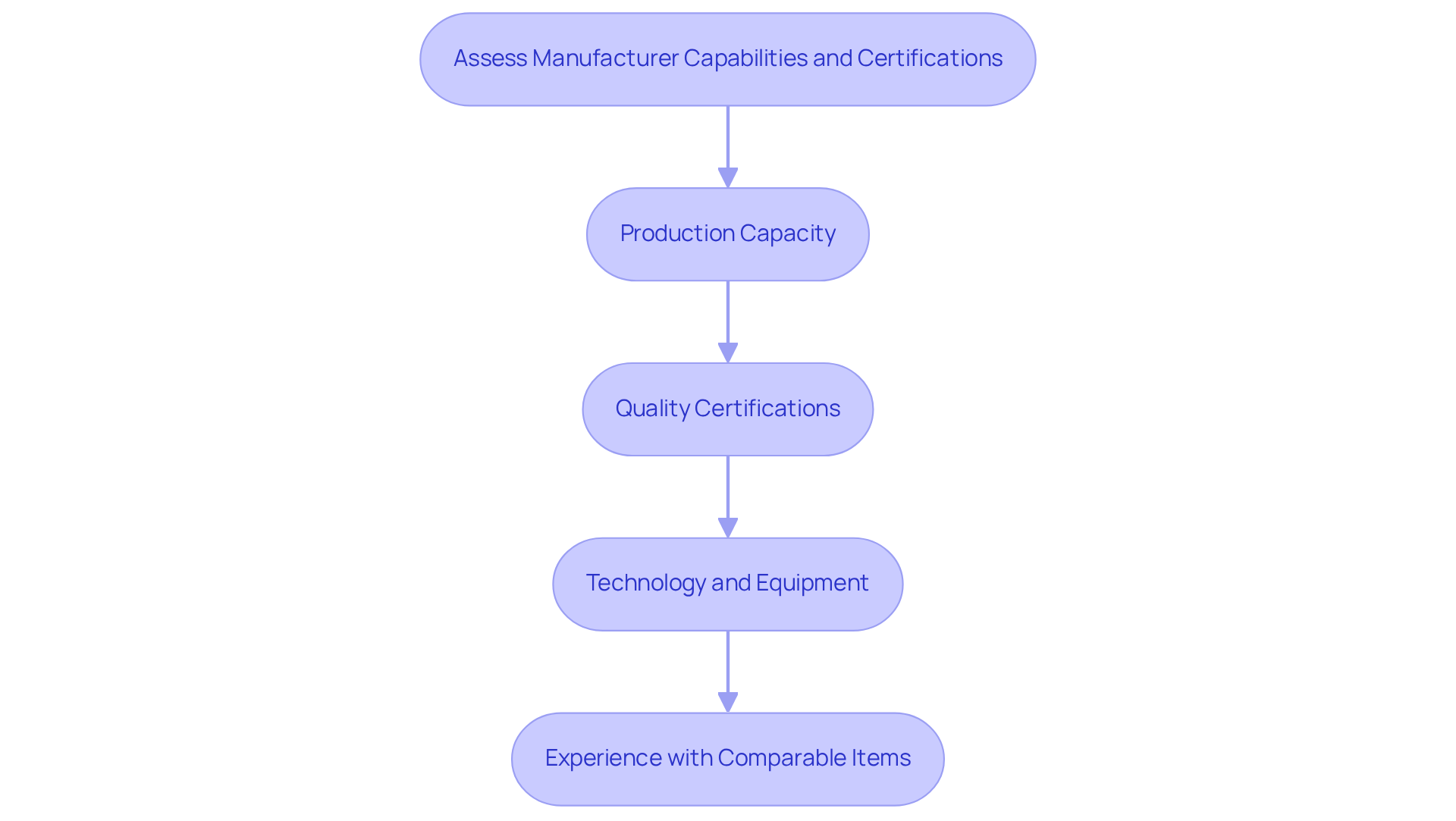

Assess Manufacturer Capabilities and Certifications

Once you have a shortlist of potential manufacturers, it is crucial to assess their capabilities and certifications.

-

Production Capacity: Inquire about their ability to handle your required volume and whether they can scale up production if needed. This is essential, as many producers may not be prepared to manage variations in demand.

