Overview

The article delineates five essential steps for effectively addressing nutraceutical packaging needs. These steps include:

- Understanding packaging requirements

- Ensuring regulatory compliance

- Selecting suitable materials

- Integrating filling services

- Optimizing distribution and inventory management

Each step underscores the significance of aligning packaging strategies with product specifications, consumer preferences, and regulatory standards. This alignment is crucial for enhancing operational efficiency and market competitiveness within the nutraceutical sector.

Introduction

Navigating the complexities of nutraceutical packaging presents a significant challenge for businesses aiming to meet market demands while ensuring compliance and enhancing brand recognition. Understanding the nuances of packaging requirements is not merely beneficial; it is essential, as these factors directly impact product safety, shelf life, and consumer appeal.

What challenges emerge when striving to balance regulatory compliance with innovative design? Moreover, how can companies effectively streamline their packaging processes to maintain a competitive edge in an ever-evolving industry? Addressing these questions is crucial for success.

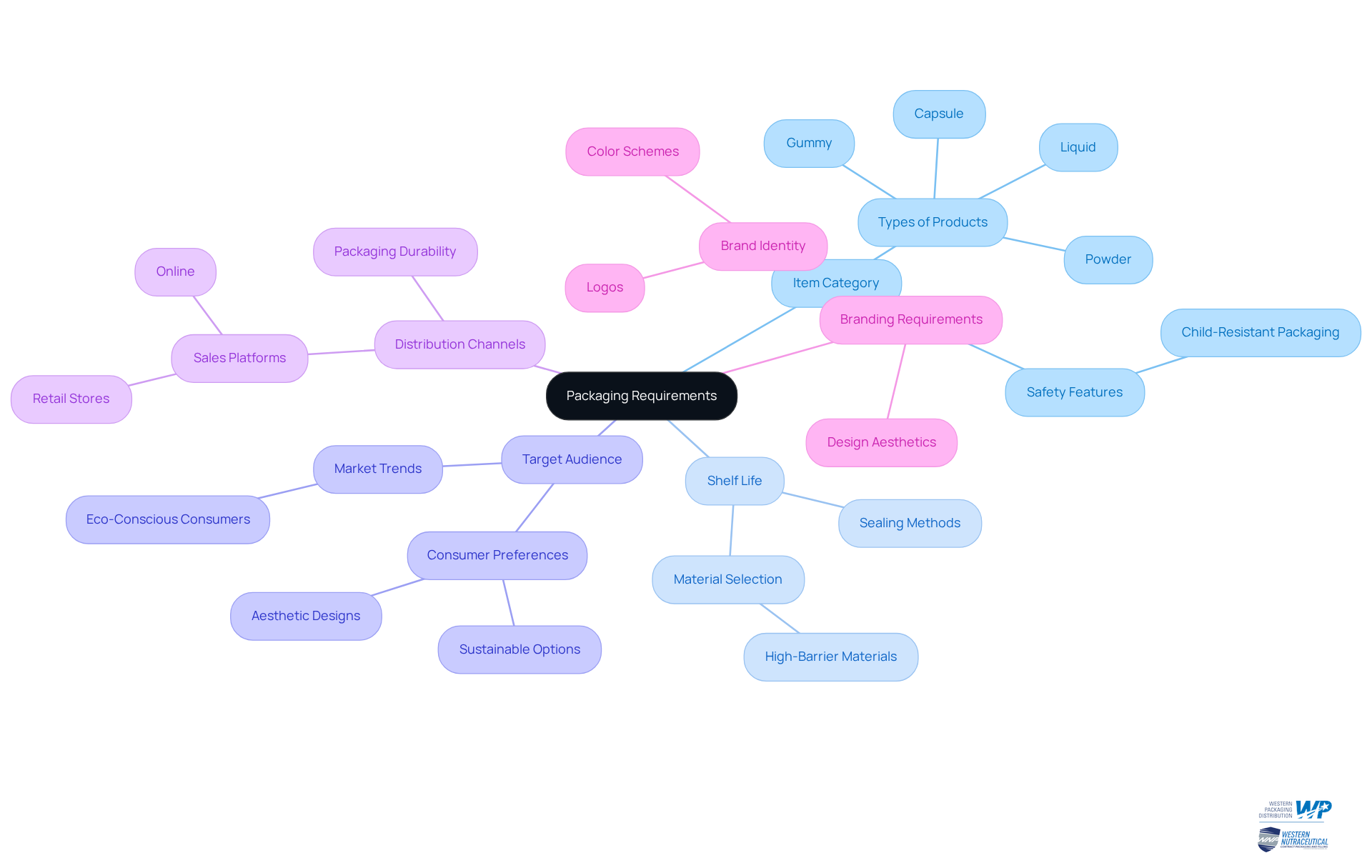

Understand Your Packaging Requirements

To efficiently address your nutraceutical container needs, begin by evaluating the specific specifications of your item. Consider the following factors:

- Item Category: Identify whether your item is a powder, capsule, liquid, or gummy, as each category has distinct container specifications. For instance, dietary supplements often require child-resistant packaging to ensure safety, especially for gummies and soft gels.

- Shelf Life: Assess the stability duration of your product, which will influence your choice of materials and sealing methods. High-barrier materials are crucial for protecting sensitive ingredients from moisture and light degradation.

- Target Audience: Gain insight into your consumers and their preferences. Eco-conscious consumers are increasingly opting for sustainable options, such as biodegradable materials and recyclable designs, which can enhance customer loyalty. Western Packaging specializes in customized flexible solutions that meet these preferences while boosting your item's shelf appeal and brand recognition.

- Distribution Channels: Reflect on how your item will be sold—whether online, in retail stores, or both. This consideration impacts the durability and aesthetics of your containers, as e-commerce demands protective yet visually appealing solutions to attract consumers. The rise of online retail necessitates containers that ensure safety during transport while also being aesthetically pleasing.

