Overview

The article delineates seven pivotal benefits of contract manufacturing nutritional supplements:

- Cost reduction

- Access to specialized expertise

- Faster time-to-market

- Scalability

- Regulatory compliance

- Quality control

- Improved supply chain management

These advantages collectively empower companies to enhance operational efficiency, uphold high product quality, and innovate effectively. Ultimately, this allows them to concentrate on core competencies, reduce costs, and meet consumer demands with greater efficacy.

Introduction

The nutritional supplement industry is currently witnessing remarkable growth, fueled by a rising consumer demand for health and wellness products. In the quest for competitiveness, brands are increasingly embracing contract manufacturing as a strategic solution. This method not only delivers substantial cost savings and grants access to specialized expertise but also ensures adherence to stringent industry regulations. Yet, with a plethora of options at their disposal, how can companies adeptly navigate the complexities of contract manufacturing to optimize their advantages and elevate their market presence?

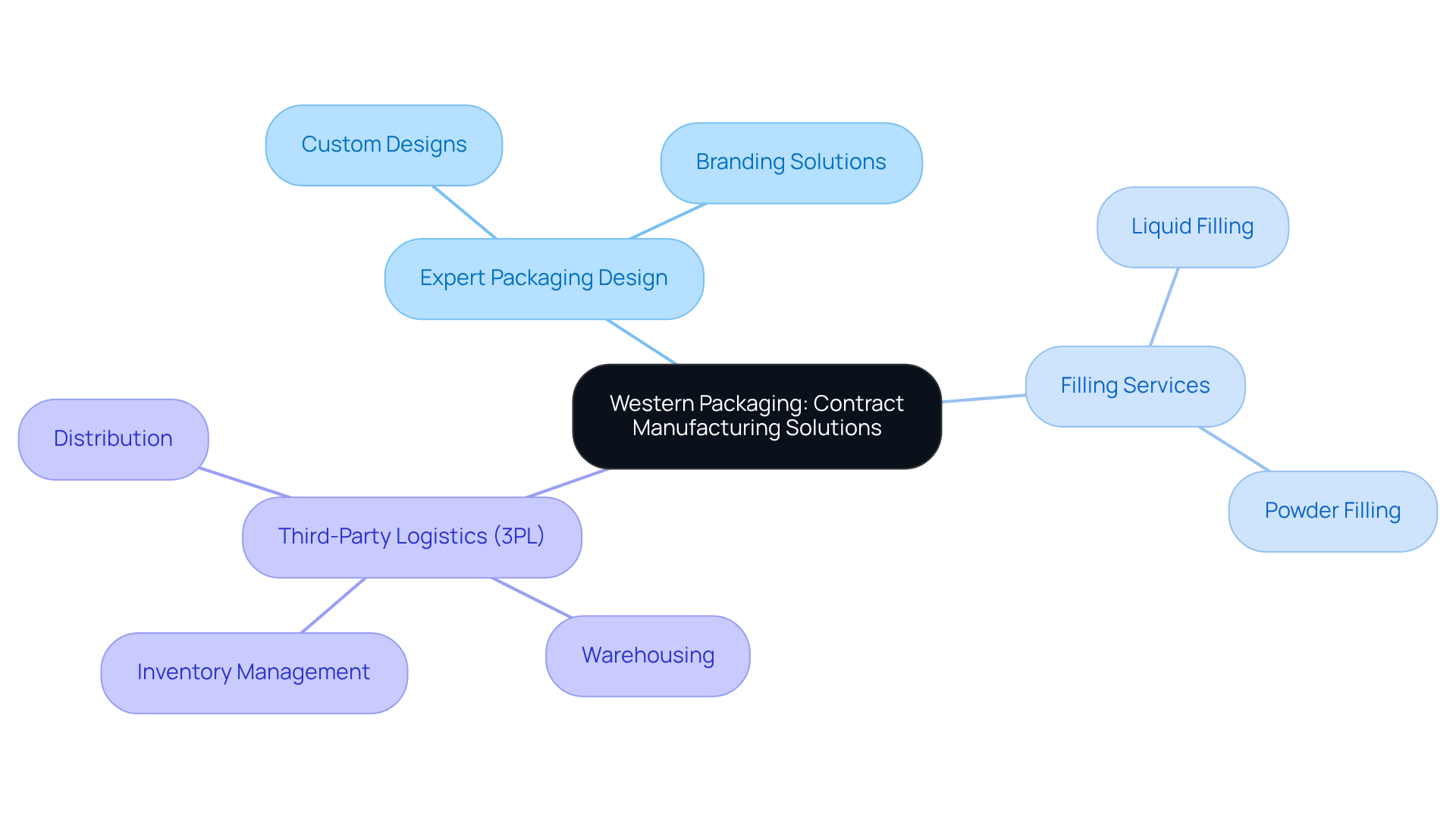

Western Packaging: Comprehensive Contract Manufacturing Solutions for Nutritional Supplements

Western Packaging & Distribution stands as a leader in contract manufacturing nutritional supplements tailored specifically for clients. Their extensive services include:

- Expert packaging design

- Filling services for a variety of item types

- Robust third-party logistics (3PL)

This integrated approach not only enhances product appeal but also streamlines supply chain operations, enabling businesses to focus on their core competencies. By leveraging customized 3PL services—such as efficient warehousing, precise inventory management, and effective distribution—companies can realize improved turnaround times and significant cost savings, all while ensuring the high-quality production of their supplements. Trust in Western Packaging & Distribution to elevate your manufacturing capabilities and drive your business forward.

