Overview

The article examines seven innovative pharmaceutical packaging solutions that enhance efficiency through various strategies, including automation, smart technologies, and sustainable practices.

Supported by industry trends and case studies, these solutions demonstrate their effectiveness in improving supply chain operations, ensuring product integrity, and promoting patient adherence.

By adopting these advanced packaging strategies, industry professionals can significantly elevate their operational capabilities and meet the evolving demands of the market.

Introduction

The pharmaceutical industry stands poised at the threshold of a packaging revolution, where innovation is no longer a luxury but a necessity for enhancing efficiency and ensuring safety. As companies grapple with the complexities of regulatory compliance, consumer expectations, and environmental concerns, the adoption of cutting-edge packaging solutions emerges as a vital strategy.

What challenges do these advancements present, and how can businesses harness them to bolster operational effectiveness and safeguard product integrity? Delving into these innovative pharmaceutical packaging solutions unveils a landscape teeming with opportunities for improvement and sustainability.

Western Packaging: Integrated Packaging Solutions for Enhanced Efficiency

Western Packaging offers a comprehensive suite of services that seamlessly integrates packaging design, filling, and third-party logistics (3PL). Our 3PL services enhance your supply chain with customized offerings, including:

- Warehousing

- Inventory management

- Logistics

This holistic approach streamlines the supply chain, significantly reducing lead times and improving product delivery. By providing tailored options, Western Packaging empowers businesses to optimize their operations, ensuring compliance with regulatory standards while meeting consumer expectations. Our expertise in adaptable wrapping solutions not only enhances brand recognition but also fortifies market presence.

Industry leaders recognize that merging container design with logistics, particularly innovative pharmaceutical packaging, can yield substantial efficiency improvements. For instance, a recent case study highlighted how a nutraceutical firm that adopted integrated wrapping strategies reported a 30% enhancement in operational workflows and a notable increase in customer satisfaction.

Furthermore, Aditi Shivarkar, a research lead in consumer goods, emphasizes that 'the combination of design and logistics is essential for improving efficiency and satisfying the changing needs of the market.' Moreover, recent trends indicate a shift towards sustainable practices and the integration of digital technologies such as RFID tags, which are becoming increasingly vital in the healthcare sector, particularly with the rise of biologics and the growing demand for innovative pharmaceutical packaging solutions.

