Overview

This article delineates four effective strategies for reducing packaging costs in the nutraceutical sector:

- Selecting cost-effective materials

- Implementing automation

- Optimizing packaging sizes

- Designing user-friendly containers

Notably, the use of biodegradable materials not only appeals to environmentally conscious consumers but also contributes to cost reduction. Furthermore, automation and size optimization are proven to significantly enhance operational efficiency and elevate customer satisfaction. These improvements ultimately lead to lower return rates and increased profitability, reinforcing the importance of strategic packaging decisions.

Introduction

The nutraceutical industry is undergoing a profound transformation as companies endeavor to strike a balance between cost efficiency and sustainability. As consumer demand for eco-friendly products continues to rise, brands are presented with a unique opportunity—not only to reduce packaging costs but also to enhance their market appeal. However, the question remains: how can businesses adeptly navigate the complexities of packaging materials, automation, and design to achieve these objectives while preserving product integrity and ensuring customer satisfaction?

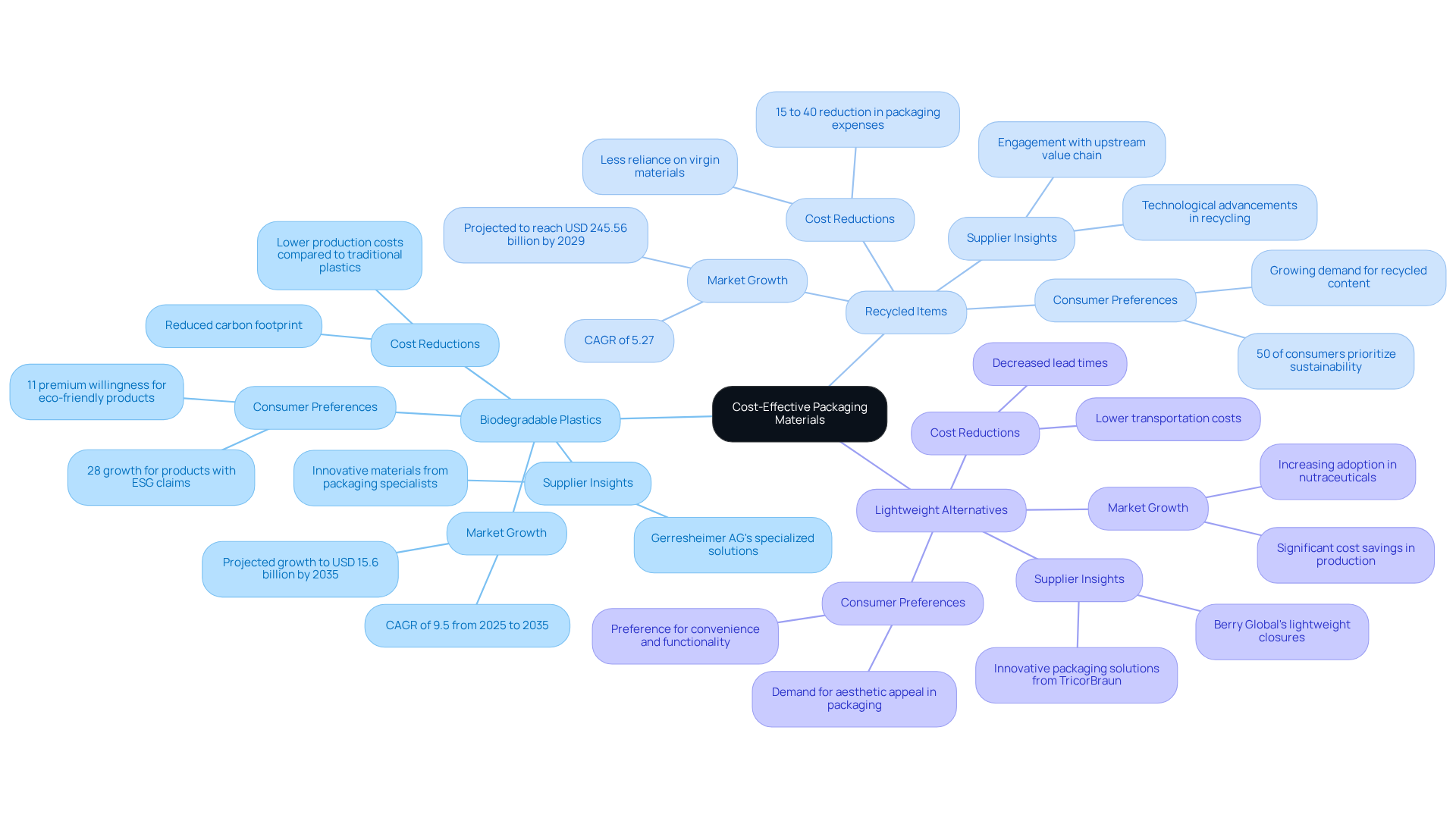

Select Cost-Effective Packaging Materials

Choosing cost-efficient packaging options requires a thorough assessment of choices, including the impact on packaging costs, such as biodegradable plastics, recycled items, and lightweight alternatives. Biodegradable plastics, derived from renewable resources like cornstarch or sugarcane, are gaining traction in the nutraceutical sector due to their environmental benefits and consumer demand for sustainable solutions. The global biobased biodegradable plastic market is projected to grow significantly, reflecting a compound annual growth rate (CAGR) of 9.5% from 2025 to 2035, driven by increasing environmental concerns and regulatory support.

Using flexible pouches instead of rigid containers can result in significant decreases in production costs and overall packaging costs. Furthermore, obtaining supplies locally not only reduces transportation expenses but also decreases lead times, improving overall efficiency. Carrying out a cost-benefit evaluation is essential to guarantee that the chosen resources comply with budgetary limitations and regulatory standards while accounting for packaging costs and preserving item integrity.

Interacting with suppliers who focus on nutraceutical containers can offer valuable insights into innovative materials that provide both sustainability advantages and reduce packaging costs. For example, firms such as Gerresheimer AG are recognized for their specialized packaging solutions that satisfy both buyer and regulatory demands, highlighting the potential of biodegradable options in enhancing item appeal and compliance. Moreover, U.S. buyers are prepared to pay an 11% extra for eco-friendly items, while the actual premium averages 28%, demonstrating the financial advantages of adopting biodegradable plastics. As the market evolves, brands that adopt biodegradable plastics can not only reduce their environmental footprint but also appeal to the growing consumer preference for eco-friendly products, which has shown an average growth of 28% for those with environmental, social, and governance (ESG) claims over five years. Conventional plastic containers, which heavily rely on fossil fuels, contribute significantly to environmental degradation, making the shift to biodegradable options not just beneficial but necessary.

