Overview

The article highlights the significant benefits of utilizing Contract Manufacturing Organizations (CMOs) within the pharmaceutical industry. These advantages encompass:

- Cost efficiency

- Scalability

- Regulatory compliance expertise

- Enhanced quality control

By leveraging these strengths, pharmaceutical firms can streamline their operations, concentrate on core competencies, and harness advanced technologies. This strategic approach ultimately results in improved product quality and a more agile response to market demands. In an industry where reliability and excellence are paramount, partnering with CMOs emerges as a pivotal strategy for success.

Introduction

In the rapidly evolving pharmaceutical landscape, the role of Contract Manufacturing Organizations (CMOs) has become increasingly vital, serving as a crucial partner for companies navigating the complexities of production and compliance. These strategic partnerships promise not only significant cost savings and operational efficiencies but also enhance scalability and foster innovation. Yet, the pressing question remains: how can pharmaceutical firms effectively leverage these collaborations to meet market demands while ensuring the highest standards of quality and compliance? By exploring the multifaceted benefits of CMOs, companies can uncover a strategic pathway to thrive in a competitive environment.

Western Packaging: Integrated Packaging Solutions for Enhanced Product Appeal

Western Packaging provides a comprehensive array of integrated packaging solutions designed to enhance item appeal and bolster brand recognition. By merging expert packaging design with filling services—spanning powders, gummies, and soft-gels—alongside robust third-party logistics (3PL), the organization ensures that products not only capture attention on retail shelves but also satisfy the logistical demands of distribution. This holistic approach empowers businesses to streamline their supply chains while upholding high standards of quality and innovation.

Industry leaders assert that effective packaging design is vital for brand recognition, with emerging trends in 2025 highlighting sustainability and smart packaging technologies that improve safety and traceability.

Businesses that leverage comprehensive packaging and logistics services provided by a contract manufacturing organization pharma have reported notable increases in customer loyalty and market presence, underscoring the significant impact of strategic packaging design on product appeal within the pharmaceutical sector.

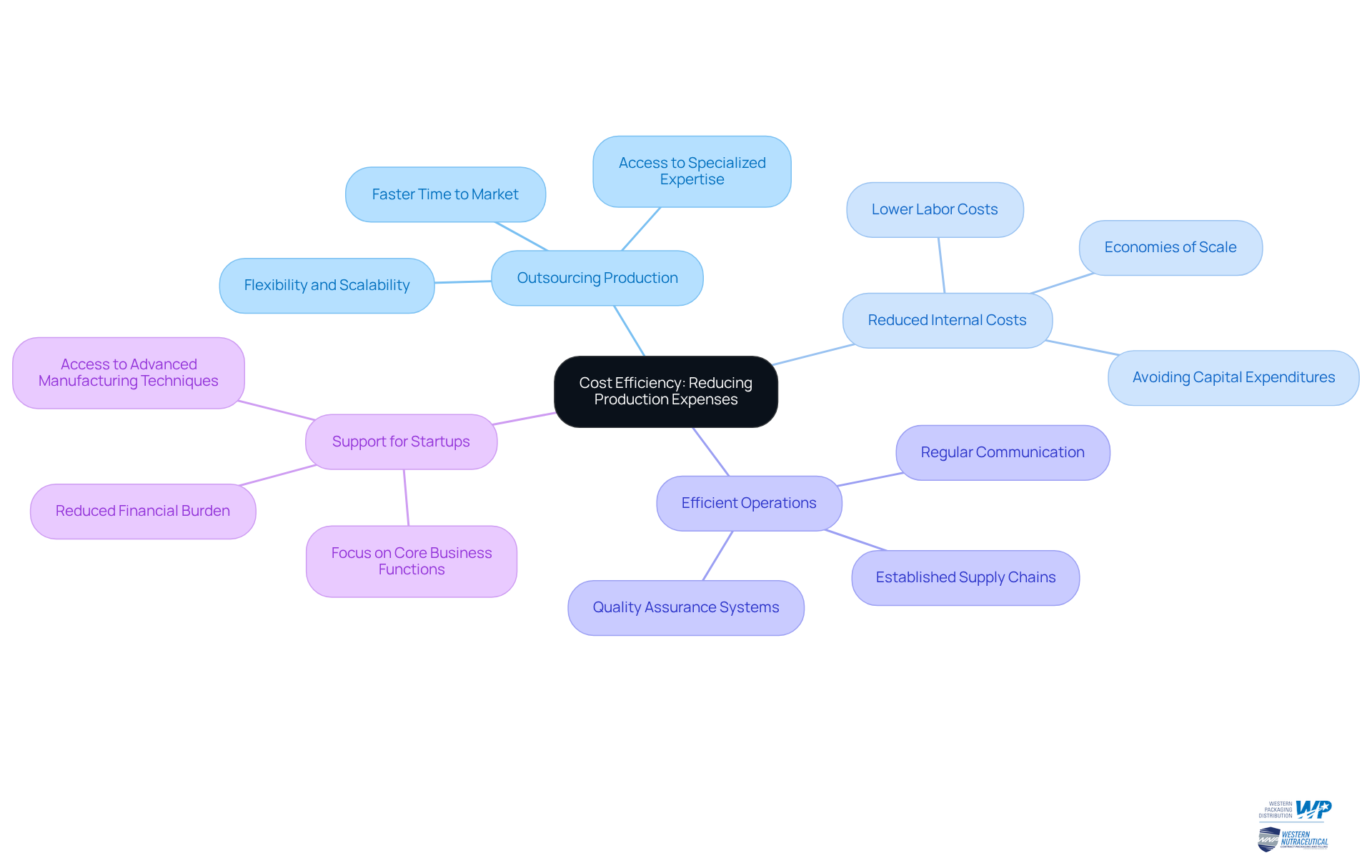

Cost Efficiency: Reducing Production Expenses with CMOs

Collaborating with chief marketing officers empowers pharmaceutical firms to significantly reduce production costs. By outsourcing production to a contract manufacturing organization pharma, organizations can avoid the high expenses associated with maintaining internal facilities and personnel. Chief marketing officers often possess established production processes and supply chains that facilitate more efficient operations, resulting in lower overall costs. This cost efficiency proves particularly beneficial for startups and smaller enterprises that may not have the capital to invest in extensive manufacturing infrastructure.

