Overview

The article titled "7 Benefits of Contract Manufacturing Organization for Nutraceuticals" presents a compelling examination of the advantages that contract manufacturing organizations (CMOs) provide to businesses within the nutraceutical sector. It articulates key benefits such as:

- Cost optimization

- Operational efficiency

- Access to specialized expertise

These advantages empower companies to enhance their productivity, reduce expenses, and improve product quality, ultimately allowing them to focus on their core competencies. By leveraging the expertise of CMOs, businesses can achieve significant operational improvements and drive success in a competitive market.

Introduction

The nutraceutical industry is witnessing remarkable growth, propelled by heightened consumer health awareness and an escalating demand for innovative products. In this dynamic landscape, contract manufacturing organizations (CMOs) have emerged as essential partners, providing a spectrum of benefits capable of transforming business operations. Yet, the pivotal question persists: how can companies effectively harness these partnerships to not only boost efficiency but also sustain a competitive edge in a swiftly evolving market? This article explores seven key advantages of employing CMOs for nutraceuticals, offering insights that could redefine operational strategies and foster sustainable growth.

Western Packaging: Integrated Packaging Solutions for Enhanced Supply Chain Efficiency

Western Packaging provides a comprehensive suite of integrated packaging solutions specifically designed to significantly enhance supply chain efficiency within the nutraceutical sector. By seamlessly combining expert packaging design, filling services, and robust third-party logistics (3PL)—including warehousing, inventory management, and distribution—the organization simplifies the entire process for its clients. This integrated approach has demonstrated a reduction in lead times, with certain firms reporting a 25% decrease after utilizing a single provider for their packaging needs. Moreover, aligning packaging production with manufacturing schedules can eliminate weeks from time-to-market, a crucial advantage in the fast-paced nutraceutical industry.

Industry leaders underscore the significance of this integration, highlighting that it not only streamlines operations but also enhances product delivery and brand consistency. For example, a prominent FMCG firm realized a 30% reduction in damage-related costs by adopting an integrated packaging solution, illustrating the tangible benefits of this strategy.

Western Packaging's unwavering commitment to innovation and quality empowers clients to concentrate on their core competencies while enjoying improved operational efficiency. As the demand for sustainable and effective packaging solutions continues to rise, the company's capacity to deliver customized services tailored to the unique needs of nutraceutical manufacturers establishes it as a preferred contract manufacturing organization in the industry. With the global product packaging design services sector projected to reach $32.42 billion by 2030, the trend towards integrated solutions is unmistakable, positioning Western Packaging as a vital player in optimizing supply chains for nutraceuticals.

Quality Control: Ensuring Safety and Compliance in Manufacturing Processes

Quality assurance in a contract manufacturing organization is paramount, encompassing rigorous testing and strict adherence to industry standards. Companies such as Western Packaging exemplify this commitment by implementing comprehensive quality assurance protocols designed to ensure that all products consistently meet safety standards. This process involves:

- Regular audits

- Thorough testing for contaminants

- Strict compliance with Good Manufacturing Practices (GMP)

By prioritizing quality control, businesses not only mitigate risks associated with product recalls but also significantly enhance consumer confidence in their offerings. Reliability in quality assurance is not just an operational necessity; it is a strategic advantage that fosters trust and loyalty in today’s competitive market.