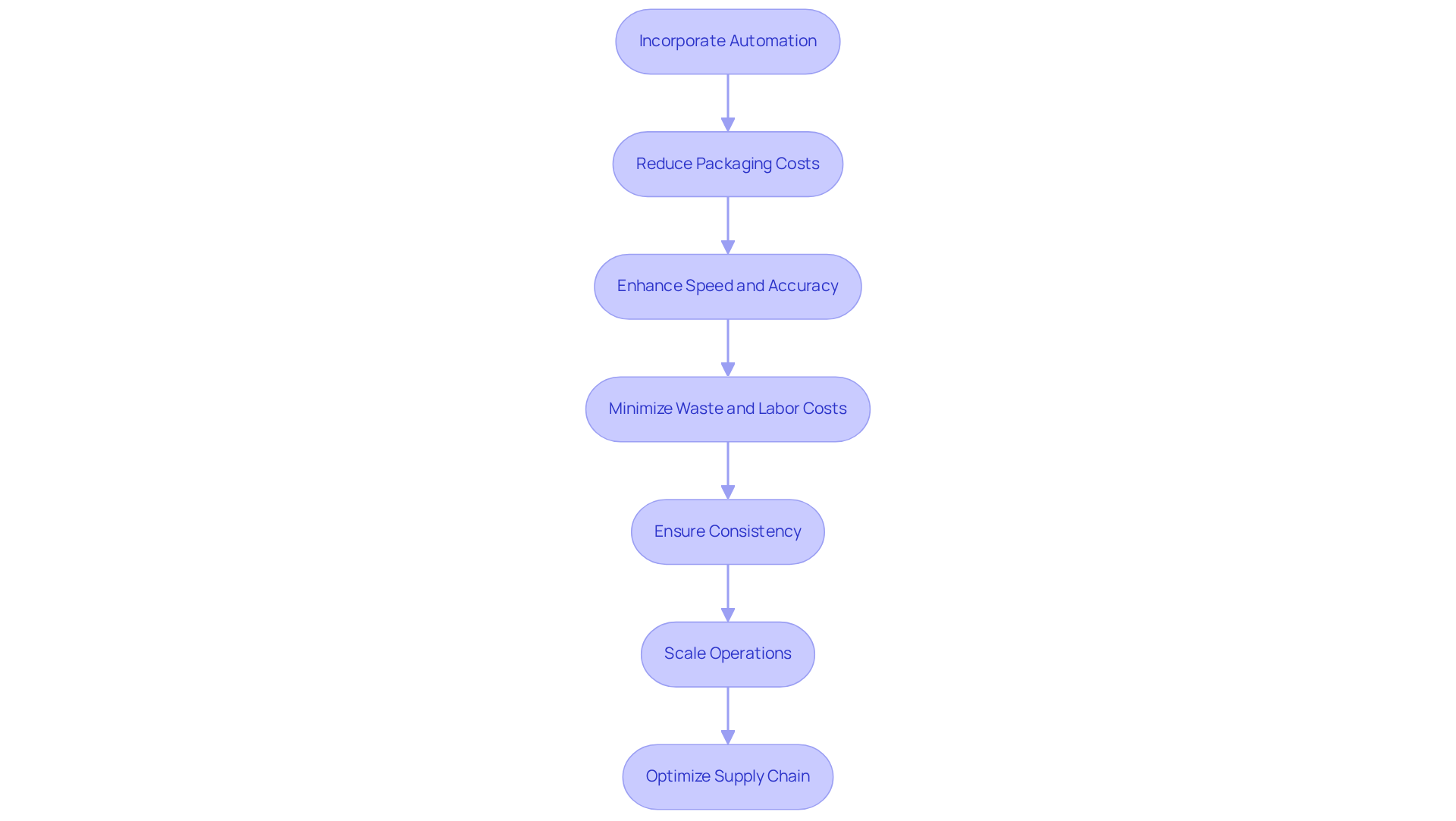

Implement Automation to Enhance Efficiency

Incorporating automation into production lines results in substantial reductions in packaging costs. Automated filling machines enhance speed and accuracy, significantly reducing waste, labor costs, and ultimately packaging costs. Moreover, automated labeling and sealing processes ensure consistency and minimize human error. By investing in modular automation systems, companies can scale operations according to production demands.

Western Packaging's filling procedure seamlessly integrates into these automated systems, delivering extensive services that optimize production and provide tailored solutions for various items, including powders, gummies, and soft-gels. This transition not only streamlines production but also equips businesses to respond effectively to market demands.

Additionally, optimizing your supply chain with Western Packaging's 3PL services—encompassing warehousing, inventory management, and distribution—further boosts operational efficiency.

