Overview

The primary focus of this article is to delineate the essential steps for selecting the right supplement contract manufacturer. It underscores the significance of:

- Defining manufacturing needs

- Assessing manufacturer capabilities

- Ensuring regulatory compliance

- Evaluating communication structures

Each of these elements is critical for identifying a suitable partner that aligns with your business goals and product specifications.

Introduction

Selecting the appropriate supplement contract manufacturer is a crucial decision for businesses operating in the rapidly expanding dietary supplement industry. With market projections indicating substantial growth, it is imperative to grasp the complexities of production—from formulation to regulatory compliance—to achieve success.

Nevertheless, navigating this landscape presents challenges: how can one ensure that a manufacturer not only fulfills specific requirements but also maintains quality and safety standards?

This guide delineates four essential steps to streamline the selection process, assisting brands in aligning with the right partner for their manufacturing journey.

Define Your Supplement Manufacturing Needs

To effectively select the appropriate contract producer, begin by detailing the specific types of products you wish to create, such as powders, capsules, or gummies. Consider the following critical aspects:

-

Product Formulation: Assess whether you possess existing formulations or require assistance in developing new ones. The dietary supplements market is diverse, with typical items including multivitamins, omega-3 fatty acids, and herbal supplements like echinacea. Understanding your formulation requirements is crucial for aligning with a producer's capabilities.

-

Volume Requirements: Estimate the quantity of products you plan to manufacture. This estimation is vital, as it directly influences your choice of producer. For instance, larger manufacturers may be better suited for high-volume production, while smaller firms might excel in specialized areas or unique formulations.

-

Target Market: Identify your target audience and their preferences. The popularity of gummies among younger demographics and those who have difficulty swallowing pills underscores the importance of tailoring your product to consumer needs. Understanding industry trends, such as the increasing demand for plant-based and sugar-free alternatives, can inform your formulation and packaging choices. Notably, around 70% of adults in the U.S. have utilized dietary products, emphasizing the significance of this sector.

-

Budget Constraints: Establish a budget for manufacturing costs, encompassing raw materials, labor, and packaging. With the dietary supplements industry projected to grow at a CAGR of 4.5% from 2025 to 2030, it’s essential to ensure that your budget aligns with expectations and potential returns on investment.

By explicitly outlining these requirements, you simplify your search for a producer that aligns with your business goals and vision for the product. This method not only enhances operational efficiency but also positions your brand for success in a competitive environment. As Steve Jobs wisely stated, "If you define the problem correctly, you almost have the solution." This principle directly applies to outlining your manufacturing needs.