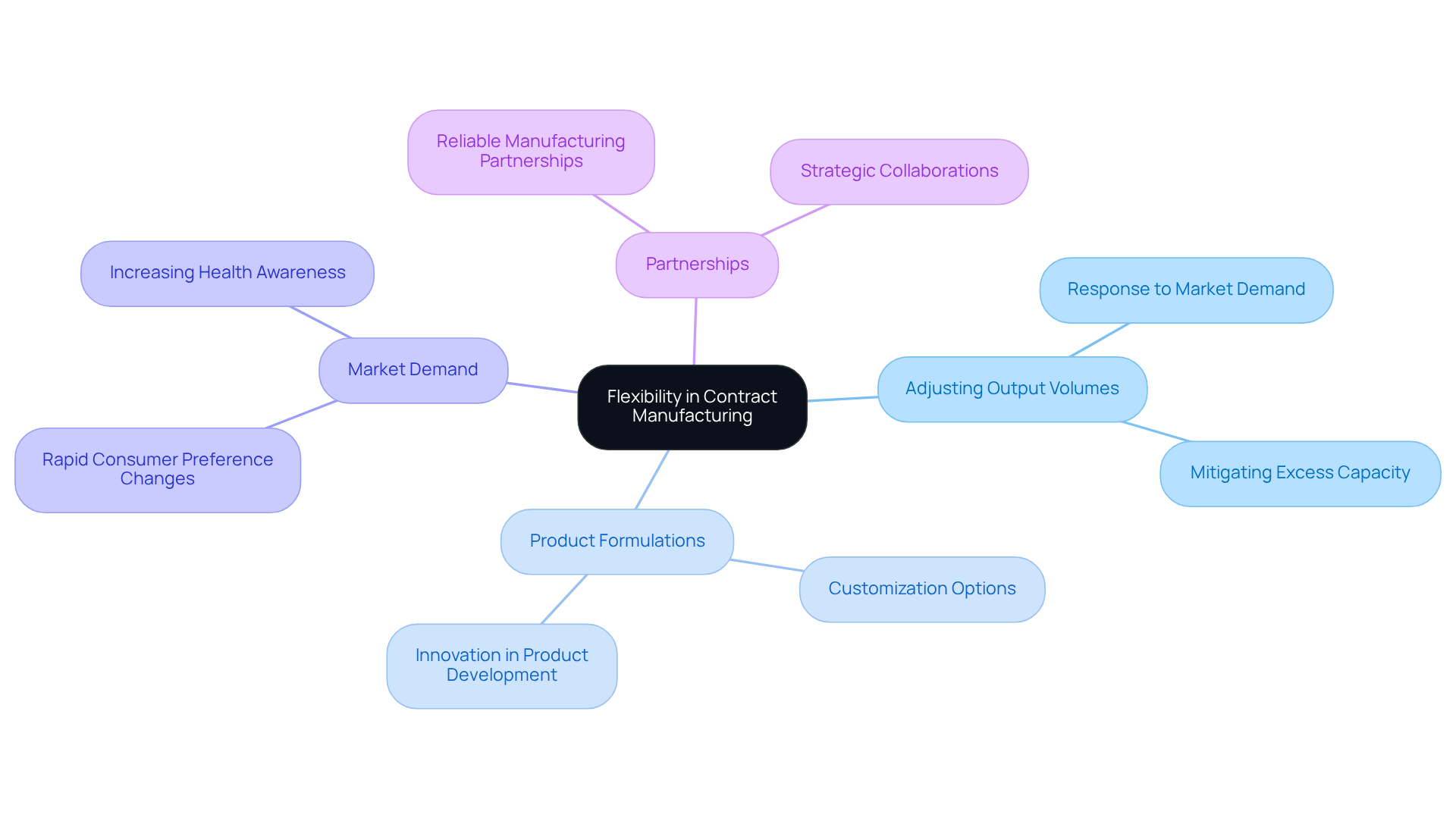

Flexibility: Adapting to Market Changes with Contract Manufacturing

Contract production provides significant flexibility, allowing businesses to adjust output volumes and product formulations in response to market demand. This adaptability is essential in the nutraceutical industry, where consumer preferences can change rapidly. By partnering with a contract manufacturing organization, companies can adjust production levels without the burden of excess capacity. This capability enables swift reactions to emerging opportunities or challenges, reinforcing the importance of reliable manufacturing partnerships.

Cost Optimization: Reducing Operational Expenses through Contract Manufacturing

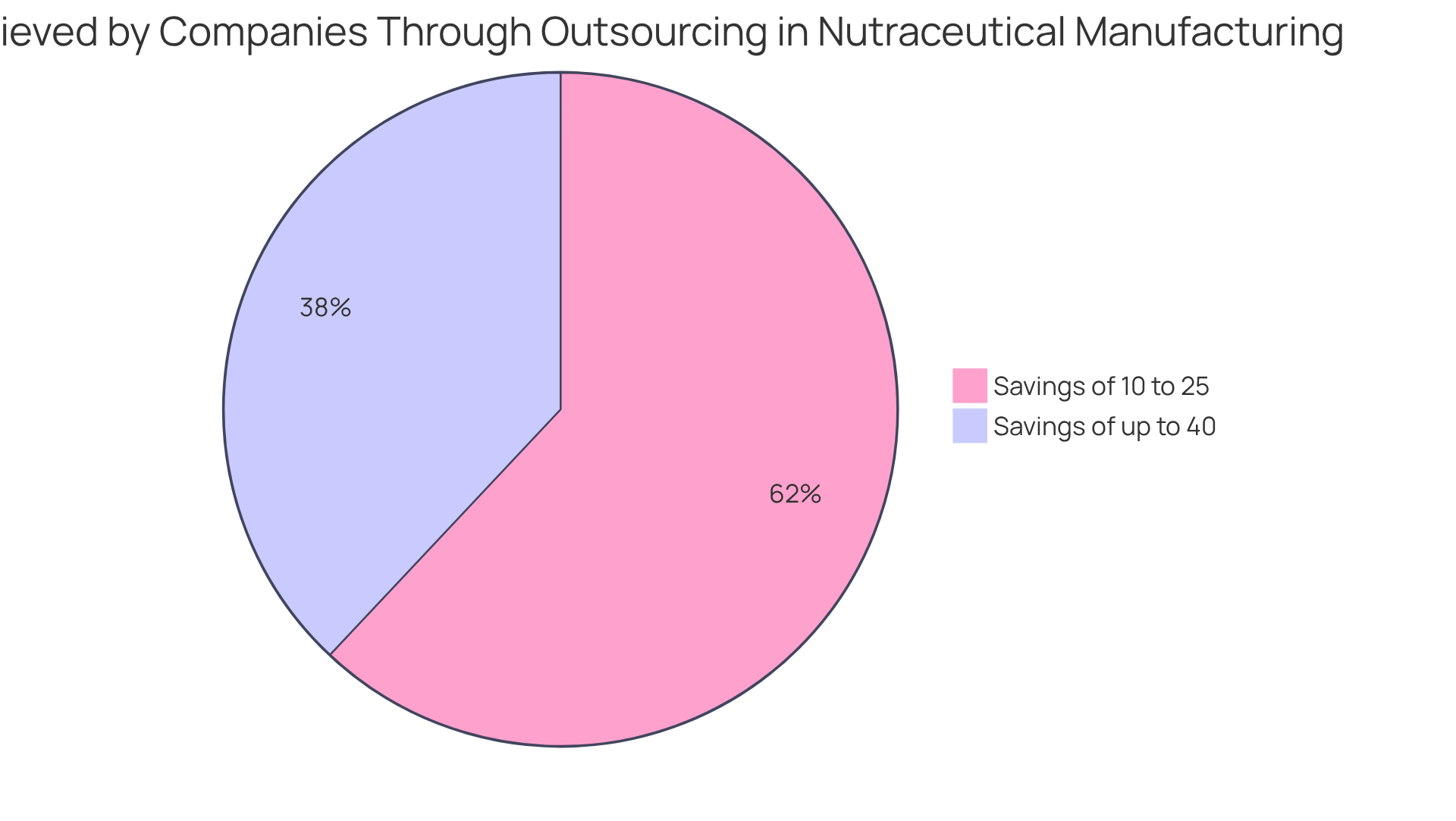

Cost optimization stands as a pivotal advantage of contract manufacturing within the nutraceutical industry. By outsourcing production, organizations can significantly reduce operational costs tied to labor, equipment, and facility upkeep. Contract manufacturing organizations capitalize on economies of scale, which enables them to offer competitive pricing and lower per-unit costs. This financial efficiency not only bolsters profitability but also allows businesses to redirect resources toward innovation and marketing initiatives rather than being encumbered by production overhead.

