Overview

Retail ready packaging (RRP) for nutraceuticals presents several significant advantages. First and foremost, it enhances shelf visibility, which is crucial in attracting consumer attention. Additionally, RRP contributes to reduced labor costs, streamlining operations for businesses. Importantly, it promotes sustainability through waste minimization, aligning with the increasing demand for eco-friendly practices. This article substantiates these claims by illustrating that RRP not only boosts consumer engagement and sales—reporting up to a 30% increase in visibility and efficiency—but also strategically positions companies to meet market demands. In a competitive landscape, adopting RRP is not just beneficial; it is essential for success.

Introduction

Retail ready packaging (RRP) is revolutionizing the nutraceutical industry by merging functionality with sustainability, thus providing businesses with a strategic advantage in a competitive market. This innovative packaging solution not only enhances product visibility and shelf appeal but also significantly reduces waste and labor costs. Such alignment with the growing consumer demand for eco-friendly practices underscores the importance of RRP in today's marketplace. However, as companies strive to adopt RRP, a critical challenge persists: how can they effectively implement these solutions to maximize their benefits while ensuring compliance with industry standards?

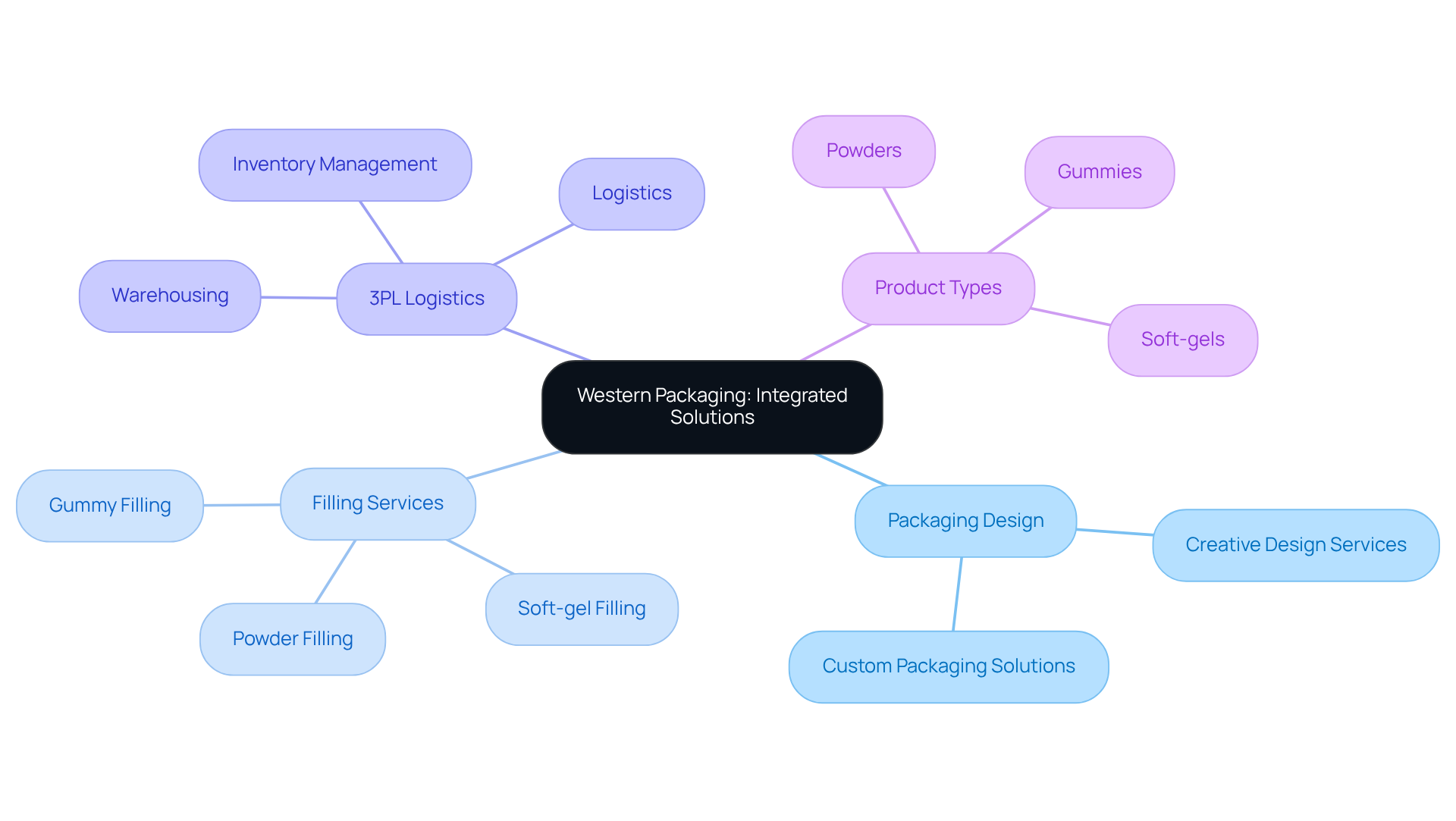

Western Packaging: Integrated Solutions for Retail Ready Packaging

Western Packaging provides a seamless integration of packaging design, filling services, and comprehensive third-party logistics (3PL) specifically tailored for the nutraceutical industry. Our extensive solutions encompass:

- Warehousing

- Inventory management

- Logistics

This ensures that products are effectively packaged and positioned for optimal market impact. We accommodate a diverse range of items, including:

- Powders

- Gummies

- Soft-gels

Thereby streamlining the production process. By merging these customized services, Western Packaging aids businesses in shortening lead times and enhancing product appeal, establishing itself as a trusted ally for firms seeking retail ready packaging. Notably, a recent client reported a 30% increase in market visibility after implementing our integrated solutions, underscoring the effectiveness of our approach in boosting consumer engagement.

