Overview

To effectively choose nutritional supplement contract manufacturers, brands must adopt a systematic approach. This includes:

- Researching potential producers

- Evaluating key criteria such as certifications and experience

- Visiting facilities for firsthand assessments

A thorough evaluation of these factors is crucial, as it ensures compliance with regulatory standards and enhances product quality. Ultimately, this diligence fosters successful partnerships in the dietary supplement market.

Introduction

Navigating the world of nutritional supplements can indeed be daunting, particularly when it comes to selecting the right contract manufacturer. These manufacturers play a pivotal role in shaping the quality and success of dietary products, offering a comprehensive range of services from formulation to packaging. By understanding the essential criteria for choosing a contract manufacturer, brands can not only ensure compliance with regulatory standards but also significantly enhance their market presence.

However, with a multitude of options available, how can a business effectively pinpoint the ideal partner that aligns with its specific needs and goals? The answer lies in a strategic approach to evaluating potential manufacturers.

Understand the Role of Nutritional Supplement Contract Manufacturers

Nutritional supplement contract manufacturers play a crucial role in the dietary supplement market, providing a comprehensive array of services that encompass formulation, production, packaging, and labeling. By outsourcing manufacturing processes, brands can launch their products without the significant investment in extensive facilities. These producers not only develop supplements but also uphold rigorous quality control practices, ensuring compliance with regulatory standards—essential for maintaining consumer trust.

Their expertise extends to additional offerings, such as comprehensive 3PL solutions from Western Packaging, which include:

- Warehousing

- Inventory management

- Logistics

- Customized flexible packaging solutions

This integrated approach empowers businesses to focus on their marketing and sales strategies while enhancing supply chain efficiency. Furthermore, Western Packaging's integrated filling services boost product appeal, enabling companies to scale operations effectively and respond swiftly to market demands. As the global market for nutritional supplement contract manufacturers continues to expand, the significance of these partnerships will only grow. Therefore, it is imperative for brands to choose the right contract producer, such as Western Packaging, to achieve their objectives.