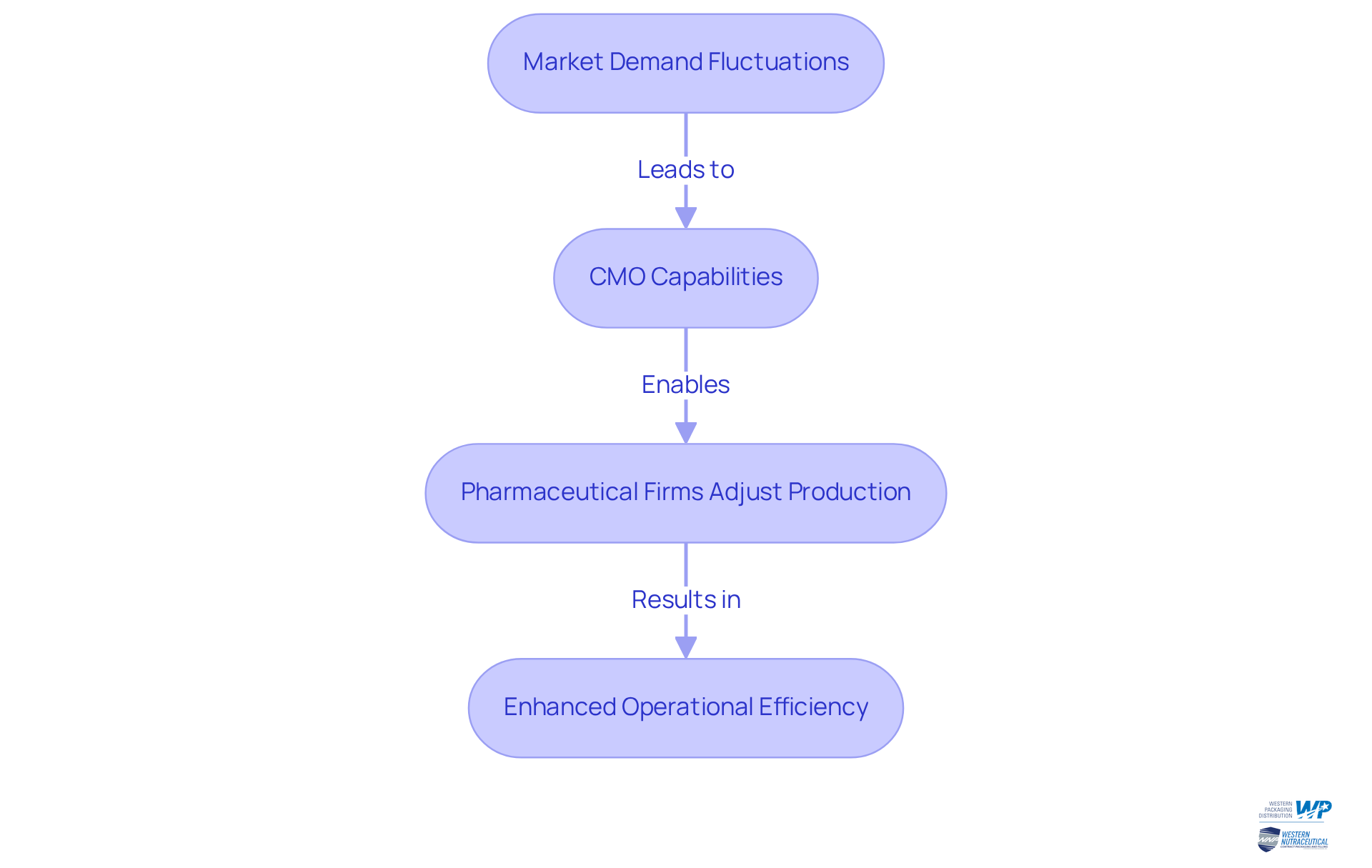

Scalability: Adapting Production to Market Demands with CMOs

Contract manufacturing organization pharma delivers unparalleled scalability, empowering pharmaceutical firms to adjust their production levels in response to market demands. This flexibility is essential in an industry characterized by rapid fluctuations in product demand. By leveraging the capabilities of a contract manufacturing organization pharma, organizations can promptly scale their operations without the constraints of excess capacity or the need for significant capital investment. Such adaptability not only boosts operational efficiency but also guarantees that companies can meet consumer needs swiftly.

Expertise and Compliance: Navigating Regulatory Challenges with CMOs

Contract manufacturing organization pharma provides essential expertise in navigating the complex regulatory landscape of the pharmaceutical industry. Their deep understanding of Good Manufacturing Practices (GMP) and other regulatory requirements ensures that products are manufactured in strict adherence to industry standards.