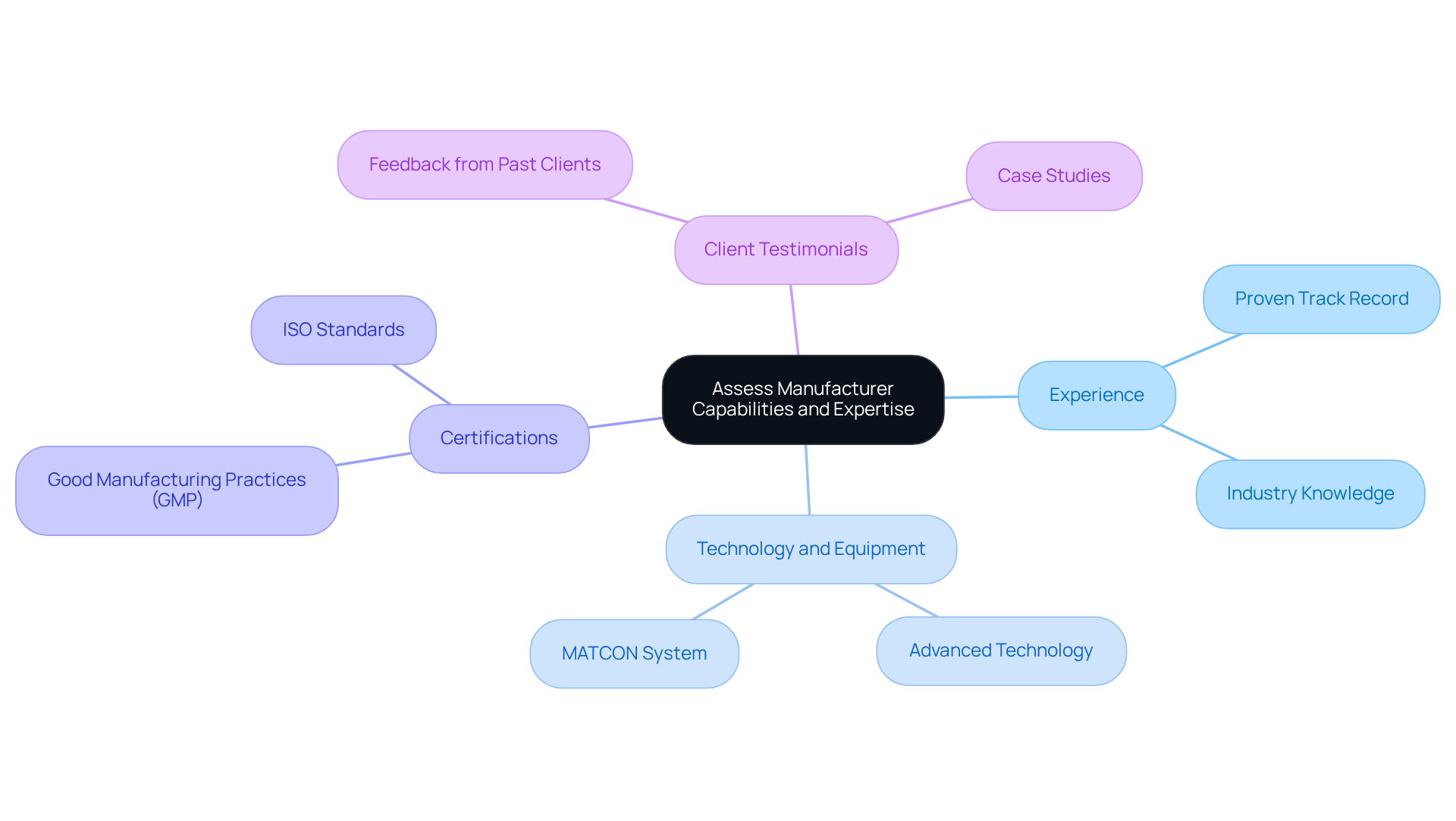

Assess Manufacturer Capabilities and Expertise

To effectively assess potential supplement manufacturers, consider the following key factors:

-

Experience: Prioritize manufacturers with a proven track record in producing supplements that align with your product specifications. Studies show that more than 70% of adults in the U.S. have utilized dietary aids, emphasizing the significance of choosing a producer well-versed in industry needs and regulatory criteria.

-

Technology and Equipment: Assess whether the producer has the most advanced technology and equipment essential for your particular types and production volumes. The integration of advanced manufacturing technologies, such as the MATCON system, is crucial for maintaining quality and efficiency in production. As Rain Nutrience indicates, "Our dedication to innovation guarantees that your product offerings are produced using the latest techniques, leading to superior quality and market competitiveness."

-

Certifications: Verify that the producer holds relevant certifications, such as Good Manufacturing Practices (GMP) and ISO standards. These certifications reflect a commitment to quality and safety, which are paramount in the supplement contract manufacturer industry, where quality concerns have led to increased scrutiny and regulatory oversight.

-

Client Testimonials: Collect feedback from past clients to evaluate their satisfaction with the provider's services and product quality. Case studies indicate that producers with strong problem-solving abilities and a dedication to innovation, such as Rain Nutrience, have effectively managed production challenges, improving their reputation as dependable collaborators. For instance, Rain Nutrience emphasizes, "We have encountered and overcome various production hurdles, making us adept at finding innovative solutions to unexpected issues that may arise during the manufacturing process."

By thoroughly assessing these factors, you can recognize producers that are well-equipped to meet your specific needs, ensuring a successful collaboration in the competitive health product market.

Evaluate Regulatory Compliance and Quality Assurance Standards

To ensure the safety and efficacy of dietary supplements, verifying that your contract manufacturer adheres to all relevant regulations is crucial.