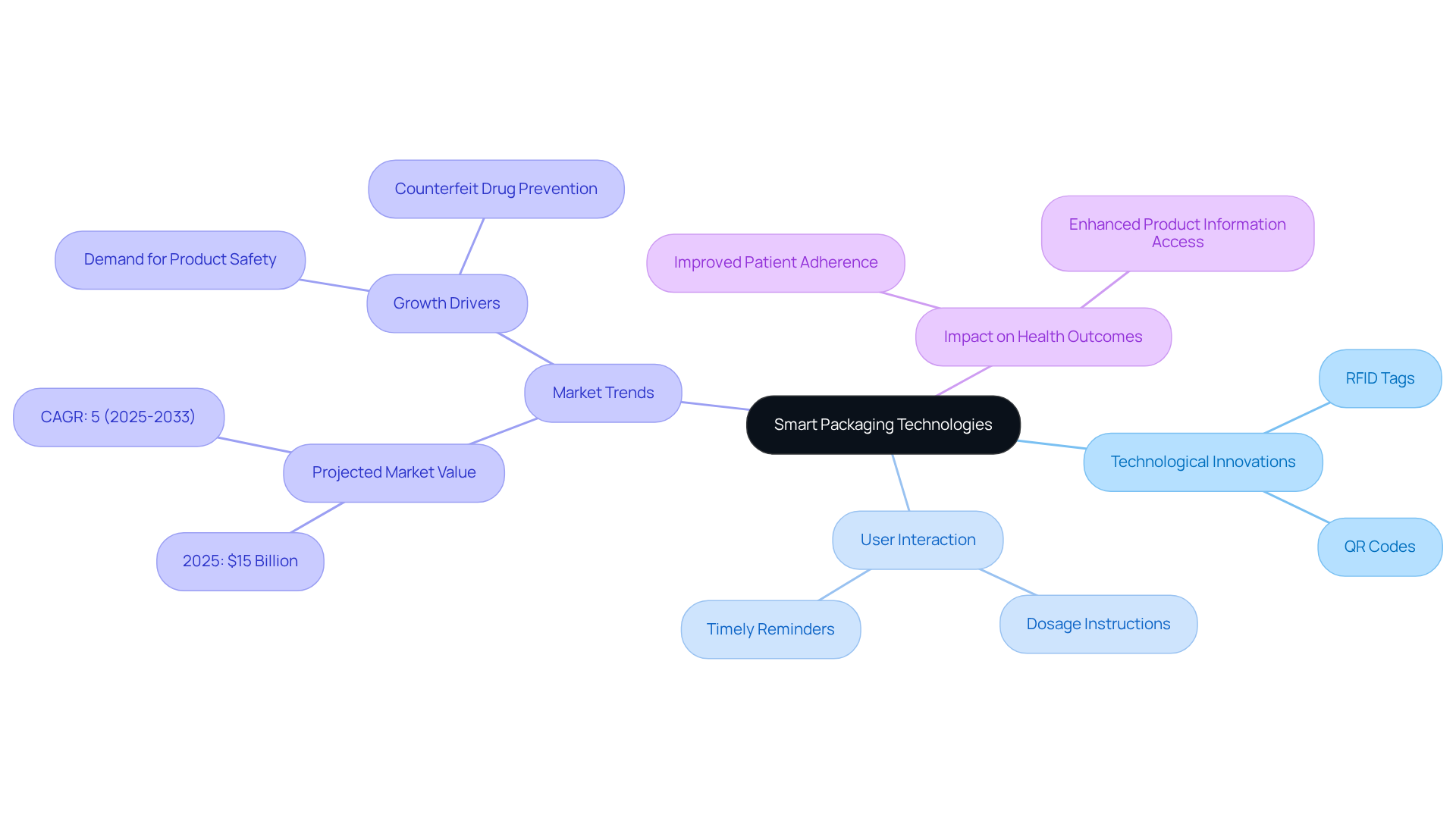

Smart Packaging Technologies: Enhancing Tracking and User Interaction

Intelligent container technologies, such as RFID tags and QR codes, are revolutionizing the pharmaceutical supply chain by enabling real-time monitoring of items, which is a key aspect of innovative pharmaceutical packaging throughout the distribution process. These innovations in innovative pharmaceutical packaging not only enhance visibility but also significantly improve user interaction by providing consumers with instant access to critical product information.

For instance, patients can scan a QR code on their medication containers to receive dosage instructions or timely reminders—an essential factor for maintaining adherence to prescribed schedules. This interactive approach is particularly crucial in the drug industry, where innovative pharmaceutical packaging is essential for improving patient adherence, which is directly linked to health outcomes.

According to industry reports, the global smart pharmaceutical container market is projected to reach approximately $15 billion by 2025, with a CAGR of 5% from 2025 to 2033. Furthermore, Suraj Gujar emphasizes that 'innovative pharmaceutical packaging, which includes intelligent wrapping methods such as sensors and RFID tags, enables the real-time monitoring of items throughout the supply chain.'

The integration of these technologies is further supported by trends indicating a growing demand for innovative pharmaceutical packaging that ensures product authenticity and safety, especially in the fight against counterfeit drugs. As the market evolves, nutraceutical producers are encouraged to consider the adoption of RFID and QR code technologies in their containers to enhance patient engagement and adherence.

Sustainable Packaging Solutions: Reducing Environmental Impact

Sustainable wrapping solutions are increasingly vital as companies strive to reduce their environmental impact. Options such as biodegradable materials, recyclable plastics, and minimalistic designs are gaining significant traction. Leading this initiative, firms like Western Packaging are providing innovative pharmaceutical packaging solutions that not only protect products but also adhere to environmentally friendly practices. By adopting eco-friendly materials, businesses can attract environmentally conscious consumers and comply with evolving regulations. This commitment not only enhances brand reputation but also positions companies as responsible market leaders. As the demand for sustainable packaging grows, it is imperative for businesses to embrace these solutions and demonstrate their commitment to the environment.