- Branding Requirements: Evaluate how your packaging can enhance recognition of your brand identity. This encompasses color schemes, logos, and overall design aesthetics that resonate with your target market. Effective packaging not only protects the item but also communicates the values and quality associated with the company. At Western Packaging, we are dedicated to creating compelling graphic assets that ensure a cohesive and captivating brand identity.

By thoroughly understanding these requirements, you can make informed decisions that align with your offerings' needs and market expectations, ultimately driving success in the competitive nutraceutical landscape.

Ensure Regulatory Compliance in Packaging

To ensure your packaging meets regulatory standards, follow these essential steps:

-

Familiarize Yourself with Regulations: Understand the specific regulations governing nutraceuticals in your region, including labeling requirements, health claims, and ingredient disclosures. As of 2025, the FDA emphasizes compliance with updated labeling standards, particularly regarding added sugars and serving sizes.

-

Labeling Requirements: Ensure your labels contain all necessary information, such as the item name, ingredient list, nutritional information, and any required disclaimers. The FDA's Dietary Supplement Labeling Guide provides comprehensive details on these requirements, including the necessity of displaying the net quantity of contents in both metric and imperial terms.

-

Good Manufacturing Practices (GMP): Follow GMP guidelines to uphold item integrity and safety throughout your wrapping processes. This includes ensuring that all ingredients are correctly listed in descending order by weight, which is essential for public safety and regulatory compliance.

-

Child-Resistant Wrapping: If your product poses a risk to children, consider implementing child-resistant wrapping to comply with safety regulations. This proactive measure not only meets legal requirements but also enhances consumer trust by demonstrating your commitment to safety and addressing packaging needs.

-

Conduct regular audits of your packaging needs to ensure ongoing compliance with evolving regulations. This proactive strategy assists in recognizing potential problems before they worsen, protecting your reputation. A single item recall can severely harm a company's reputation, making vigilance essential.

By prioritizing regulatory compliance, you not only safeguard your business but also cultivate trust with customers, positioning your brand as a dependable option in the nutraceutical market.

