Overview

This article delineates five essential steps to optimize packaging for nutraceuticals in Texas. It emphasizes the importance of:

- Understanding product requirements

- Evaluating packaging options

- Ensuring regulatory compliance

- Considering logistics

- Selecting a capable packaging partner

Each step is underpinned by practical considerations, including:

- Material selection

- Design capabilities

- Consumer preferences

Aligning packaging strategies with market trends and regulatory standards is crucial for enhancing product appeal and safety. By adhering to these guidelines, businesses can not only meet industry demands but also position themselves as leaders in the nutraceutical market.

Introduction

Navigating the competitive landscape of nutraceuticals in Texas necessitates more than just a superior product; it requires strategic packaging that resonates with consumers while adhering to regulatory standards. Optimizing packaging not only amplifies product appeal but also guarantees longevity and safety—critical factors in a market projected to reach USD 6.24 billion by 2032.

With a plethora of materials, design options, and compliance requirements to navigate, how can businesses effectively streamline their packaging processes to align with consumer expectations and industry regulations? This guide explores five essential steps to optimize nutraceutical packaging in Texas, equipping businesses with the expertise needed to distinguish themselves and thrive.

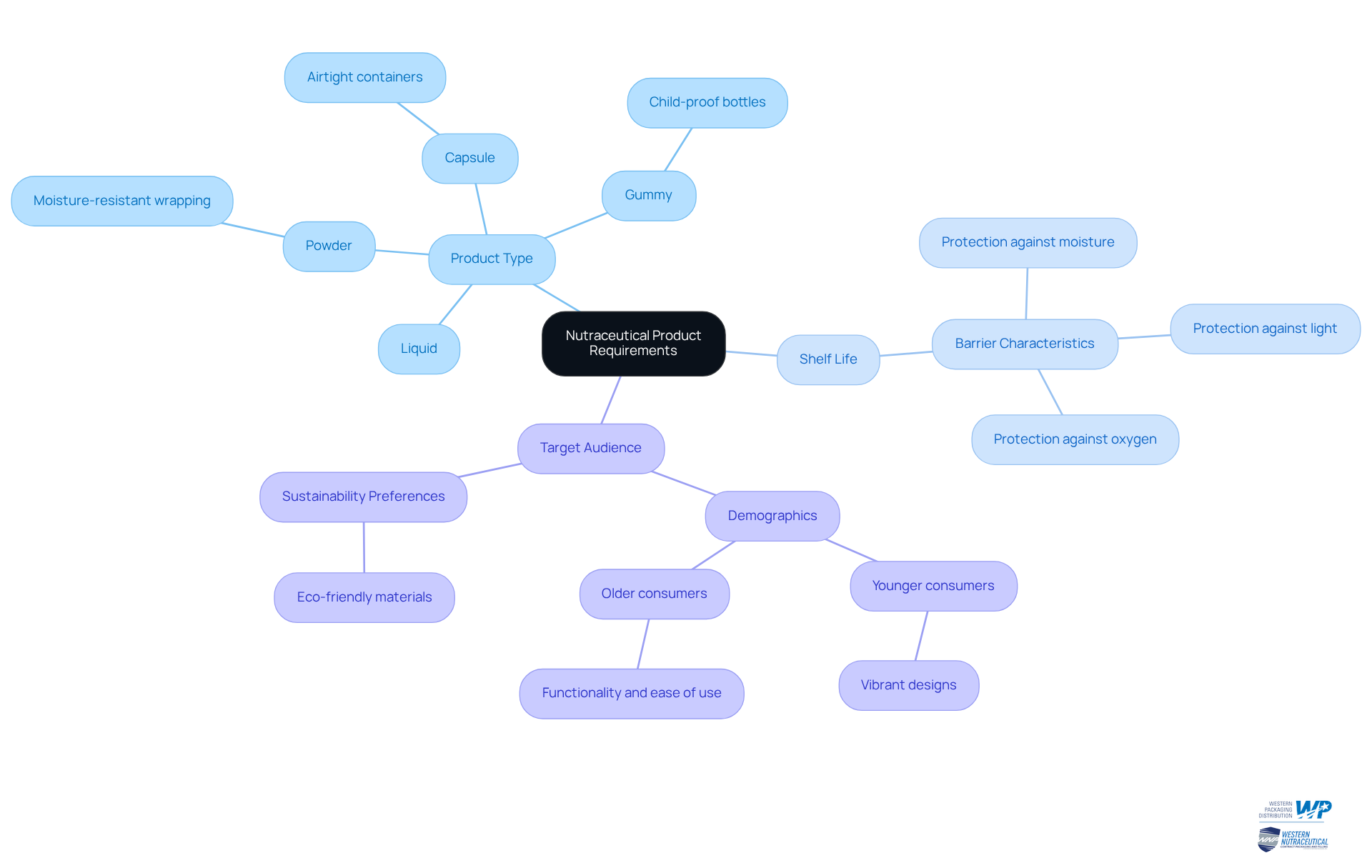

Assess Nutraceutical Product Requirements

To efficiently enhance your containers for nutraceuticals, it is essential to recognize the distinctive traits of your items. Key considerations include:

- Product Type: Determine whether your product is a powder, capsule, gummy, or liquid, as each type necessitates specific packaging solutions. For instance, powders frequently require moisture-resistant wrapping to ensure stability, while gummies benefit from child-proof characteristics. This includes child-proof bottles for gummies, moisture-proof pouches for powders, and airtight containers for capsules. At Western Packaging Texas, we focus on discovering optimal flexible solutions customized to your requirements, whether it's large pouches for protein items or stick packs for nutraceuticals.

- Shelf Life: Evaluate the necessary shelf life for your item, as this factor greatly influences your selection of materials. Specific container types provide improved barrier characteristics that safeguard against moisture, oxygen, and light, thus extending efficacy. Our innovative design solutions not only enhance product appeal but also ensure that your nutraceuticals remain effective for extended durations.

- Target Audience: Comprehend your customer demographics and their container preferences. Research indicates that younger individuals are attracted to vibrant, eye-catching designs, while older individuals may prioritize functionality and ease of use. For instance, 71% of respondents in a recent survey preferred flexible materials due to their convenience and visual attractiveness. Furthermore, the rising trend towards sustainable alternatives is essential, as individuals increasingly pursue environmentally friendly items that align with their principles. At Western Packaging, we craft compelling graphic assets, from labels to brochures, ensuring a cohesive and captivating brand identity that resonates with your target audience.

Once you have a thorough understanding of these requirements, document them to guide your container choices. This organized method will not only enhance product attractiveness but also align with changing consumer preferences for sustainable and innovative packaging in Texas. Considering that the nutraceutical container market is anticipated to reach USD 6.24 billion by 2032, enhancing your containers is crucial for remaining competitive in this expanding market.