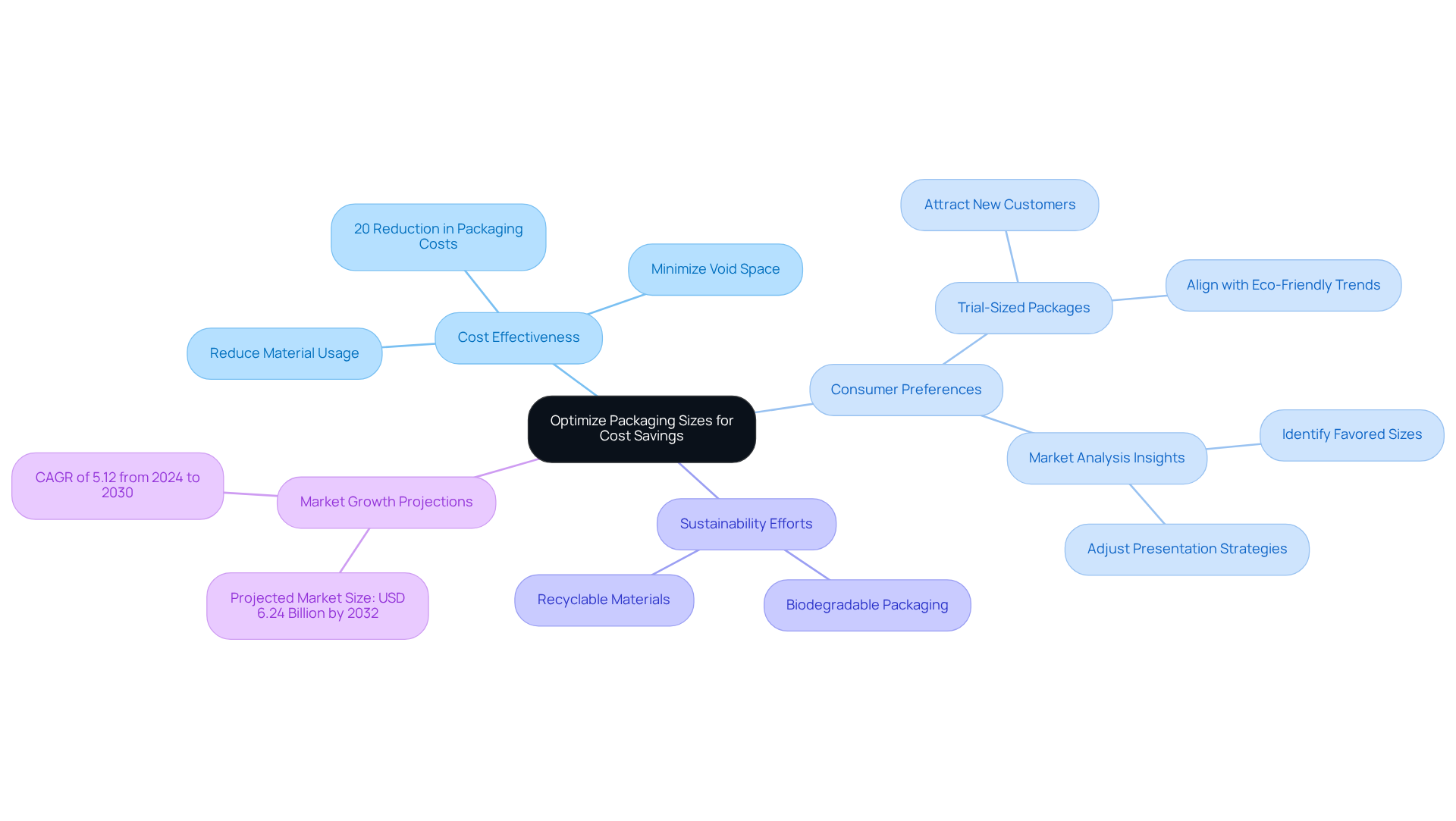

Optimize Packaging Sizes for Cost Savings

Enhancing package dimensions is essential for improving cost effectiveness and reducing packaging costs while satisfying buyer preferences in the nutraceutical industry. By examining product dimensions alongside consumer buying habits, companies can determine the most effective container formats.

For instance, offering smaller, trial-sized packages not only attracts new customers but also reduces material usage, thereby contributing to sustainability efforts. Furthermore, snug-fitting containers minimize void space, which can significantly reduce packaging costs.

Market analysis is crucial to identify favored sizes within target groups, enabling brands to adjust their strategy for presentation effectively. In a competitive environment where the nutraceutical container market is anticipated to hit USD 6.24 billion by 2032, brands must focus on optimizing their containers to remain relevant.