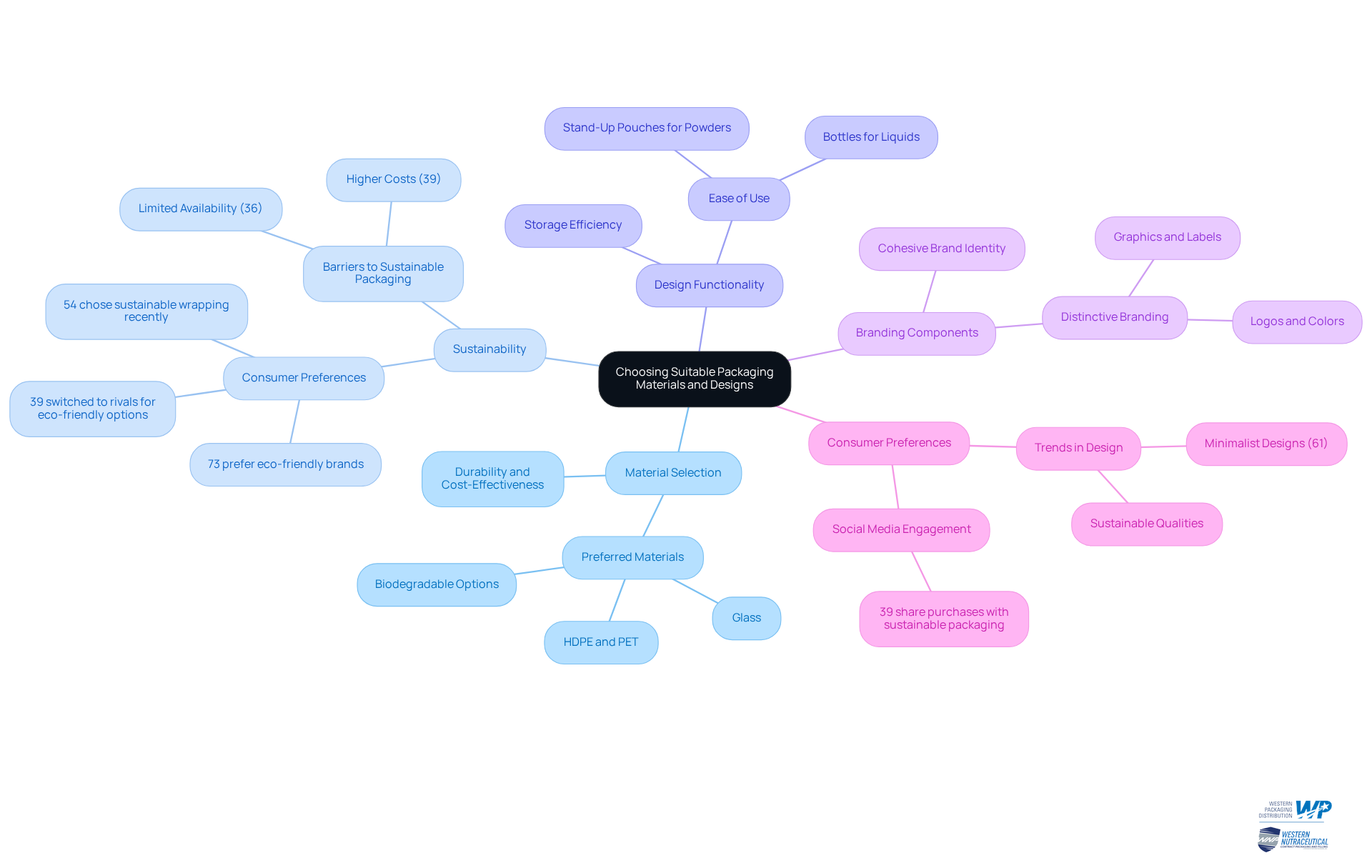

Choose Suitable Packaging Materials and Designs

When selecting packaging materials and designs for nutraceutical products, consider the following key factors:

-

Material Selection: Assess various options such as plastics, glass, and biodegradable materials. High-density polyethylene (HDPE) and polyethylene terephthalate (PET) are preferred for their durability and cost-effectiveness, while glass offers a premium appearance that attracts individuals looking for quality. At Western Packaging, we specialize in discovering optimal flexible solutions tailored to your needs, whether it's large pouches for protein products or stick packs for nutraceuticals.