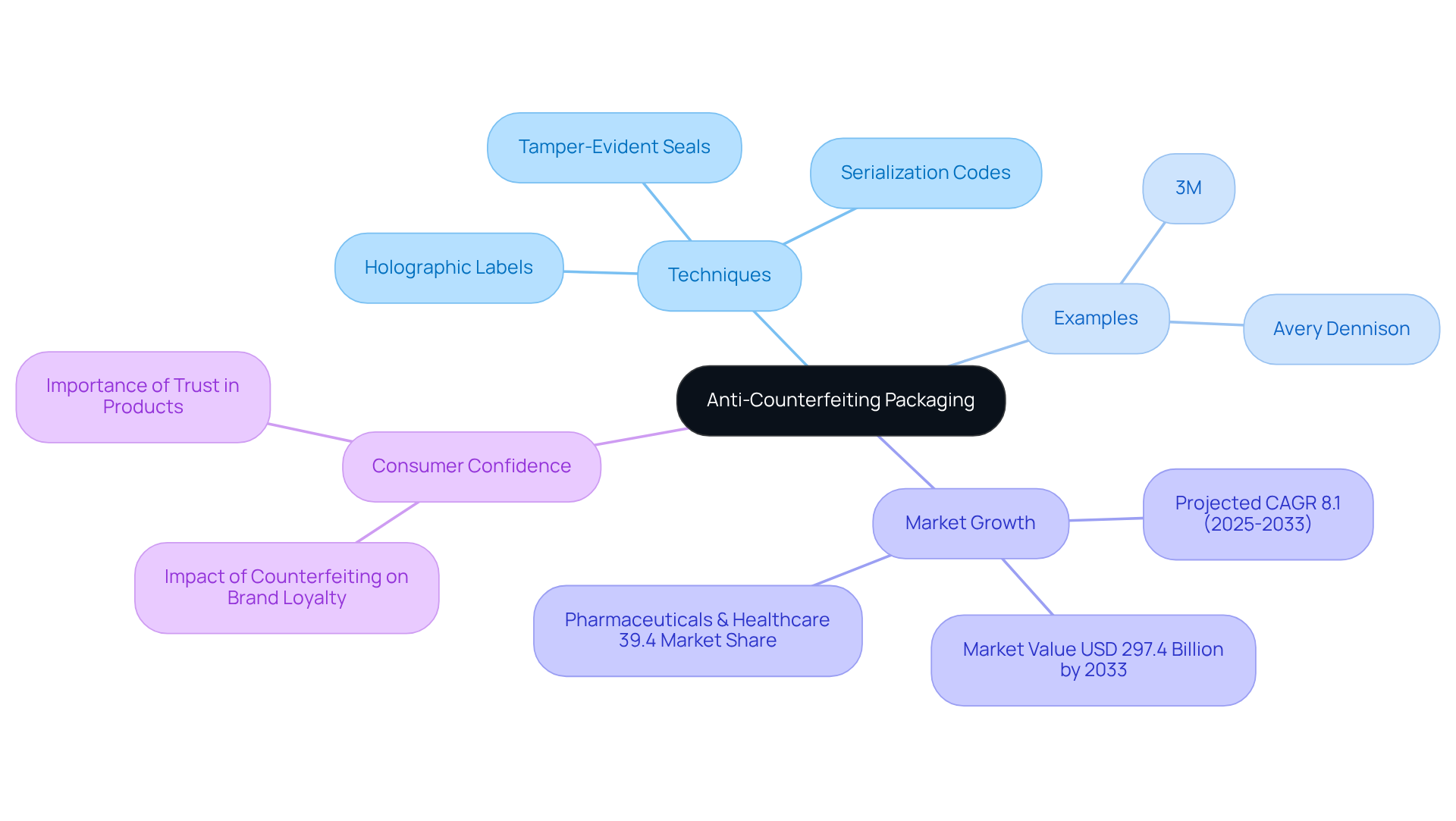

Anti-Counterfeiting Packaging: Ensuring Product Integrity and Safety

Anti-counterfeiting wrapping solutions are critical for safeguarding item integrity and ensuring consumer safety. Techniques such as holographic labels, tamper-evident seals, and unique serialization codes are effectively employed to combat counterfeit products.

For instance, companies like 3M and Avery Dennison have integrated tamper-evident features into their containers, significantly enhancing the security of pharmaceuticals. According to the Pharmaceutical Security Institute, these measures are vital for maintaining consumer confidence and protecting public health.