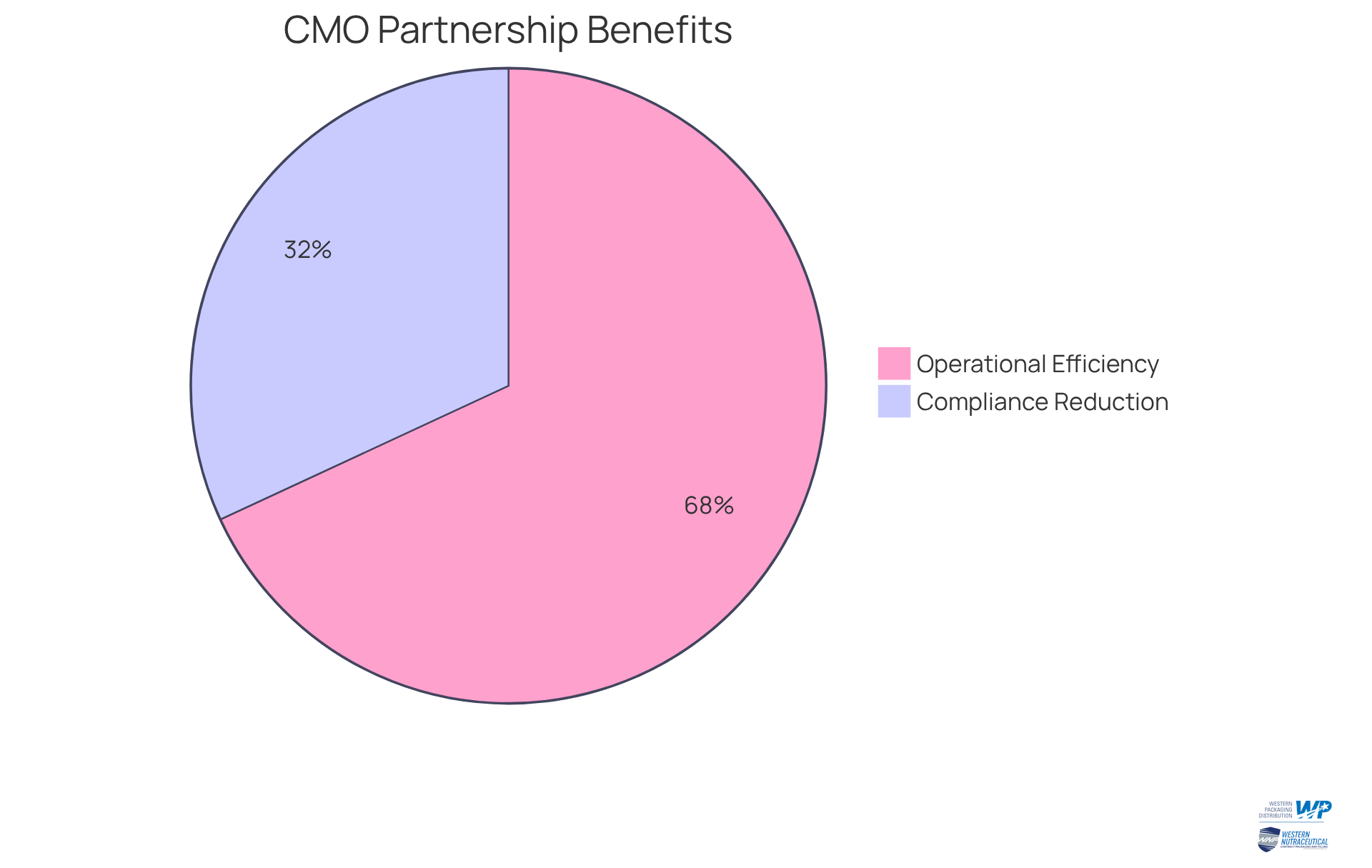

Notably, a recent report reveals that organizations partnering with CMOs experience a 30% reduction in compliance-related issues, underscoring the effectiveness of these collaborations. This specialized knowledge not only mitigates the risk of regulatory complications but also significantly enhances the quality and safety of the products produced.

By engaging with a contract manufacturing organization pharma, companies can concentrate on their core competencies while leveraging their partner's expertise to effectively manage compliance challenges. Furthermore, 64% of organizations employing Chief Marketing Officers report improved operational efficiency, illustrating the strategic advantage of such partnerships.

This collaboration fosters a more streamlined approach to regulatory adherence, ultimately leading to enhanced operational efficiency and product integrity. Additionally, implementing robust reporting mechanisms, as advocated by industry experts, can further strengthen compliance efforts and ensure that any potential issues are addressed promptly.