In 2018, 62% of companies reported savings ranging from 10% to 25% due to outsourcing, while 38% noted savings as high as 40%. For example, NutraLab, a specialist in vitamins providing both OEM and private-label services, has effectively lowered costs while upholding high-quality standards by collaborating with specialized contract manufacturers.

As the nutraceutical market continues to expand—projected to reach USD 386.6 billion by 2033 with a CAGR of 8.7% during the forecast period from 2025 to 2033—the trend of outsourcing production is poised to play a crucial role in enabling businesses to optimize their operations and maintain a competitive edge.

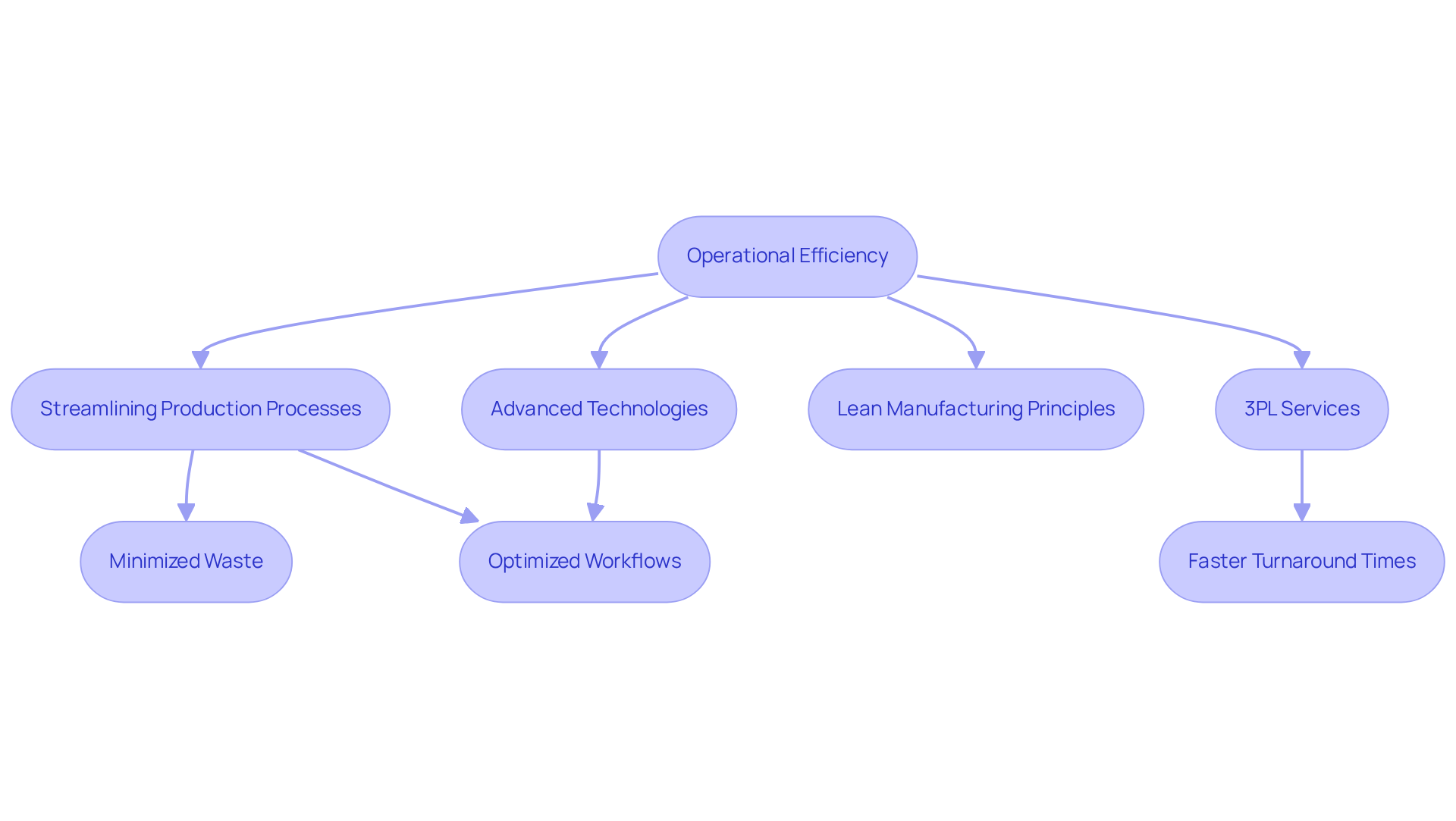

Operational Efficiency: Streamlining Production for Increased Productivity

A contract manufacturing organization significantly enhances operational efficiency by streamlining production processes. Manufacturers, such as Western Packaging, leverage advanced technologies and lean manufacturing principles to minimize waste and optimize workflows effectively. Their filling process seamlessly integrates into comprehensive end-to-end solutions tailored for flexible packaging needs, accommodating a diverse range of products from powders to gummies and soft-gels.

Furthermore, Western Packaging’s extensive 3PL services—including warehousing, inventory management, and logistics—further optimize the supply chain. This strategic approach results in faster turnaround times and increased productivity, empowering businesses to meet consumer demand more effectively.

