Overview

The article delineates four essential steps to optimize a packaging room for nutraceuticals:

- Identifying necessary equipment

- Designing an efficient layout

- Establishing standard operating procedures (SOPs)

- Implementing quality control protocols

Each step encompasses specific strategies and practices aimed at enhancing operational efficiency, maintaining product integrity, and ensuring compliance with industry standards. This comprehensive approach facilitates a more effective packaging process, ultimately reinforcing the importance of reliability in achieving operational excellence.

Introduction

Optimizing a packaging room for nutraceuticals transcends mere organization; it stands as a strategic endeavor poised to significantly enhance operational efficiency and product quality. By concentrating on essential equipment, effective layout design, and robust standard operating procedures, businesses can streamline their packaging processes while ensuring compliance with industry standards. Yet, amidst the myriad choices and potential pitfalls, how can companies adeptly navigate this complex landscape to achieve optimal results? This article explores four critical steps that can transform any packaging room into a paragon of efficiency and reliability, ultimately safeguarding product integrity and elevating customer satisfaction.

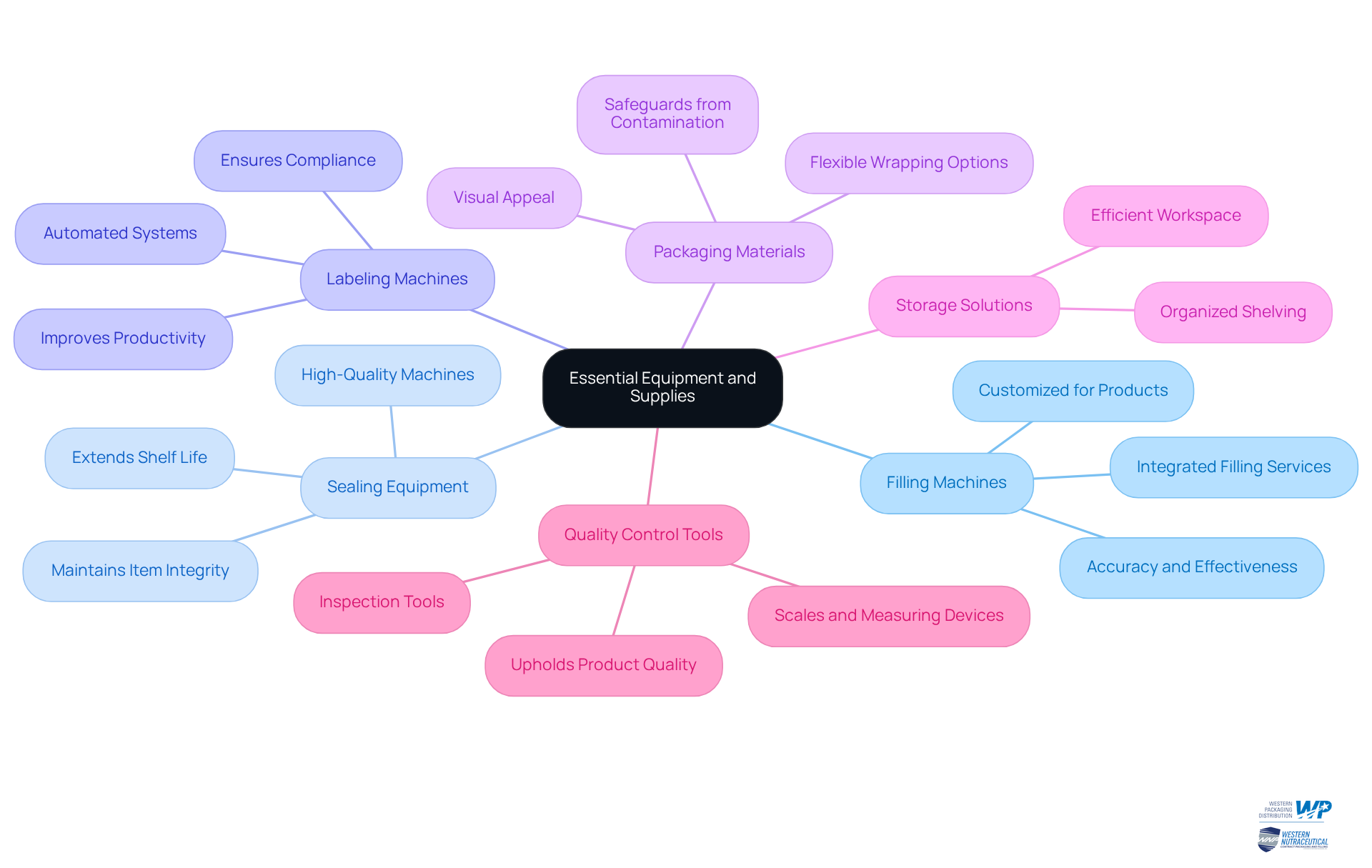

Identify Essential Equipment and Supplies

To optimize the packaging room, begin by identifying the essential equipment needed for your operations. Key components include:

- Filling Machines: Choose filling machines customized for your specific products—powders, gummies, or soft gels—to guarantee accuracy and effectiveness. Western Packaging offers integrated filling services that enhance production capabilities and streamline your process.

- Sealing Equipment: Invest in high-quality sealing machines that maintain item integrity and extend shelf life, which is crucial for preserving the efficacy of nutraceuticals.

- Labeling Machines: Automated labeling machines improve productivity and ensure compliance with regulatory standards, vital in the nutraceutical sector.

- Packaging Materials: Select materials that safeguard your items from moisture, light, and contamination. Flexible wrapping alternatives are increasingly popular, offering both functionality and visual appeal.

- Storage Solutions: Organize your supplies with shelving and bins to maintain a tidy and efficient workspace, facilitating smoother operations.

- Quality Control Tools: Incorporate scales, measuring devices, and inspection tools to uphold product quality at every stage of the wrapping process.

By carefully selecting the appropriate equipment and utilizing integrated filling and 3PL solutions from Western Packaging, you establish a robust foundation for a smooth and efficient operation in the packaging room.

