Overview

The article delineates four pivotal strategies for the effective packaging of capsules, emphasizing:

- Regulatory compliance

- Material selection

- Integration of filling services

- Best practices for efficiency

Each strategy underscores the critical importance of safety, sustainability, and market responsiveness. It illustrates how companies can bolster consumer trust and enhance operational effectiveness through:

- Rigorous quality control

- Innovative packaging materials

- Streamlined processes

- Data-driven design improvements

By implementing these strategies, organizations can not only meet regulatory standards but also position themselves as leaders in the industry, fostering reliability and consumer confidence.

Introduction

Navigating the intricate landscape of capsule packaging demands a profound understanding of regulatory compliance and innovative design strategies. As dietary supplement brands endeavor to meet stringent safety standards while appealing to eco-conscious consumers, the challenge resides in striking a balance between quality, efficiency, and market presence.

How can companies effectively integrate these elements to not only safeguard their products but also enhance their brand image within a competitive market? This article explores four strategic approaches that promise to elevate capsule packaging, ensuring safety, sustainability, and consumer engagement.

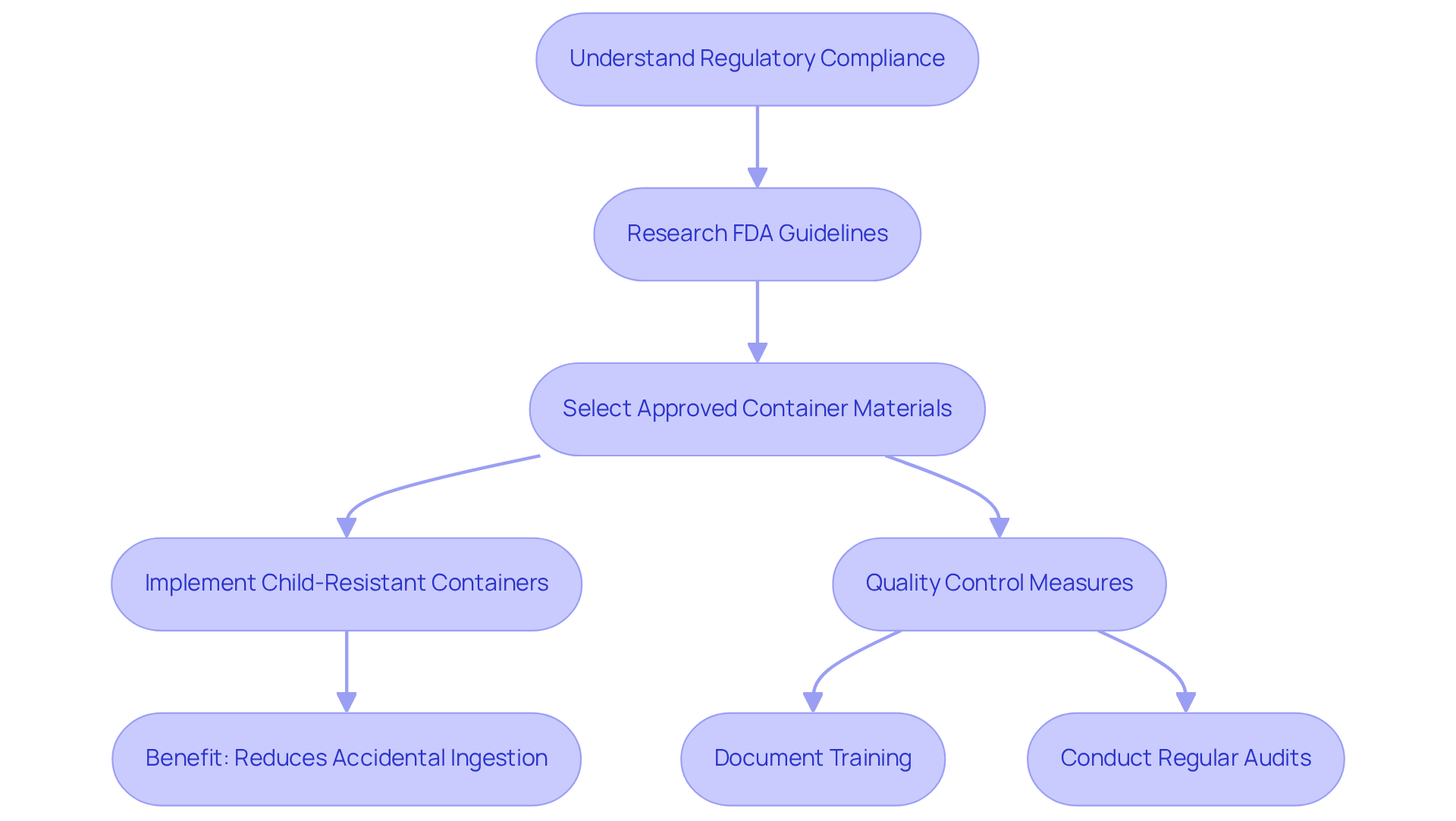

Understand Regulatory Compliance and Quality Standards

To effectively implement packaging for capsules, understanding the regulatory landscape governing dietary supplements is essential. This encompasses compliance with the FDA's guidelines on labeling, ingredient disclosure, and safety standards. Brands must conduct thorough research to ensure that their container materials are approved for use with health products. For instance, utilizing child-resistant containers not only enhances safety but also aligns with regulatory standards. Statistics indicate that child-resistant containers can reduce the risk of accidental ingestion by up to 85%, according to the Consumer Product Safety Commission, underscoring their critical role in consumer safety.

Quality control is paramount throughout the wrapping process. The DS CGMP regulation mandates comprehensive documentation of training, including the date, type, and individual(s) trained, along with the review and approval of quality control staff concerning complaints. Implementing rigorous quality assurance measures, including regular audits and testing of packaging for capsules, guarantees that products remain safe and effective for users. By prioritizing compliance and quality, companies can establish trust and credibility in the market, ultimately resulting in enhanced consumer loyalty.

As Jesse M. Ehrenfeld, MD, MPH, emphasizes, "The need for federal regulation of the dietary supplement industry is crucial to ensure safety and accurate labeling." This commitment to safety and quality not only fulfills regulatory expectations but also positions companies as responsible leaders in the dietary supplement sector.