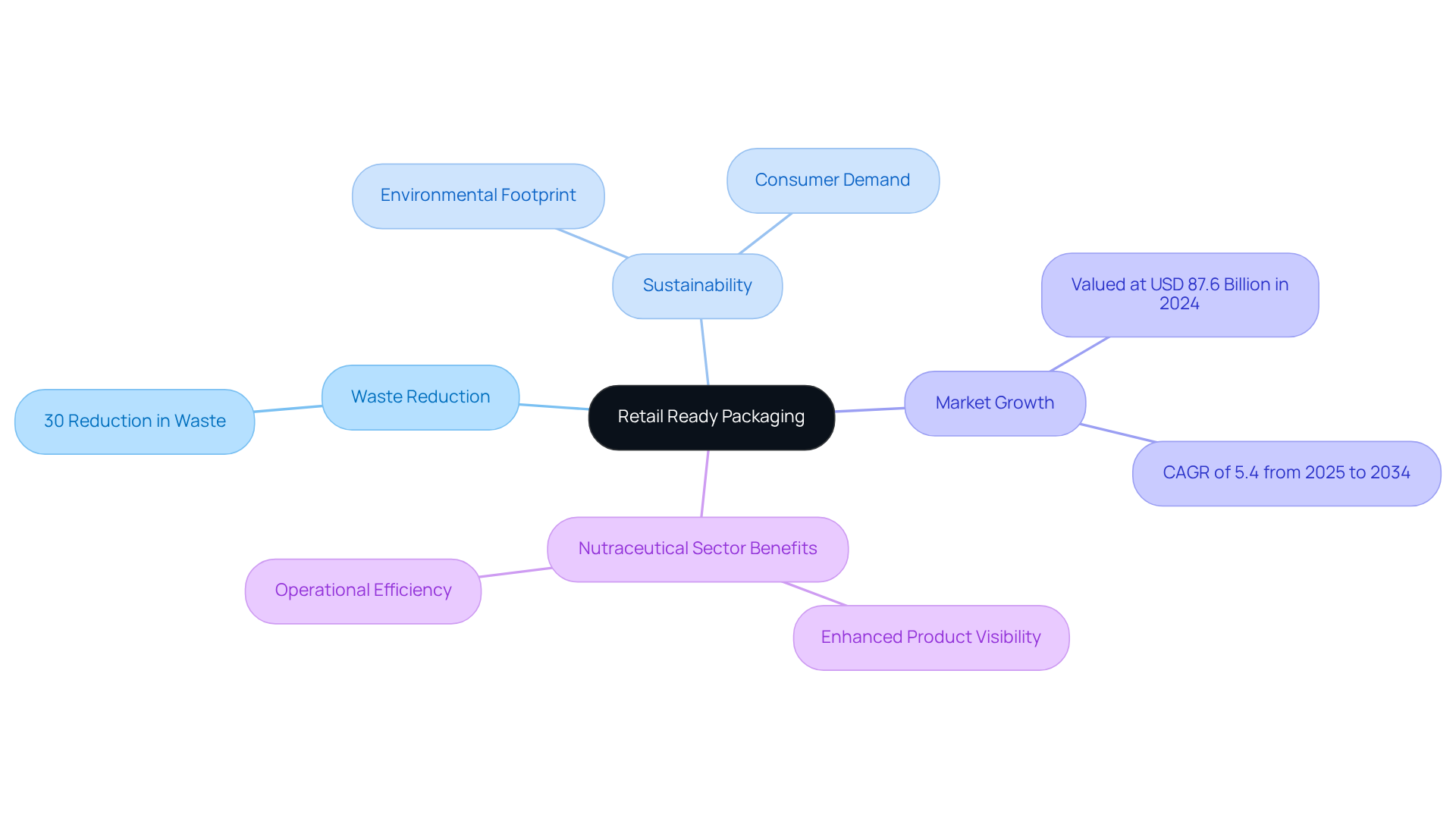

Eliminate Packing Waste with Retail Ready Packaging

Retail ready containers (RRP) are strategically designed to minimize excess materials, enabling products to be shipped in containers that are ready for display. This innovative approach significantly reduces the need for additional packing materials, leading to a substantial decrease in waste. Companies implementing RRP have reported reductions in waste by up to 30%, demonstrating its effectiveness in promoting sustainability. By utilizing RRP, businesses not only lower their environmental footprint but also cater to the growing consumer demand for eco-friendly practices.

In the nutraceutical sector, where product display is vital, RRP boosts visibility while ensuring that the containers are both functional and sustainable. Case studies indicate that brands adopting RRP have achieved enhanced operational efficiency and reduced expenses related to surplus materials. For instance, a recent initiative by Graphic Packaging International and Morrisons introduced recyclable paperboard trays expected to eliminate 250 metric tons of plastic annually, underscoring the potential of RRP to drive significant environmental benefits.

Moreover, the global retail ready containers market was valued at USD 87.6 billion in 2024 and is anticipated to expand at a CAGR of 5.4% from 2025 to 2034, reflecting a broader industry shift towards sustainable solutions. As companies increasingly prioritize sustainability, RRP stands out as a viable option that not only meets regulatory demands but also enhances brand loyalty among environmentally conscious consumers. By embracing RRP, nutraceutical manufacturers can effectively reduce packing waste while reinforcing their commitment to sustainability.