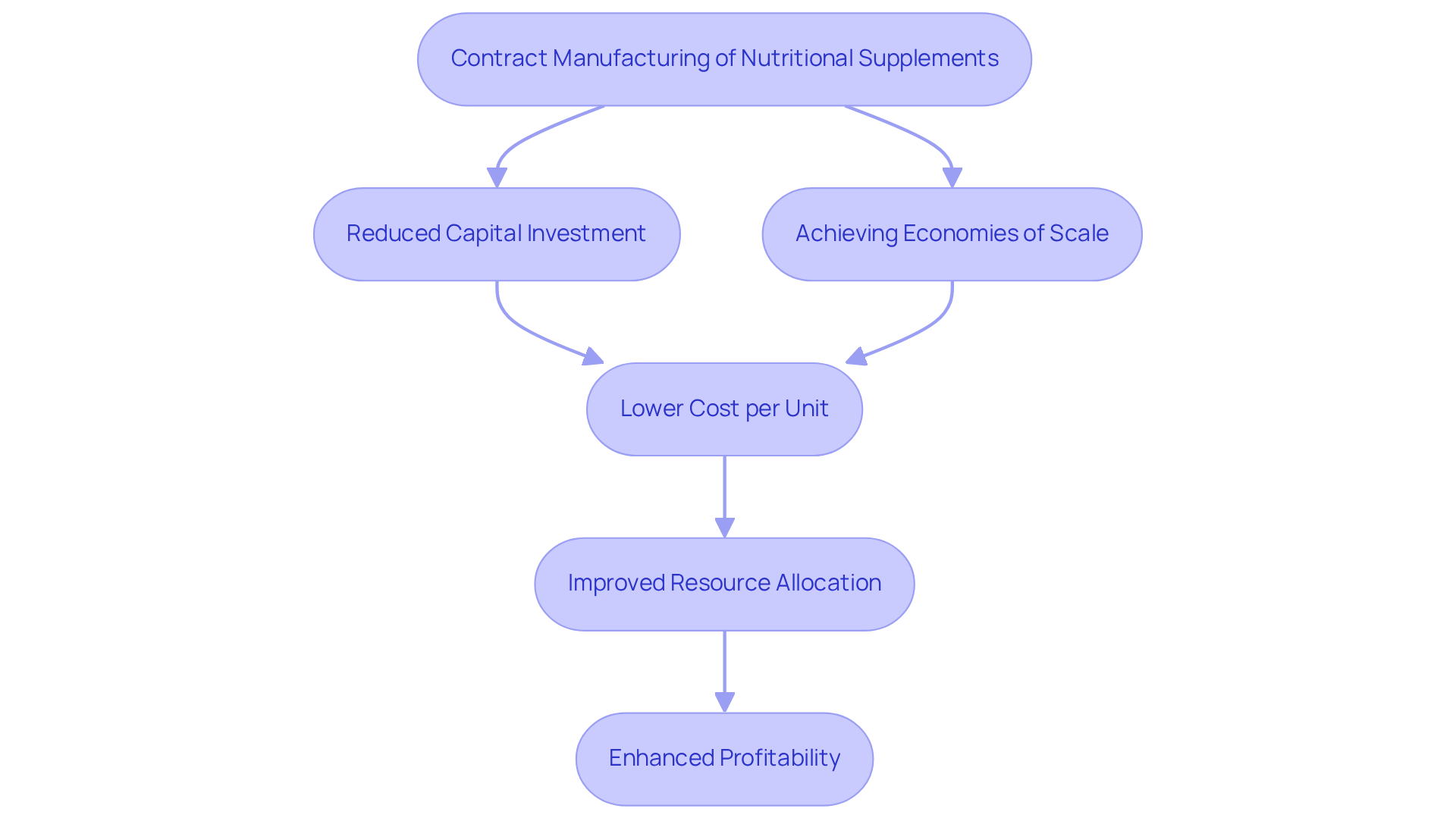

Cost Reduction: Save on Production and Operational Expenses

One of the most compelling benefits of contract manufacturing nutritional supplements lies in its potential for cost reduction. By using contract manufacturing nutritional supplements, companies can circumvent the substantial capital investment typically required for establishing manufacturing facilities and acquiring equipment. Producers engaged in contract manufacturing nutritional supplements frequently achieve economies of scale, which allows them to produce supplements at a lower cost per unit. This financial flexibility empowers brands to allocate resources more effectively, ultimately enhancing their overall profitability. Embrace the opportunity to optimize your production strategy and realize significant cost savings.