By prioritizing operational excellence and utilizing a contract manufacturing organization along with integrated filling and 3PL solutions, companies can significantly elevate their overall performance and profitability.

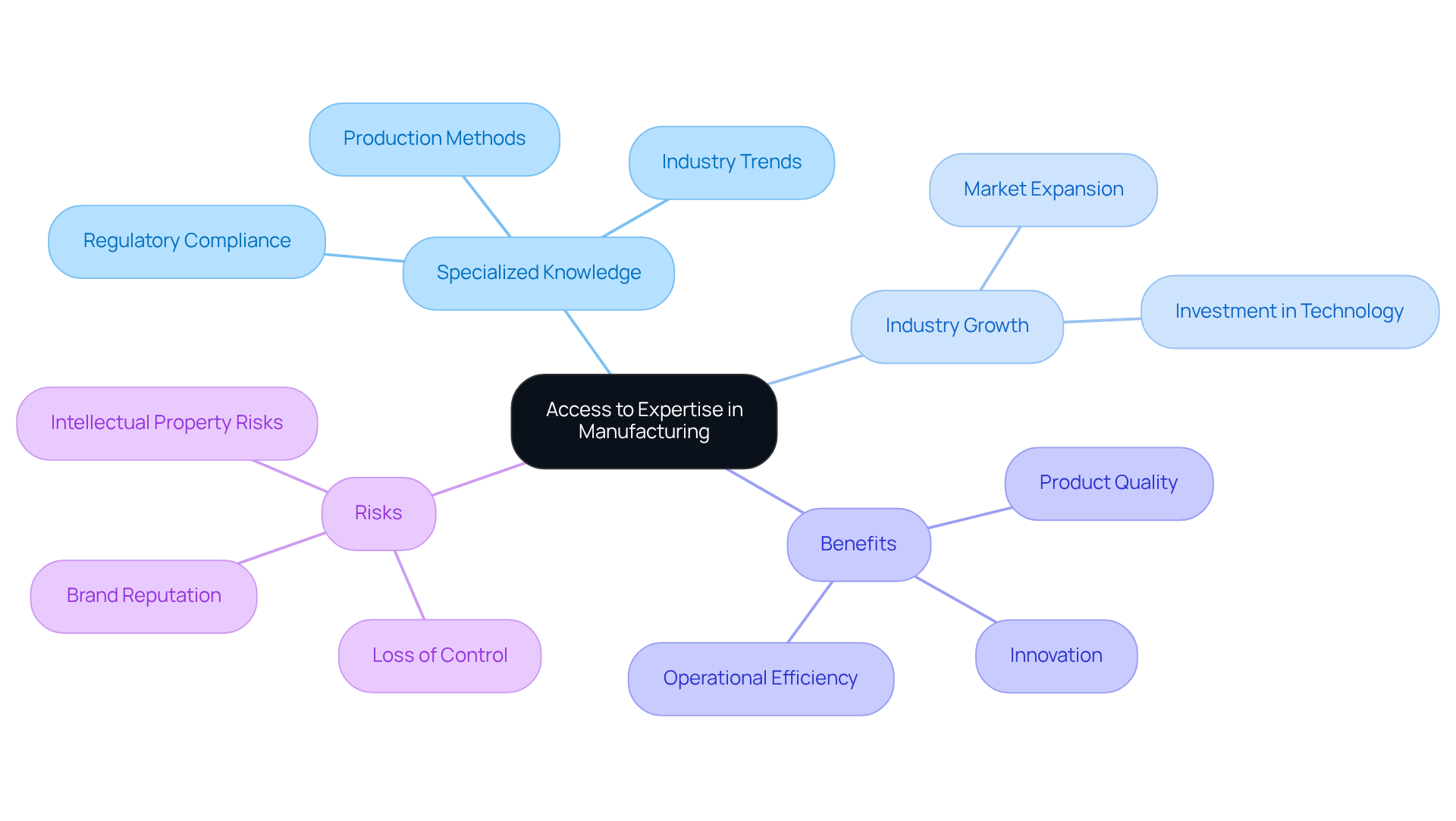

Access to Expertise: Leveraging Specialized Knowledge in Manufacturing

Collaborating with a contract manufacturer provides businesses with access to specialized expertise that may be lacking internally. This encompasses vital information regarding regulatory compliance, advanced production methods, and current industry trends. By leveraging this expertise, organizations can significantly enhance product quality, foster innovation, and maintain a competitive edge in the dynamic nutraceutical landscape.

Notably, industry forecasts predict that the contract manufacturing organization sector will expand from 162.52 USD billion in 2024 to 300.0 USD billion by 2035, reflecting a growing reliance on specialized production capabilities. Contract manufacturers are dedicated to investing in training and cutting-edge technology, positioning themselves at the forefront of industry advancements. Firms that utilize the services of manufacturers frequently report increased operational efficiencies and improved product offerings, enabling them to swiftly respond to evolving consumer demands and regulatory standards.

However, nutraceutical manufacturers must remain vigilant about potential risks, such as loss of control over production processes and brand reputation, which can arise from outsourcing. As highlighted by industry specialist Snehal Singh, "The expansion of the food production market is propelled by rising demand for outsourcing food creation and an emphasis on sustainability." This underscores the importance of selecting the right partner to mitigate risks while maximizing the benefits of contract production.