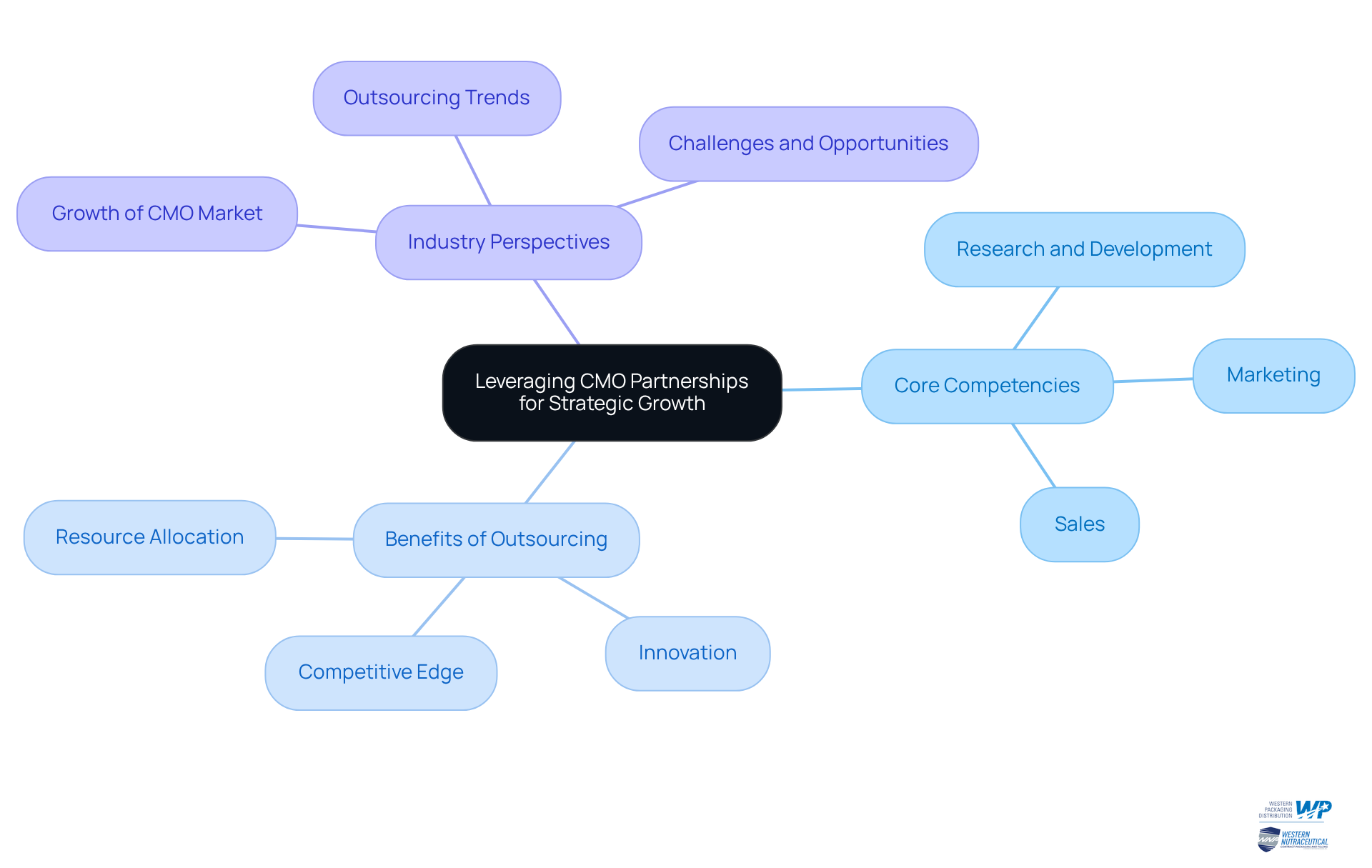

Focus on Core Competencies: Leveraging CMO Partnerships for Strategic Growth

Outsourcing production to a contract manufacturing organization pharma enables pharmaceutical firms to focus on their core competencies, including research and development, marketing, and sales. This strategic emphasis not only optimizes resource allocation but also cultivates innovation within these key areas of expertise. By entrusting the complexities of production to Chief Marketing Officers, businesses can enhance their strategic growth while minimizing the distractions linked to manufacturing logistics. Notably, organizations that actively involve CMOs often report elevated innovation rates, as they can dedicate more time and resources to developing new products and refining existing ones.

A survey reveals that nearly 25% of small business owners outsource primarily to improve efficiency, underscoring the effectiveness of this strategy. Industry leaders assert that these partnerships are vital for sustaining a competitive edge, enabling firms to swiftly adapt to market demands and regulatory shifts. As Tim Wright, Editor-in-Chief, aptly notes, 'outsourcing enables organizations to focus on their core strengths by assigning other tasks to external specialists.'

In the evolving biopharmaceutical landscape, leveraging contract manufacturing organization pharma partnerships emerges as a crucial strategy for companies aspiring to thrive in a rapidly changing environment.

Flexibility: Adapting to Market Changes with CMO Partnerships

Chief Marketing Officers are pivotal in providing the flexibility necessary to swiftly adapt to market changes. In an industry characterized by rapid shifts in demand and evolving consumer preferences, the ability to adjust production schedules and capacities is invaluable. For instance, when confronted with a sudden increase in demand for a specific product or the necessity to shift to new formulations, a contract manufacturing organization pharma can seamlessly adjust its operations. This agility is crucial in the fast-paced pharmaceutical landscape, where responsiveness to consumer trends can significantly influence a company's competitive edge.

Moreover, Chief Marketing Officers leverage advanced analytics to monitor and track Key Performance Indicators (KPIs), enabling them to make informed decisions that enhance operational efficiency. As indicated in Deloitte's Fall 2024 CMO Survey, 68% of marketing leaders are concentrating on urgent requirements instead of long-term strategy, emphasizing the strategic difficulties executives encounter in adjusting to industry shifts.

Cooperation among Chief Marketing Officers and other divisions is crucial for cohesive strategies, enabling companies to stay competitive and adaptable to changing industry conditions. For instance, firms such as Lonza Group and Catalent have effectively adjusted to industry changes through strategic CMO collaborations, showcasing the success of this method.

As the biologics sector is anticipated to expand at a compound annual growth rate of 15% until 2027, the strategic partnership with a contract manufacturing organization pharma becomes increasingly vital for managing these changes efficiently. By leveraging these partnerships, businesses can enhance their operational efficiency and ensure they remain at the forefront of market dynamics.