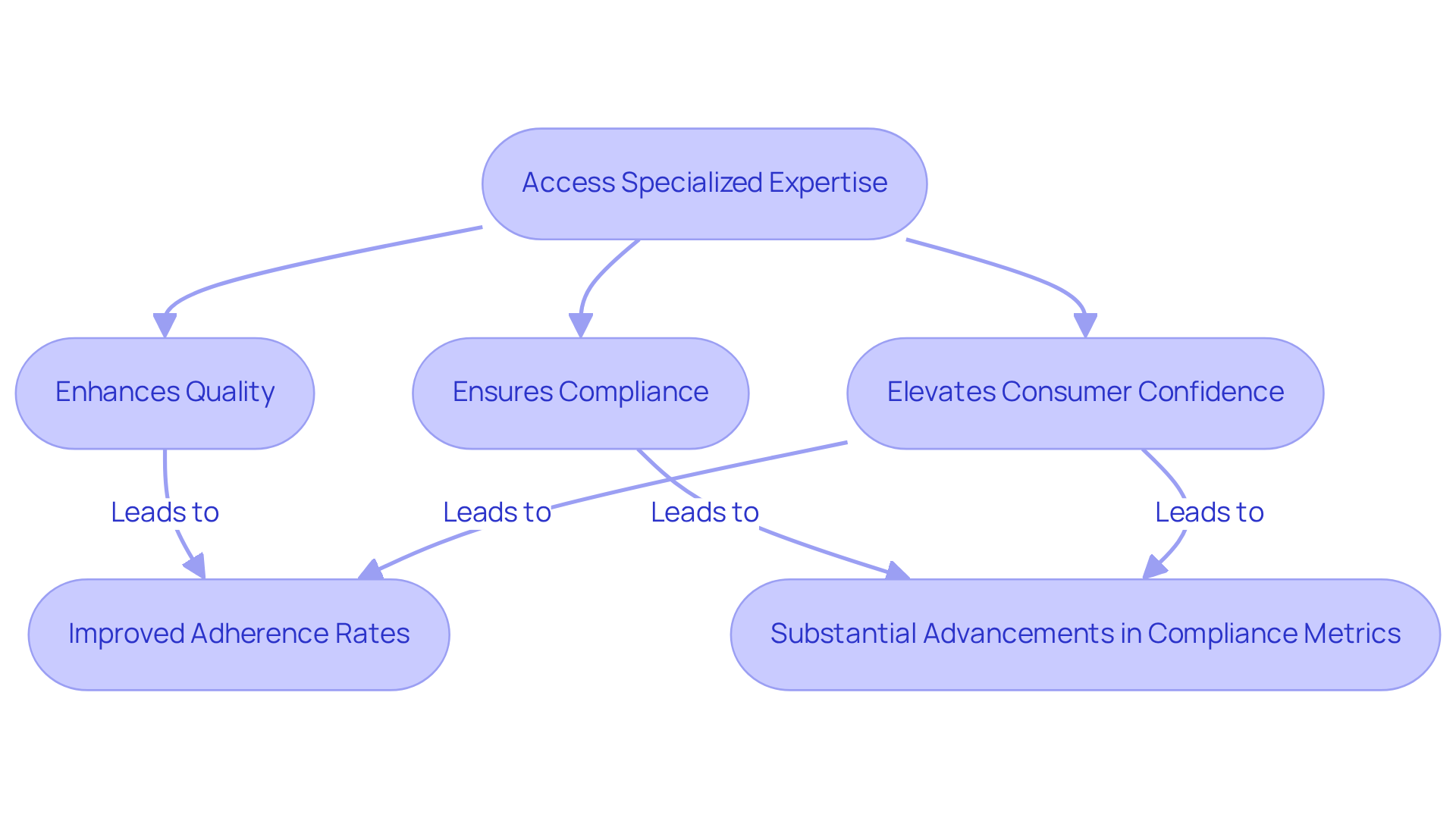

Access to Specialized Expertise: Enhance Product Quality and Compliance

Contract producers offer specialized knowledge that significantly enhances quality and ensures compliance with industry regulations. These producers are often well-versed in Good Manufacturing Practices (GMP) and hold the necessary certifications to meet stringent quality standards. By leveraging their expertise, brands can refine their product formulations, ensuring that their supplements are not only safe and effective but also compliant with regulatory requirements—ultimately elevating consumer confidence.

Looking ahead to 2025, adherence rates among production firms in the nutraceutical sector are anticipated to improve, reflecting an increasing emphasis on quality assurance. Notably, companies that have partnered with manufacturing experts have reported substantial advancements in compliance metrics, underscoring the tangible benefits of such collaborations.

As the sector evolves, the importance of GMP in manufacturing agreements becomes ever more apparent, serving as a cornerstone for supplement production that meets both consumer expectations and regulatory standards.