Case studies demonstrate that nutraceutical brands implementing size optimization have realized reductions in packaging costs of up to 20%, while also enhancing customer satisfaction and loyalty. Significant instances include brands that have effectively adopted trial-sized containers, improving customer acquisition and aligning with the increasing consumer demand for eco-friendly and innovative solutions.

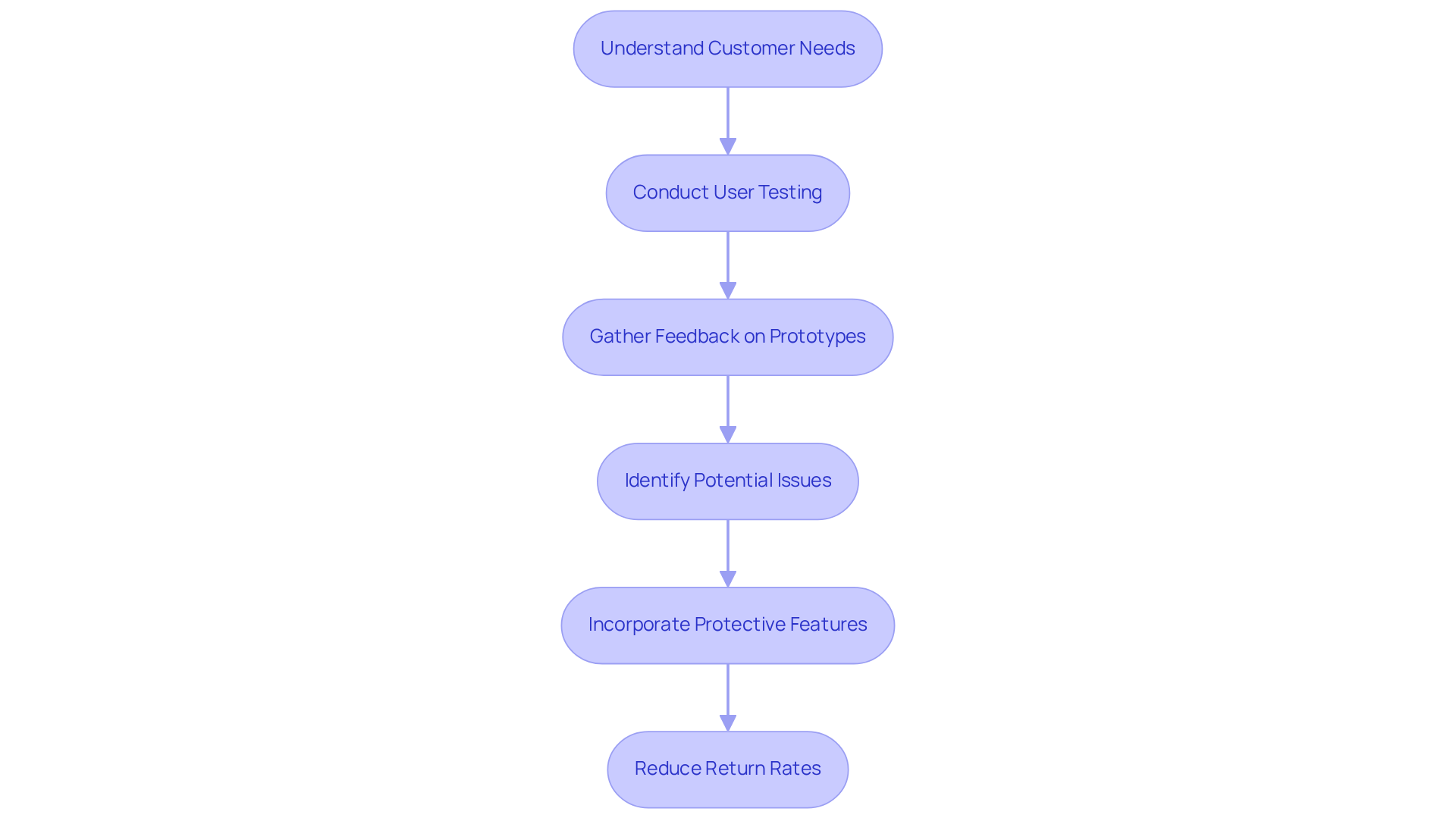

Design and Test Packaging to Minimize Returns

Creating containers that minimize returns necessitates a deep understanding of customer needs and preferences. By conducting user testing and gathering feedback on prototype designs, potential issues can be identified before products reach the market.