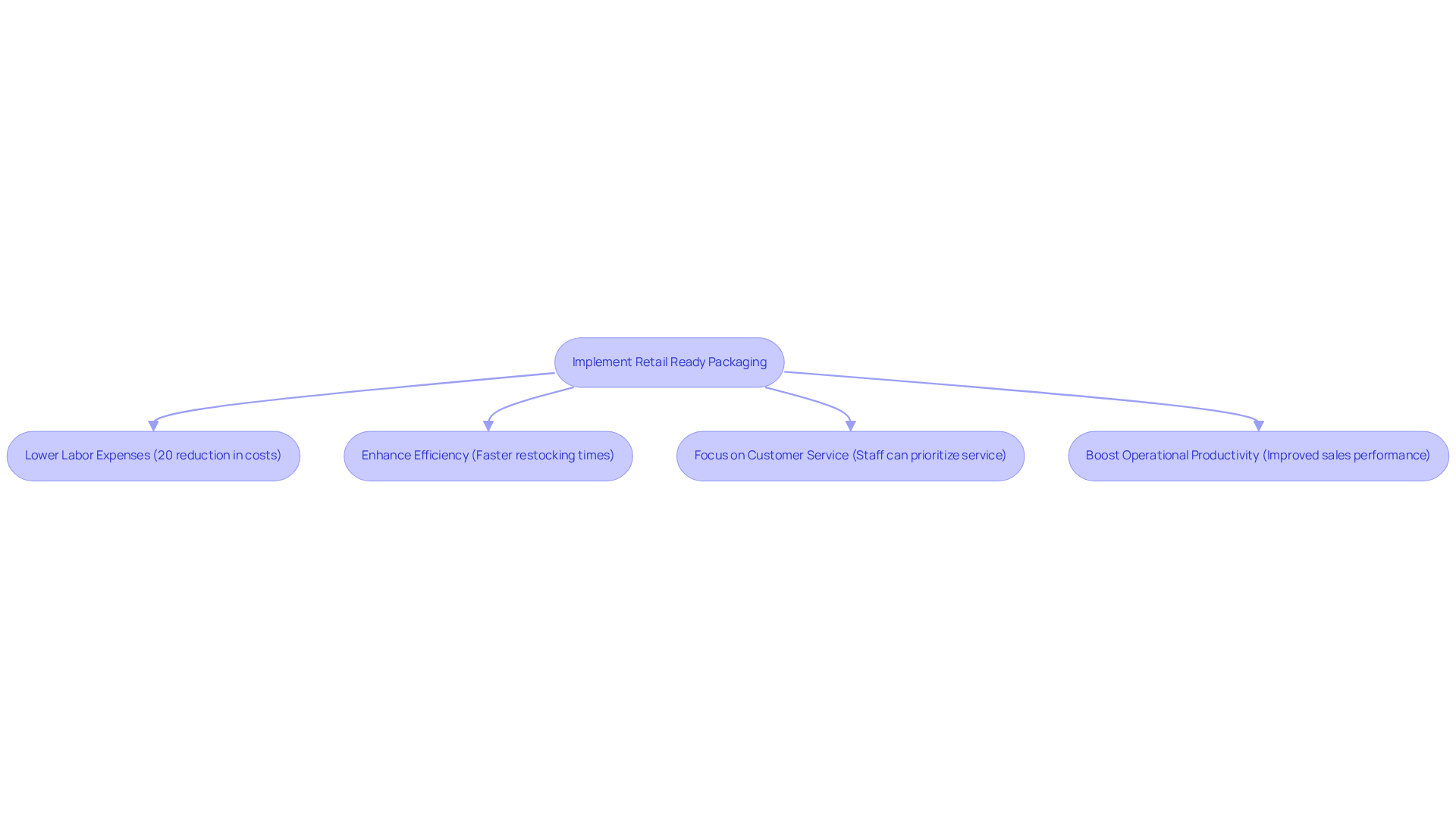

Achieve Time and Payroll Savings through Efficient Packaging

Implementing retail ready packaging significantly lowers labor expenses and enhances efficiency during the stocking process. Items with retail ready packaging are designed for direct placement on shelves, eliminating the need for unpacking and streamlining operations. This approach not only saves valuable time but also allows staff to focus on customer service and other essential tasks, ultimately boosting overall operational productivity.

Statistics indicate that effective shelf-ready containers can cut in-store labor costs by approximately 20%, underscoring their impact on efficiency. Case studies reveal that businesses utilizing retail ready packaging experience faster restocking times, which leads to reduced downtime and improved sales performance.

Industry specialists highlight that retail ready packaging (RRP) not only streamlines the stocking process but also improves item visibility, fostering impulse purchases and enhancing brand recognition. As Stephen Fowler observes, 'shelf-ready presentation helps your product stand out and makes restocking simpler.'

By adopting retail ready packaging (RRP), nutraceutical manufacturers can achieve substantial time and payroll savings, positioning themselves for greater success in a competitive market. Furthermore, reducing materials and providing clear opening instructions are essential for effective wrapping, further improving operational efficiency.

Western Packaging's integrated approach, which combines design, filling, and logistics services, ensures that manufacturers can fully leverage the benefits of retail ready packaging.

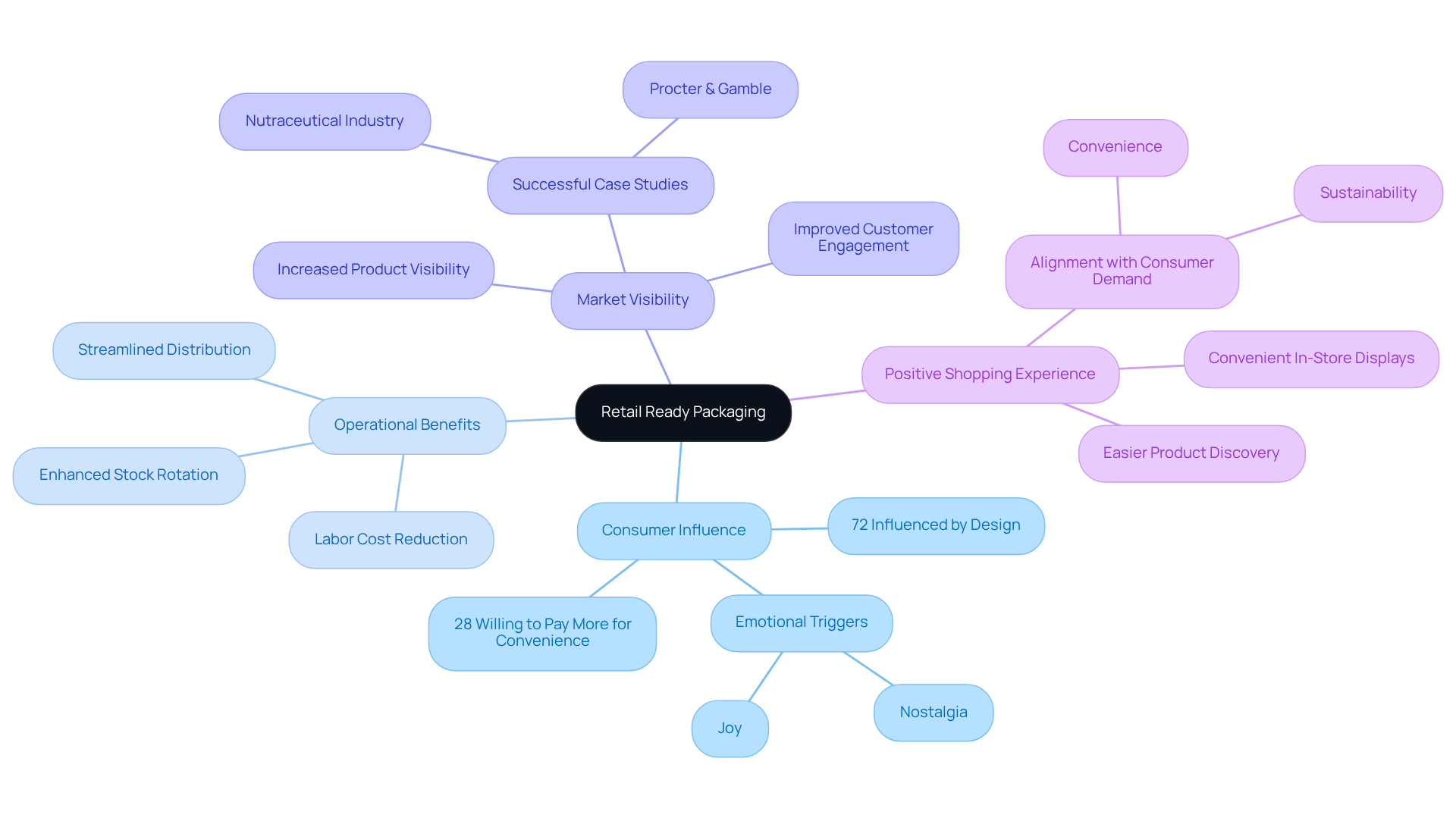

Enhance Shelf Marketing with Retail Ready Packaging

Retail ready packaging significantly enhances shelf marketing by delivering a visually appealing display that captures shopper attention. The design of retail ready packaging integrates essential branding components and emotional triggers, ensuring that items stand out prominently on shelves, thereby increasing the likelihood of impulse purchases.

Research indicates that effective packaging design influences buyer behavior, with nearly 72% of American shoppers swayed by packaging design in their purchasing decisions, and 28% willing to pay a premium for added conveniences in packaging. By presenting offerings attractively and accessibly, companies can not only elevate their market presence but also drive sales effectively.