-

Quality Certifications: Confirm that the producer holds relevant certifications such as GMP, NSF, or ISO. These certifications indicate adherence to high-quality standards. Significantly, just a small number of manufacturers obtain NPA certification, which guarantees items are comprehensively examined for safety and excellence, emphasizing the stringent standards in the sector.

-

Technology and Equipment: Evaluate the technology and equipment used in their manufacturing processes. Advanced technology can enhance efficiency and quality, reducing the likelihood of errors and contamination.

-

Experience with Comparable Items: Verify if the creator has experience making items similar to yours. This can be a strong indicator of their capability to meet your specific needs effectively.

By thoroughly assessing these factors, you can ensure that the nutraceutical contract manufacturer you choose is capable of delivering high-quality nutraceutical products that meet industry standards. As William A. Foster stated, "Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution." This highlights the significance of choosing a manufacturer dedicated to excellence.

Establish Communication and Support Expectations

To foster a successful partnership, establishing clear communication and support expectations is essential:

- Point of Contact: Designate a primary point of contact on both sides to streamline communication and ensure accountability. This role is crucial for maintaining clarity and responsiveness throughout the manufacturing process.

- Regular Updates: Set expectations for regular updates on production progress, quality checks, and any potential issues that may arise. Research indicates that manufacturers implementing structured communication protocols experience a 25% improvement in project outcomes, highlighting the importance of consistent information flow.

- Feedback Mechanism: Implement a feedback mechanism to address concerns promptly and make necessary adjustments during the manufacturing process. Successful partnerships often rely on effective feedback loops, significantly enhancing product quality and operational efficiency.

- Support Services: Discuss the level of support you can expect from the manufacturer, including assistance with regulatory compliance, packaging, and logistics. A well-defined support structure can mitigate risks and streamline operations, ensuring that both parties align in their objectives.

By establishing these communication protocols, you enhance collaboration and ensure that your manufacturing project runs smoothly, ultimately leading to better outcomes and a stronger partnership.

Conclusion

Selecting a reliable nutraceutical contract manufacturer is a crucial decision that can profoundly influence product success. By clearly defining manufacturing needs, conducting thorough research, assessing capabilities, and establishing effective communication, businesses can create partnerships that enhance quality and efficiency. This structured approach not only aligns manufacturing processes with market demands but also ensures compliance with industry standards.

The article delineates essential steps, including:

- Defining product types and volume requirements

- Researching potential manufacturers through industry associations and trade shows

- Evaluating their certifications and production capabilities

Furthermore, establishing clear communication expectations fosters a collaborative environment that significantly improves project outcomes. These insights collectively underscore the necessity of a strategic selection process within the nutraceutical manufacturing landscape.

Ultimately, the choice of a contract manufacturer should be regarded as a long-term partnership that demands careful consideration and due diligence. By prioritizing these steps, businesses can safeguard product quality and position themselves for success in a competitive marketplace. Embracing this proactive approach to selecting a nutraceutical manufacturer will result in superior product outcomes and enhanced consumer trust.

Frequently Asked Questions

What should I consider when defining my nutraceutical manufacturing needs?

You should consider the product type (capsules, powders, gummies, or liquids), volume requirements, target market demographics, and regulatory compliance with industry standards.

Why is it important to identify the product type?

Identifying the product type is essential because each format requires unique manufacturing processes, which can significantly influence the quality and consumer appeal of the final product.

How do volume requirements affect the selection of a contract manufacturer?

Volume requirements determine the quantity of products you plan to manufacture, which affects your choice of producer based on their production capacity and ability to scale operations effectively.

What role does understanding the target market play in selecting a manufacturer?

Understanding the demographics and preferences of your target audience helps you choose a manufacturer that can accommodate specific market trends, such as the demand for clean label items and plant-based formulations.

Why is regulatory compliance important in nutraceutical manufacturing?

Regulatory compliance, such as adhering to Good Manufacturing Practices (GMP), is crucial to ensure safety and quality, especially as consumer awareness around ingredient transparency continues to rise.

How can clearly defining my manufacturing needs benefit my product?

Clearly defining your needs will streamline the search for a reliable nutraceutical contract manufacturer, ultimately enhancing your product's market presence and operational efficiency.