For instance, ensuring that containers are easy to open and provide clear usage instructions significantly enhances user experience and reduces the likelihood of returns due to dissatisfaction. Furthermore, incorporating protective features during transit, such as cushioning or tamper-evident seals, can further diminish return rates.

Brands that prioritize thoughtful packaging design often report lower return rates and heightened customer loyalty, which can significantly reduce packaging costs and ultimately lead to increased profitability. Emphasizing the importance of strategic packaging design is not merely a suggestion; it is a necessity for brands aiming to thrive in a competitive market.

Conclusion

Exploring effective strategies for reducing packaging costs in the nutraceutical sector reveals a path toward both financial savings and environmental responsibility. By focusing on cost-effective materials, embracing automation, optimizing packaging sizes, and designing user-friendly containers, companies can significantly enhance their operational efficiency while catering to consumer demands for sustainability and quality.

The article discusses various approaches, such as:

- Selecting biodegradable materials that not only lower costs but also resonate with the growing eco-conscious market.

- Implementing automation in production processes to streamline operations and reduce waste.

- Optimizing packaging sizes to cut costs and improve customer satisfaction.

- Thoughtful design and testing of packaging to minimize returns, further contributing to cost savings and brand loyalty.

In a market where the demand for nutraceuticals continues to rise, adopting these strategies is not merely advantageous but essential. Companies that prioritize innovative and sustainable packaging solutions will thrive in a competitive landscape and play a crucial role in fostering a more sustainable future. Embracing these best practices can lead to significant cost reductions and position brands as leaders in the evolving nutraceutical industry.

Frequently Asked Questions

What are cost-effective packaging materials?

Cost-effective packaging materials include biodegradable plastics, recycled items, and lightweight alternatives that help reduce packaging costs while maintaining product integrity.

Why are biodegradable plastics gaining popularity in the nutraceutical sector?

Biodegradable plastics, made from renewable resources like cornstarch or sugarcane, are gaining traction due to their environmental benefits and the increasing consumer demand for sustainable solutions.

What is the projected growth rate for the biobased biodegradable plastic market?

The global biobased biodegradable plastic market is projected to grow at a compound annual growth rate (CAGR) of 9.5% from 2025 to 2035.

How can using flexible pouches benefit packaging costs?

Using flexible pouches instead of rigid containers can lead to significant decreases in production and overall packaging costs.

What are the advantages of sourcing packaging supplies locally?

Sourcing supplies locally reduces transportation expenses and lead times, improving overall efficiency in the packaging process.

Why is a cost-benefit evaluation important when selecting packaging materials?

A cost-benefit evaluation ensures that the chosen materials comply with budgetary limitations and regulatory standards while accounting for packaging costs and preserving product integrity.

How can suppliers contribute to finding innovative packaging materials?

Suppliers specializing in nutraceutical containers can provide valuable insights into innovative materials that offer sustainability advantages and help reduce packaging costs.

What financial benefits do consumers see in eco-friendly products?

U.S. buyers are willing to pay an 11% premium for eco-friendly items, while the actual premium averages 28%, indicating financial advantages for adopting biodegradable plastics.

How does the adoption of biodegradable plastics impact brands?

Brands that adopt biodegradable plastics can reduce their environmental footprint and appeal to the growing consumer preference for eco-friendly products, which have shown an average growth of 28% for those with environmental, social, and governance (ESG) claims over five years.

Why is the shift to biodegradable options considered necessary?

The shift is necessary because conventional plastic containers, which rely heavily on fossil fuels, contribute significantly to environmental degradation.