Overview

The key benefits of kit assembly for nutraceutical manufacturers are substantial:

- Enhanced operational efficiency

- Improved compliance with regulations

- Increased customer satisfaction through personalized packaging

Streamlined kit assembly processes significantly reduce production time and errors, ensuring adherence to safety standards. Moreover, they create customized solutions that resonate with consumer preferences, ultimately driving brand loyalty and enhancing market competitiveness. This expertise in kit assembly not only meets industry standards but also positions manufacturers for sustained success.

Introduction

The nutraceutical industry is rapidly evolving, with manufacturers consistently seeking innovative methods to enhance production processes and meet consumer demands. Kit assembly has emerged as a pivotal strategy, offering a multitude of benefits that streamline operations and improve product delivery. As companies strive for efficiency and compliance in an increasingly competitive market, one must consider: how can effective kit assembly not only optimize production but also elevate brand loyalty and customer satisfaction? This article delves into the seven key advantages of kit assembly for nutraceutical manufacturers, uncovering how this approach can transform their operational landscape.

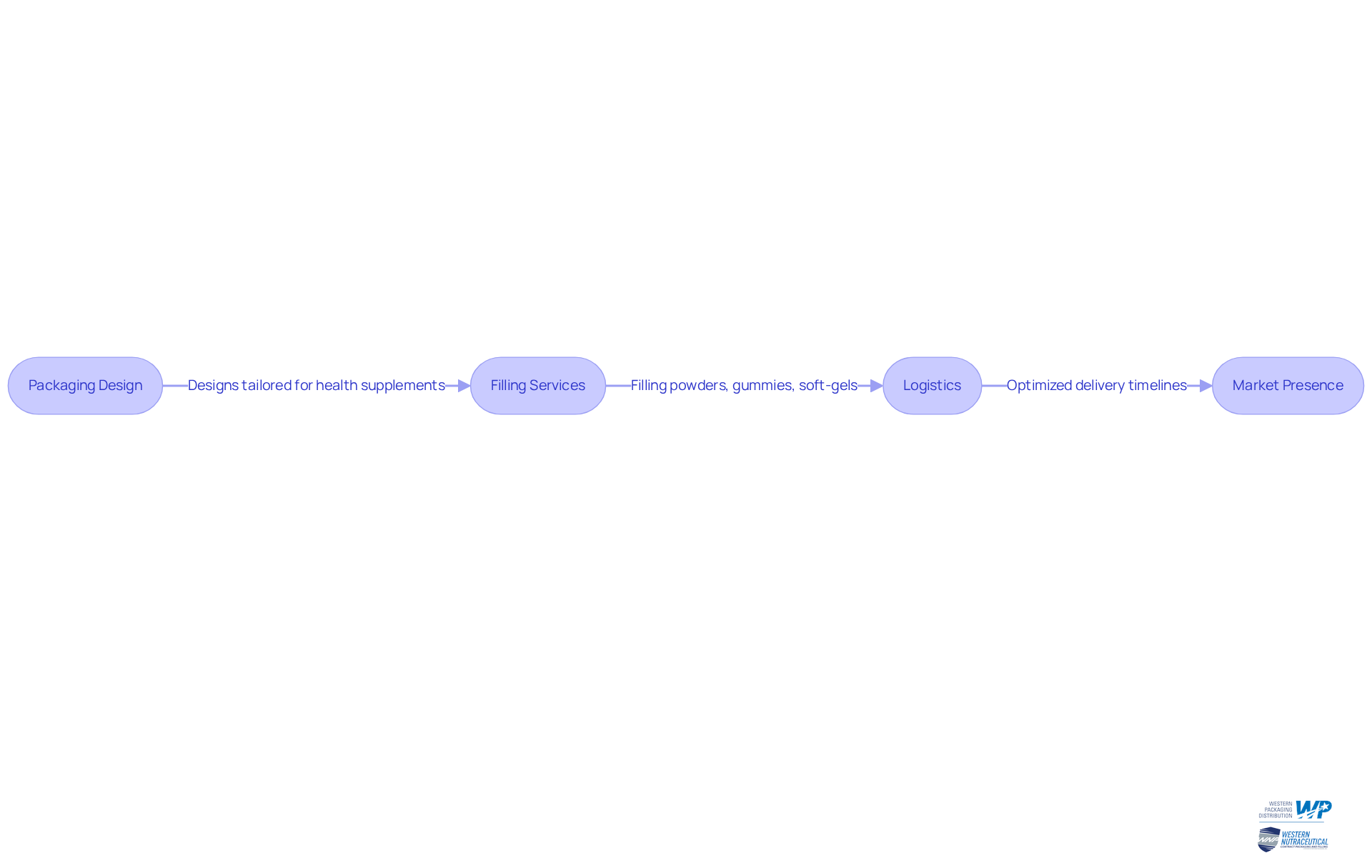

Western Packaging: Integrated Kit Assembly Services for Nutraceuticals

Western Packaging specializes in providing kit assembly services specifically tailored for the health supplement sector. Our comprehensive 3PL solutions seamlessly integrate packaging design, filling services—including powders, gummies, and soft-gels—and logistics. This tailored approach optimizes processes, allowing producers to concentrate on their core competencies. By enhancing operational efficiency and improving product delivery timelines, our services are indispensable for health supplement businesses.

Recent trends reveal that companies implementing integrated packaging and logistics solutions achieve a notable reduction in lead times. Studies indicate that 70% of customers are influenced by packaging design in their purchasing choices. Industry leaders assert that holistic packaging solutions not only boost product visibility but also cultivate brand loyalty; indeed, 94% of consumers prefer brands that demonstrate transparency in their packaging.

Successful case studies illustrate how companies have optimized their supply chains through Western Packaging's end-to-end services, resulting in enhanced market presence and operational effectiveness. As the demand for eco-friendly and effective packaging continues to rise—evidenced by the worldwide biodegradable paper and plastic packaging market projected to reach $23.4 billion by 2030—Western Packaging's kit assembly services provide a strategic advantage for health supplement producers.