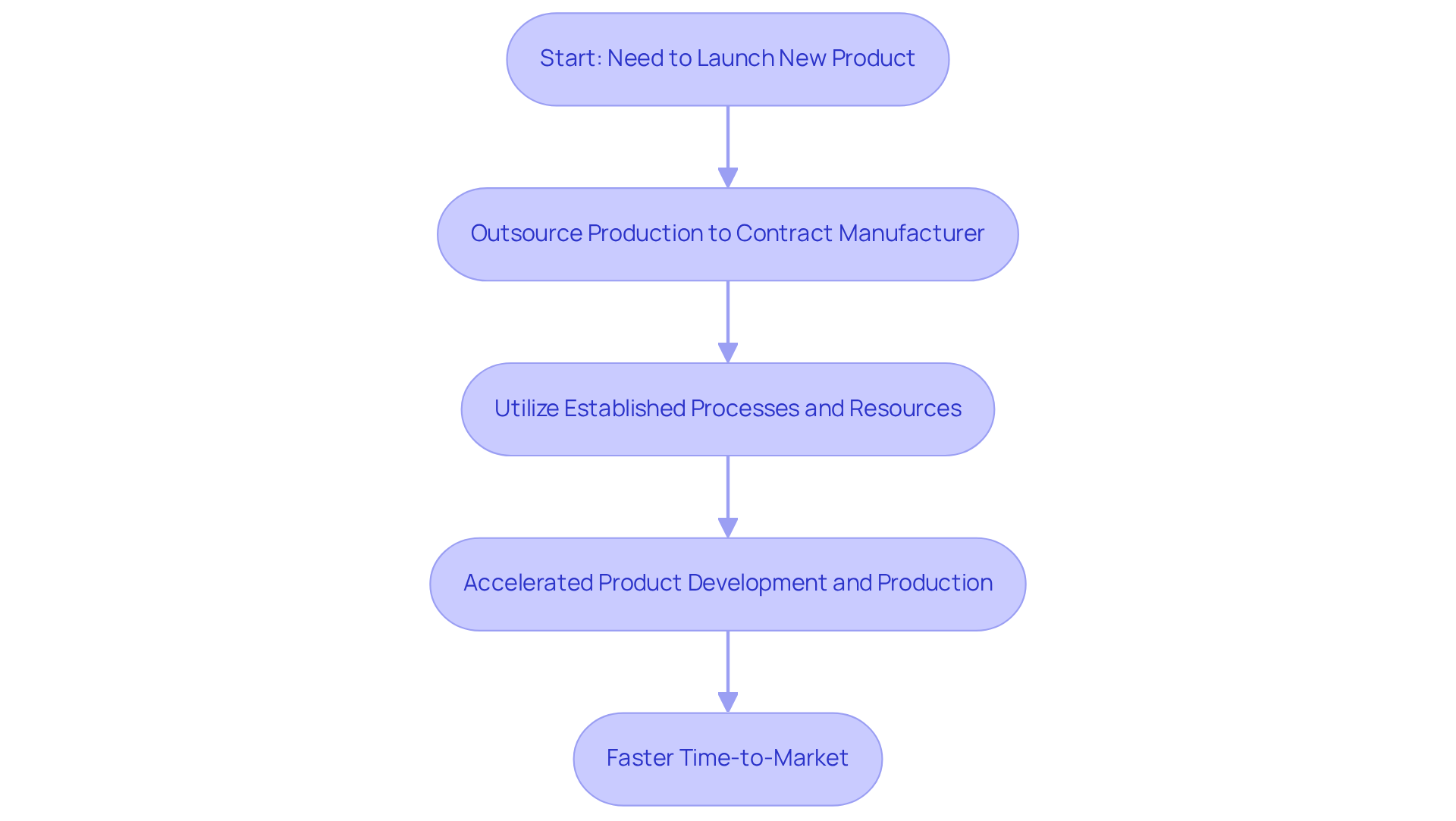

Faster Time-to-Market: Accelerate Product Launches and Market Entry

Employing contract manufacturing significantly accelerates the time required to launch a new product in the market. By outsourcing production, companies can effectively bypass the lengthy setup processes associated with in-house manufacturing. Contract manufacturers typically possess established processes and resources, which enable quicker turnaround times for product development and production. This agility empowers companies to respond swiftly to market trends and consumer demands, thereby gaining a competitive advantage. In an industry where speed and efficiency are paramount, leveraging contract manufacturing is not just a strategy; it is a necessity for sustained success.

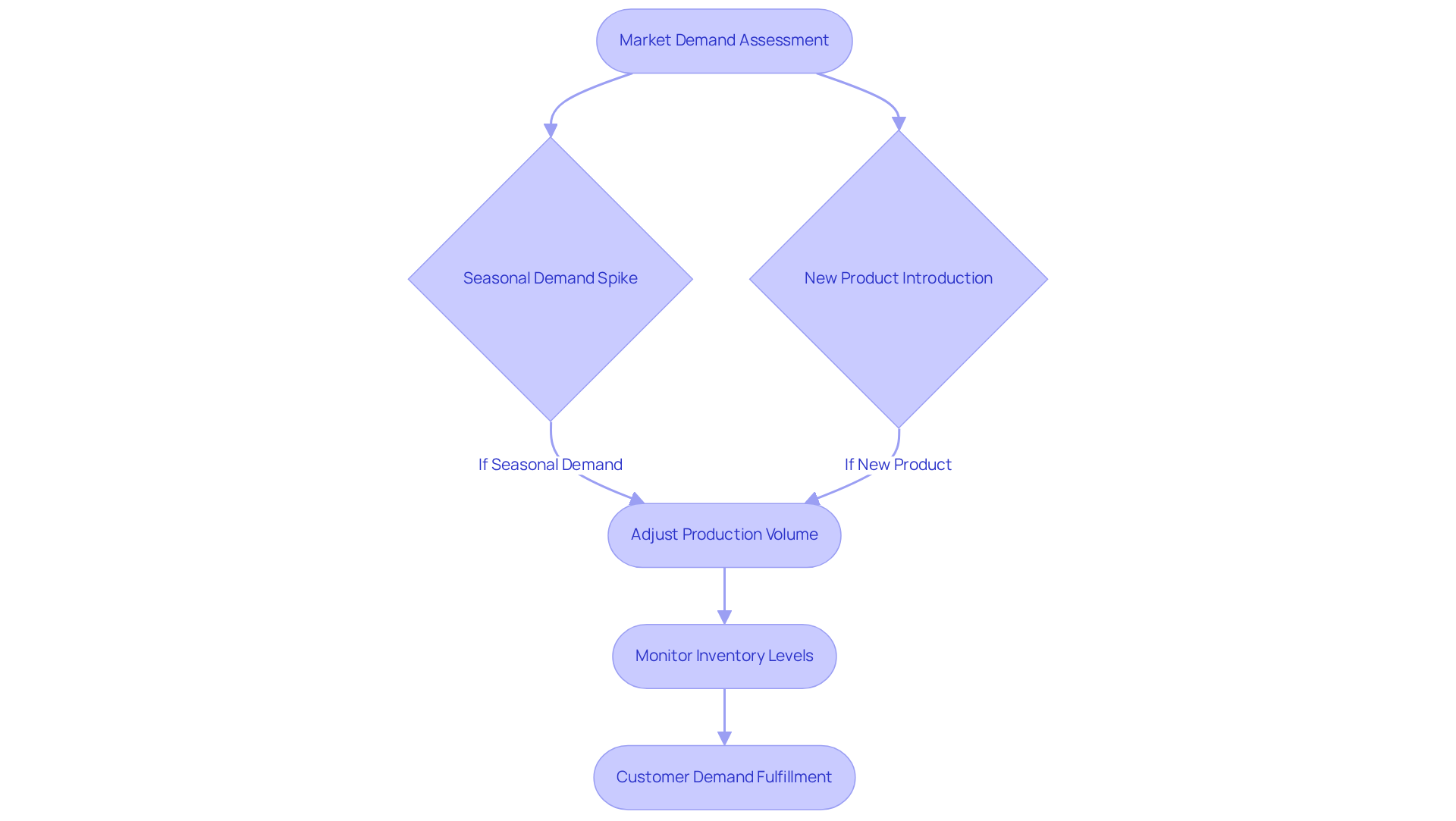

Scalability and Flexibility: Adjust Production to Meet Market Needs

Contract manufacturing nutritional supplements provides unparalleled scalability and flexibility, empowering companies to adjust their production volumes in response to market fluctuations. In scenarios such as seasonal demand spikes or the introduction of new products, contract manufacturers exhibit a remarkable ability to swiftly adapt to evolving requirements. This adaptability not only helps companies avoid the pitfalls of overproduction or stock shortages but also ensures they can meet customer demand efficiently, minimizing unnecessary costs. Embrace the reliability of contract manufacturing nutritional supplements to enhance your operational efficiency and responsiveness in a dynamic market.