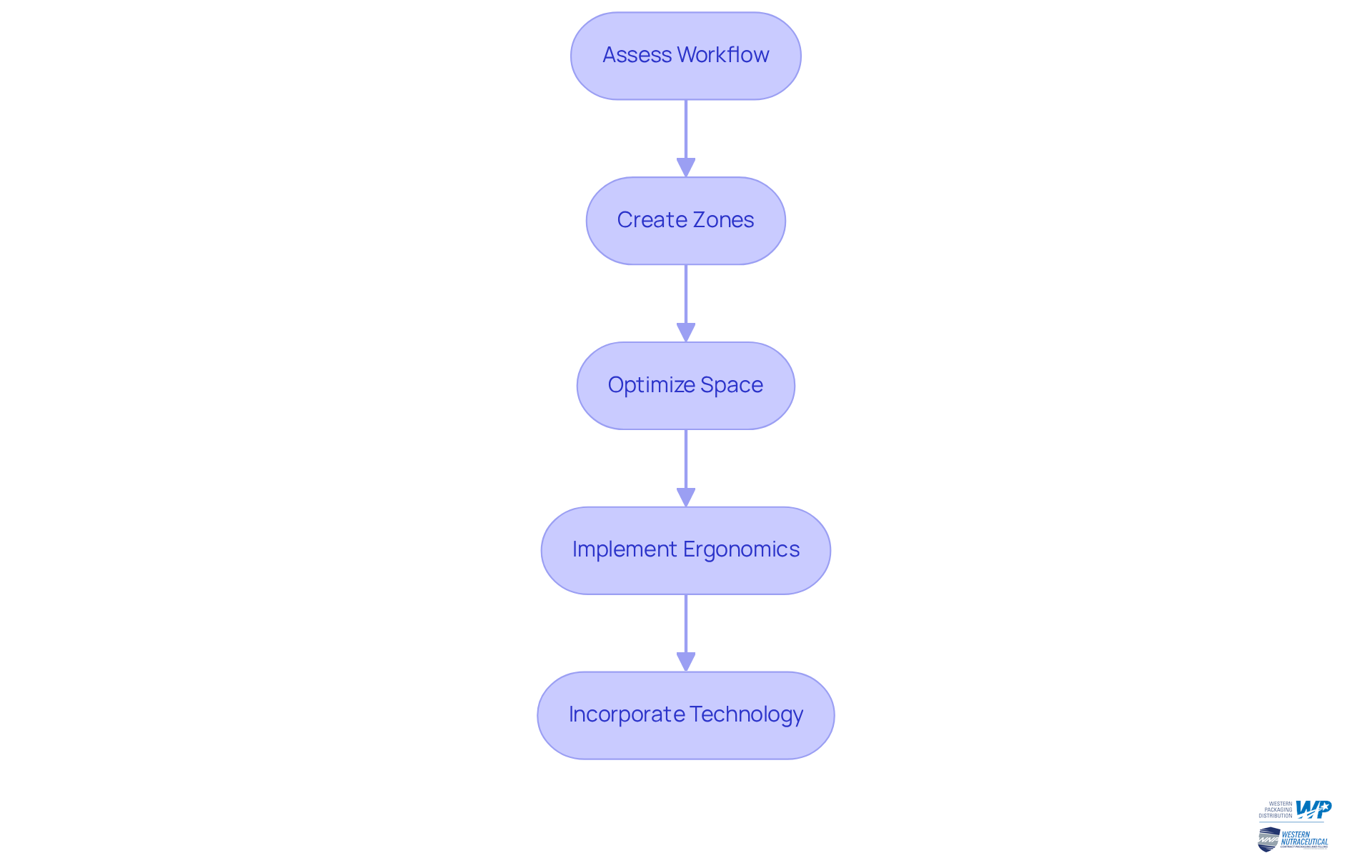

Design an Efficient Room Layout

To design an efficient packaging room layout, follow these crucial steps:

-

Assess Workflow: Begin by mapping out the entire process, from receiving raw materials to shipping completed products. Identify critical areas such as filling, sealing, labeling, and storage. This assessment is vital; studies indicate that workflow automation can improve efficiency by 40-60%, significantly enhancing operational performance.

-

Create Zones: Designate specific areas for each stage of the packing process. For instance, establish separate areas for filling, sealing, and quality control to minimize cross-contamination and streamline operations. This zoning approach not only enhances workflow but also reduces the risk of errors, with 44% of businesses citing repetitive errors as a top inefficiency that automation could solve.

-

Optimize Space: Utilize vertical space for storage and ensure that frequently used items are easily accessible. This strategy reduces unnecessary movement, potentially leading to time savings of up to 77% on routine activities. Efficient space management in the packaging room is essential for maintaining a smooth workflow in packaging operations.

-

Implement Ergonomics: Arrange workstations to minimize strain on workers. Ensure that equipment is at a comfortable height and that tools are within easy reach. Ergonomic design not only enhances employee satisfaction but also contributes to productivity, as workers can focus on their tasks without physical discomfort.

-

Incorporate Technology: Consider integrating automated systems for filling and labeling to enhance efficiency and accuracy. Automation can reduce order processing costs by 10-15% and significantly decrease manual errors, with organizations reporting a 32% reduction in human errors due to automation.

By thoughtfully organizing your room arrangement and integrating these optimal strategies, you can establish an environment that enhances both productivity and standards, ultimately resulting in a more efficient operation.