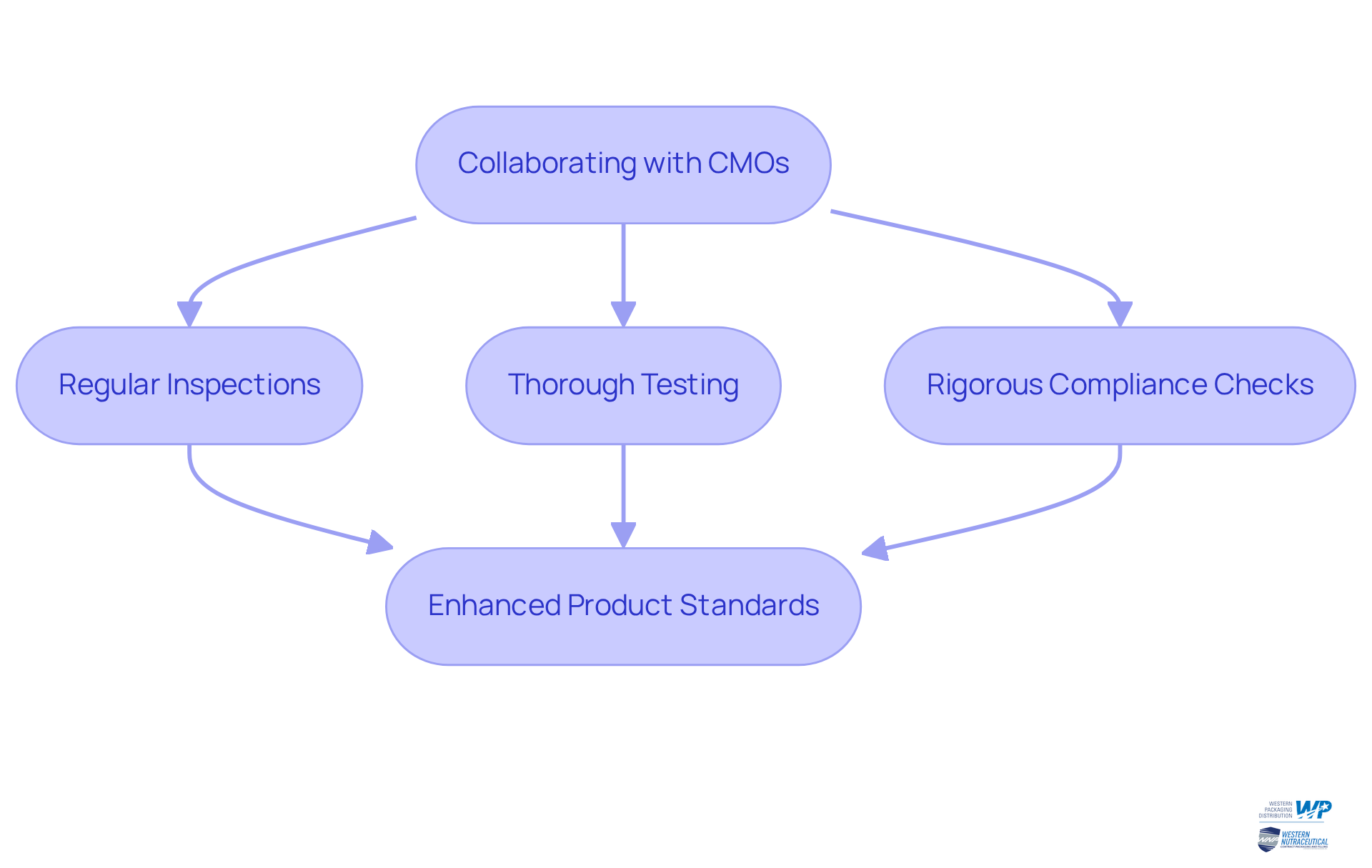

Quality Control: Ensuring High Standards through CMO Collaboration

Collaborating with marketing executives significantly enhances quality control processes, ensuring that products adhere to the highest standards of safety and efficacy. Chief Marketing Officers (CMOs) implement stringent quality management systems, which encompass:

- Regular inspections

- Thorough testing

- Rigorous compliance checks

This meticulous approach to quality control not only safeguards consumers but also fortifies companies' reputations in the marketplace. By partnering with a CMO, businesses can leverage their associate's expertise in quality assurance, leading to improved outcomes.

Moreover, with Western Packaging's integrated filling services—catering to a diverse range of products from powders to gummies, soft-gels, kitting, and beyond—nutraceutical manufacturers can access customized, flexible packaging solutions that streamline production.

Our comprehensive third-party logistics (3PL) services, which include warehousing and inventory management, enhance supply chain efficiency, allowing organizations to focus on their core competencies while maintaining high-quality standards throughout the entire process.