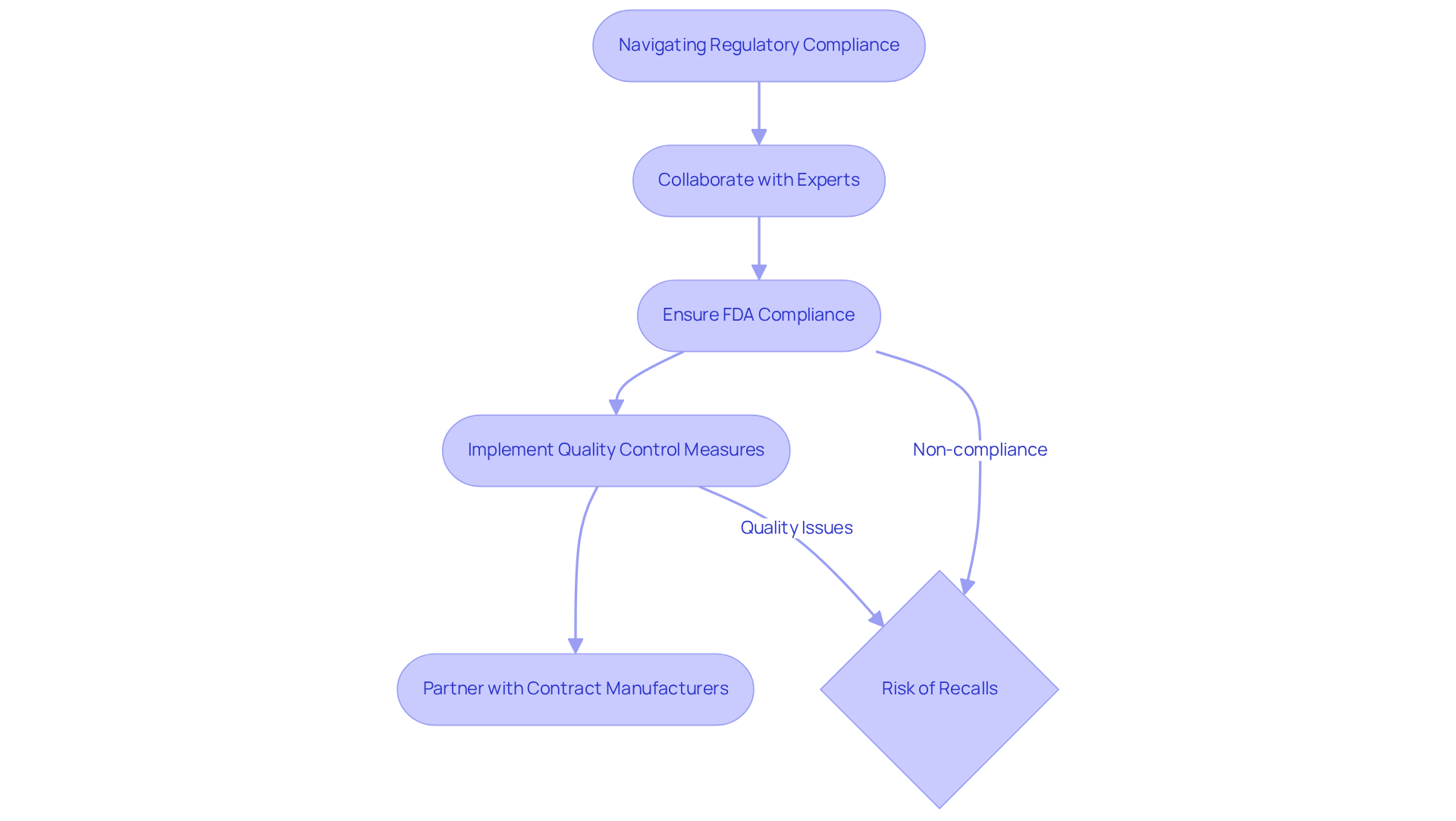

Regulatory Compliance: Ensure Adherence to Industry Standards

Navigating the regulatory landscape presents a significant challenge for nutraceutical companies, especially in 2025, where strict adherence to regulations is imperative. Contract manufacturing nutritional supplements entails manufacturers offering extensive knowledge of the regulations governing dietary supplements, including labeling, safety, and quality standards.

By collaborating with these experts, companies can effectively ensure compliance with the FDA's 21 CFR 111, which outlines essential specifications for identity, purity, strength, composition, and potential contaminants. This proactive strategy not only mitigates the risk of costly recalls—statistics indicate that non-compliant dietary supplements face recall rates exceeding 10%—but also bolsters consumer confidence in the brand.

Furthermore, successful companies often demonstrate compliance with industry standards through strategic outsourcing, leveraging the expertise of external producers to maintain rigorous quality control. For instance, companies that implement a robust statistical sampling plan for finished product testing significantly enhance their capability to meet regulatory requirements.

Ultimately, partnering with a GMP-compliant and ISO 17025 accredited contract manufacturer for contract manufacturing nutritional supplements empowers nutraceutical brands to navigate the complexities of regulatory compliance while concentrating on their core competencies.