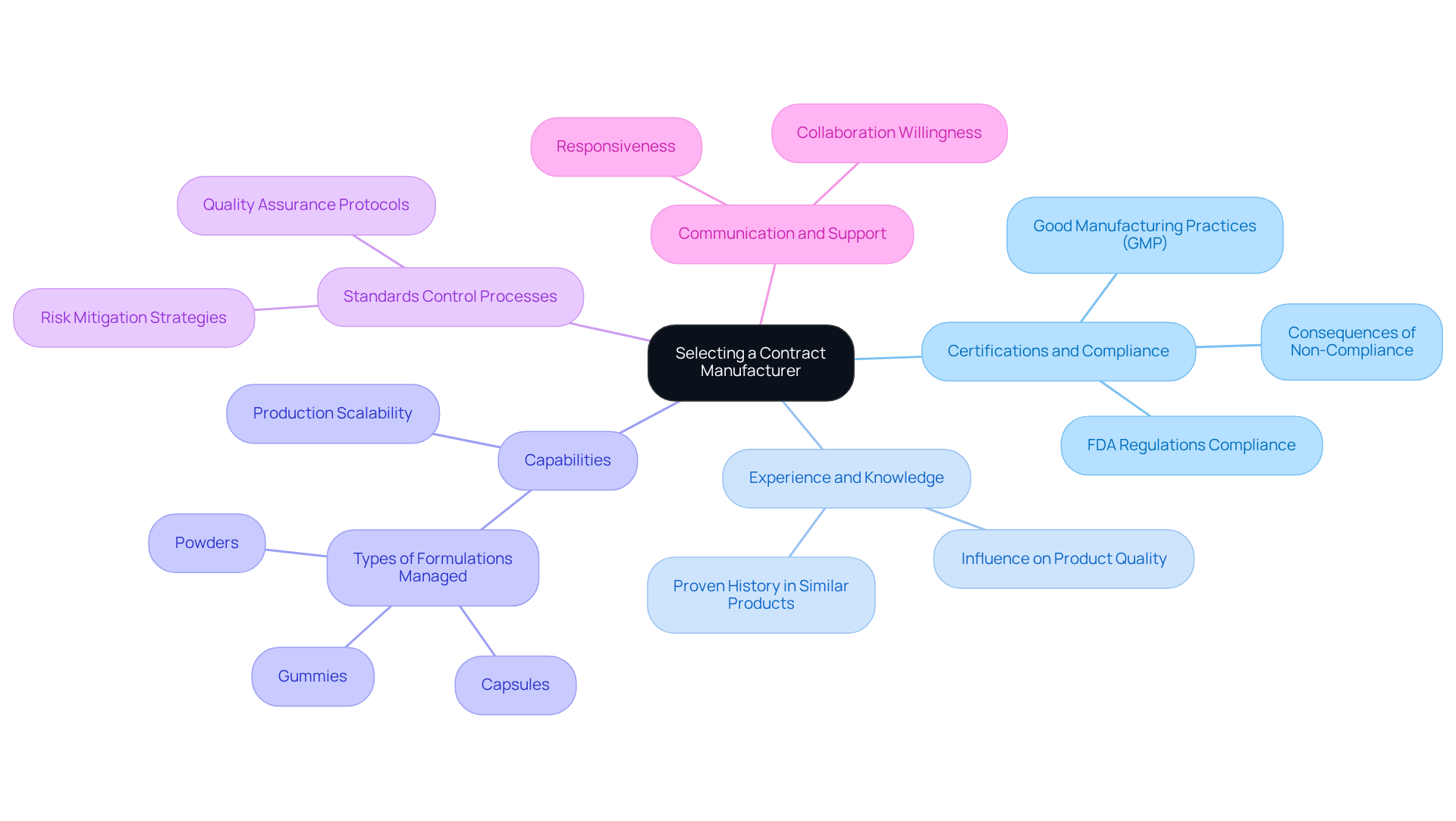

Evaluate Key Criteria for Selecting a Contract Manufacturer

When selecting a contract manufacturer, several key criteria warrant thorough evaluation:

-

Certifications and Compliance: It is essential to ensure that the manufacturer holds relevant certifications, such as Good Manufacturing Practices (GMP), and is compliant with FDA regulations. GMP certification establishes a framework for quality control and regulatory compliance, which is critical for maintaining consumer trust and ensuring safety. Non-compliance can lead to severe repercussions, including recalls and damage to brand reputation.

-

Experience and Knowledge: Nutritional supplement contract manufacturers with a proven history in creating products similar to yours should be prioritized. The expertise of nutritional supplement contract manufacturers significantly influences the quality and reliability of the final product, as evidenced by case studies that underscore the importance of selecting manufacturers with relevant industry experience.

-

Capabilities: Assess the manufacturer’s production capabilities, including the types of formulations they can manage (e.g., powders, capsules, gummies) and their ability to scale production in response to demand fluctuations. This flexibility is crucial for adapting to market changes and ensuring timely delivery.

-

Standards Control Processes: It is vital to examine their assurance protocols to confirm that they maintain high standards throughout the manufacturing process. Robust assurance procedures are essential for mitigating risks and ensuring compliance with regulatory standards. Manufacturers that prioritize quality control are more likely to avoid compliance issues that could disrupt operations.

-

Communication and Support: Evaluate their responsiveness and willingness to collaborate, as effective communication is paramount for a successful partnership. A manufacturer that emphasizes customer service and provides ongoing support can enhance the overall efficiency of the production process, ensuring that any issues are addressed promptly.

By meticulously evaluating these criteria, businesses can refine their choices and identify suppliers that align with their specific requirements, ultimately leading to a more successful collaboration.