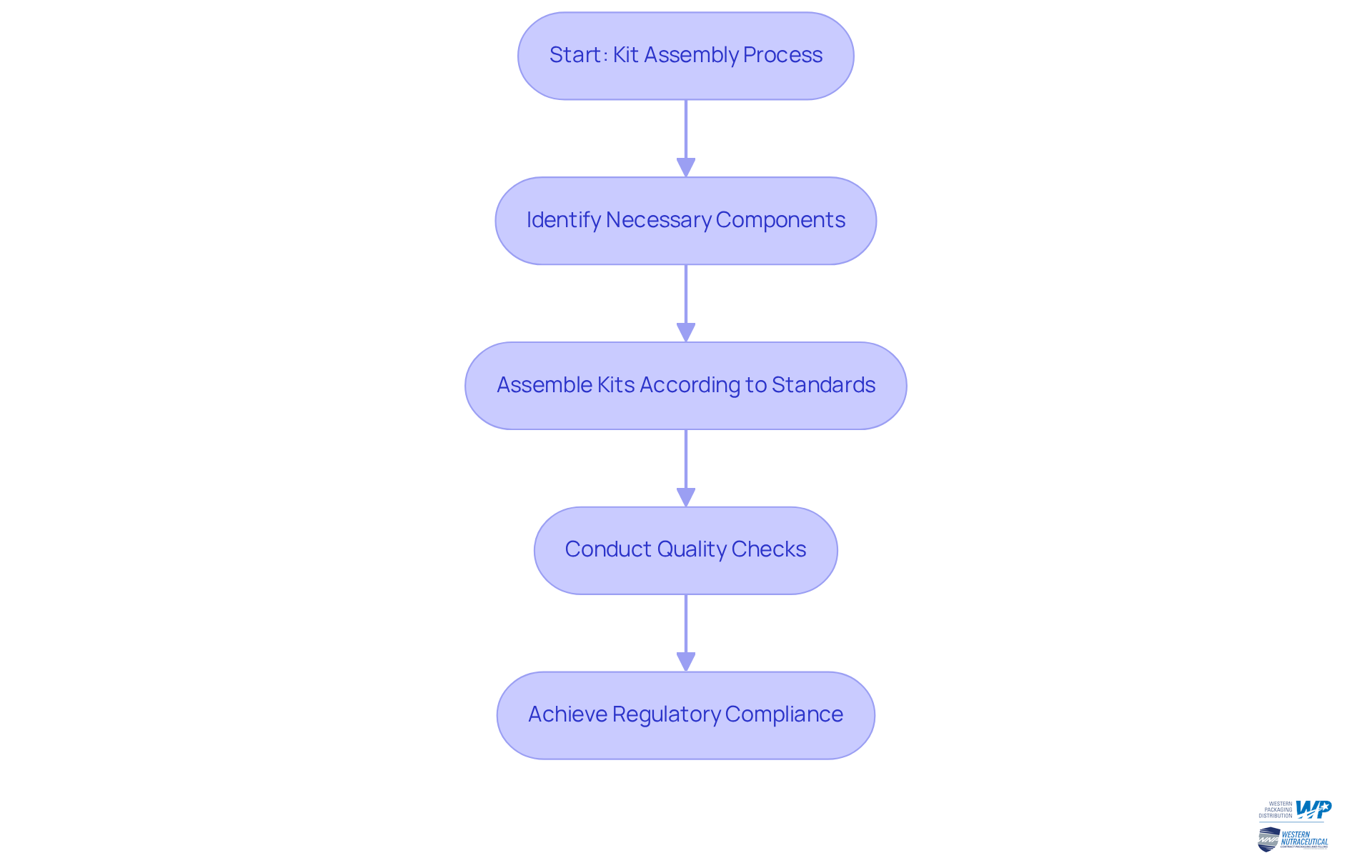

Ensure Regulatory Compliance with Effective Kit Assembly

Nutraceutical producers striving to meet industry regulations, particularly concerning labeling and safety standards established by key regulatory agencies such as the FDA and cGMP, find that effective kit assembly is essential. By utilizing kit assembly that includes all necessary components, companies can streamline their compliance processes, significantly diminishing the risk of errors that could lead to regulatory penalties, including recalls, legal action, and erosion of consumer trust.

Western Packaging's expertise in kit assembly ensures that each kit adheres to the stringent standards set by these regulatory organizations, thereby protecting producers from potential legal repercussions. This proactive approach not only enhances product safety but also fosters consumer confidence, as accurate labeling and compliance with safety regulations are vital in the health supplement sector.

Moreover, the emphasis on quality, accuracy, and precision in product offerings highlights Western Packaging's dedication to assisting clients in effectively navigating the intricate compliance landscape.