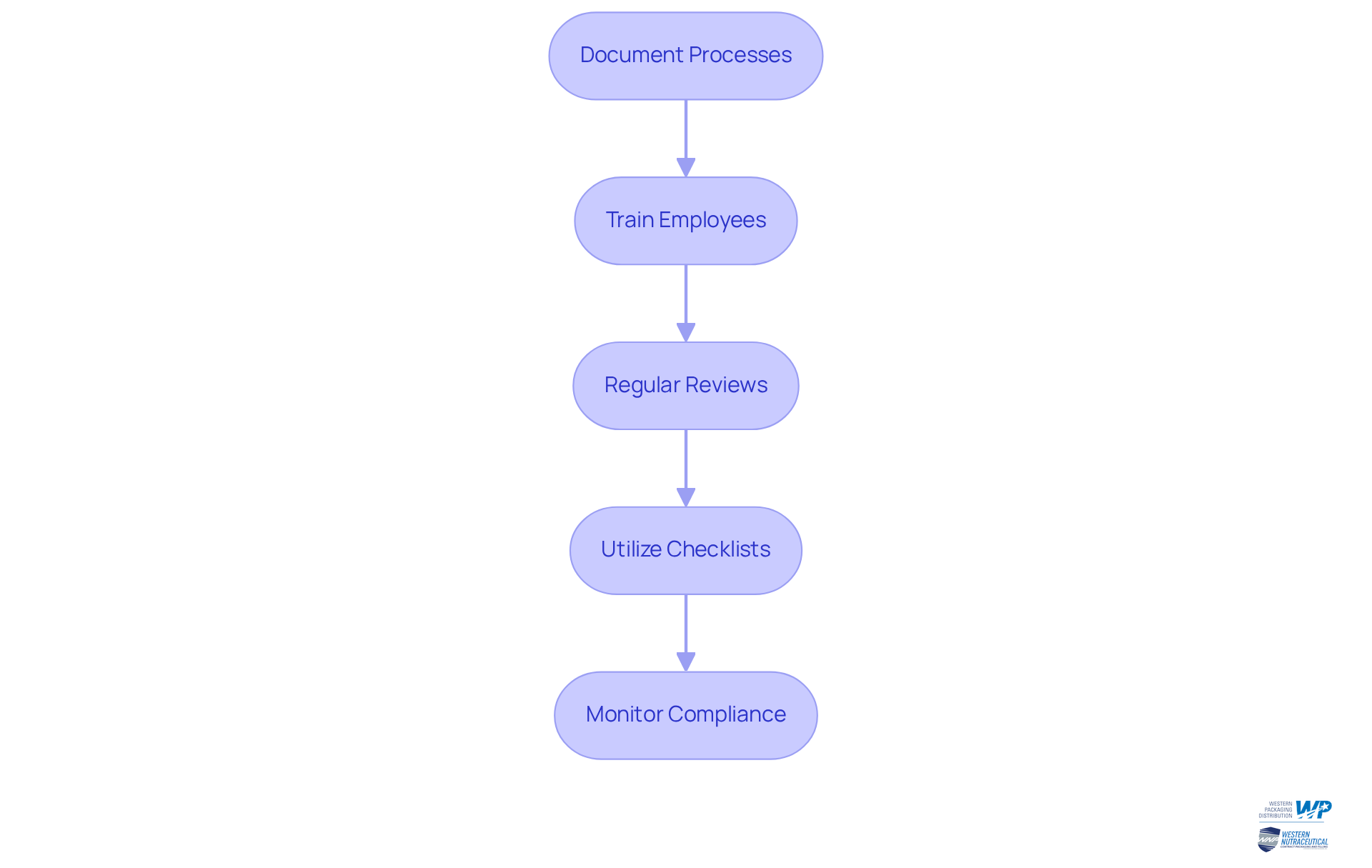

Establish Standard Operating Procedures

To establish effective Standard Operating Procedures (SOPs) for your packaging room, consider the following steps:

-

Document Processes: Create detailed instructions for each packaging task, including filling, sealing, labeling, and inspection. Ensure these documents are easily accessible to all staff, as clarity is essential for compliance and efficiency.

-

Train Employees: Conduct comprehensive training sessions to familiarize staff with the SOPs. Highlight the significance of adhering to these procedures to uphold product quality and safety. Research indicates that 59% of staff members believe training directly enhances their job performance, underscoring the value of effective training programs. Furthermore, companies with extensive staff training programs have 218% greater income per worker than those lacking structured training, demonstrating the financial advantages of investing in personnel development.

-

Regular Reviews: Schedule periodic reviews of the SOPs to ensure they remain relevant and effective. Update them as necessary to reflect changes in equipment or regulations, ensuring that your processes evolve with industry standards.

-

Utilize checklists in the packaging room to guide employees through each step of the packing process. This practice helps guarantee that no essential tasks are neglected, contributing to consistent standard maintenance.