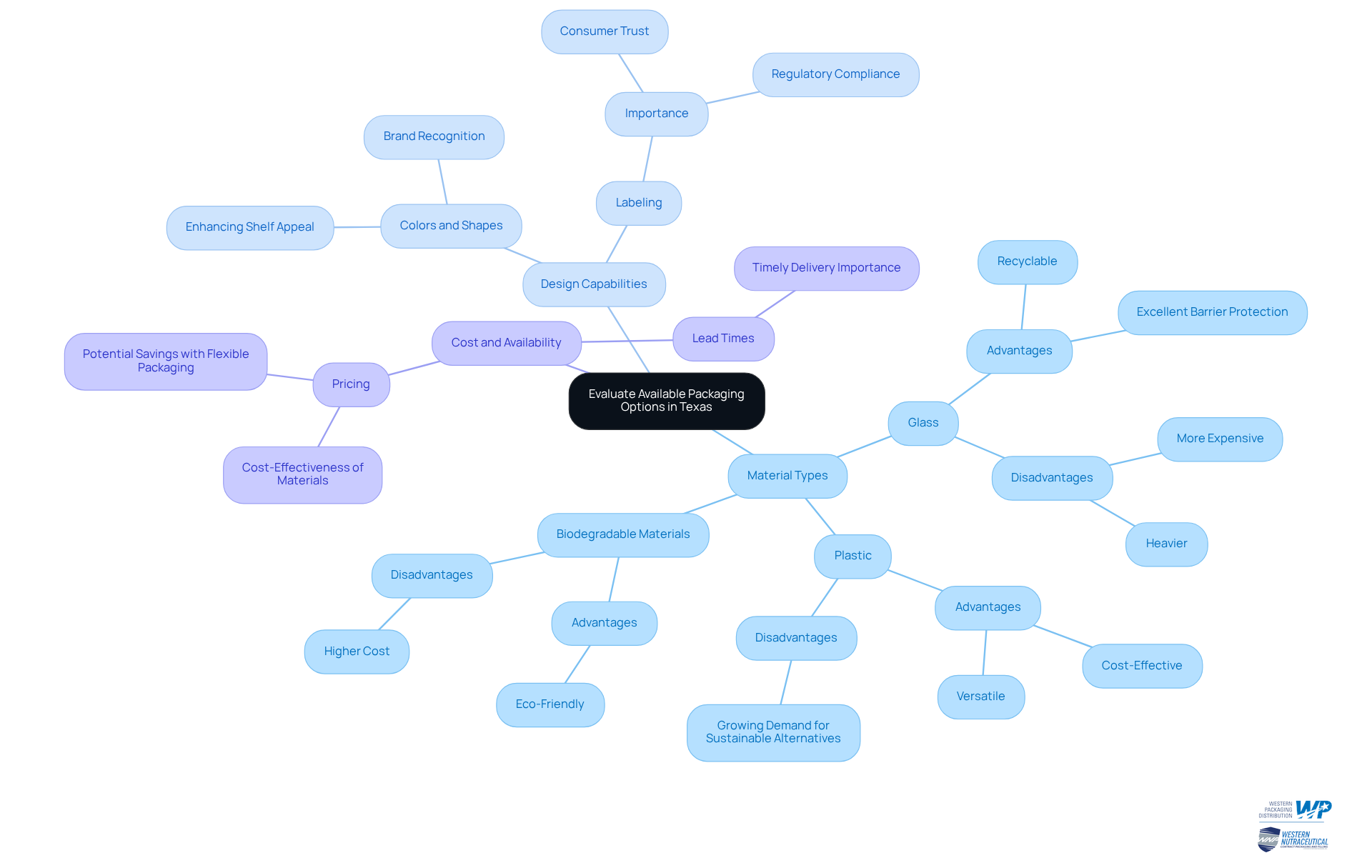

Evaluate Available Packaging Options in Texas

When evaluating packaging Texas suppliers and manufacturers specializing in nutraceuticals, it is essential to consider various material types, design capabilities, and cost factors. Here’s a breakdown of key considerations:

-

Material Types: Explore options such as glass, plastic, and biodegradable materials. Each material presents distinct advantages and disadvantages:

- Glass: Offers excellent barrier protection and is recyclable, but can be heavier and more expensive.

- Plastic: Dominates the market with over 58.3% revenue share due to its versatility and cost-effectiveness. However, there is a growing demand for sustainable alternatives, such as biodegradable plastics.

- Biodegradable Materials: Gaining popularity among buyers looking for eco-friendly alternatives, these materials align with sustainability objectives but may be pricier.

-

Design Capabilities: Assess suppliers based on their ability to create custom designs that resonate with your brand identity. This includes evaluating their expertise in:

- Labeling: Clear and compliant labeling is crucial for consumer trust and regulatory adherence. The need for containers that guarantee item integrity has increased alongside health-oriented changes. Western Packaging excels in crafting compelling graphic assets, ensuring a cohesive and captivating brand identity.