- FDA Regulations: Confirm compliance with the Food and Drug Administration (FDA) guidelines, which govern the manufacturing, labeling, and safety of dietary supplements. As of 2025, the FDA continues to emphasize the need for rigorous adherence to these standards to protect consumer health. Notably, in 2008, the FDA received only 596 serious adverse event (AE) reports despite an estimated 50,000 AEs occurring annually, underscoring the importance of compliance.

- Quality Assurance Protocols: Inquire about their quality assurance processes, which should include thorough testing of raw materials and completed items. Quality is not merely a goal but a continuous journey, as highlighted by industry experts who stress that effective quality management is essential for maintaining competitive advantage. The American Medical Association indicates that dietary additives are linked to an estimated 23,000 emergency department visits annually, highlighting the importance of rigorous quality assurance measures.

- Traceability: Ensure that the manufacturer has robust systems in place for tracking components and items throughout the manufacturing process. This traceability is vital for identifying potential issues and ensuring accountability in the supply chain, especially since many dietary supplements are marketed without adequate safety evaluations.

- Recall Procedures: Understand their protocols for recalls in case of quality issues. Efficient recall processes are essential, as they can reduce risks related to contaminated or mislabeled items, which have been connected to thousands of emergency room visits each year. Furthermore, 64% of voluntarily reported mild or moderate AEs met criteria for serious events, highlighting the urgency of having robust recall protocols in place.

By thoroughly evaluating these compliance and quality assurance standards, you can ensure that your products are not only safe but also meet the legal requirements necessary for market success.