-

Monitor Compliance: Establish a robust system for monitoring adherence to SOPs. Regular audits and feedback sessions can help identify and address any compliance issues, fostering a culture of accountability and continuous improvement.

By implementing these robust SOPs, you can significantly enhance the reliability and standard of your operations, ultimately leading to improved product integrity and customer satisfaction. As Devlin Peck remarked, '92% of employees believe workplace training positively influences their job engagement,' emphasizing the significance of effective training in upholding standards.

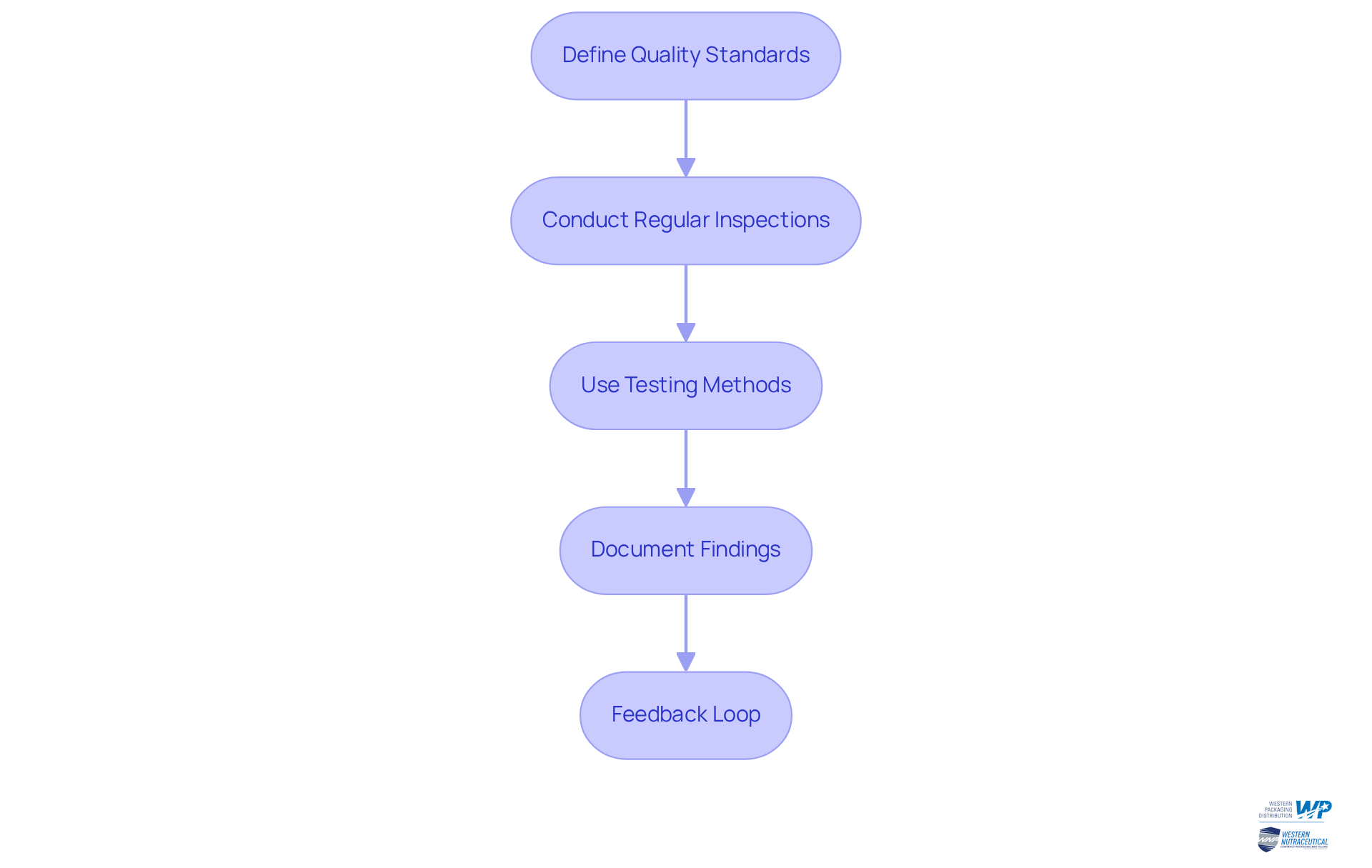

Implement Quality Control Protocols

To implement effective quality control protocols in your packaging room, it is essential to adhere to the following guidelines:

-

Define Quality Standards: Establish clear quality standards for your offerings, encompassing specifications for appearance, weight, and labeling accuracy. This foundational step ensures that all items meet consumer expectations and regulatory requirements.