-

Sustainability: With 73% of buyers indicating a preference for brands that emphasize eco-friendly materials, incorporating recyclable or biodegradable components can greatly improve your brand's attractiveness. This change is vital as 39% of buyers have turned to rivals providing eco-friendly container options. Moreover, 54% of American buyers deliberately selected items with sustainable wrapping in the past six months, suggesting a significant demand for eco-friendly alternatives.

-

Design Functionality: Ensure that your container design promotes ease of use and storage. For instance, stand-up pouches are ideal for powders and gummies, while bottles are preferred for liquids and capsules, maximizing convenience for consumers. Our innovative packaging solutions at Western Packaging enhance your product's shelf appeal and identity, ensuring that your packaging not only protects but also attracts.

-

Branding Components: Incorporate distinctive branding components such as logos, colors, and graphics that connect with your identity. This method not only promotes recognition but also leaves a lasting impression on consumers. Trust Western Packaging to craft compelling graphic assets, from labels to brochures, ensuring a cohesive and captivating brand identity that highlights your unique offerings.

-

Consumer Preferences: Stay attuned to current trends in design for containers. Minimalist designs are becoming more popular, with 61% of shoppers appreciating minimal wrapping as a sought-after sustainable quality, as they suggest a sense of purity and health. As highlighted by Shorr Packaging, 'sustainable solutions don’t just drive purchases, they ignite discussions.'

By carefully choosing materials and designs, you can create solutions that fulfill packaging needs, protecting your item while also attracting buyers who increasingly demand eco-friendly and visually appealing options.