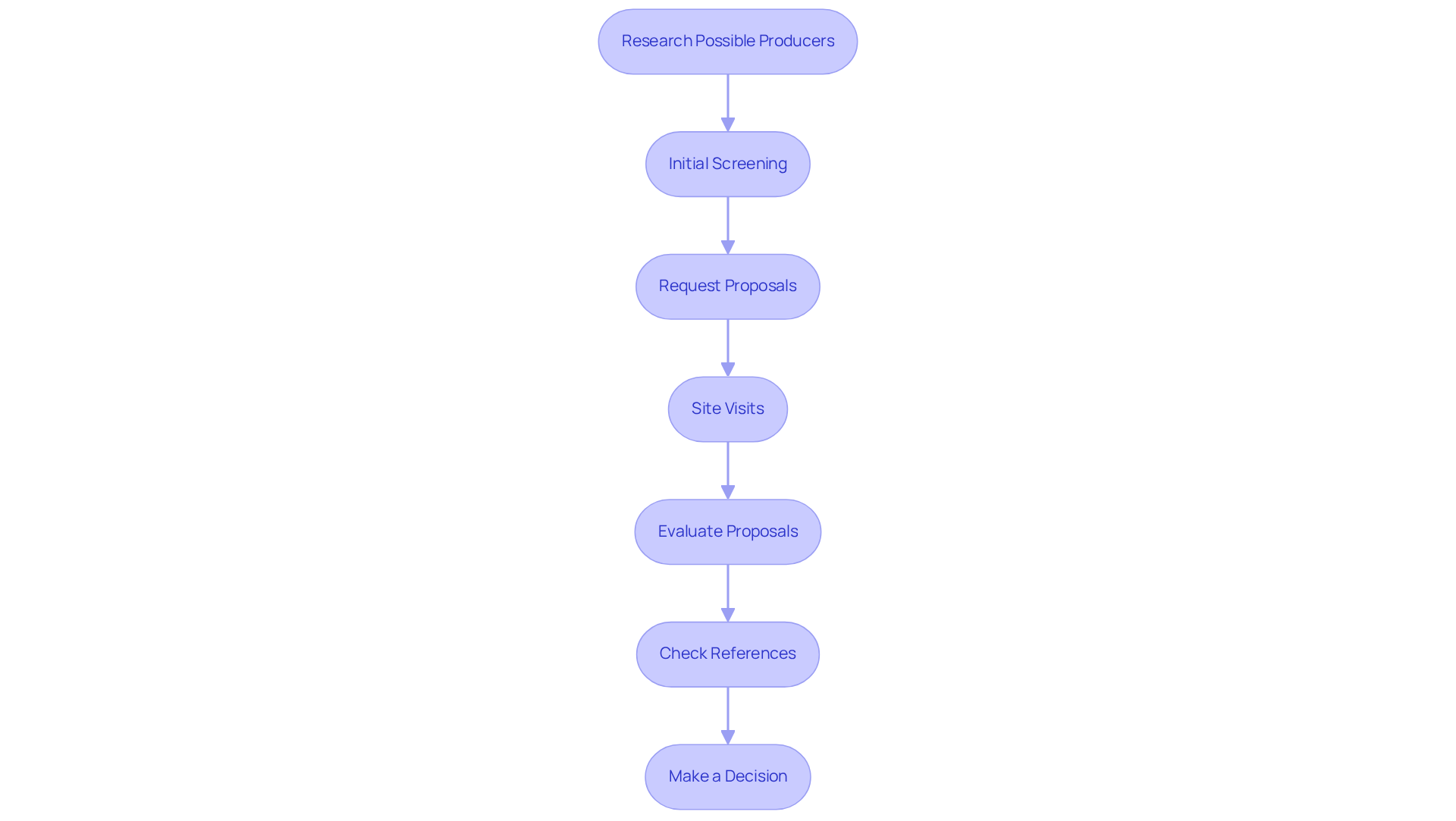

Follow a Step-by-Step Process for Choosing the Right Manufacturer

To select the ideal nutritional supplement contract manufacturers, adhere to the following steps:

- Research Possible Producers: Start by compiling a list of potential manufacturers through industry directories, trade shows, and referrals.

- Initial Screening: Perform preliminary research to evaluate their capabilities, certifications, and reputation, narrowing your list to a select few candidates.

- Request Proposals: Contact the shortlisted manufacturers and solicit detailed proposals that outline their services, pricing, and production timelines.

- Site Visits: If possible, tour the production facilities to evaluate their operations, cleanliness, and compliance with standards. This step is crucial, as it allows you to witness firsthand the environment in which your products will be manufactured. As Eubioco emphasizes, 'We facilitate the creation of items in the White Label model with nutritional supplement contract manufacturers,' showcasing their commitment to quality and flexibility.