As regulatory frameworks tighten, businesses are increasingly compelled to invest in innovative pharmaceutical packaging technologies to comply with safety standards and defend their products against fraud. The anti-counterfeiting materials market is projected to grow at a CAGR of 8.1% from 2025 to 2033, underscoring the escalating demand for effective solutions.

The implementation of these technologies is essential; studies indicate that robust anti-counterfeiting measures can bolster consumer confidence and loyalty, ultimately driving market success.

Personalized Packaging: Tailoring Solutions for Patient Needs

Innovative pharmaceutical packaging with customized container solutions is increasingly vital in the pharmaceutical sector, particularly for medications that require specific dosing instructions. By tailoring containers to address individual patient needs—such as incorporating clear labeling and user-friendly designs—companies can significantly enhance medication adherence.

For instance, studies have shown that patients utilizing daily-dose blister containers exhibit higher medication possession ratios, with adherence rates improving by 12% compared to conventional pill bottles. This customized strategy not only enhances the user experience but also promotes improved health outcomes, making innovative pharmaceutical packaging a crucial factor for drug manufacturers.

Healthcare professionals underscore that providing medications in packages that clearly indicate the day and time for each dose can lead to better treatment regimen adherence, especially among elderly patients. As the prevalence of chronic conditions rises, the significance of tailored solutions in promoting patient compliance cannot be overstated.