Successful examples from the nutraceutical industry demonstrate that brands utilizing retail ready packaging (RRP) have achieved greater visibility and improved customer engagement, ultimately leading to higher sales figures. Moreover, retail ready packaging (RRP) offers operational benefits, such as reducing labor costs and enhancing stock rotation, which further underscores its value in retail strategies.

The strategic implementation of retail ready packaging not only optimizes shelf space but also fosters a positive shopping experience, facilitating easier product discovery and purchase for shoppers. This approach aligns with the increasing consumer demand for convenience and sustainability, further solidifying the role of retail ready packaging in contemporary retail strategies.

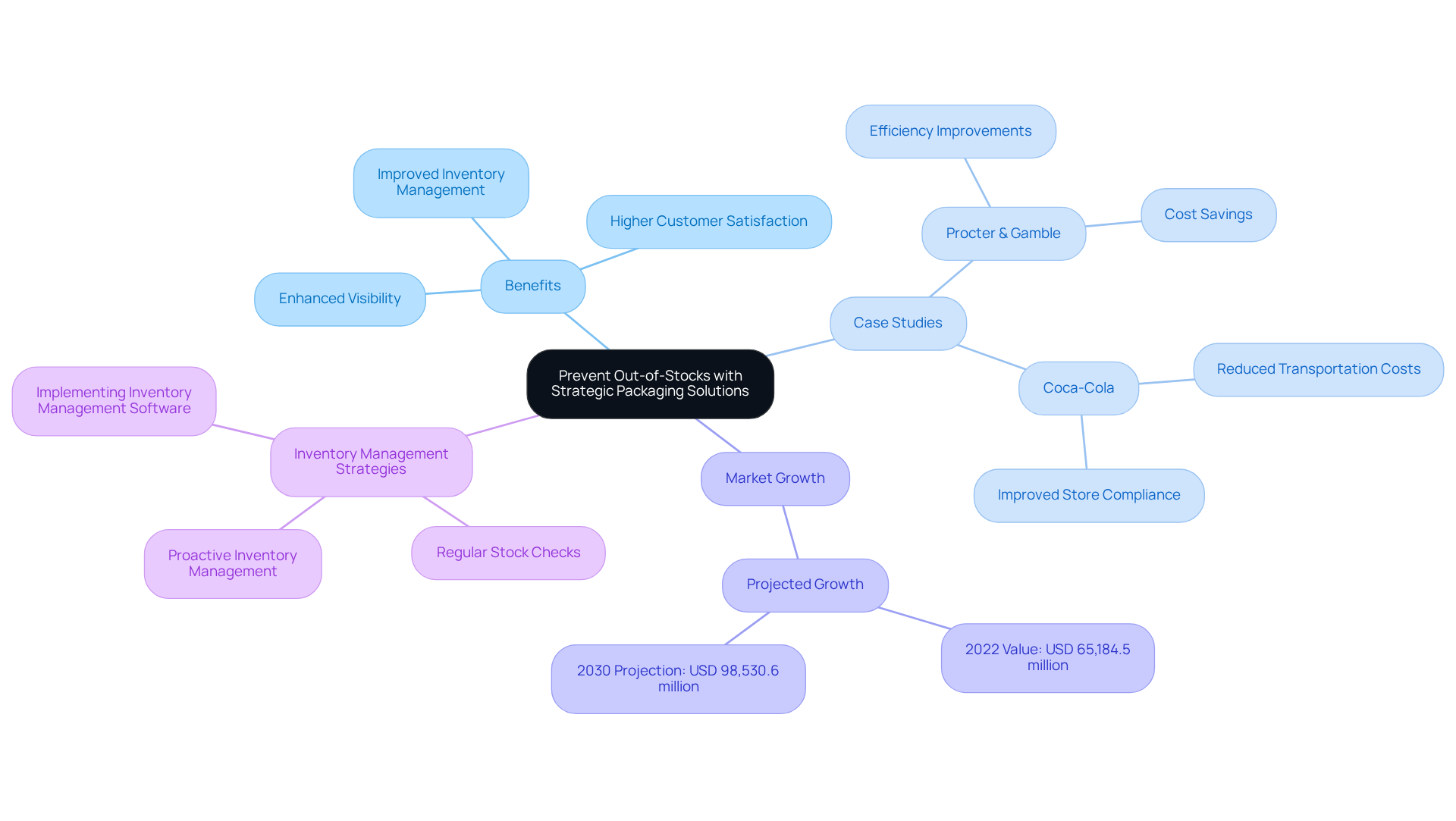

Prevent Out-of-Stocks with Strategic Packaging Solutions

Strategic retail ready packaging solutions are essential in preventing out-of-stocks by optimizing inventory management. By implementing retail ready packaging, retailers can significantly streamline their restocking processes, ensuring that items are consistently available on shelves. This proactive approach not only boosts customer satisfaction but also minimizes lost sales opportunities due to stockouts.

For instance, companies like Procter & Gamble and Coca-Cola have adopted RRP, resulting in substantial efficiency improvements, reduced transportation costs, and enhanced store compliance. Additionally, retail ready packaging improves item visibility and display, making it easier to search for necessary products, which directly leads to higher sales.

Research indicates that retail ready packaging can significantly increase buyer engagement and purchasing behavior for products. As the retail-ready container market continues to expand—projected to rise from USD 65,184.5 million in 2022 to USD 98,530.6 million by 2030, driven by consumer demand for convenience and sustainability—companies that prioritize effective inventory management through strategic container solutions will be better positioned to meet evolving market needs and enhance their operational efficiency.

Furthermore, implementing inventory management software and conducting regular stock checks can further optimize inventory levels, ensuring that retailers can respond swiftly to consumer demands while supporting sustainable practices.