- Evaluate Proposals: Analyze the proposals based on pricing, services provided, and alignment with your product specifications.

- Check References: Reach out to previous clients to gather their insights regarding their experiences with the manufacturer.

- Make a Decision: Based on your assessments, select the manufacturer that best fulfills your criteria and aligns with your business objectives.

By following these steps, you can ensure a partnership with a dependable manufacturer capable of meeting your specific needs.

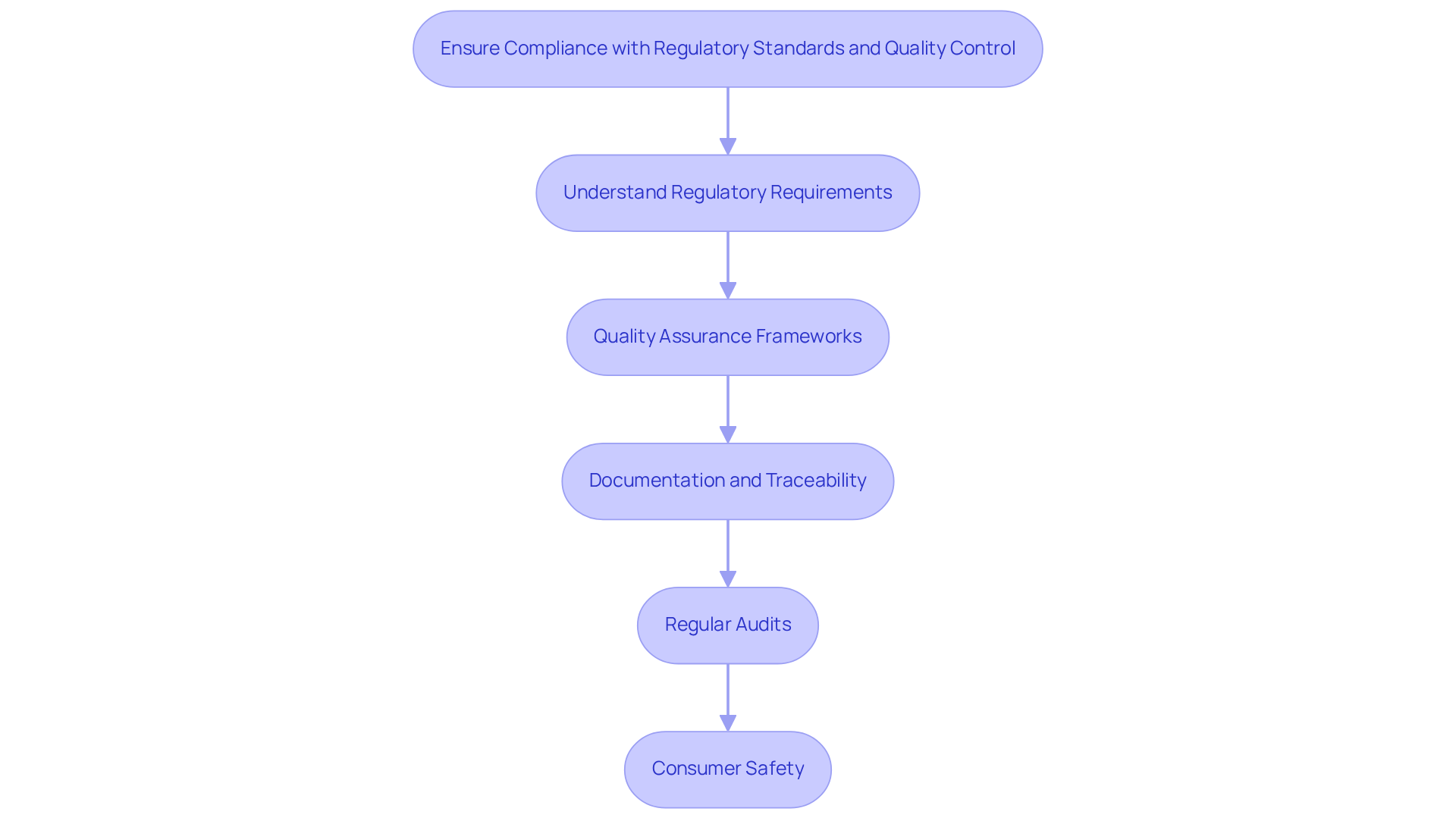

Ensure Compliance with Regulatory Standards and Quality Control

Adherence to regulatory standards and assurance of excellence is crucial in the nutritional supplement sector.