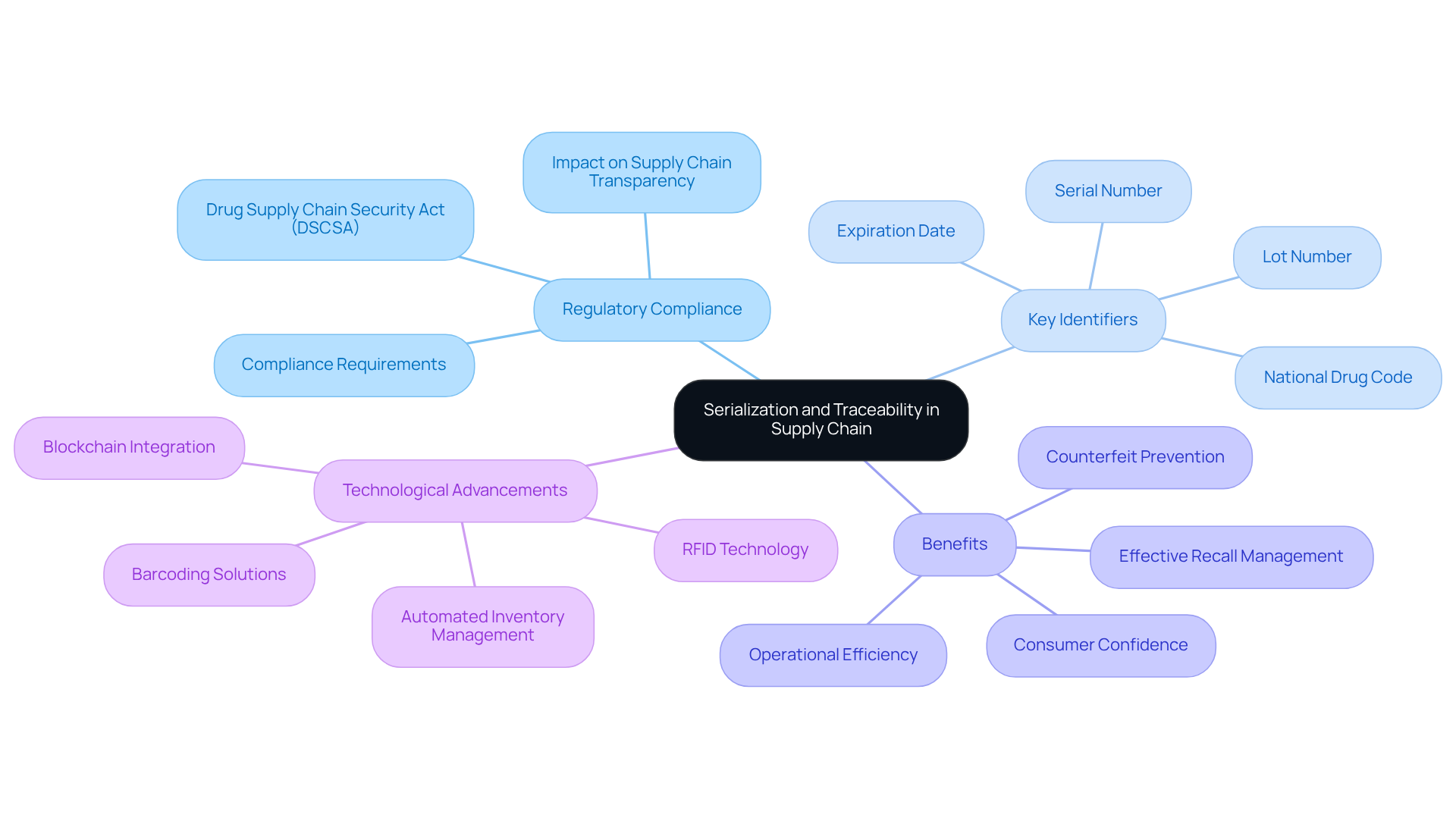

Serialization and Traceability: Enhancing Supply Chain Transparency

Serialization and traceability stand as pillars in modern medicine packaging, empowering companies to assign unique identifiers to each item. This essential practice not only facilitates tracking throughout the supply chain but also ensures compliance with regulations such as the Drug Supply Chain Security Act (DSCSA). The DSCSA mandates that pharmaceutical items bear critical identifiers, including:

- National Drug Code

- Serial number

- Lot number

- Expiration date

Thereby enhancing transparency and accountability within the industry.

The implementation of robust serialization systems significantly aids effective recall management while bolstering consumer confidence through authenticity assurance. As one regulatory expert aptly stated, "Serialization is more than putting a number on a bottle; it fundamentally changes how your company conducts business." This transformation is vital for companies aiming to streamline operations while adhering to stringent regulatory requirements.

Furthermore, the influence of the DSCSA transcends mere compliance; it cultivates greater supply chain transparency. By embedding serialization into packaging practices, companies can elevate their operational efficiency and mitigate risks associated with counterfeit products. The adoption of advanced traceability technologies, such as RFID, plays a transformative role in enhancing tracking capabilities and safeguarding the integrity of the supply chain. As the medical industry continues to evolve, the demand for effective traceability solutions will only escalate, making it imperative for businesses to invest in cutting-edge serialization technologies that ensure safety and compliance. Moreover, the drug serialization services market is projected to experience significant growth, underscoring the increasing importance of these practices in the industry.