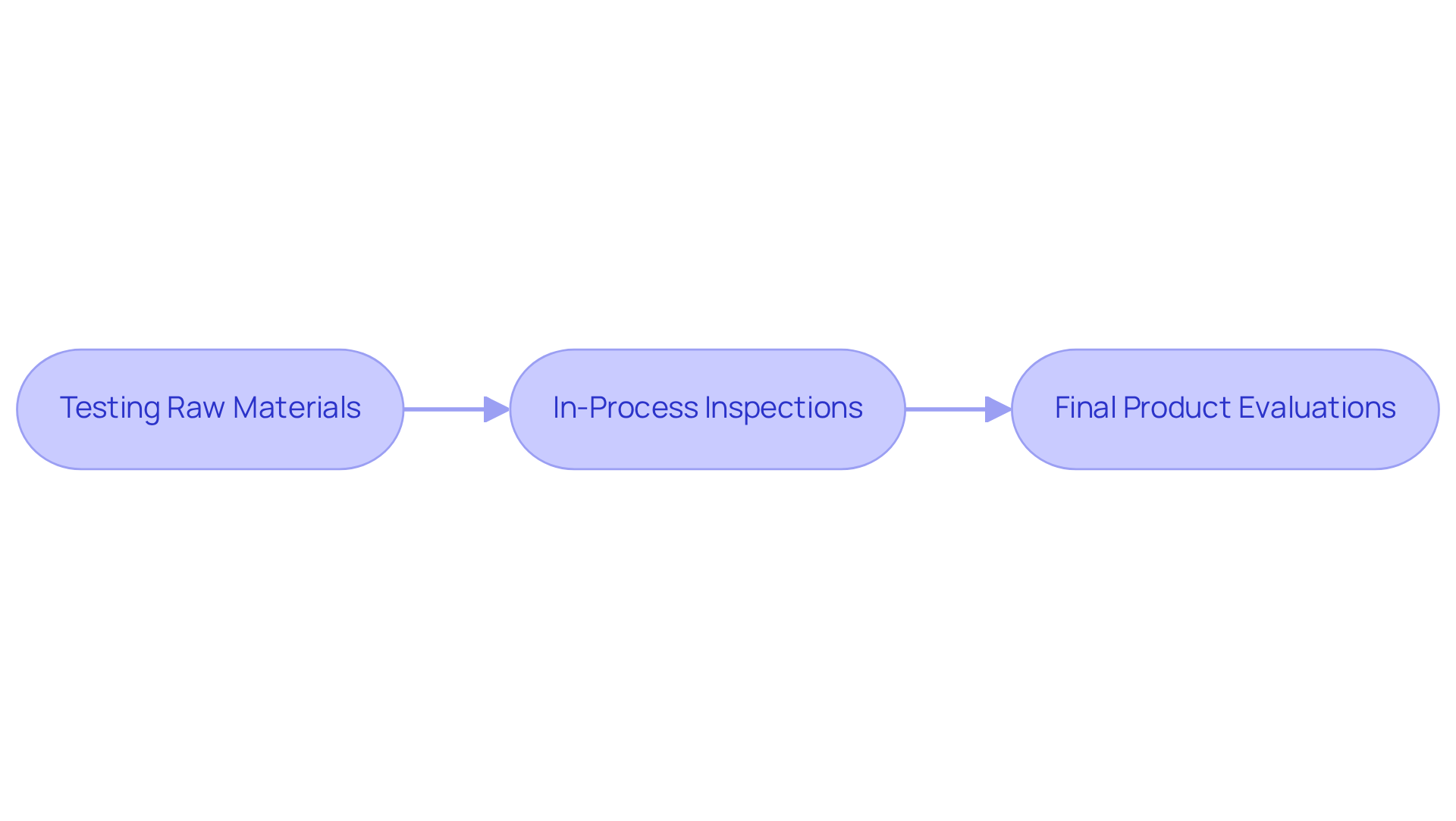

Quality Control: Maintain High Standards in Supplement Production

Contract manufacturing nutritional supplements ensures that contract producers uphold exceptional production standards through rigorous quality control measures at every stage of the supplement production process. This commitment includes:

- Comprehensive testing of raw materials

- Meticulous in-process inspections

- Thorough evaluations of final products

By adhering to these stringent protocols, producers significantly lower defect rates, which are anticipated to remain below industry averages in 2025. For instance, the Medical Laboratories of the Reinier de Graaf Hospital have successfully automated their vitamin testing services, resulting in substantial time and cost savings while maintaining high-quality standards. Such diligence in the contract manufacturing of nutritional supplements not only ensures their safety and efficacy but also strengthens the company's reputation and enhances consumer trust.

As Dr. Frans van der Horst noted, "This flexible set-up enables us to perform the wide range of individual sample processing steps we require," highlighting the importance of adaptable quality control systems. Brands that utilize contract manufacturing nutritional supplements with production partners recognized for their quality assurance practices often report higher customer satisfaction and loyalty. As the nutraceutical market continues to evolve, maintaining these high standards will be essential for companies aiming to thrive in a competitive landscape.

Focus on Core Competencies: Streamline Operations and Enhance Efficiency

Delegating production to external manufacturers empowers companies to concentrate on their core strengths—marketing, sales, and product development. This strategic realignment enables a more effective allocation of resources, significantly enhancing operational efficiency.

As Elisa Martínez de Miguel notes, 'outsourced manufacturing enables companies to reduce capital expenditure, as they can invest less in manufacturing infrastructure and equipment.' By entrusting production to specialized experts, companies can dedicate more time and energy to expanding their business and addressing customer needs. This focus not only drives success in the competitive nutraceutical market but also fosters innovation and responsiveness to market demands.

Businesses that have embraced manufacturing agreements have reported improved inventory turnover rates and shortened lead times—critical factors for sustaining a competitive advantage. Jesper Momme emphasizes that 'outsourcing reduces the cost of assets, facilitates core competencies to reduce production costs,' underscoring the financial benefits of this approach.

As the nutraceutical sector continues to evolve, companies aiming to optimize operations and enhance market presence will find that contract manufacturing nutritional supplements is essential. To implement these strategies effectively, companies should consider evaluating potential producers for contract manufacturing nutritional supplements based on their expertise and alignment with business objectives.