- Colors and Shapes: Innovative designs can enhance shelf appeal and distinguish your offering in a competitive market. With Western Packaging's expertise in design, you can enhance your product's shelf appeal and brand recognition through customized flexible solutions, such as large pouches for protein items or stick packs for nutraceuticals.

-

Cost and Availability: Compare pricing and lead times from various suppliers to ensure alignment with your budget and timeline. Consider the following:

- Pricing: Analyze the cost-effectiveness of each material type, keeping in mind that flexible packaging can reduce material usage and shipping costs, with potential savings of up to 30%.

- Lead Times: Timely delivery is critical; ensure that suppliers can meet your production schedules without compromising quality.

By compiling a list of potential container options and their specifications, you can make informed decisions that balance cost, sustainability, and brand identity, ultimately optimizing your strategy for packaging Texas nutraceuticals.

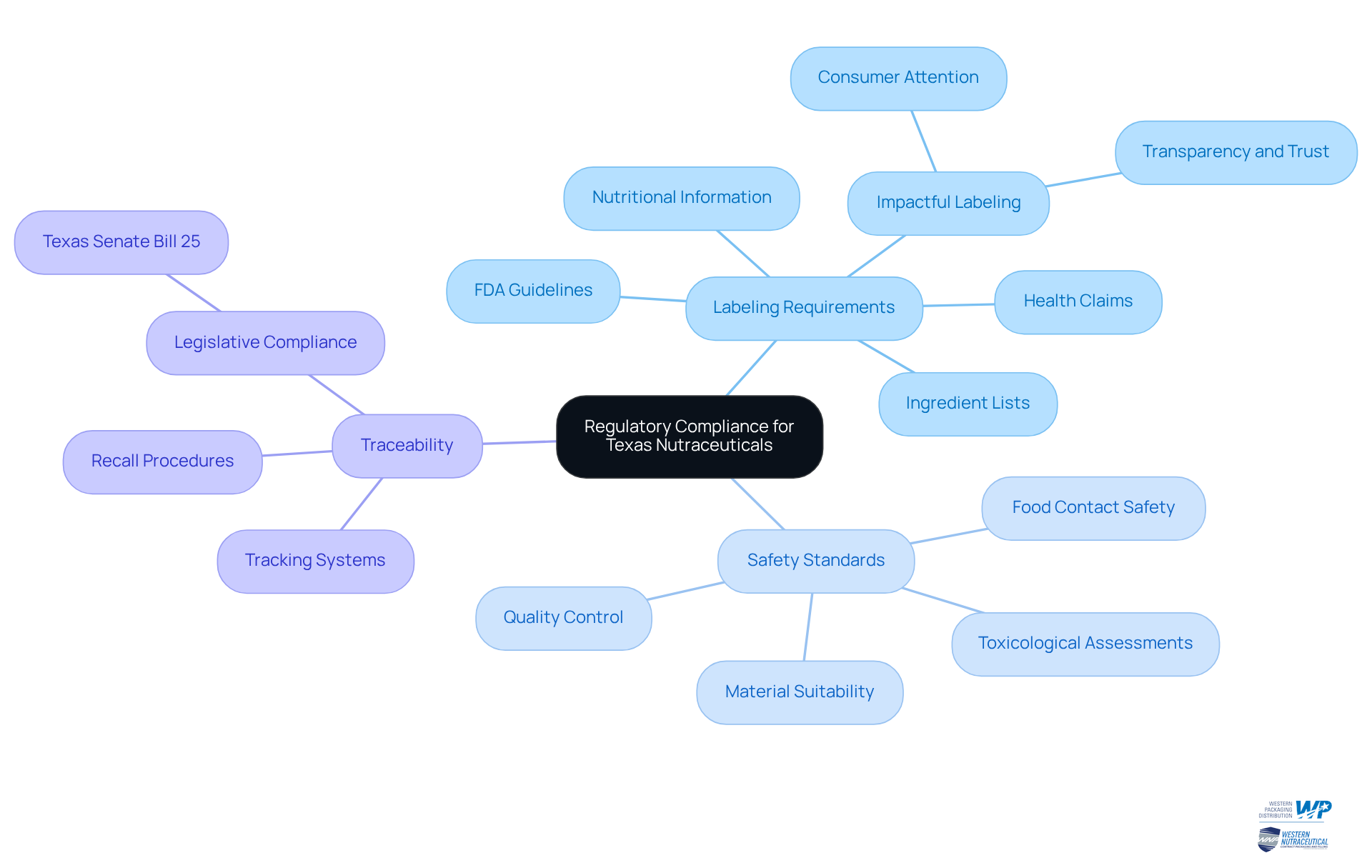

Ensure Compliance with Regulatory Standards

Familiarize yourself with the regulatory requirements for packaging Texas nutraceuticals. Key considerations include:

-

Labeling Requirements: Ensure that your labels contain all necessary information, including ingredient lists, nutritional information, and health claims, in accordance with FDA guidelines. Adhering to these requirements is essential, as the FDA mandates that specific details must be clearly presented to the public, enhancing transparency and trust. Significantly, the average shopper spends under 20 seconds deciding on a retail purchase, underscoring the necessity for impactful labeling that swiftly grabs attention.

-

Safety Standards: Confirm that your containers are safe for food contact and do not release harmful substances into the item. Following safety standards is crucial for preserving the integrity of items and ensuring user safety, as unsuitable materials can undermine the effectiveness of nutraceuticals. Quality control and toxicological assessments are essential in guaranteeing that packaging meets safety standards, thereby safeguarding both the item and the buyer.

-

Traceability: Implement systems that allow for tracking and tracing of items in the event of recalls. This is essential for ensuring user safety and maintaining adherence to regulatory expectations, as effective traceability can mitigate risks linked to recalls. For instance, the recent Texas Senate Bill 25 highlights the significance of traceability in food items, mandating clear labeling for specific additives to enhance public safety.

Consult with legal experts or regulatory consultants if needed to ensure full compliance. Their expertise can provide valuable insights into navigating the complexities of FDA regulations and assist you in upholding high safety standards in your containers. As highlighted by industry specialists, "Comprehending and following safety standards is not merely a regulatory obligation; it is crucial for establishing consumer confidence and guaranteeing success in the market.