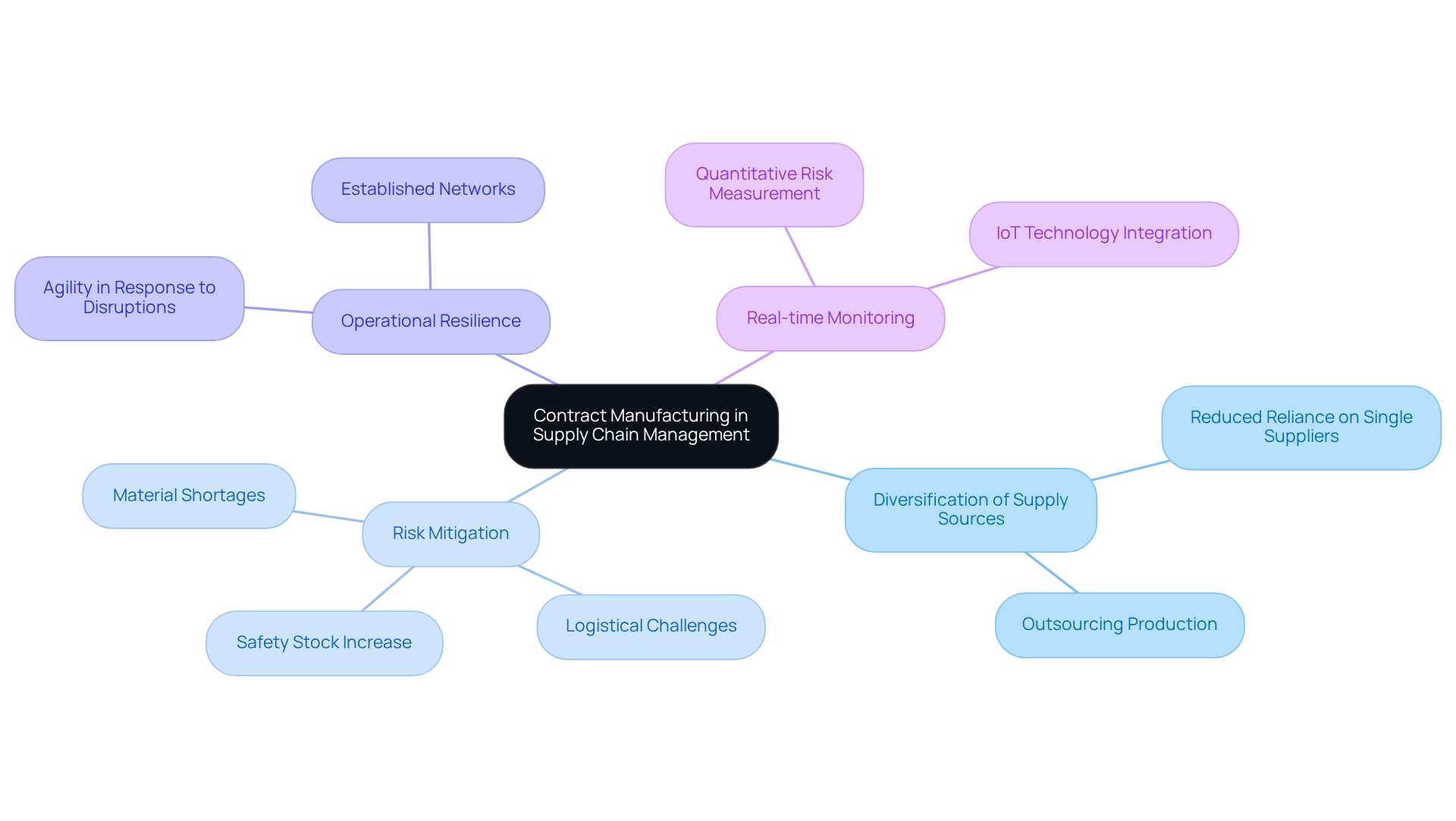

Supply Chain Management: Mitigating Disruptions with Contract Manufacturing

A contract manufacturing organization plays a pivotal role in supply chain management, equipping businesses with the agility required to effectively navigate disruptions. By outsourcing production, companies can diversify their supply sources, thereby significantly reducing reliance on single suppliers. This strategic shift not only mitigates risks associated with supply chain interruptions—such as material shortages and logistical challenges—but also bolsters operational resilience.

Contract manufacturing organizations often possess established networks that facilitate smoother operations and enable swift responses to industry fluctuations. Furthermore, with 93% of businesses actively taking steps to quantifiably measure and analyze supply chain risk, the integration of advanced systems allows for real-time monitoring and adjustments, further enhancing the capacity to manage disruptions.

By leveraging these capabilities, businesses in the nutraceutical sector can maintain continuity and meet consumer demands, even in challenging circumstances.