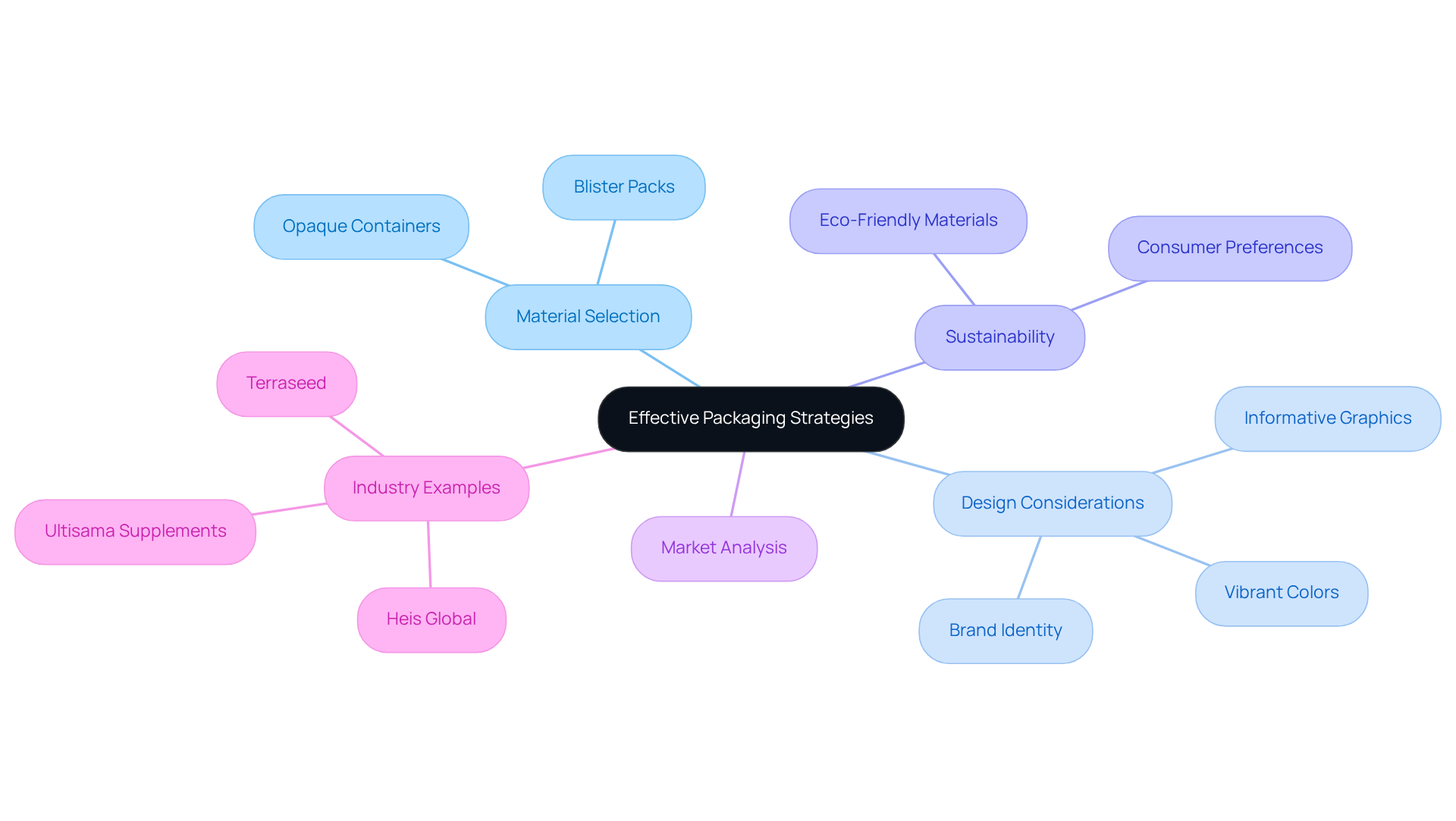

Implement Effective Packaging Materials and Design Strategies

Efficient packaging for capsules begins with selecting materials that protect the product from environmental factors such as moisture, light, and air. For instance, effective packaging for capsules can include utilizing blister packs or opaque containers to preserve their integrity. Furthermore, the design must resonate with the brand's identity while appealing to the target audience. By incorporating vibrant colors, clear labeling, and informative graphics, brands can significantly enhance shelf appeal.

Sustainability should also be a priority in material selection, as eco-friendly resources are increasingly favored by consumers. Current trends indicate that buyers are willing to spend an average of $34 for a $30 multivitamin, reflecting a premium for packaging for capsules that is environmentally conscious. Moreover, 'responsible wrapping' has emerged as the second most important eco-priority among individuals on social media, underscoring the importance of sustainability in container design.

Conducting market analysis to understand consumer preferences can guide the design process, ensuring that the container not only protects the product but also attracts potential customers. Successful industry examples include:

- Terraseed's transition to compostable cellulose tubes

- Heis Global's plant-based compostable bottles

- Ultisama Supplements' recyclable aluminum bottles

These examples demonstrate how innovative solutions can meet both sustainability goals and consumer demands while addressing the challenges of plastic waste in the supplement sector.