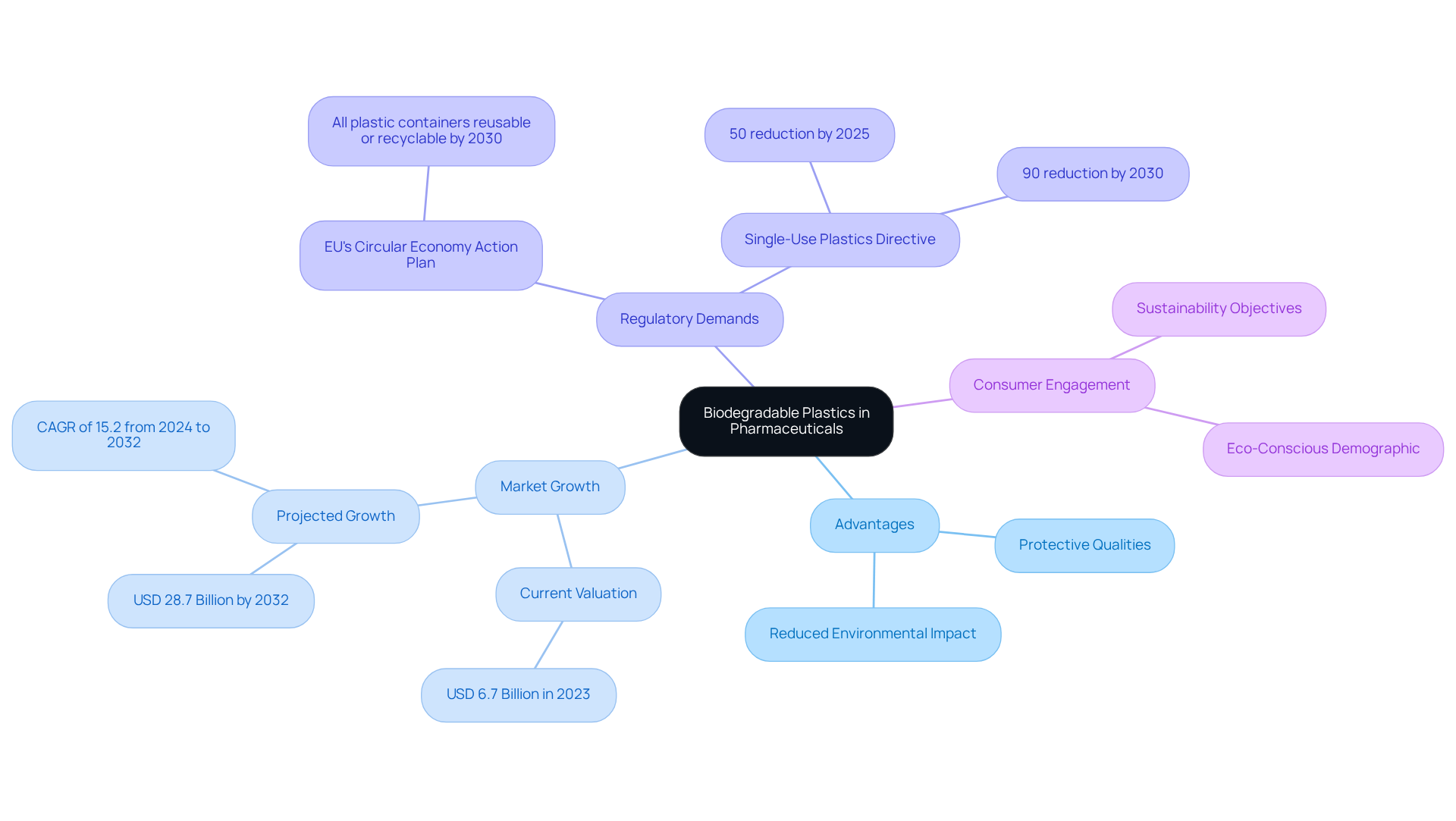

Innovative Materials: Biodegradable Plastics for Sustainable Packaging

Innovative materials, particularly biodegradable plastics, are transforming the pharmaceutical container landscape. These materials provide the same protective qualities as traditional plastics while significantly reducing environmental impact. Companies in the nutraceutical sector are increasingly adopting bioplastics derived from renewable resources, which decompose more easily than conventional plastics. This advantage not only aids in minimizing waste but also aligns with regulatory demands, such as the EU's Circular Economy Action Plan, which aims to make all plastic containers reusable or recyclable by 2030.

By integrating these materials into their products, nutraceutical producers can achieve sustainability objectives and engage a growing demographic of environmentally conscious consumers. This shift is vital, as the biodegradable plastics market, valued at USD 6.7 billion in 2023, is projected to expand to USD 28.7 billion by 2032, reflecting a compound annual growth rate of 15.2% from 2024 to 2032.

Companies in the nutraceutical sector that utilize innovative pharmaceutical packaging with biodegradable plastics can enhance their sustainability profiles and meet the demands of eco-aware consumers, positioning these materials as a critical component of modern pharmaceutical solutions.