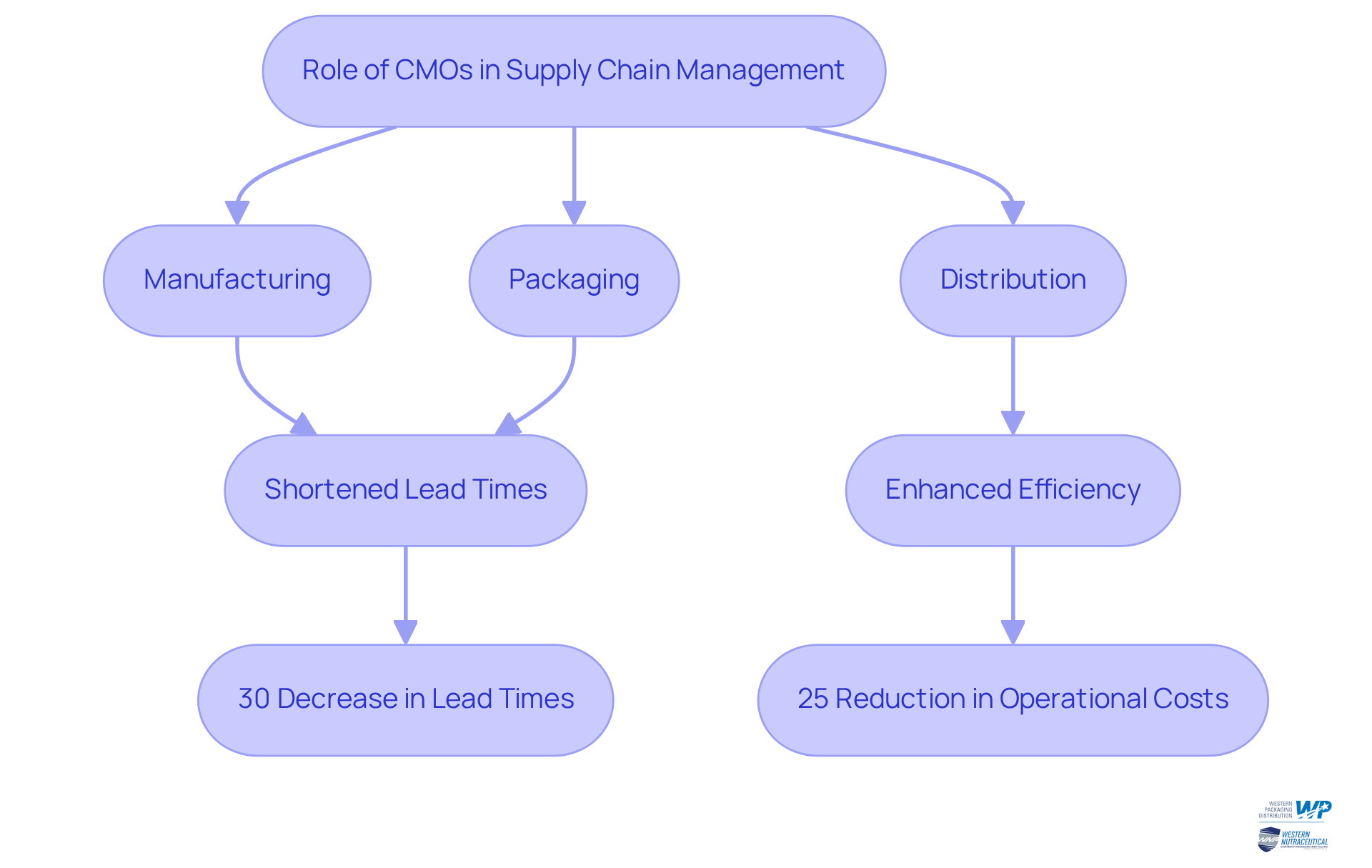

Supply Chain Management: Streamlining Operations with CMOs

Chief Marketing Officers are pivotal in enhancing supply chain management for pharmaceutical firms. By overseeing manufacturing, packaging, and distribution, contract manufacturing organization pharma streamline the logistics involved in bringing products to market. This integrated approach not only shortens lead times—organizations that collaborate with contract manufacturers have reported decreases of up to 30%—but also boosts operational efficiency, allowing firms to focus on their core activities.

Western Packaging amplifies this integrated strategy with its filling process, which seamlessly integrates into end-to-end solutions for flexible packaging needs, encompassing powders, gummies, and soft-gels. Additionally, with Western Packaging's comprehensive 3PL services, including warehousing, inventory management, and logistics, effective supply chain management through contract manufacturing organization pharma partnerships can yield significant cost savings and enhanced service delivery.

For example, a leading pharmaceutical firm recently optimized its operations by outsourcing its manufacturing to a CMO, resulting in a 25% reduction in operational costs and a 40% improvement in delivery timelines. Such outcomes underscore the transformative potential of contract manufacturing organization pharma partnerships within the pharmaceutical sector.