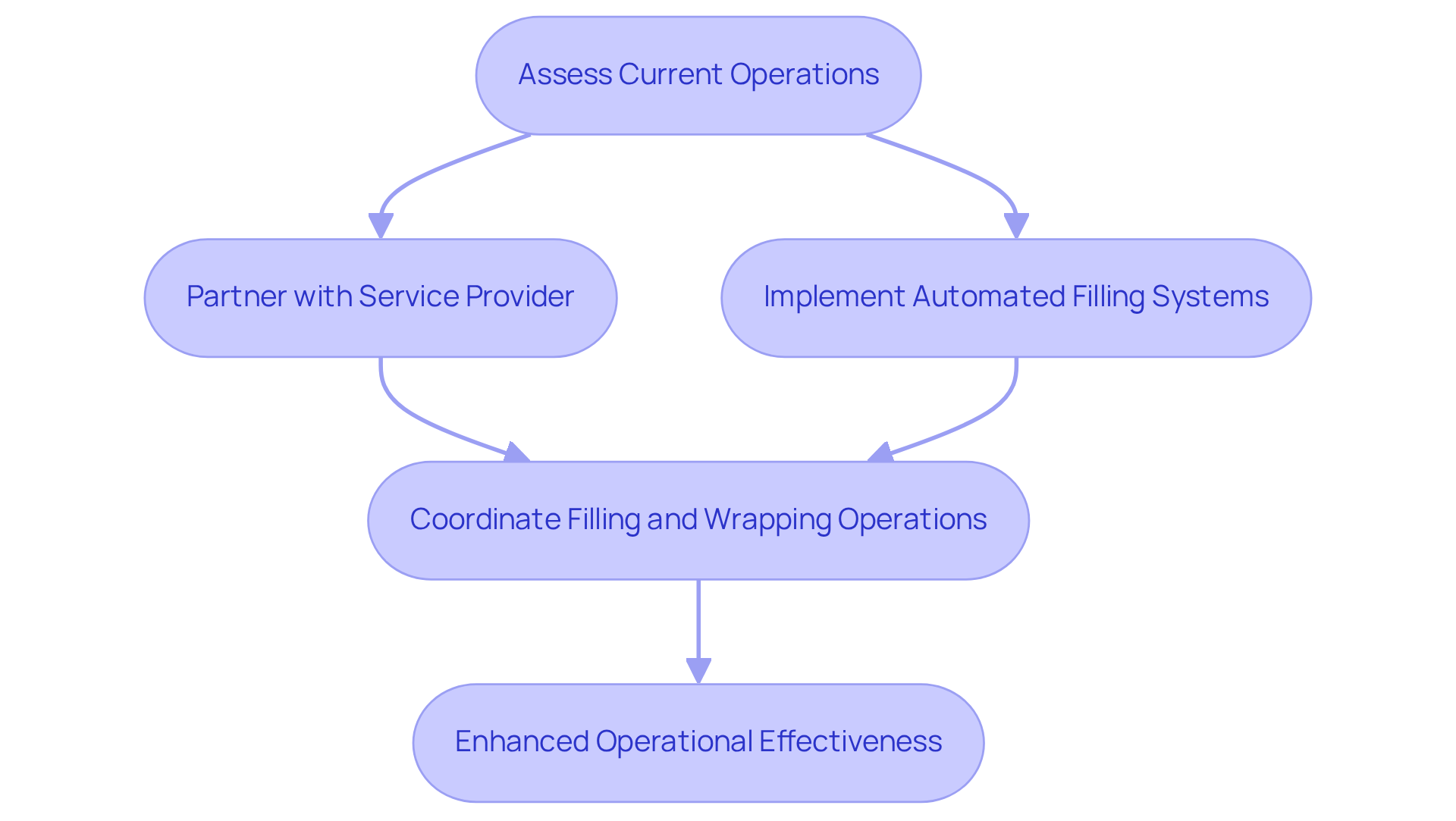

Integrate Filling Services for Streamlined Operations

To achieve a streamlined operation, companies must consider merging their filling services with packaging for capsules processes. This strategic approach can be realized by partnering with a provider that offers packaging for capsules and other related services, facilitating a more cohesive workflow.