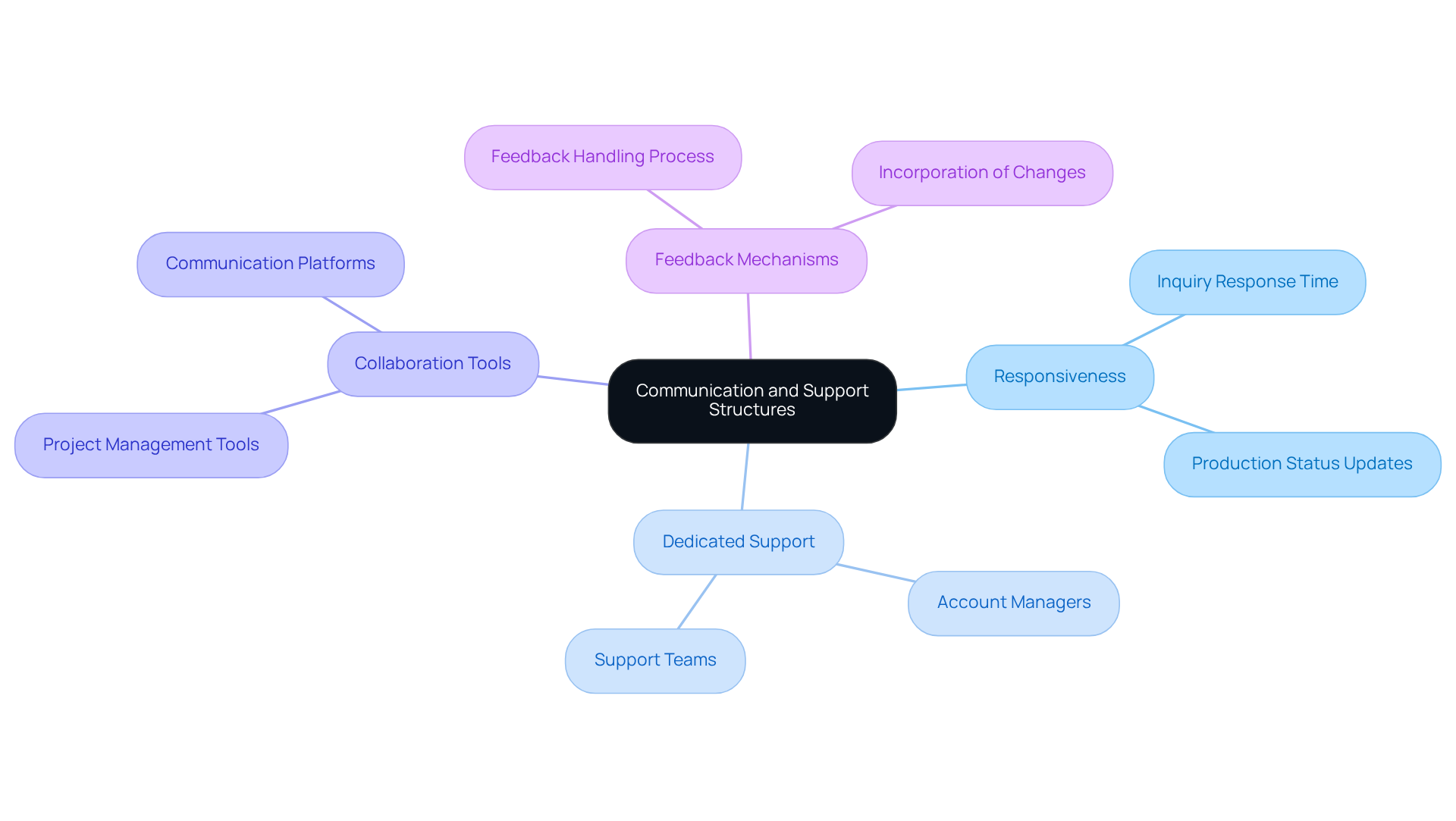

Consider Communication and Support Structures

Assess the manufacturer's communication practices by considering the following key areas:

- Responsiveness: Evaluate how quickly they respond to inquiries and provide updates on production status.

- Dedicated Support: Determine if they offer dedicated account managers or support teams to assist you throughout the manufacturing process.

- Collaboration Tools: Inquire about the tools they use for project management and communication, ensuring they align with your preferences.

- Feedback Mechanisms: Understand how they handle feedback and incorporate changes during the manufacturing process.

By prioritizing these communication and support structures, you can foster a collaborative relationship that significantly enhances the overall manufacturing experience.

Conclusion

Selecting the appropriate supplement contract manufacturer is a pivotal step in guaranteeing the success of a dietary supplement brand. By meticulously defining manufacturing needs, assessing manufacturer capabilities, evaluating regulatory compliance, and considering communication structures, businesses can make informed decisions that resonate with their goals and market demands.

This article delineates essential steps, including the significance of comprehending product formulation, volume requirements, and target markets. It underscores the necessity for manufacturers to possess the requisite experience, advanced technology, and pertinent certifications to ensure product quality and safety. Moreover, the importance of effective communication and support structures between manufacturers and brands is paramount, as these elements are crucial in cultivating successful partnerships.

Ultimately, a well-informed selection process not only enhances operational efficiency but also positions a brand for sustained success in a competitive landscape. By dedicating time to thoroughly evaluate potential manufacturers, businesses can guarantee that their products adhere to the highest standards of quality and compliance, fostering greater consumer trust and satisfaction. This strategic approach is indispensable for navigating the complexities of the dietary supplement industry and seizing its growth potential.

Frequently Asked Questions

What should I consider when defining my supplement manufacturing needs?

You should consider product formulation, volume requirements, target market, and budget constraints.

How important is product formulation in selecting a contract producer?

Product formulation is crucial as it determines whether you need existing formulations or assistance in developing new ones, aligning with the producer's capabilities.

Why are volume requirements significant when choosing a manufacturer?

Volume requirements are significant because they influence your choice of producer; larger manufacturers may be more suitable for high-volume production, while smaller firms may excel in specialized or unique formulations.

How does my target market affect my supplement manufacturing decisions?

Identifying your target audience and their preferences is important, as it helps tailor your product to meet consumer needs and aligns with industry trends, such as the demand for plant-based and sugar-free alternatives.

What role do budget constraints play in the manufacturing process?

Establishing a budget for manufacturing costs, including raw materials, labor, and packaging, is essential to ensure that your expenditures align with expectations and potential returns on investment.

How can clearly outlining my manufacturing needs benefit my business?

Clearly outlining your manufacturing needs simplifies the search for a suitable producer, enhances operational efficiency, and positions your brand for success in a competitive market.