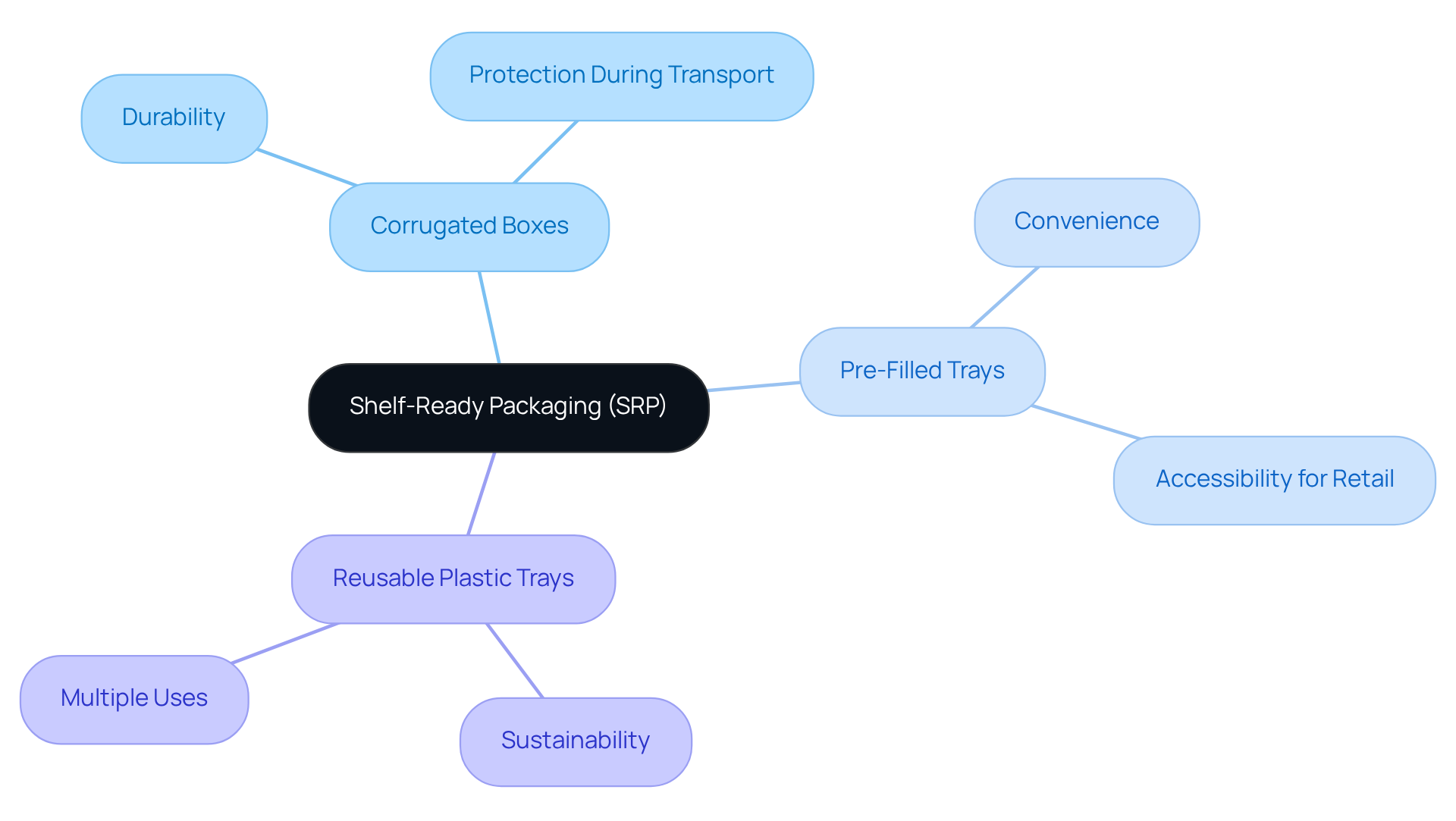

Explore Types of Shelf-Ready Packaging for Your Products

Shelf-ready packaging (SRP) encompasses various types, including:

- Corrugated boxes

- Pre-filled trays

- Reusable plastic trays

Each meticulously designed to fulfill specific roles in presentation and distribution. Corrugated boxes excel in handling bulk items, providing exceptional durability and protection throughout transport. Conversely, pre-filled trays deliver convenience and accessibility for smaller items, making them particularly suitable for retail environments where swift restocking is critical. Reusable plastic trays not only promote sustainability but also offer the advantage of multiple uses, aligning with the increasing consumer demand for eco-friendly solutions.

Understanding retail ready packaging options is essential for businesses aiming to elevate their product offerings. For instance, a case study involving a nutraceutical producer demonstrated that the adoption of pre-filled trays significantly improved shelf visibility while reducing labor costs by up to 25%. This underscores the importance of selecting the right container type. Additionally, statistics reveal that 83% of consumers prioritize convenience in their shopping experiences, further emphasizing the need for efficient packaging solutions.

Industry experts assert that when choosing containers, companies must consider factors such as:

- Item protection

- Branding opportunities

- Logistical efficiency

As the retail ready packaging market is projected to expand to USD 98.78 billion by 2031, businesses that strategically utilize customized packaging solutions—including graphic design services like labels and brochures from Western Packaging—are likely to enhance their market presence and operational effectiveness.