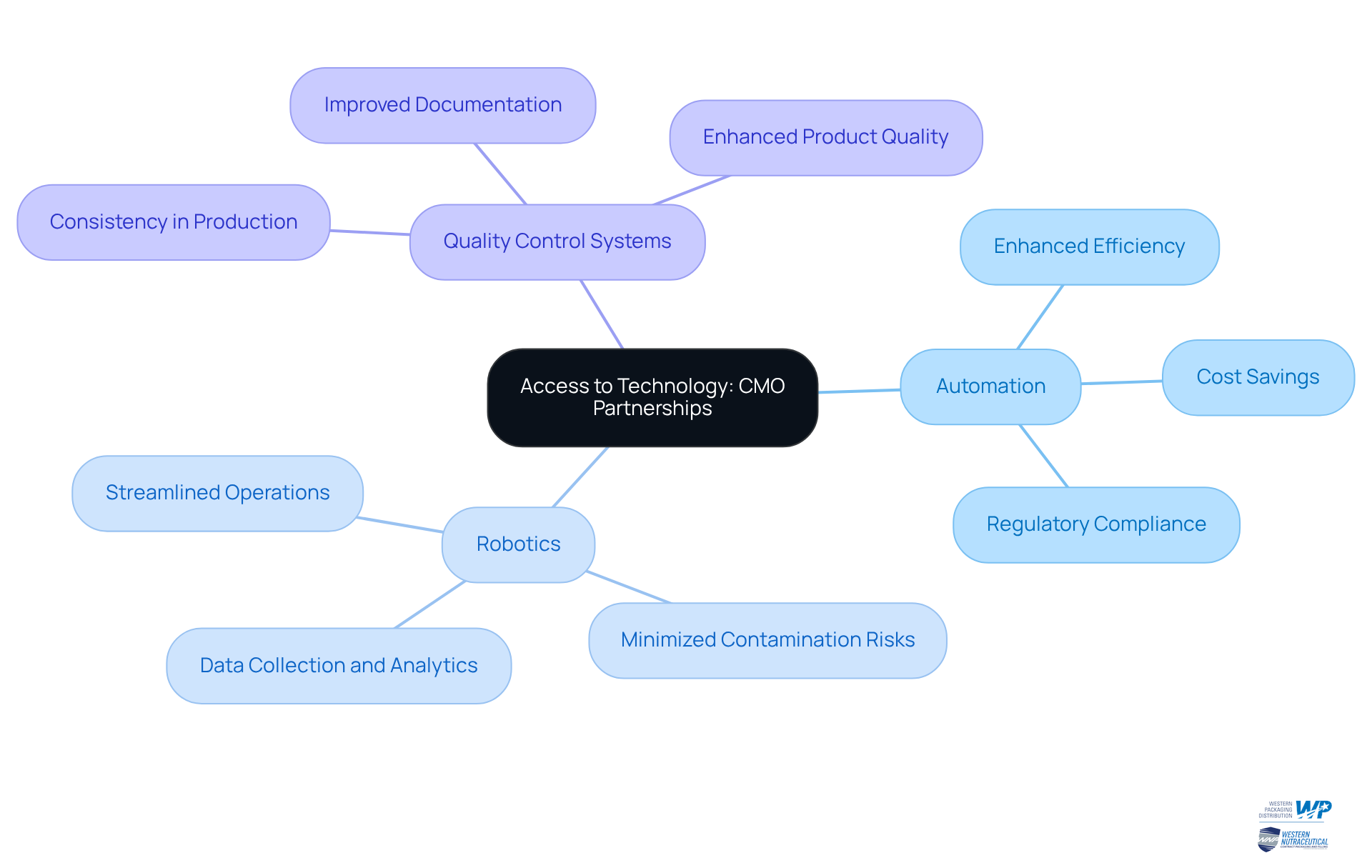

Access to Technology: Leveraging Innovations through CMO Partnerships

Partnering with a contract manufacturing organization (CMO) in pharma provides pharmaceutical firms with access to cutting-edge technologies that may be impractical to implement internally. Many CMOs lead the way in investing in modern manufacturing innovations, such as:

- Automation

- Robotics

- Sophisticated quality control systems

This strategic partnership empowers businesses to enhance their production capabilities without incurring the significant capital expenses associated with developing these technologies independently. By leveraging innovations through CMO collaborations, firms can achieve enhanced operational efficiency and superior product quality.

For instance, the integration of robotic systems in manufacturing processes not only streamlines operations but also minimizes contamination risks, ensuring compliance with stringent regulatory standards. Consequently, businesses can focus on their core strengths while benefiting from the advanced expertise that CMOs provide.