For instance, Western Packaging & Distribution's methodology integrates filling and wrapping, significantly reducing handling time and minimizing the risk of errors. Furthermore, implementing automated filling systems can bolster efficiency in the packaging for capsules, ensuring that the capsules are filled accurately and swiftly.

By coordinating filling and wrapping operations, companies can enhance turnaround times, reduce costs, and improve the availability of packaging for capsules in the market. Embrace this opportunity to optimize your processes and elevate your operational effectiveness.

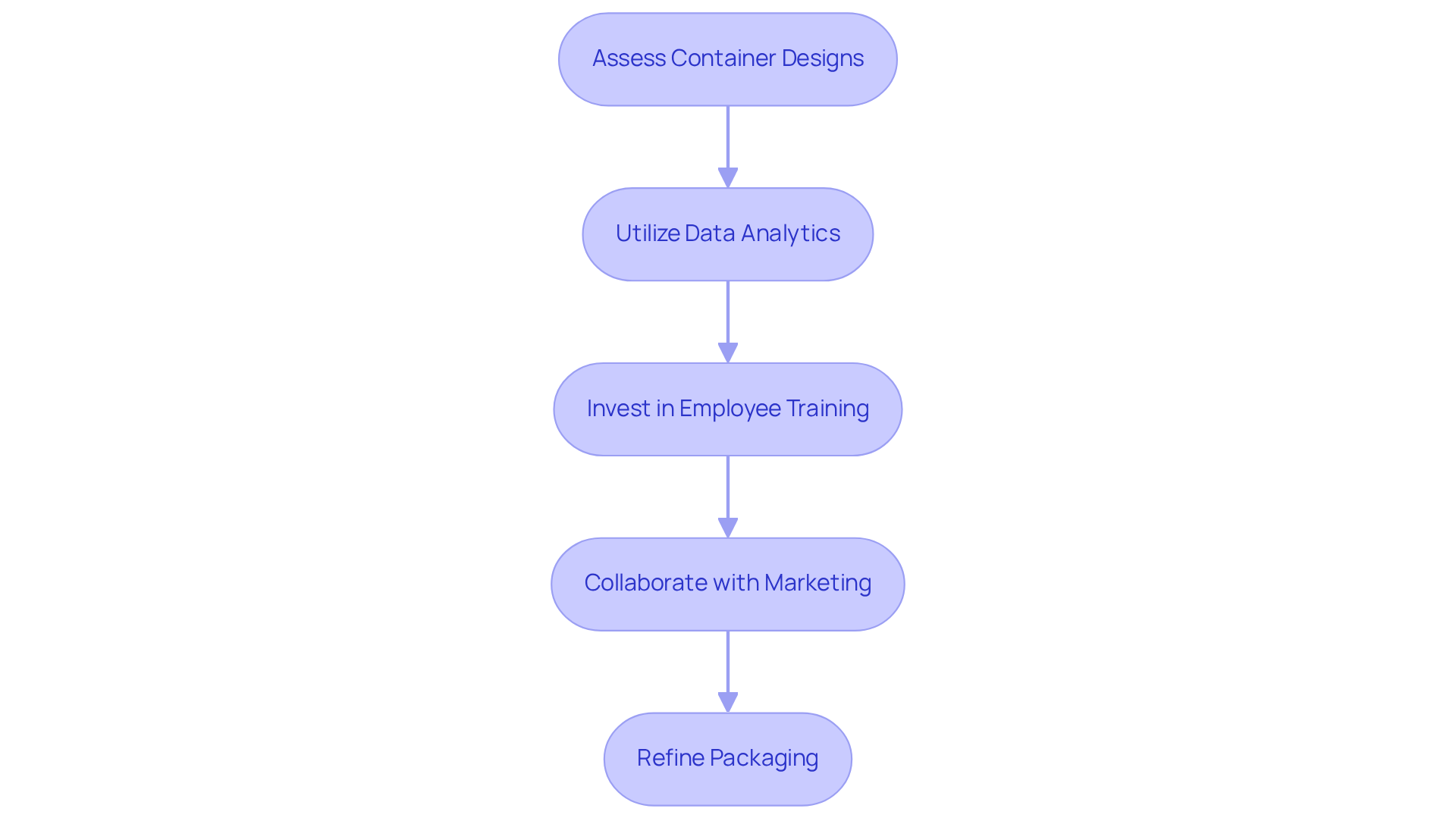

Adopt Best Practices for Enhanced Efficiency and Market Presence

To enhance efficiency and strengthen market presence, brands must implement best practices in their wrapping processes. This begins with a thorough assessment and continuous improvement of container designs, guided by user feedback and prevailing market trends. Utilizing data analytics is crucial in identifying which design concepts yield optimal results in sales and consumer engagement. Nithya Seshachalam, Strategy & Insights Lead at Global Innovation, asserts, "With Revuze, we’ve moved from assumptions to evidence. The data shows us not just what’s trending, but why and what to do about it."

Moreover, investing in employee training focused on wrapping techniques and quality control fosters improved outcomes and minimizes errors. Collaborating with marketing teams to ensure product presentation aligns with promotional strategies significantly enhances the company's visibility. Companies like Coty exemplify this approach, successfully leveraging consumer feedback to refine their presentation strategies, showcasing the power of data-driven decision-making.

By persistently refining their packaging for capsules, brands can not only elevate operational efficiency but also fortify their position within the competitive nutraceutical market.

Conclusion

Effective packaging for capsules is not merely a necessity; it represents a strategic advantage that encompasses:

- Regulatory compliance

- Quality assurance

- Innovative materials

- Streamlined operations

- Best practices

By concentrating on these critical elements, brands can significantly enhance consumer trust, improve product integrity, and elevate their market presence.

This article outlines essential strategies, including:

- A thorough understanding of regulatory requirements and quality standards