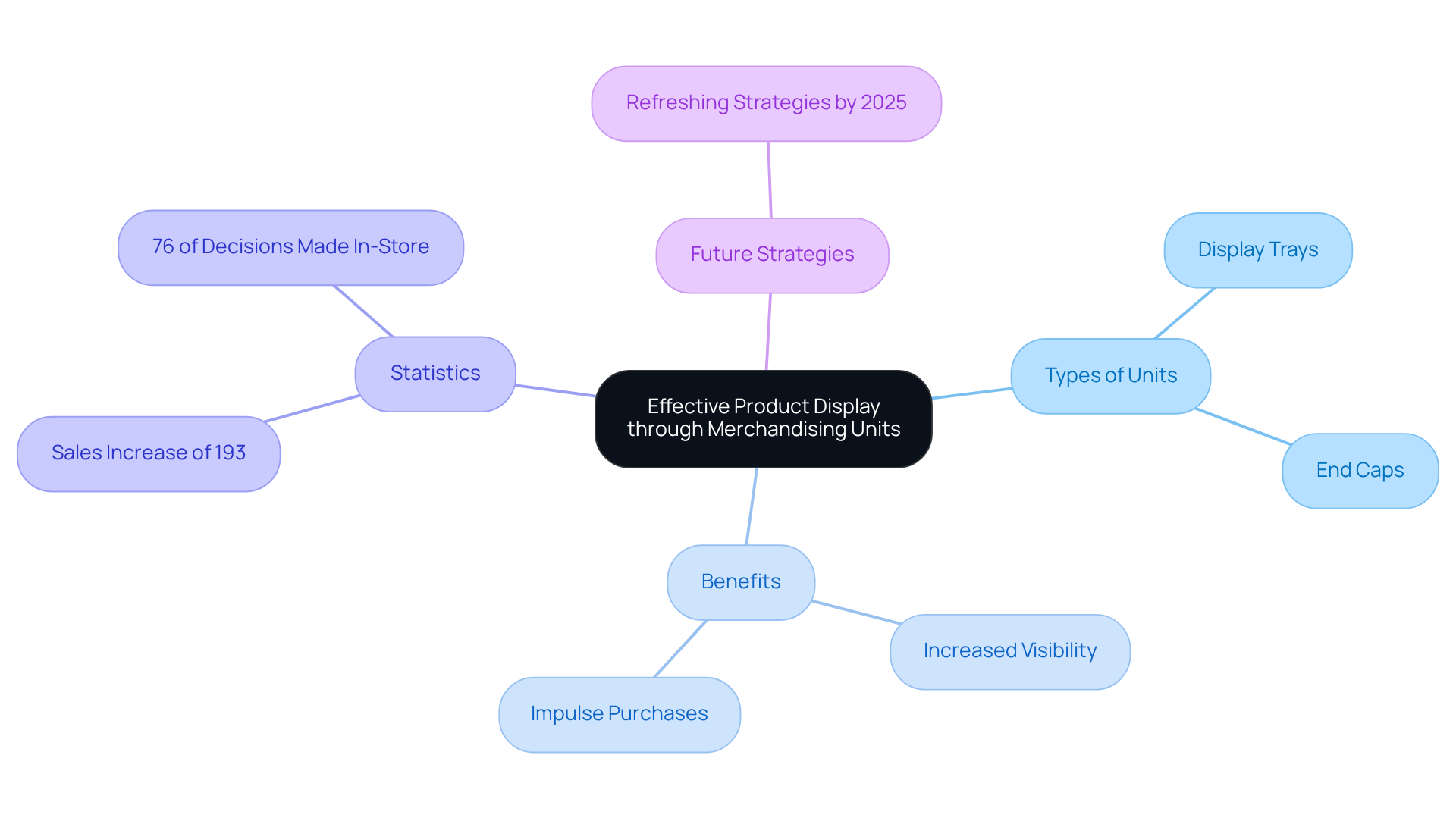

Utilize Merchandising Units for Effective Product Display

Merchandising units, including display trays and end caps, are essential components of retail ready packaging for effective merchandise presentation in retail environments. These strategically designed units featuring retail ready packaging not only enhance item visibility but also create opportunities for impulse purchases, significantly impacting sales performance. Research indicates that retailers employing a planned display strategy can experience sales increases of up to 193%, as noted by Nikita Sherbina, Founder & CEO of AIScreen.

Case studies demonstrate that incorporating retail ready packaging, like display trays, effectively showcases nutraceutical items, drawing customer attention and facilitating easier access. End caps, positioned at the ends of aisles, act as visual anchors that highlight new arrivals or seasonal offerings, further enticing shoppers. Notably, statistics reveal that 76% of purchase decisions occur in-store, underscoring the importance of these merchandising units in influencing consumer behavior. Furthermore, up to 35% of customers leave without making a purchase if they cannot find what they need, emphasizing the critical role of effective merchandising in retaining customers and preventing lost sales.

The integration of display trays and end caps enhances the overall shopping experience by creating retail ready packaging that boosts item visibility. By developing a structured and aesthetically pleasing arrangement with retail ready packaging, retailers can effectively guide customers through their selections, facilitating their ability to find and choose items. This approach aligns with contemporary buyer expectations for intuitive and engaging shopping experiences through retail ready packaging, ultimately leading to increased sales and customer satisfaction.

As we look ahead to 2025, the retail landscape will continue to evolve, and the effectiveness of retail ready packaging will remain a key focus for brands aiming to optimize their product displays and drive sales in competitive markets. Retailers are encouraged to regularly refresh their merchandising strategies to align with consumer behavior and maximize their impact.

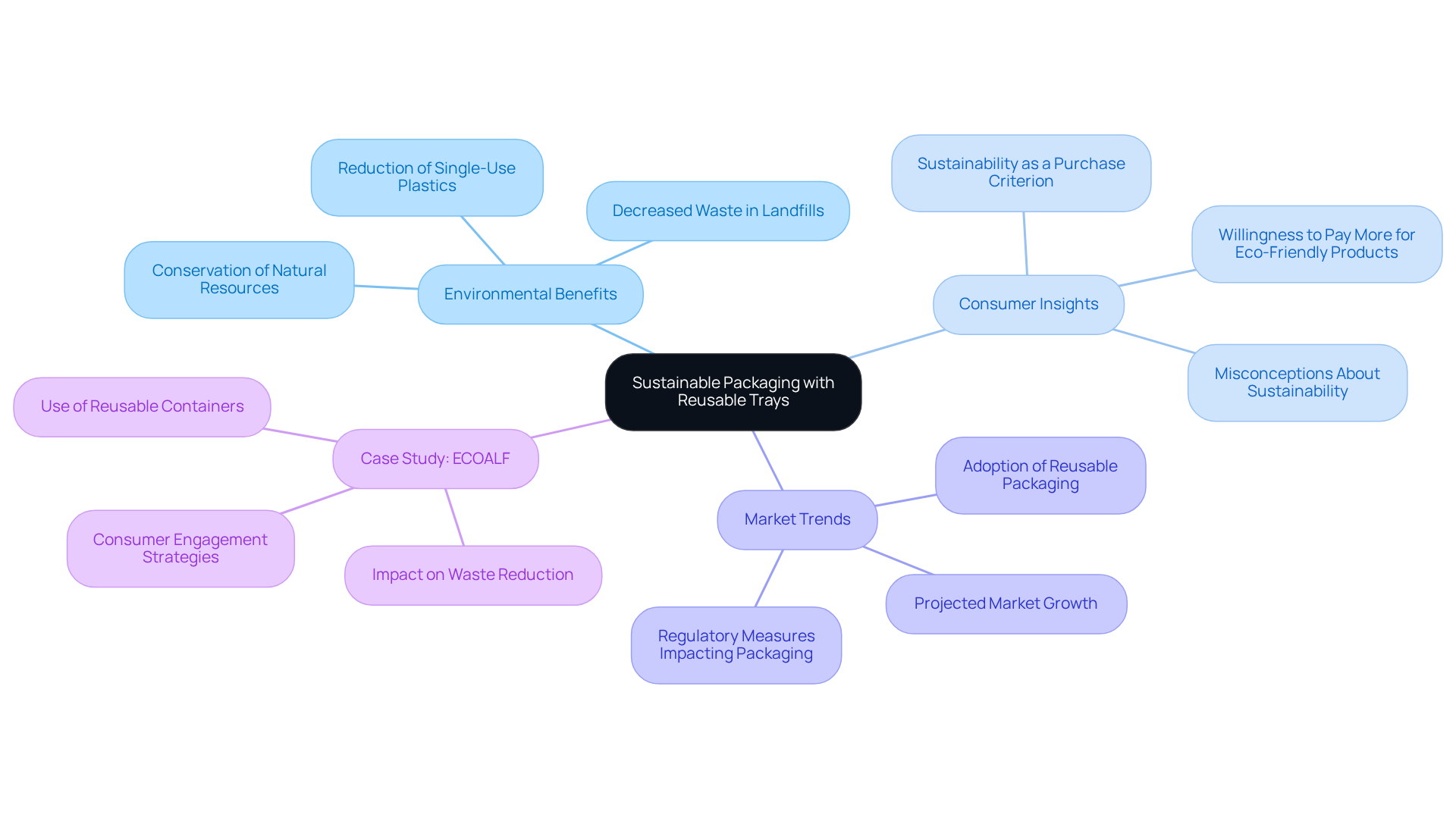

Incorporate Reusable Plastic Trays for Sustainable Packaging

Incorporating reusable plastic trays into retail ready packaging solutions presents a sustainable alternative to traditional packaging methods. These trays can be utilized multiple times, significantly reducing reliance on disposable products and aiding in the elimination of single-use plastics. By adopting reusable trays, businesses not only contribute to sustainability efforts but also attract environmentally conscious consumers who prioritize eco-friendly practices.