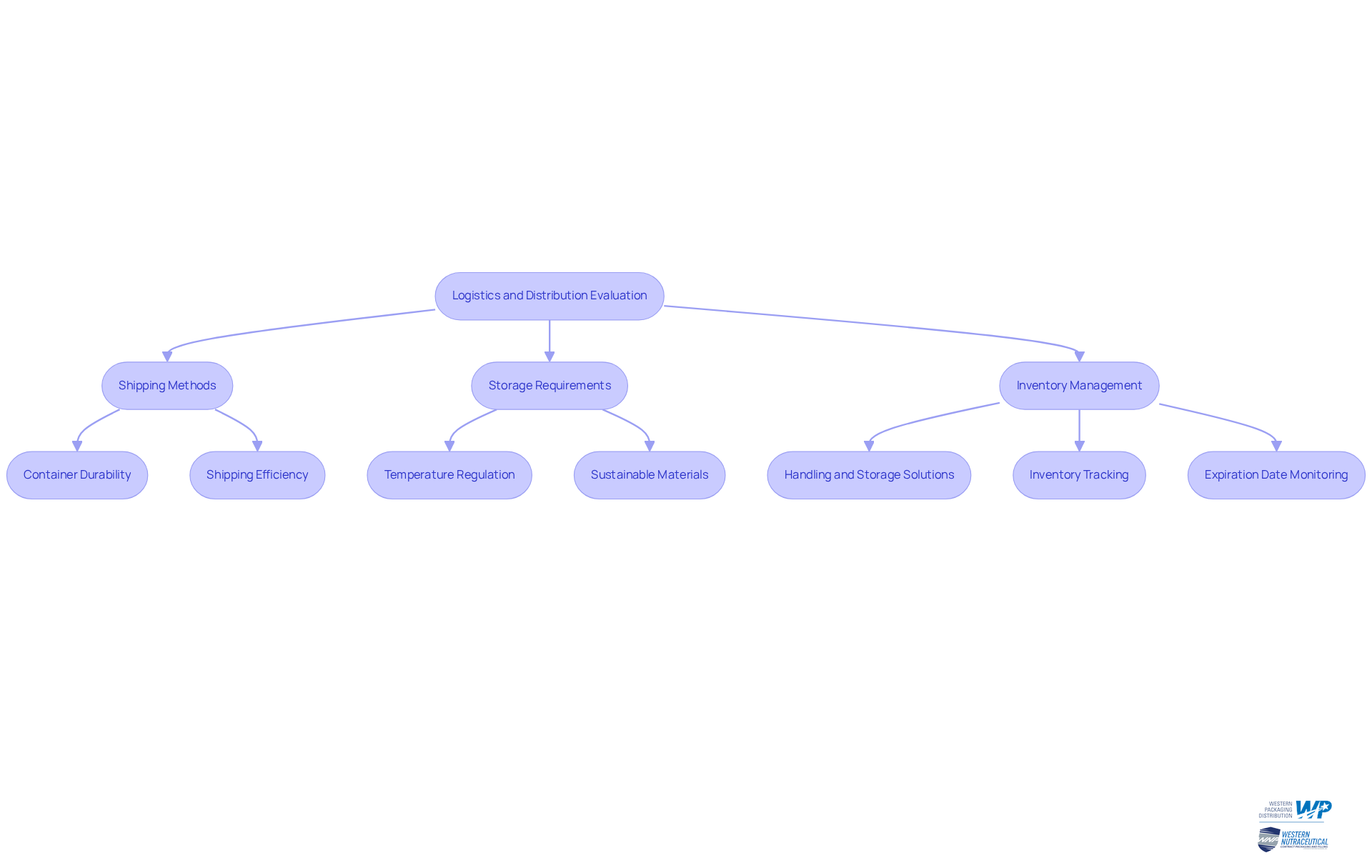

Consider Logistics and Distribution Capabilities

Evaluate your logistics and distribution needs by considering the following key factors:

-

Shipping Methods: Identify the shipping methods you will utilize, such as ground or air transport. Choose containers that can withstand the challenges of these transportation modes, ensuring that your items arrive intact and preserve their quality. Consider the effect of container selections on shipping efficiency; flexible materials can enhance protection and lower shipping expenses. Western Packaging’s integrated filling services ensure that your items, including powders, gummies, and soft-gels, benefit from packaging Texas efficiently, further optimizing your logistics.

-

Storage Requirements: Assess if your containers require particular storage conditions, such as temperature regulation, to maintain item integrity. For instance, nutraceuticals often require protection from moisture and light, making high-barrier materials essential. Furthermore, choosing sustainable materials provided by packaging Texas can connect with eco-conscious consumers and align with current market trends, enhancing both product integrity and brand appeal.

-

Inventory Management: Adopt wrapping solutions that simplify handling and storage, thereby reducing labor costs and enhancing operational efficiency. Advanced container designs can facilitate better inventory tracking and management, ensuring that stock levels and expiration dates are easily monitored. Utilizing adaptable containers can further enhance inventory management by permitting more efficient use of space and resources. With Western Packaging Texas’s comprehensive 3PL services, you can streamline your inventory processes and focus on your core business operations.

Work closely with your logistics team to ensure that your container choices align with your overall distribution strategy. This alignment is crucial for optimizing shipping efficiency and effectively meeting consumer demands.