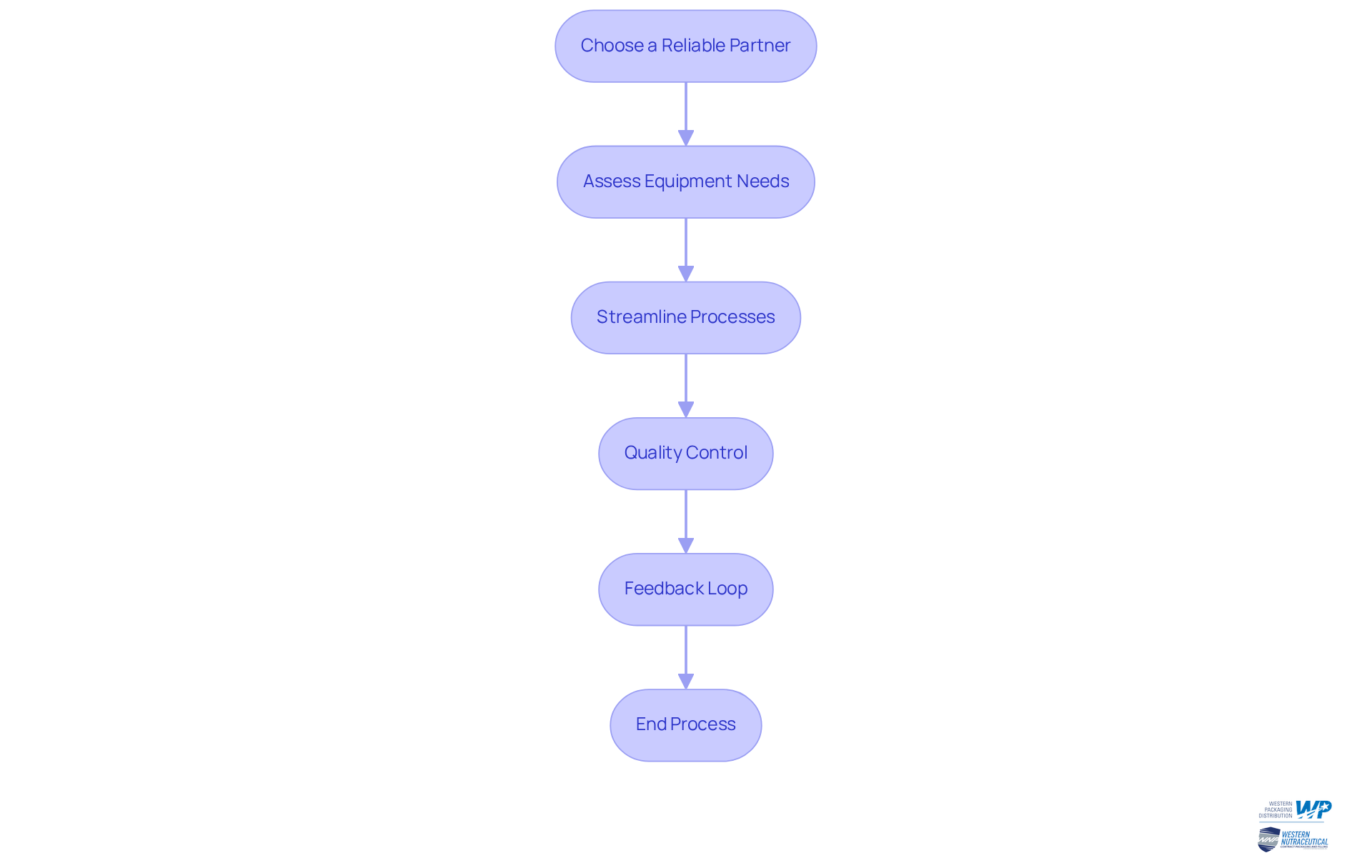

Integrate Filling Services for Streamlined Operations

To effectively integrate filling services into your operations, consider the following steps:

-

Choose a Reliable Partner: Opt for a filling service provider with proven expertise in nutraceuticals. Verify their certifications and review their history of maintaining high-quality standards. As noted by Bosch Packaging Technology, "AI-powered liquid capsule filling technology ensures precision and sterility, which are crucial in the nutraceutical industry."

-

Assess Equipment Needs: Identify the suitable filling machinery tailored to your item type. For instance, liquid filling machines are distinct from those designed for powders or gummies, each requiring specialized technology to ensure optimal performance. The market shows that over 55% of small-scale pharmaceutical manufacturers prefer semi-automatic machines for their cost-effectiveness and versatility.

-

Streamline Processes: Collaborate closely with your filling partner to refine processes, ensuring that filling, sealing, and labeling are seamlessly coordinated for maximum efficiency. This collaboration can lead to significant improvements in operational workflows.

-

Quality Control: Establish rigorous quality control protocols at every stage of the filling process. This reduces errors and protects integrity, which is essential in the nutraceutical sector where consumer trust is vital. As Capsugel emphasizes, "Quality control is not just a step; it's a culture that must be ingrained in every process."

-

Feedback Loop: Create a continuous feedback mechanism with your filling partner. This allows for ongoing process improvements and quick resolution of any issues that may arise, fostering a culture of excellence. Ongoing enhancement is crucial, as emphasized in several case studies where firms that established feedback loops experienced a significant rise in quality and customer satisfaction.

By effectively incorporating filling services into your packaging needs, you can significantly enhance efficiency and ensure that your items are filled with precision and consistency.