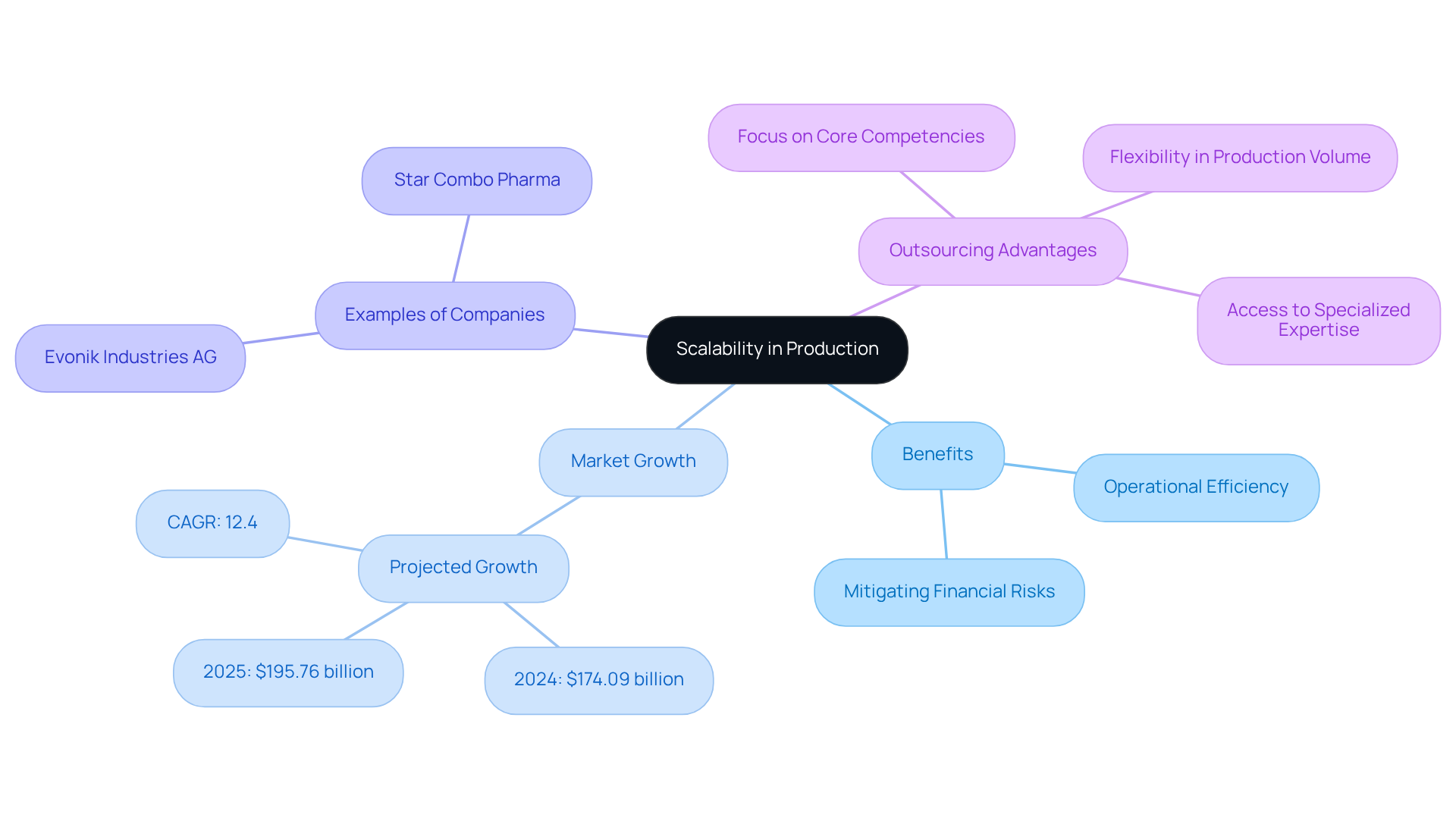

Scalability: Expanding Production Capacity without Major Investments

A contract manufacturing organization offers substantial scalability, allowing businesses to expand production capacity without significant investments in facilities or equipment. This adaptability is crucial for companies facing fluctuating demand or aiming to penetrate new markets. By leveraging the resources and expertise of a contract manufacturing organization, businesses can swiftly increase production to accommodate rising orders, thereby mitigating financial risks. This approach not only fosters sustainable growth but also enables companies to seize opportunities effectively.

For instance, the contract manufacturing organization in the nutraceutical production services sector is projected to grow from $174.09 billion in 2024 to $195.76 billion in 2025, reflecting a compound annual growth rate (CAGR) of 12.4%. This expansion is fueled by heightened consumer health awareness and the growing demand for tailored products. Noteworthy companies such as Evonik Industries AG and Star Combo Pharma have recently enhanced their production capabilities without incurring major capital expenditures, exemplifying the trend of optimizing operations through strategic partnerships.

Industry leaders assert that outsourcing production operations to a contract manufacturing organization enables companies to concentrate on core competencies like research and development, while entrusting production to specialists. Chris Barrett, a Client Partner, articulates, "A contract manufacturing organization provides adaptability in output volume, enabling companies to adjust their production levels according to demand trends." This strategic approach not only enhances operational efficiency but also empowers companies to respond adeptly to industry dynamics, ensuring they remain competitive in a rapidly evolving landscape.