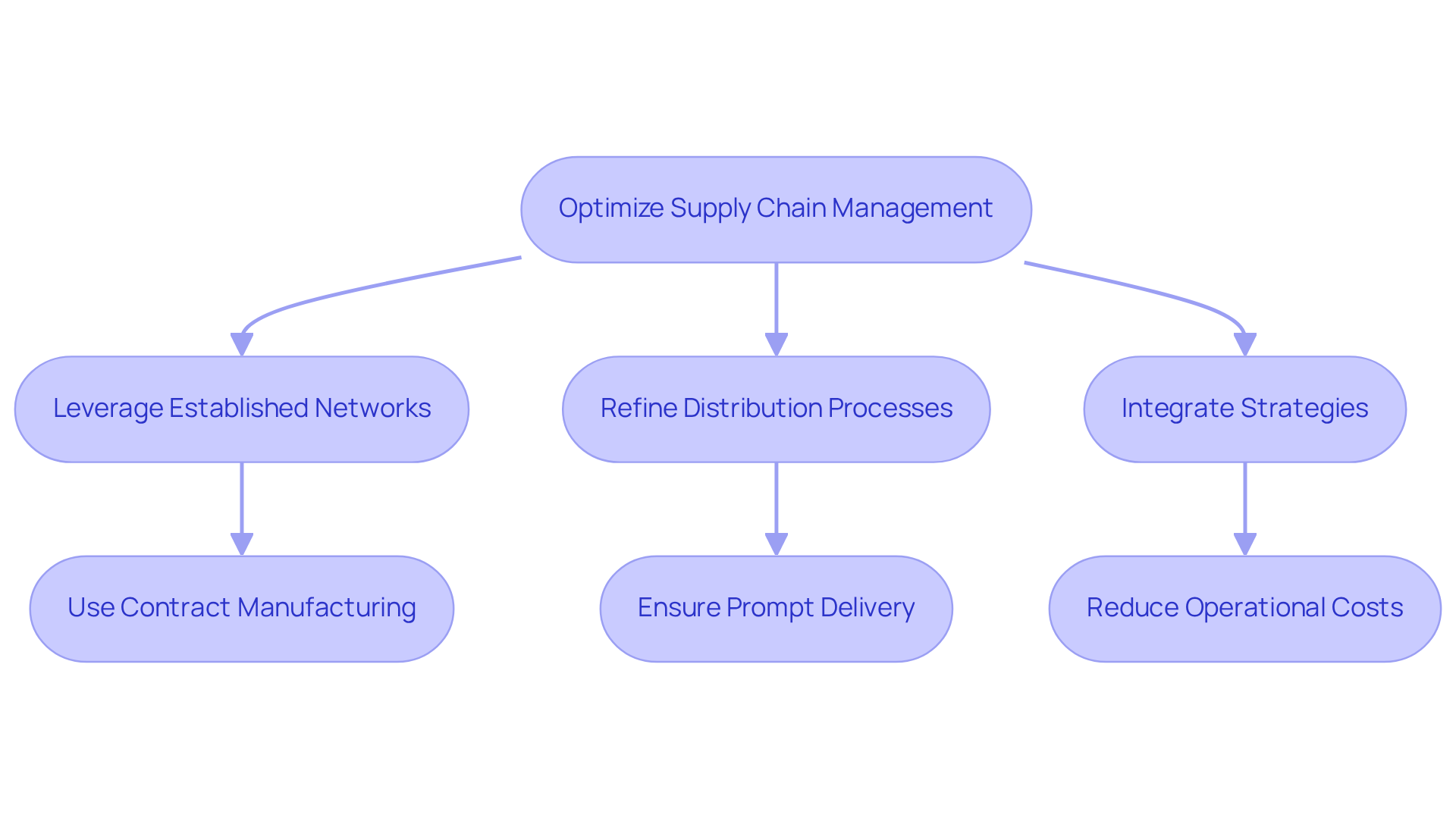

Improved Supply Chain Management: Optimize Logistics and Distribution

Contract manufacturing nutritional supplements allows manufacturers to leverage established logistics and distribution networks that can significantly enhance supply chain management for brands. By leveraging these networks, companies can refine their distribution processes, ensuring prompt delivery of goods to customers.

Western Packaging amplifies this efficiency through its integrated filling process, adeptly accommodating a diverse range of products, from powders to gummies and soft-gels. Our comprehensive 3PL services optimize warehousing and logistics, empowering companies to reduce operational costs while concentrating on their core business activities.

To fully capitalize on these advantages, companies should contemplate integrating similar strategies into their operations, thereby achieving improved supply chain efficiency.

Innovation in Product Development: Leverage Manufacturer Expertise for New Formulations