Choose a Partner with Integrated Packaging Services

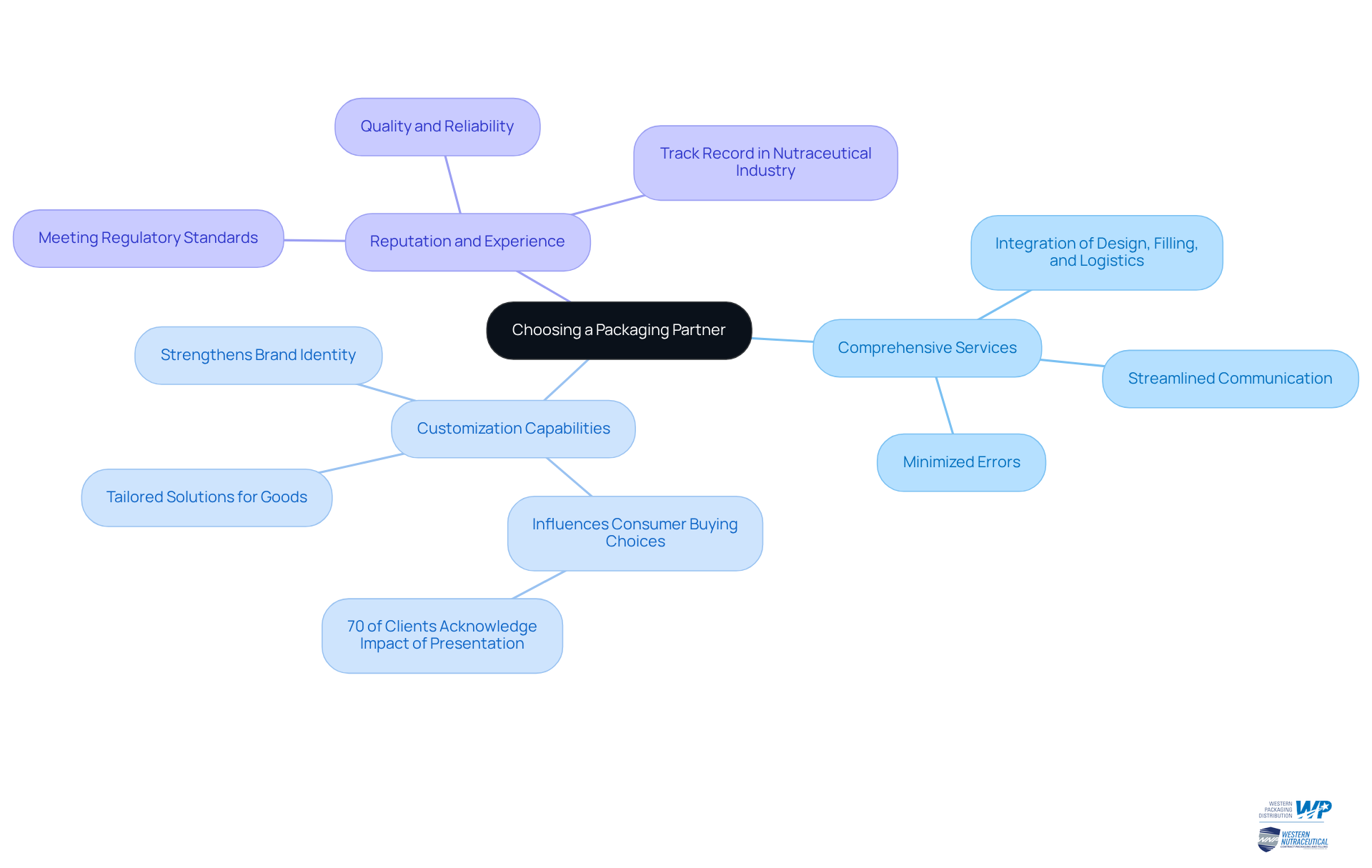

When selecting a packaging partner, it is crucial to consider several key factors that can significantly impact your operations:

-

Comprehensive Services: Choose a provider like Western Packaging that integrates design, filling, and logistics services. This holistic approach streamlines communication and minimizes the potential for errors, ultimately ensuring a smoother workflow.