Expert insights underscore that the transition towards sustainable solutions is vital in the nutraceutical industry, where half of consumers consider sustainability a primary purchase criterion. Firms such as ECOALF exemplify the importance of minimizing single-use containers in their operations, stating, 'At ECOALF, we have selected reusable vessels for our wellness cosmetics line, which can be cleaned and refilled several times, thereby preventing the accumulation of disposable containers.'

The sustainable container market is projected to expand significantly, reaching USD 423.56 billion by 2029, highlighting the strategic advantages of implementing such solutions for companies aiming to thrive in a competitive landscape.

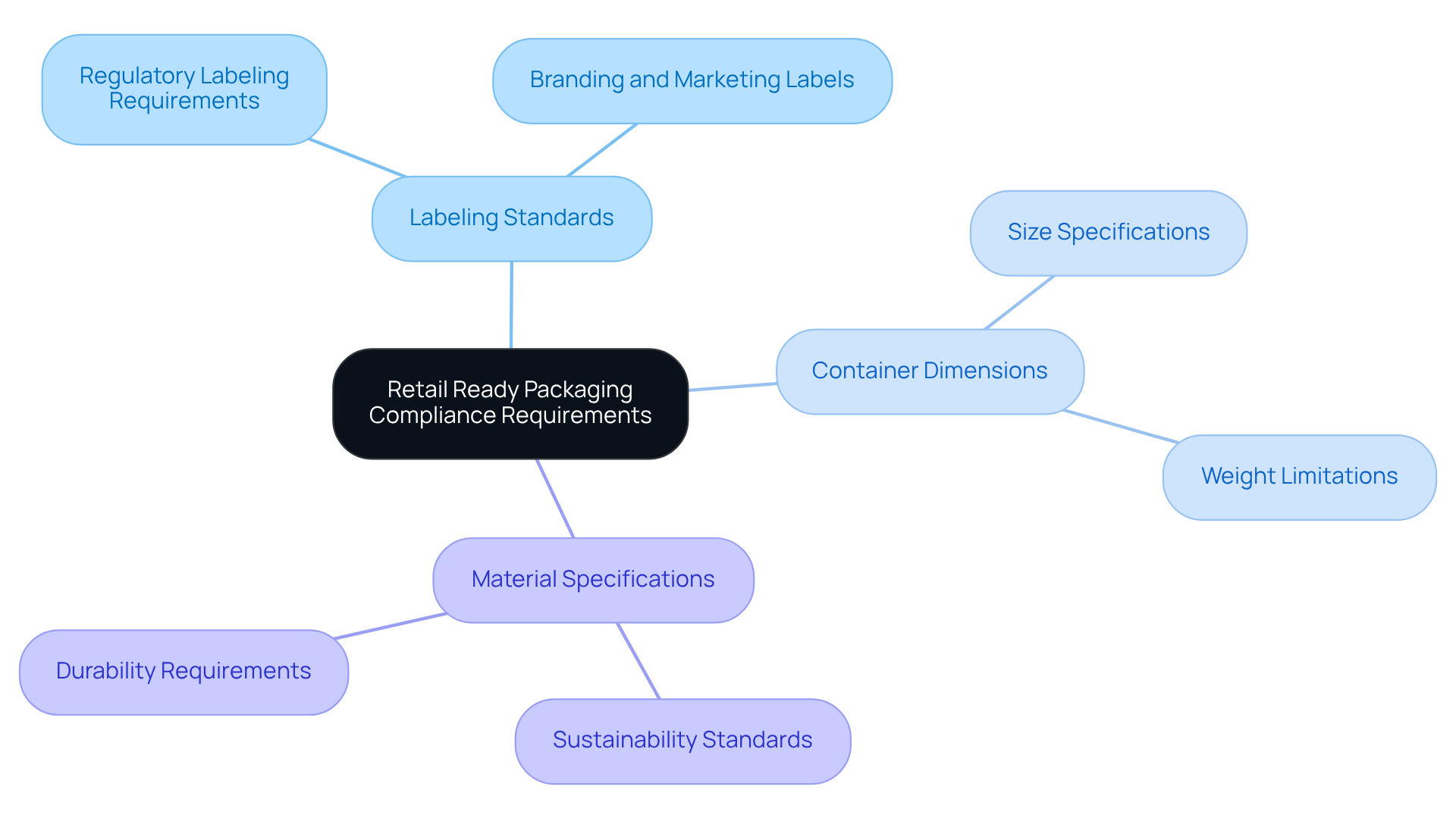

Understand Retail Ready Packaging Requirements for Compliance

Retail ready packaging must comply with specific requirements established by retailers and regulatory bodies. These requirements typically encompass:

- Labeling standards

- Container dimensions

- Material specifications

Understanding and adhering to these compliance standards is crucial for businesses aiming to ensure their products meet the requirements for retail ready packaging and are accepted by retailers. This not only helps avoid potential penalties but also facilitates a smoother market entry. By prioritizing compliance, businesses can position themselves as reliable partners in the logistics and packaging sector, ultimately enhancing their market viability.