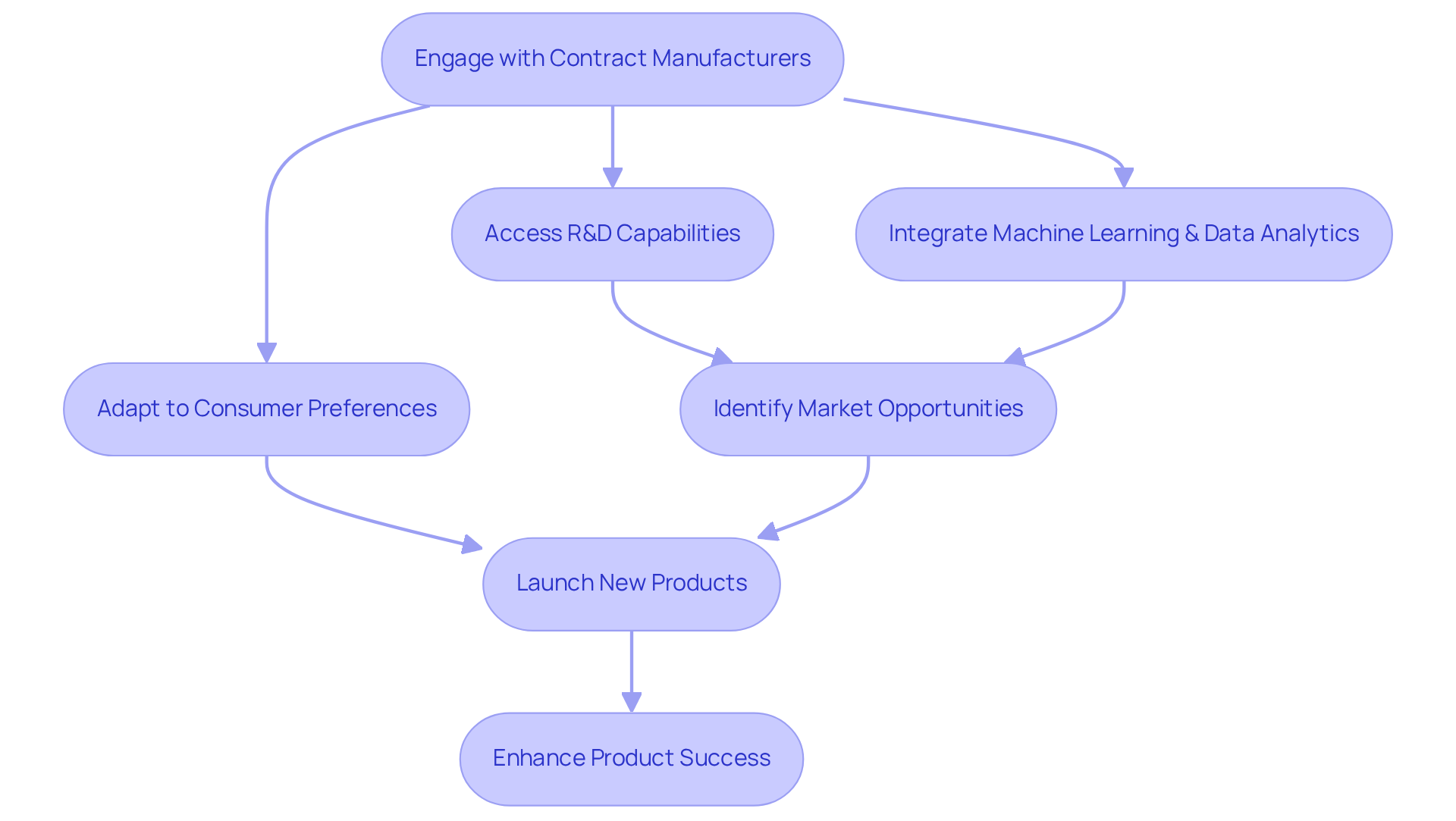

Engaging with contract manufacturing nutritional supplements allows brands to access advanced research and development capabilities, which are essential for crafting innovative nutraceutical formulations. These producers possess specialized knowledge and resources that empower them to develop new product varieties tailored to evolving consumer preferences. For instance, companies like Funtrition®, boasting over 20 years of expertise in advanced gummy technologies, have effectively launched a diverse range of gummy products, showcasing their ability to adapt to market demands with agility. By leveraging the expertise and technological advancements of contract producers, brands can adeptly navigate the complexities of development, ensuring they remain competitive in a rapidly changing market.

The integration of machine learning and data analytics into development processes enables creators to identify emerging trends and consumer needs more effectively. Research reveals that machine learning algorithms can uncover up to 50% more market opportunities compared to traditional methods. This strategic approach not only accelerates the development cycle but also enhances the likelihood of success for new offerings. Leading firms achieve development cycle times that are 20%-25% faster than their competitors, particularly during challenging periods such as the COVID-19 pandemic, when many increased their new product development investments by over 20%.

Moreover, the flexibility afforded by production companies allows brands to scale output in response to demand, thereby mitigating the risks associated with new product introductions. This adaptability is critical, especially given that nearly 95% of new products fail, with approximately 30,000 new products launched each year, underscoring the necessity for a robust support system in product development. By partnering with seasoned experts in contract manufacturing nutritional supplements, brands can significantly enhance their chances of success, ensuring that their new formulations resonate with consumers and effectively meet market demands.

Conclusion

Engaging in contract manufacturing for nutritional supplements presents businesses with a strategic avenue to enhance efficiency, reduce costs, and improve product quality. By collaborating with specialized manufacturers, companies can leverage expert knowledge and established processes that streamline production while ensuring compliance with industry regulations. This partnership not only allows brands to concentrate on their core competencies but also positions them to respond swiftly to market demands, making it a vital component of a successful business strategy.

Throughout this discussion, several key benefits of contract manufacturing have been underscored, including:

- Significant cost reductions through economies of scale

- Accelerated time-to-market

- Improved supply chain management

The ability to adapt production levels to meet fluctuating market demands further highlights the flexibility that contract manufacturing offers. Additionally, maintaining high standards of quality control and regulatory compliance guarantees that products meet consumer expectations and safety standards.

Ultimately, embracing contract manufacturing in the nutritional supplement industry is not merely a tactical decision; it is a strategic imperative for sustained growth and innovation. As the market continues to evolve, companies are urged to evaluate their manufacturing partnerships carefully, ensuring alignment with their business objectives. By doing so, they can not only enhance their operational capabilities but also position themselves as leaders in the competitive landscape of nutritional supplements.

Frequently Asked Questions

What services does Western Packaging & Distribution offer for nutritional supplements?

Western Packaging & Distribution provides expert packaging design, filling services for various item types, and robust third-party logistics (3PL) to enhance product appeal and streamline supply chain operations.

How does contract manufacturing help in cost reduction for nutritional supplements?

Contract manufacturing allows companies to avoid substantial capital investments needed for manufacturing facilities and equipment. It enables producers to achieve economies of scale, resulting in a lower cost per unit, which enhances overall profitability.

What specialized expertise do contract producers provide?

Contract producers offer specialized knowledge in Good Manufacturing Practices (GMP) and hold necessary certifications to meet quality standards. This expertise helps brands refine product formulations, ensuring safety, effectiveness, and regulatory compliance.

What is the anticipated trend for compliance rates in the nutraceutical sector by 2025?

Compliance rates among production firms in the nutraceutical sector are expected to improve by 2025, reflecting a growing emphasis on quality assurance.

Why is adherence to Good Manufacturing Practices (GMP) important in supplement production?

Adherence to GMP is crucial as it ensures that supplement production meets consumer expectations and regulatory standards, thereby elevating product quality and consumer confidence.