Strategic Partnerships: Building Collaborative Opportunities with CMOs

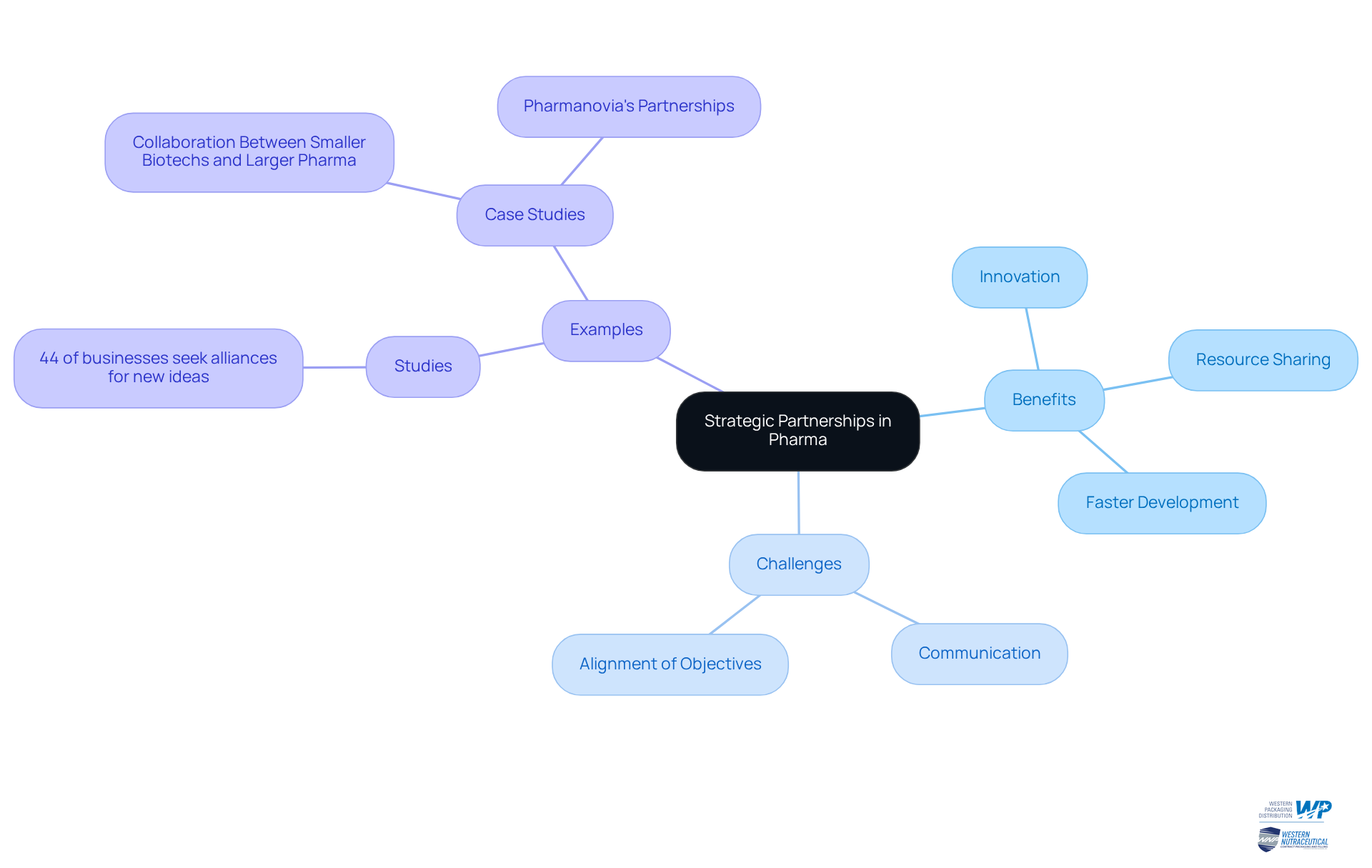

Strategic partnerships with contract manufacturing organization pharma are pivotal in fostering collaborative opportunities that propel innovation and growth within the pharmaceutical sector. These partnerships enable businesses to combine resources, exchange knowledge, and leverage expertise, resulting in faster development of offerings and enhanced responsiveness to the marketplace. By cultivating robust relationships with chief marketing officers, businesses can harness their partners' strengths to achieve shared objectives and adeptly navigate the complexities of the pharmaceutical landscape.

For instance, studies indicate that 44% of businesses seek alliances for new ideas, insights, and innovation, which often leads to faster commercialization timelines and improved patient care. Industry leaders emphasize that successful partnerships hinge on transparency, shared values, and a commitment to long-term goals, ultimately driving sustainable growth. As Sarah Wang, a partner at Andreessen Horowitz, states, "Partnerships are more important than ever, specifically because you are bringing in pipeline, shortening sales cycles, and increasing conversion rates."

Furthermore, case studies like the cooperation between smaller biotech firms and larger pharmaceutical entities demonstrate how these partnerships can result in quicker product development and expanded reach. However, it is essential to recognize the challenges that may arise, including the need for clear communication and alignment of objectives. As the pharmaceutical industry evolves, the ability to collaborate effectively with a contract manufacturing organization pharma will be crucial for companies aiming to maintain a competitive edge and meet the dynamic demands of the market. To foster such partnerships, businesses should prioritize open dialogue and establish shared metrics to ensure alignment and mutual success.

Conclusion

The advantages of partnering with contract manufacturing organizations (CMOs) in the pharmaceutical industry are both numerous and impactful. By outsourcing production, companies can not only reduce costs and enhance scalability but also concentrate on their core competencies, ultimately driving innovation and growth. This strategic collaboration enables businesses to leverage the expertise and technological advancements that CMOs offer, ensuring compliance with regulatory standards while maintaining high-quality production.

Key insights from the article underscore the importance of:

- Flexibility

- Quality control

- Integrated supply chain management

in fostering operational efficiency. Organizations engaging with CMOs can swiftly adapt to market demands, benefiting from advanced technologies and streamlined processes that significantly enhance their competitive edge. Furthermore, collaboration with CMOs facilitates access to specialized knowledge and resources, empowering firms to navigate the complexities of the pharmaceutical landscape more effectively.

In conclusion, the role of contract manufacturing organizations is crucial for pharmaceutical companies aiming to thrive in a rapidly changing market. Embracing these partnerships not only enhances operational capabilities but also positions businesses for sustainable growth and innovation. By prioritizing collaboration and leveraging the strengths of CMOs, organizations can significantly improve their market responsiveness and ultimately deliver better outcomes for patients and stakeholders alike.

Frequently Asked Questions

What integrated packaging solutions does Western Packaging offer?

Western Packaging provides a comprehensive array of integrated packaging solutions that include expert packaging design, filling services for powders, gummies, and soft-gels, as well as robust third-party logistics (3PL) to enhance product appeal and brand recognition.

How does effective packaging design impact brand recognition?

Effective packaging design is vital for brand recognition, and emerging trends in 2025 emphasize sustainability and smart packaging technologies that improve safety and traceability.

What benefits do businesses experience by using comprehensive packaging and logistics services from a contract manufacturing organization?

Businesses that utilize these services have reported notable increases in customer loyalty and market presence, highlighting the significant impact of strategic packaging design on product appeal, especially within the pharmaceutical sector.

How can collaborating with chief marketing officers reduce production costs for pharmaceutical firms?

Collaborating with chief marketing officers allows pharmaceutical firms to outsource production to contract manufacturing organizations, helping them avoid high expenses related to maintaining internal facilities and personnel, leading to lower overall costs.

Why is cost efficiency important for startups and smaller enterprises in the pharmaceutical industry?

Cost efficiency is particularly beneficial for startups and smaller enterprises that may not have the capital to invest in extensive manufacturing infrastructure, allowing them to operate more effectively.

What scalability advantages do contract manufacturing organizations provide?

Contract manufacturing organizations offer unparalleled scalability, enabling pharmaceutical firms to adjust their production levels in response to market demands, which is essential in an industry with rapid fluctuations in product demand.

How does leveraging a contract manufacturing organization enhance operational efficiency?

By leveraging the capabilities of a contract manufacturing organization, companies can scale their operations promptly without the constraints of excess capacity or the need for significant capital investment, ensuring they can meet consumer needs swiftly.