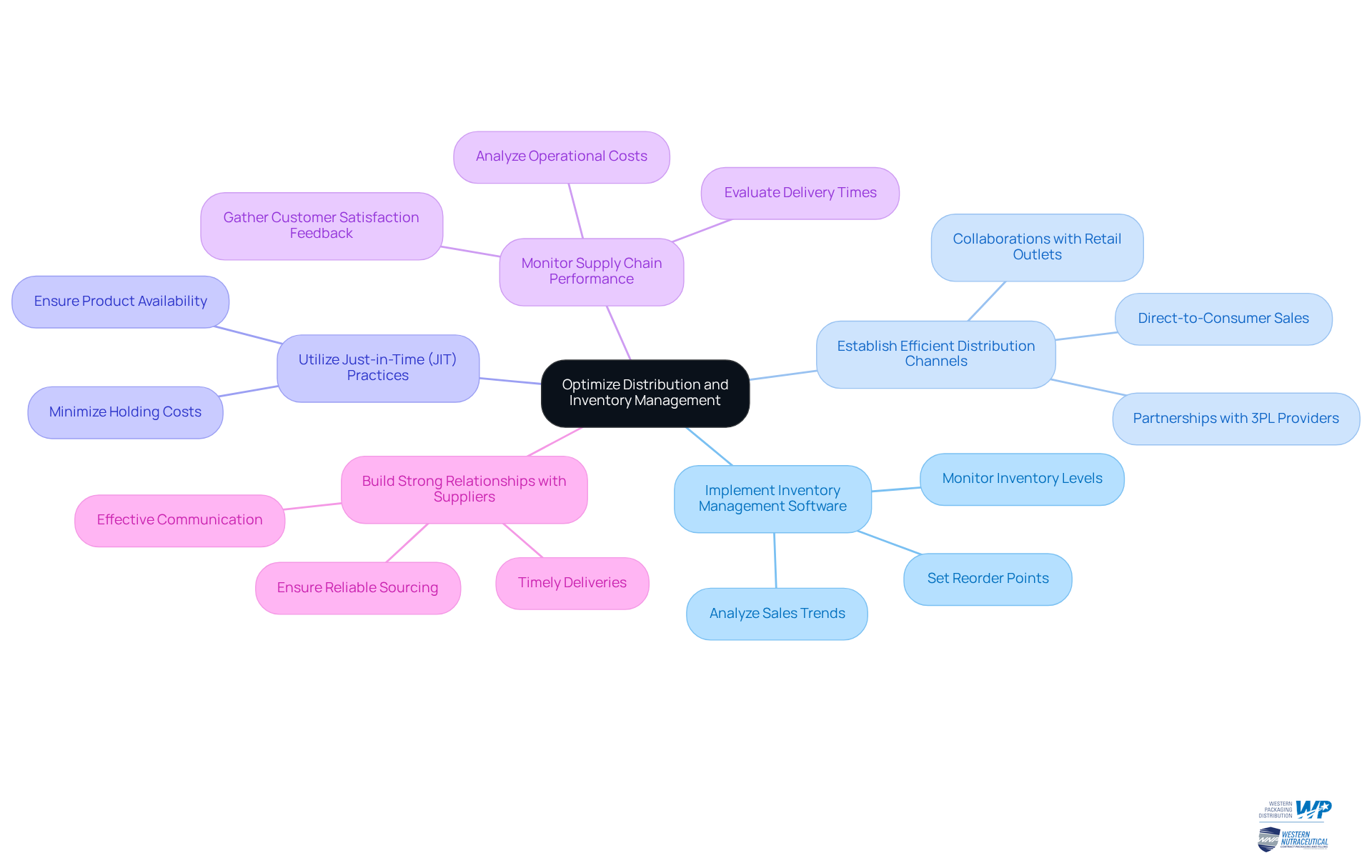

Optimize Distribution and Inventory Management

To enhance your distribution and inventory management in the nutraceutical sector, consider the following strategies:

-

Implement Inventory Management Software: Leverage advanced software solutions to monitor inventory levels, analyze sales trends, and set reorder points. This proactive approach minimizes the risk of stockouts and overstock situations, which can significantly impact profitability.

-

Establish Efficient Distribution Channels: Identify and utilize the most effective distribution avenues for your items. This may include direct-to-consumer sales, partnerships with third-party logistics (3PL) providers like Western Packaging, or collaborations with retail outlets to maximize reach and efficiency.

-

Utilize Just-in-Time (JIT) Practices: Adopt JIT inventory practices to minimize holding costs while ensuring product availability. This strategy helps maintain optimal inventory levels, reducing waste and enhancing responsiveness to market demands.