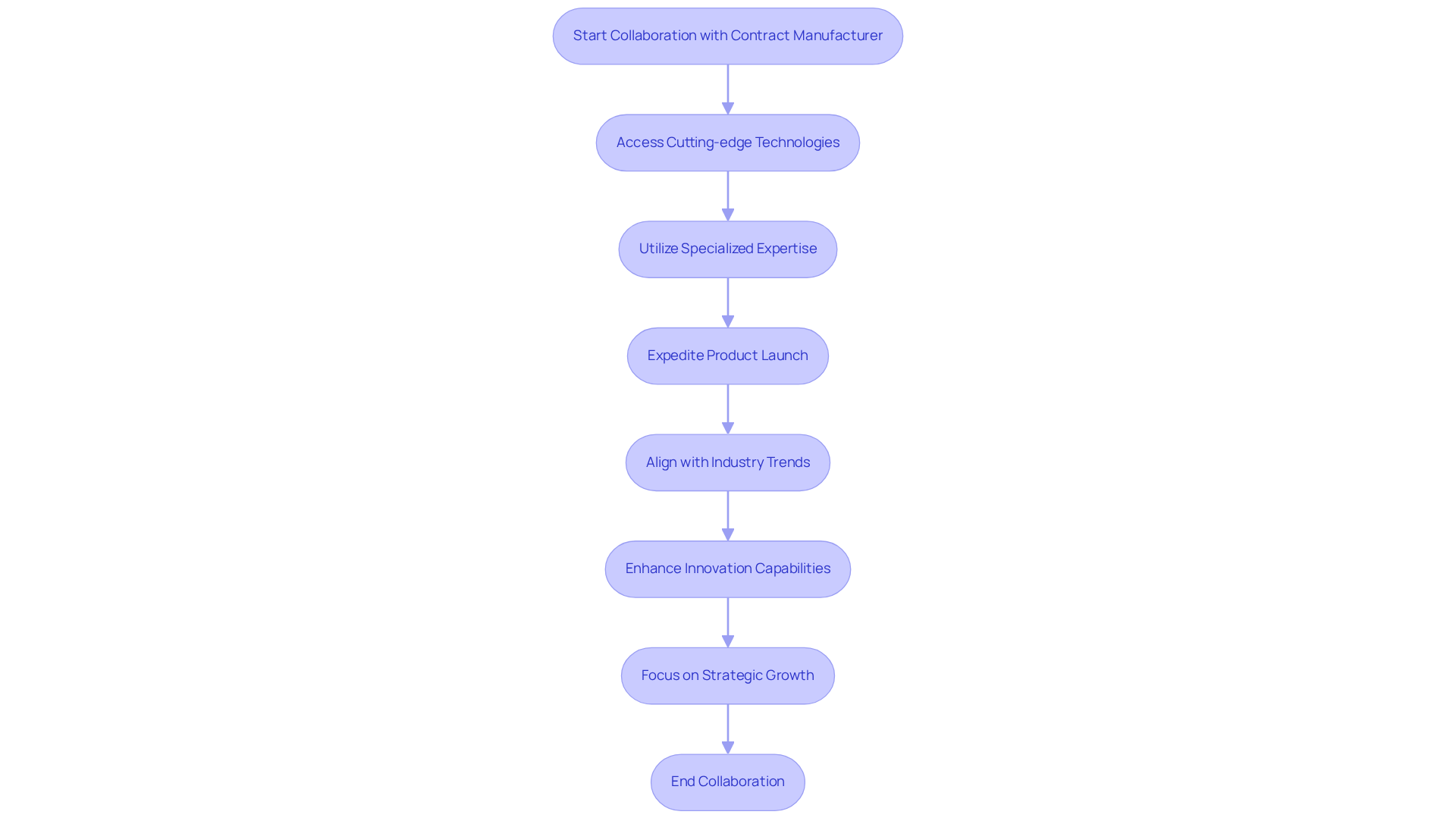

Innovation: Accelerating Product Development through Contract Manufacturing

A contract manufacturing organization significantly accelerates product development, granting access to cutting-edge technologies and specialized expertise. These manufacturers are equipped with the latest machinery and possess in-depth knowledge in formulation, enabling businesses to expedite their product launches. This agility is particularly vital in the nutraceutical sector, where consumer preferences shift rapidly. By collaborating with a contract manufacturing organization, companies can enhance their innovation capabilities, ensuring their products align with current industry trends and needs. Industry leaders highlight that outsourcing to a contract manufacturing organization simplifies the development process and encourages creativity, allowing brands to focus on strategic growth while utilizing the technical expertise of their production partners.

Recent advancements in formulation technologies, such as the integration of e-commerce solutions and sustainable practices, further illustrate how manufacturers are adapting to meet the demands of the nutraceutical industry. For instance, businesses like Arizona Nutritional Supplements have effectively employed outsourced production to enhance their product offerings, showcasing the efficiency of this strategy in boosting competitiveness in the industry. With the contract manufacturing organization sector for nutraceutical production services anticipated to reach USD 329.12 billion by 2032, expanding at a CAGR of 8.4%, the significance of these collaborations is increasingly evident. Moreover, concerns regarding ingredient contamination underscore the necessity of high-quality raw materials, reinforcing the importance of partnering with trustworthy manufacturers who prioritize quality and sustainability.