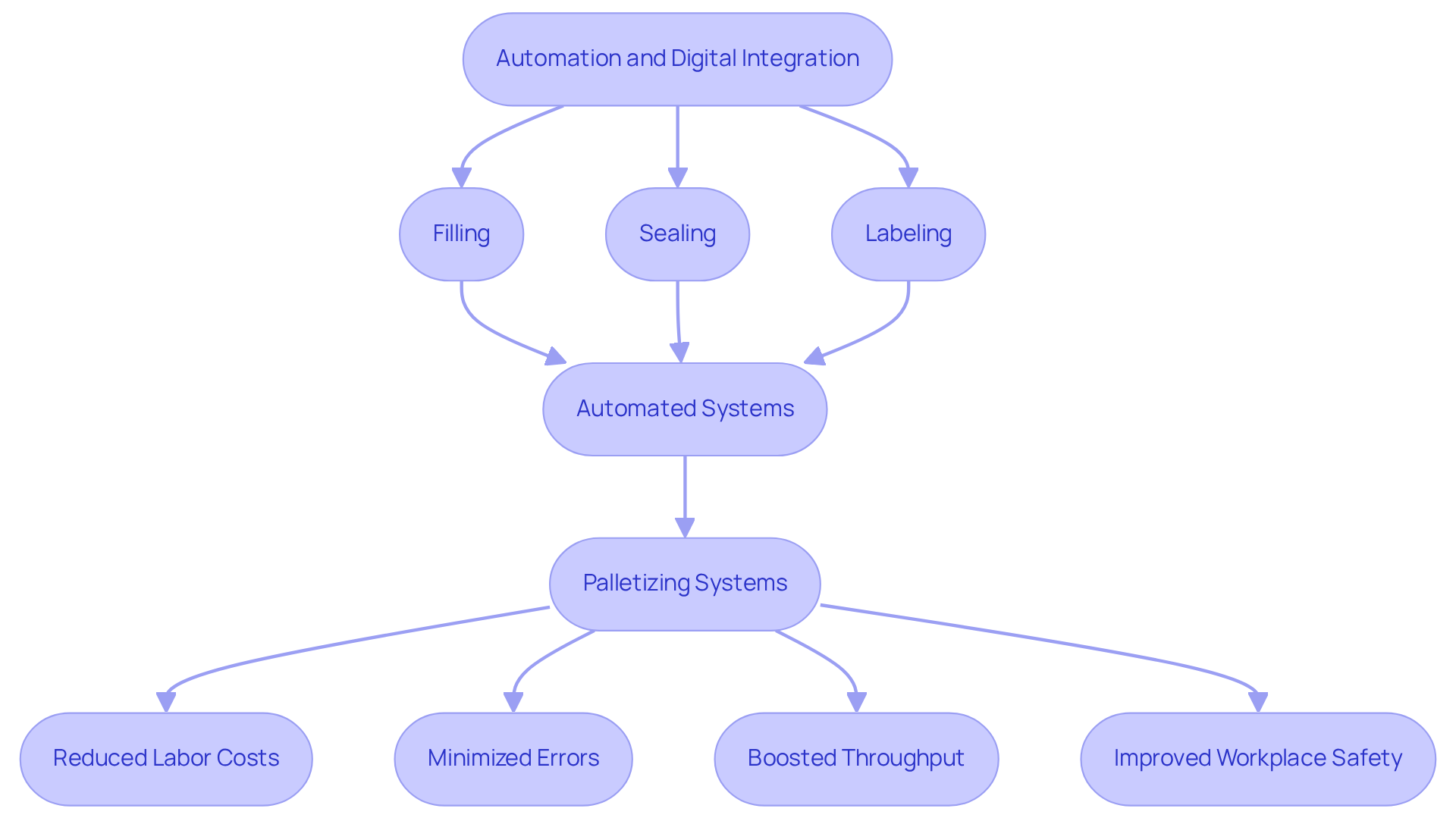

Automation and Digital Integration: Streamlining Packaging Operations

Automation and digital integration are essential for enhancing efficiency in production operations. By implementing automated systems for filling, sealing, and labeling, companies can realize substantial reductions in labor costs and minimize errors. For example, automated palletizing systems can manage up to 30 units per minute, optimizing the packing process and boosting throughput by as much as 200%. Moreover, digital tools enable real-time monitoring of production processes, allowing for rapid adjustments that strengthen quality control.

As the container industry progresses, the incorporation of automation is not just advantageous but vital for companies seeking to improve operational capabilities and sustain a competitive advantage. Notably, trends reveal that over 70% of automation users report improved workplace safety, underscoring the diverse benefits of these technologies. Embracing these innovations is imperative for businesses aiming to excel in an ever-evolving market landscape.

Enhanced Safety Features: Protecting Products and Ensuring Compliance

Enhanced safety attributes in containers are essential for protecting items from contamination and ensuring compliance with health regulations. Key features such as:

- Tamper-evident seals

- Child-resistant closures

- Moisture barriers

are vital in preserving item integrity. By prioritizing safety in container design, companies not only protect their products but also foster consumer trust and meet stringent regulatory standards. This commitment to quality not only safeguards your brand but establishes a reliable reputation in the marketplace. Embrace these advancements in innovative pharmaceutical packaging to secure your products and enhance your brand's integrity.