-

Monitor Supply Chain Performance: Regularly evaluate your supply chain's performance to pinpoint areas for improvement. Key metrics to analyze include delivery times, operational costs, and customer satisfaction feedback, which can guide strategic adjustments.

-

Build Strong Relationships with Suppliers: Cultivate robust relationships with your suppliers to ensure reliable sourcing and timely deliveries. Effective communication is essential for managing expectations and swiftly addressing any issues that may arise.

By implementing these strategies and leveraging tailored 3PL services from Western Packaging to meet their packaging needs, nutraceutical businesses can significantly enhance operational efficiency, better align with consumer demand, and ultimately improve their market competitiveness.

Conclusion

Efficiently meeting nutraceutical packaging needs is crucial for success in a competitive market. By thoroughly understanding the specific requirements of your products, businesses can enhance safety, appeal, and compliance, ultimately driving consumer trust and brand loyalty. Prioritizing these elements ensures that products not only meet market expectations but also stand out on the shelves.

Key arguments discussed highlight the importance of evaluating packaging requirements based on:

- Item category

- Shelf life

- Target audience

- Distribution channels

- Branding needs

Additionally, ensuring regulatory compliance through familiarization with local regulations and implementing good manufacturing practices is essential for maintaining product integrity. Choosing suitable materials and designs, integrating filling services, and optimizing distribution and inventory management further solidify a comprehensive approach to packaging.

Reflecting on these strategies, businesses in the nutraceutical sector are encouraged to adopt a proactive stance toward their packaging solutions. By embracing sustainable practices, adhering to regulations, and focusing on consumer preferences, companies can not only enhance their operational efficiency but also position themselves as leaders in the evolving nutraceutical market. Taking these steps not only protects the brand but also resonates with an increasingly eco-conscious consumer base, paving the way for sustained growth and success.

Frequently Asked Questions

What should I consider when evaluating my nutraceutical packaging requirements?

You should consider the item category (powder, capsule, liquid, or gummy), shelf life, target audience preferences, distribution channels, and branding requirements.

Why is the item category important for packaging?

Each item category has distinct container specifications. For example, dietary supplements often require child-resistant packaging, especially for gummies and soft gels.

How does shelf life influence packaging choices?

The stability duration of your product affects the choice of materials and sealing methods. High-barrier materials are essential for protecting sensitive ingredients from moisture and light degradation.

What role does the target audience play in packaging decisions?

Understanding consumer preferences, such as the demand for sustainable options, can enhance customer loyalty. Eco-conscious consumers may prefer biodegradable materials and recyclable designs.

How do distribution channels affect packaging design?

The way your item is sold (online, retail stores, or both) impacts the durability and aesthetics of containers. E-commerce requires protective yet visually appealing solutions for safe transport and consumer attraction.

What branding elements should be considered in packaging?

Evaluate color schemes, logos, and design aesthetics that resonate with your target market. Effective packaging not only protects the item but also communicates the brand's values and quality.

What are the essential steps to ensure regulatory compliance in packaging?

Familiarize yourself with relevant regulations, ensure proper labeling, follow Good Manufacturing Practices (GMP), consider child-resistant wrapping if necessary, and conduct regular audits of your packaging.

What specific labeling requirements must be followed for nutraceuticals?

Labels must include the item name, ingredient list, nutritional information, and required disclaimers, adhering to the FDA's Dietary Supplement Labeling Guide.

Why is Good Manufacturing Practices (GMP) important in packaging?

GMP guidelines help maintain item integrity and safety throughout the packaging process, ensuring that all ingredients are correctly listed in descending order by weight for public safety and regulatory compliance.

How can child-resistant wrapping benefit my product?

Implementing child-resistant wrapping not only complies with safety regulations but also enhances consumer trust by demonstrating your commitment to safety.

Why is it important to conduct regular audits of packaging needs?

Regular audits help ensure ongoing compliance with evolving regulations, allowing you to identify potential problems before they escalate, thus protecting your reputation in the market.