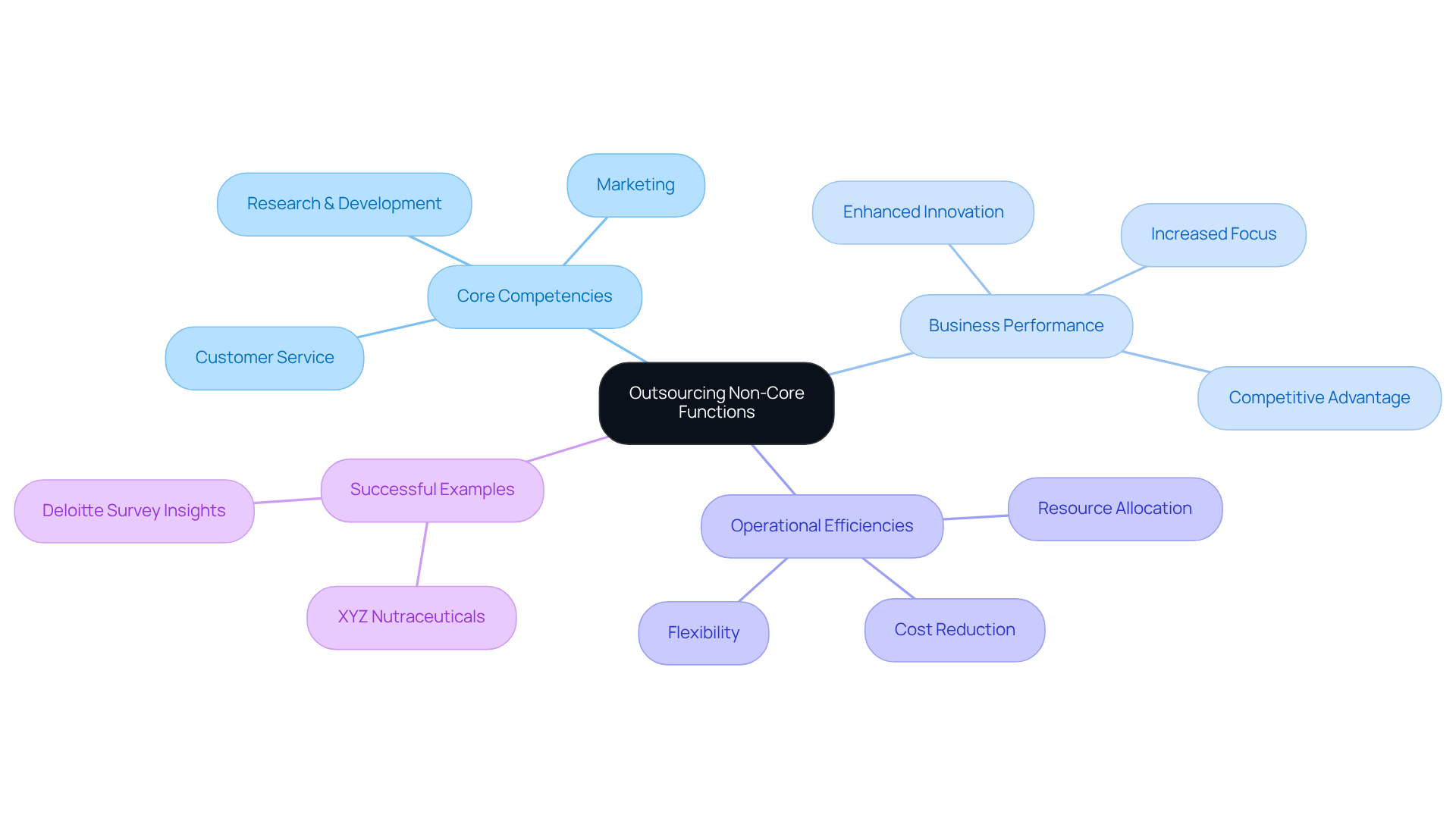

Focus on Core Competencies: Enhancing Business Strengths through Outsourcing

Outsourcing non-core functions, such as manufacturing, empowers businesses to concentrate on their core competencies. By partnering with a contract manufacturing organization, companies can redirect resources toward essential areas like research and development, marketing, and customer service. This strategic focus not only enhances overall business performance but also fosters innovation and growth. Utilizing the knowledge of a production partner enables companies to enhance their competitive stance in the industry.

As industry leaders emphasize, focusing on what you do best while outsourcing the rest can lead to significant operational efficiencies and improved market responsiveness. According to a Deloitte survey, around 70% of businesses globally are turning to outsourcing to reduce operational expenses and manage supply chain issues.

Azim Premji aptly states, "Focus on your core competence and outsource the rest," highlighting the importance of this strategy. Furthermore, companies like XYZ Nutraceuticals have successfully partnered with a contract manufacturing organization to enhance their product offerings and streamline operations, demonstrating the tangible benefits of outsourcing non-core functions.

Conclusion

The advantages of partnering with a contract manufacturing organization (CMO) in the nutraceutical sector are multifaceted, providing businesses with a pathway to enhanced efficiency, quality, and adaptability. Leveraging the specialized capabilities of a CMO allows companies to streamline operations, mitigate risks, and concentrate on core competencies, ultimately driving growth in a competitive marketplace.

Key benefits highlighted throughout the article include:

- Integrated packaging solutions that enhance supply chain efficiency

- Rigorous quality control measures that ensure compliance and safety

- Flexibility to adjust production levels according to market demand

- Cost optimization through outsourcing

- Operational efficiency achieved via advanced technologies

- Access to specialized expertise that empowers businesses to innovate and effectively respond to consumer needs

In a rapidly evolving industry, the significance of these benefits cannot be overstated. The trend towards contract manufacturing is poised for substantial growth in the coming years. As organizations strive to enhance operational capabilities while maintaining focus on strategic areas, embracing the advantages of contract manufacturing becomes essential. Companies are encouraged to explore these partnerships, not only to optimize production processes but also to foster innovation and ensure long-term sustainability in the nutraceutical landscape.

Frequently Asked Questions

What integrated packaging solutions does Western Packaging offer?

Western Packaging provides a comprehensive suite of integrated packaging solutions that include expert packaging design, filling services, and robust third-party logistics (3PL) such as warehousing, inventory management, and distribution.

How does Western Packaging enhance supply chain efficiency?

By combining various packaging services into one solution, Western Packaging simplifies the process for clients, leading to reduced lead times and improved alignment of packaging production with manufacturing schedules.

What are the reported benefits of using Western Packaging's integrated solutions?

Clients have reported a 25% decrease in lead times and a 30% reduction in damage-related costs after adopting integrated packaging solutions, demonstrating significant operational benefits.

Why is quality control important in contract manufacturing?

Quality control is crucial as it ensures products meet safety standards, mitigates risks associated with product recalls, and enhances consumer confidence in the offerings.

What quality assurance measures does Western Packaging implement?

Western Packaging conducts regular audits, thorough testing for contaminants, and strict compliance with Good Manufacturing Practices (GMP) to ensure product safety and quality.

How does contract manufacturing provide flexibility to businesses?

Contract manufacturing allows businesses to adjust output volumes and product formulations according to market demand, enabling them to respond quickly to changes in consumer preferences without incurring the costs of excess capacity.

What is the projected growth of the global product packaging design services sector?

The global product packaging design services sector is projected to reach $32.42 billion by 2030, indicating a growing trend towards integrated solutions in the industry.

How does Western Packaging position itself in the nutraceutical industry?

Western Packaging is positioned as a vital player in optimizing supply chains for nutraceuticals by delivering customized services that meet the unique needs of manufacturers, while also focusing on innovation and quality.