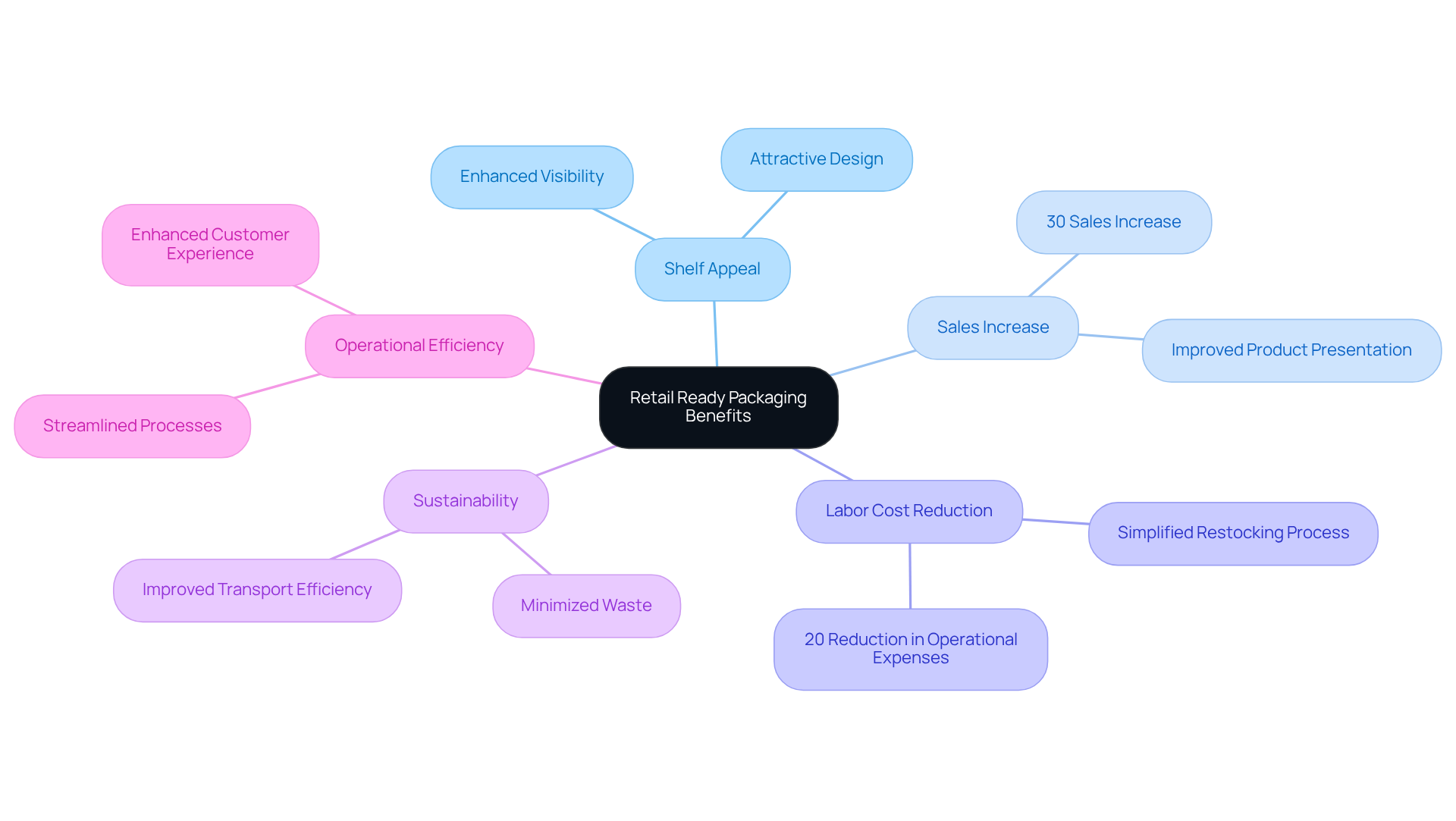

Discover the Comprehensive Benefits of Retail Ready Packaging

Retail ready packaging offers numerous advantages, particularly within the nutraceutical sector. By enhancing shelf appeal and brand visibility, retail ready packaging plays a crucial role in influencing consumer purchasing decisions. Statistics indicate that effective RRP can lead to a sales increase of up to 30%, as products become more visually appealing and easier to locate on crowded shelves. Furthermore, retail ready packaging decreases labor costs by simplifying the restocking process, which enables store personnel to efficiently place products on shelves with minimal handling.

Integrating retail ready packaging into supply chains also supports sustainability initiatives, as it minimizes waste from containers and improves transport efficiency, potentially reducing CO2 emissions. Companies that have adopted retail ready packaging report not only enhanced operational efficiency but also improved customer experiences, fostering increased brand loyalty.

For instance, key players in the nutraceutical sector have leveraged RRP to gain competitive advantages, with some reporting a 20% reduction in operational expenses due to improved design that facilitates easier handling and restocking. This strategic approach to retail ready packaging not only meets consumer demands for convenience but also aligns with the growing trend towards eco-friendly solutions, as brands increasingly prioritize sustainable materials, including FSC-certified options.

By 2025, the retail ready packaging market is projected to reach USD 126.5 billion, highlighting its pivotal role in the future of packaging solutions. By utilizing retail ready packaging, nutraceutical companies can position themselves for growth, enhance their market presence, and ultimately drive sales through superior product presentation and operational efficiencies. Moreover, following the five easies of retail ready packaging—easy to identify, open, replenish, shop, and dispose of—can further optimize operational efficiency and meet retailer requirements.

Conclusion

Retail ready packaging (RRP) emerges as a transformative solution for the nutraceutical industry, providing numerous benefits that enhance product visibility, streamline operations, and promote sustainability. By adopting RRP, businesses can significantly elevate their market presence while addressing consumer demands for convenience and eco-friendliness. This strategic approach not only simplifies the restocking process but also aligns with the growing trend towards sustainable practices, making it a vital component for success in today’s competitive landscape.

The article delineates several key advantages of retail ready packaging, including:

- Reduced packing waste

- Increased operational efficiency

- Improved shelf marketing

Companies that implement RRP report substantial savings in labor costs and enhanced customer engagement through visually appealing displays. Furthermore, the integration of reusable plastic trays and compliance with packaging regulations ensures that businesses can meet both consumer expectations and industry standards, reinforcing their commitment to sustainability.

As the retail ready packaging market continues to expand, it is crucial for nutraceutical manufacturers to embrace these innovative solutions. By prioritizing effective packaging strategies, companies can not only elevate their product offerings but also drive sales and foster brand loyalty. The journey towards sustainable and efficient retail practices begins with the adoption of retail ready packaging, positioning businesses to thrive in an evolving market landscape.

Frequently Asked Questions

What services does Western Packaging provide for the nutraceutical industry?

Western Packaging offers integrated solutions that include packaging design, filling services, and comprehensive third-party logistics (3PL), specifically tailored for the nutraceutical industry. Their services encompass warehousing, inventory management, and logistics.

What types of products can Western Packaging accommodate?

Western Packaging can accommodate a diverse range of items, including powders, gummies, and soft-gels.

How does Western Packaging help businesses improve their market impact?

By merging customized services, Western Packaging helps businesses shorten lead times and enhance product appeal, which establishes them as a trusted ally for firms seeking retail ready packaging.

What is retail ready packaging (RRP)?

Retail ready packaging (RRP) is designed to minimize excess materials, allowing products to be shipped in containers that are ready for display, significantly reducing the need for additional packing materials and waste.

How does RRP contribute to sustainability?

Companies implementing RRP have reported waste reductions of up to 30%, promoting sustainability by lowering their environmental footprint and catering to consumer demand for eco-friendly practices.

What benefits does RRP offer to the nutraceutical sector?

RRP boosts product visibility and ensures that containers are functional and sustainable, which is vital in the nutraceutical sector where product display is important.

What is the market outlook for retail ready containers?

The global retail ready containers market was valued at USD 87.6 billion in 2024 and is expected to grow at a CAGR of 5.4% from 2025 to 2034, indicating a shift towards sustainable solutions in the industry.

How does RRP impact labor costs and operational efficiency?

Implementing retail ready packaging can lower labor expenses by approximately 20% and enhance efficiency during the stocking process, as items are designed for direct placement on shelves, saving time and allowing staff to focus on customer service.

What additional benefits does adopting RRP provide?

Adopting RRP leads to faster restocking times, reduced downtime, improved sales performance, and enhances item visibility, fostering impulse purchases and brand recognition.

How does Western Packaging facilitate the benefits of RRP for manufacturers?

Western Packaging's integrated approach combines design, filling, and logistics services, enabling manufacturers to fully leverage the advantages of retail ready packaging.