- Understand Regulatory Requirements: Familiarize yourself with the regulations set forth by the FDA and other relevant authorities regarding dietary supplements. This knowledge is essential for ensuring that items meet safety and efficacy standards.

- Quality Assurance Frameworks: Ensure that the producer has strong quality assurance frameworks established, including thorough testing of raw materials and completed items. Effective quality control is vital for maintaining product integrity and consumer trust.

- According to industry insights, the dietary supplement compliance services market in North America is projected to reach USD 1.5 billion by 2032, growing at a CAGR of 7.5%, highlighting the increasing importance of compliance in this sector.

- Documentation and Traceability: Verify that the producer maintains thorough documentation of their processes, which is essential for traceability and accountability. This allows for quick identification and resolution of any issues that may arise.

- Regular Audits: Check if the producer undergoes regular audits by third-party organizations to ensure compliance with industry standards. These audits are critical for verifying adherence to quality control measures.

- Consumer Safety: Prioritize manufacturers that emphasize consumer safety through rigorous testing and adherence to best practices. A commitment to safety not only protects consumers but also enhances the credibility of the products in the marketplace.

By concentrating on adherence and standards, nutritional supplement contract manufacturers can reduce risks and enhance the reputation of their nutritional supplements, ultimately resulting in increased market success. Incorporating insights from industry leaders, such as those from MarketsandMarkets™, can further enhance the understanding of quality control systems in supplement manufacturing.

Conclusion

Selecting the right nutritional supplement contract manufacturer is pivotal for brands aiming to thrive in a competitive market. Understanding the vital role these manufacturers play allows businesses to leverage their expertise in formulation, production, and quality control. This not only enhances product offerings but also minimizes operational burdens. Partnerships formed with reliable contract manufacturers streamline processes and instill confidence in consumers regarding product safety and efficacy.

Key criteria for evaluating potential manufacturers include:

- Certifications

- Experience

- Production capabilities

- Quality control processes

Each of these factors significantly contributes to ensuring that the selected manufacturer aligns with the specific needs and objectives of the brand. A step-by-step approach to selecting a manufacturer—ranging from thorough research to site visits—provides a structured pathway to making informed decisions that foster successful collaborations.

In conclusion, the importance of choosing a reputable nutritional supplement contract manufacturer cannot be overstated. As the dietary supplement industry continues to evolve, brands must prioritize partnerships that uphold regulatory standards and quality assurance. By doing so, they enhance their market presence and contribute to consumer safety and trust. Evaluating potential partners thoroughly will ultimately lead to a more successful and sustainable business model in the nutritional supplement market.

Frequently Asked Questions

What is the role of nutritional supplement contract manufacturers?

Nutritional supplement contract manufacturers provide services that include formulation, production, packaging, and labeling of dietary supplements, allowing brands to launch products without heavy investments in facilities.

Why do brands choose to outsource manufacturing to contract manufacturers?

Brands outsource manufacturing to avoid significant investments in extensive facilities and to benefit from the expertise and quality control practices of contract manufacturers.

What quality control practices do nutritional supplement contract manufacturers uphold?

They ensure compliance with regulatory standards, which is essential for maintaining consumer trust in the products.

What additional services do some contract manufacturers, like Western Packaging, offer?

They offer comprehensive 3PL solutions including warehousing, inventory management, logistics, and customized flexible packaging solutions.

How do these services benefit businesses?

These services allow businesses to focus on marketing and sales strategies while improving supply chain efficiency and product appeal.

What is the importance of choosing the right contract producer?

Choosing the right contract producer, such as Western Packaging, is crucial for brands to achieve their objectives and respond effectively to market demands.

How is the market for nutritional supplement contract manufacturers evolving?

The global market for nutritional supplement contract manufacturers is expanding, increasing the significance of partnerships between brands and these producers.