-

Conduct regular inspections by scheduling routine checks of both the packaging room and the completed items. This includes verifying proper sealing, labeling, and overall presentation. Regular inspections are crucial; they can significantly reduce the risk of errors that may lead to costly recalls or reputational damage. It is recommended to conduct thorough inspections a few times a year to maintain high standards.

-

Use Testing Methods: Implement testing methods to assess item integrity, such as moisture content analysis and stability testing for shelf life. These tests assist in ensuring that products uphold their standards throughout their intended shelf life, which is essential for consumer safety and satisfaction.

-

Document Findings: Maintain detailed records of control inspections and tests. This documentation is essential for compliance with regulatory requirements and for identifying trends over time, enabling proactive adjustments to processes. Ensure that all information gathered during inspections is documented for future reference.

-

Feedback Loop: Establish a feedback loop allowing employees to report concerns and propose enhancements. This promotes a culture of excellence and continuous improvement, nurturing an environment where everyone is committed to upholding high standards. It is essential to have a plan in place for addressing problems identified during assessments to avoid shipping delays or backlogs.

By prioritizing quality control, you can ensure that your nutraceutical products are safe, effective, and appealing to consumers, ultimately enhancing your brand's reputation and market presence.

Conclusion

Optimizing a packaging room for nutraceuticals is a multifaceted process that demands careful consideration of equipment, layout, standard operating procedures, and quality control measures. By concentrating on these critical elements, businesses can significantly enhance their operational efficiency, ensuring that products are packaged accurately and safely while adhering to regulatory standards.

Key steps include:

- Identifying essential equipment tailored to specific products

- Designing an efficient room layout that promotes workflow and minimizes errors

- Establishing comprehensive SOPs for consistency and training

- Implementing rigorous quality control protocols to maintain product integrity

Each of these components is vital in creating a streamlined packaging environment that not only boosts productivity but also safeguards the quality of nutraceuticals.

Ultimately, investing in the optimization of the packaging room transcends mere operational improvement; it lays the groundwork for future growth and success in the nutraceutical market. By embracing these best practices, companies can enhance their reputation, ensure customer satisfaction, and position themselves as leaders in an increasingly competitive industry. Prioritizing these strategies will yield a more efficient, compliant, and high-quality packaging process, benefiting both the organization and its consumers.

Frequently Asked Questions

What essential equipment is needed for optimizing a packaging room?

Essential equipment includes filling machines, sealing equipment, labeling machines, packaging materials, storage solutions, and quality control tools.

Why are filling machines important in the packaging process?

Filling machines are customized for specific products, such as powders, gummies, or soft gels, ensuring accuracy and effectiveness in the packaging process.

What role does sealing equipment play in packaging?

High-quality sealing machines maintain item integrity and extend shelf life, which is crucial for preserving the efficacy of nutraceuticals.

How do labeling machines benefit the packaging process?

Automated labeling machines improve productivity and ensure compliance with regulatory standards, which is vital in the nutraceutical sector.

What should be considered when selecting packaging materials?

Packaging materials should safeguard items from moisture, light, and contamination, with flexible wrapping alternatives being popular for their functionality and visual appeal.

What are effective storage solutions for a packaging room?

Organizing supplies with shelving and bins helps maintain a tidy and efficient workspace, facilitating smoother operations.

Why are quality control tools important in packaging?

Quality control tools, such as scales, measuring devices, and inspection tools, help uphold product quality at every stage of the wrapping process.

How can integrated filling and 3PL solutions from Western Packaging enhance operations?

Utilizing integrated filling and 3PL solutions establishes a robust foundation for a smooth and efficient operation in the packaging room.