-

Customization Capabilities: Your partner must possess the ability to tailor solutions that align with your specific goods needs and branding requirements. Personalization not only strengthens brand identity but also influences consumer buying choices; in fact, 70% of clients acknowledge that presentation alone affects their purchasing decisions.

-

Reputation and Experience: It is essential to investigate the track record of potential partners within the nutraceutical industry. A provider with a strong history of quality and reliability is vital for meeting regulatory standards and ensuring product integrity.

Establishing a collaborative relationship with your chosen partner will further optimize your packaging Texas solutions, which will enhance both operational efficiency and market presence.

Conclusion

Optimizing packaging for nutraceuticals in Texas necessitates a multifaceted approach that encompasses product requirements, material selection, regulatory compliance, logistics, and partnership strategies. By comprehensively understanding the unique characteristics of nutraceutical products alongside the preferences of target consumers, businesses can develop packaging that not only safeguards the product but also amplifies its market appeal.

Key considerations entail:

- A thorough evaluation of the specific needs of various product types

- Strict adherence to FDA regulations

- The selection of materials that align with sustainability trends

- Efficient logistics and distribution capabilities that are essential in preserving product integrity and enhancing operational efficiency

- Collaborating with a dependable packaging provider that offers integrated services to streamline the process, ensuring that all facets of packaging—from design to distribution—are cohesive and efficient

In conclusion, the importance of well-optimized packaging is paramount in the competitive nutraceutical market. By adopting these strategies, businesses can not only fulfill consumer demands but also strategically position themselves for success in a dynamic industry. Embracing innovation and sustainability in packaging will not only meet regulatory requirements but also resonate with environmentally conscious consumers, ultimately fostering brand loyalty and driving growth.

Frequently Asked Questions

What should I consider when assessing nutraceutical product requirements?

Key considerations include the product type (powder, capsule, gummy, or liquid), shelf life, and target audience preferences. Each product type requires specific packaging solutions, and understanding shelf life helps in selecting appropriate materials that protect against moisture, oxygen, and light. Additionally, knowing your target audience's preferences can influence design and material choices.

How does product type affect packaging choices for nutraceuticals?

Different product types necessitate specific packaging solutions. For example, powders often require moisture-resistant wrapping, gummies benefit from child-proof containers, and capsules need airtight packaging. Tailoring the packaging to the product type ensures stability and safety.

Why is shelf life an important factor in packaging nutraceuticals?

Shelf life influences the selection of materials, as certain container types provide better barrier characteristics to protect against moisture, oxygen, and light, thereby extending the product's efficacy. This ensures that nutraceuticals remain effective for a longer duration.

How does understanding the target audience impact packaging design?

Knowing the target audience helps in creating packaging that resonates with their preferences. Younger consumers may prefer vibrant designs, while older individuals may prioritize functionality. Additionally, there is a growing trend towards sustainable packaging, which is increasingly important to environmentally conscious consumers.

What types of materials are available for nutraceutical packaging?

Common material options include glass, plastic, and biodegradable materials. Glass offers excellent barrier protection but can be heavier and more expensive. Plastic is cost-effective and versatile, while biodegradable materials are gaining popularity among eco-conscious consumers, though they may come at a higher price.

What should I consider regarding design capabilities when selecting a packaging supplier?

Evaluate suppliers based on their ability to create custom designs that align with your brand identity. This includes assessing their expertise in labeling for regulatory compliance, as well as their ability to create appealing colors and shapes that enhance shelf appeal and differentiate your product in the market.

How do cost and availability factor into packaging decisions?

It is important to compare pricing and lead times from various suppliers to ensure they align with your budget and production schedules. Analyzing the cost-effectiveness of materials, especially flexible packaging which can reduce material usage and shipping costs, is essential for optimizing your packaging strategy.

What is the projected market value for the nutraceutical container market?

The nutraceutical container market is anticipated to reach USD 6.24 billion by 2032, highlighting the importance of enhancing packaging to remain competitive in this growing market.