User-Friendly Packaging Design: Improving Patient Adherence

User-friendly container design is crucial for enhancing patient adherence to medication regimens. Intuitive containers that are easy to open, clearly labeled, and user-focused significantly reduce barriers to medication use. For instance, blister packs enable patients to easily track their doses, resulting in improved compliance rates.

Research indicates that container interventions, such as blister packs and pill boxes, effectively increase medication adherence, with treatment subjects demonstrating a 71% adherence rate compared to 63% in control groups. By prioritizing the end-user experience, pharmaceutical companies can develop solutions that not only comply with regulatory standards but also promote better health outcomes.

As healthcare professionals have observed, "Inadequate medication adherence is a widespread problem that contributes to increased chronic disease complications and healthcare expenditures." This highlights the urgent need for innovative packaging designs that facilitate medication management, ultimately benefiting patient health and reducing overall healthcare costs.

Conclusion

The exploration of innovative pharmaceutical packaging solutions reveals a transformative shift in the industry, emphasizing the critical role of efficiency, safety, and sustainability. As companies navigate regulatory complexities and rising consumer expectations, adopting advanced packaging technologies becomes essential for maintaining competitiveness and ensuring product integrity.

Key insights from this discussion highlight the importance of:

- Integrated packaging solutions

- Smart technologies

- Sustainable practices

Companies like Western Packaging are leading the charge by offering tailored services that streamline operations and enhance supply chain transparency. Moreover, the integration of features such as anti-counterfeiting measures, user-friendly designs, and biodegradable materials illustrates a commitment to both consumer safety and environmental responsibility.

As the pharmaceutical landscape continues to evolve, businesses must embrace these innovations not only to meet current demands but also to anticipate future trends. Investing in smart packaging technologies and sustainable solutions is not just a strategic move; it is a necessary step towards fostering a more efficient, transparent, and responsible industry. The call to action for stakeholders is clear: prioritize innovative packaging strategies that enhance patient adherence, protect product integrity, and contribute positively to the environment.

Frequently Asked Questions

What services does Western Packaging offer?

Western Packaging offers integrated packaging solutions that include packaging design, filling, and third-party logistics (3PL) services such as warehousing, inventory management, and logistics.

How does Western Packaging enhance supply chain efficiency?

By providing a holistic approach that streamlines the supply chain, Western Packaging reduces lead times, improves product delivery, and empowers businesses to optimize their operations while ensuring compliance with regulatory standards.

What impact can integrated wrapping strategies have on operational workflows?

A case study showed that a nutraceutical firm that adopted integrated wrapping strategies reported a 30% enhancement in operational workflows and an increase in customer satisfaction.

What is the significance of merging container design with logistics?

Merging container design with logistics is essential for improving efficiency and meeting the changing needs of the market, particularly in the pharmaceutical sector.

What are some emerging trends in pharmaceutical packaging?

Emerging trends include a shift towards sustainable practices and the integration of digital technologies such as RFID tags, which are crucial for innovative pharmaceutical packaging solutions.

How do intelligent container technologies enhance the pharmaceutical supply chain?

Technologies like RFID tags and QR codes enable real-time monitoring of items, enhancing visibility and improving user interaction by providing consumers with instant access to critical product information.

How can QR codes improve patient adherence in medication?

Patients can scan QR codes on medication containers to receive dosage instructions or reminders, which helps maintain adherence to prescribed schedules.

What is the projected market size for smart pharmaceutical containers?

The global smart pharmaceutical container market is projected to reach approximately $15 billion by 2025, with a compound annual growth rate (CAGR) of 5% from 2025 to 2033.

Why are sustainable packaging solutions important?

Sustainable packaging solutions are crucial for reducing environmental impact, attracting environmentally conscious consumers, and complying with evolving regulations, thus enhancing brand reputation.

What materials are being adopted for sustainable packaging?

Companies are increasingly using biodegradable materials, recyclable plastics, and minimalistic designs in their packaging to align with environmentally friendly practices.