- The selection of effective and sustainable packaging materials

- The integration of filling services for operational efficiency

- The adoption of best practices for continuous improvement

These insights underscore the importance of a holistic approach to capsule packaging, ensuring that safety and consumer engagement are prioritized.

Ultimately, investing in effective packaging strategies is crucial for companies aspiring to thrive in the competitive nutraceutical market. By embracing innovation and sustainability in packaging, brands can not only meet regulatory demands but also resonate with environmentally conscious consumers. The time to refine packaging practices is now; it presents an opportunity to enhance product appeal while fostering long-term loyalty and success in the industry.

Frequently Asked Questions

Why is understanding regulatory compliance important for packaging capsules?

Understanding regulatory compliance is essential for packaging capsules as it ensures adherence to the FDA's guidelines on labeling, ingredient disclosure, and safety standards, which helps maintain consumer safety and product integrity.

What role do child-resistant containers play in regulatory compliance?

Child-resistant containers enhance safety and align with regulatory standards, significantly reducing the risk of accidental ingestion by up to 85%, according to the Consumer Product Safety Commission.

What does the DS CGMP regulation require for quality control in packaging?

The DS CGMP regulation mandates comprehensive documentation of training, including details such as the date, type, and individuals trained, as well as the review and approval of quality control staff regarding complaints.

How can companies ensure the safety and effectiveness of their products?

Companies can ensure safety and effectiveness by implementing rigorous quality assurance measures, including regular audits and testing of packaging for capsules.

What is the impact of prioritizing compliance and quality on consumer trust?

Prioritizing compliance and quality helps establish trust and credibility in the market, ultimately resulting in enhanced consumer loyalty.

What does Jesse M. Ehrenfeld emphasize about federal regulation in the dietary supplement industry?

Jesse M. Ehrenfeld emphasizes that federal regulation of the dietary supplement industry is crucial to ensure safety and accurate labeling, positioning companies as responsible leaders in the sector.