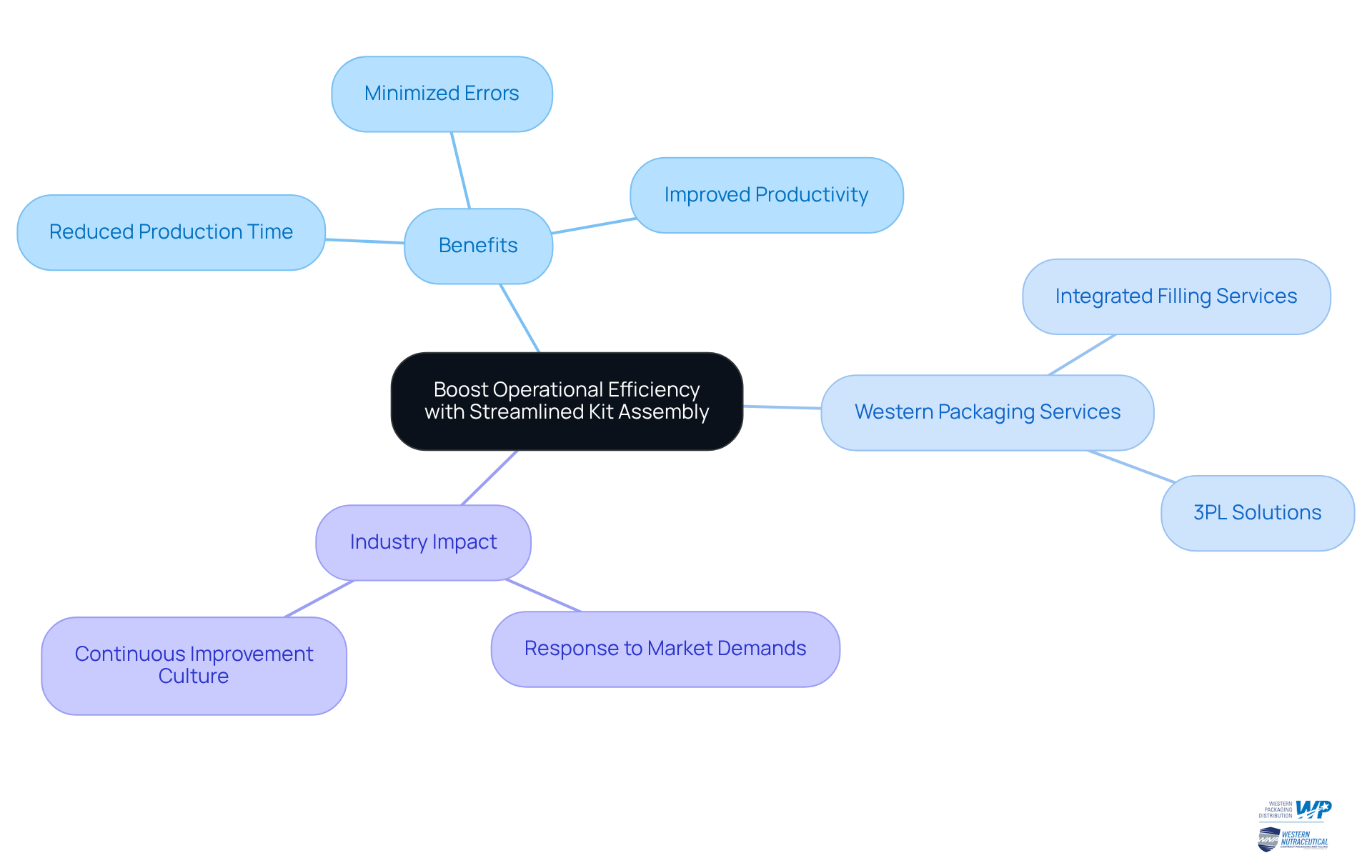

Boost Operational Efficiency with Streamlined Kit Assembly

Streamlined kit assembly is essential for enhancing operational efficiency among nutraceutical producers. By organizing components into kit assembly, companies can drastically reduce production time and minimize the risk of errors. Statistics reveal that kitting can significantly cut downtime in manufacturing, providing workers with all necessary components at their fingertips, which results in faster turnaround times and improved productivity. This heightened efficiency empowers manufacturers to respond swiftly to market demands, ensuring they maintain a competitive edge.

Western Packaging's integrated filling services and comprehensive 3PL solutions are meticulously designed to optimize every facet of the production process, delivering tailored solutions that enhance productivity and accuracy. These solutions cater to a diverse range of products, including powders, gummies, and soft-gels, streamlining both production and supply chain efficiency.

As highlighted by industry experts, effective kit assembly not only simplifies fulfillment but also fosters a culture of continuous improvement, ultimately driving operational excellence.

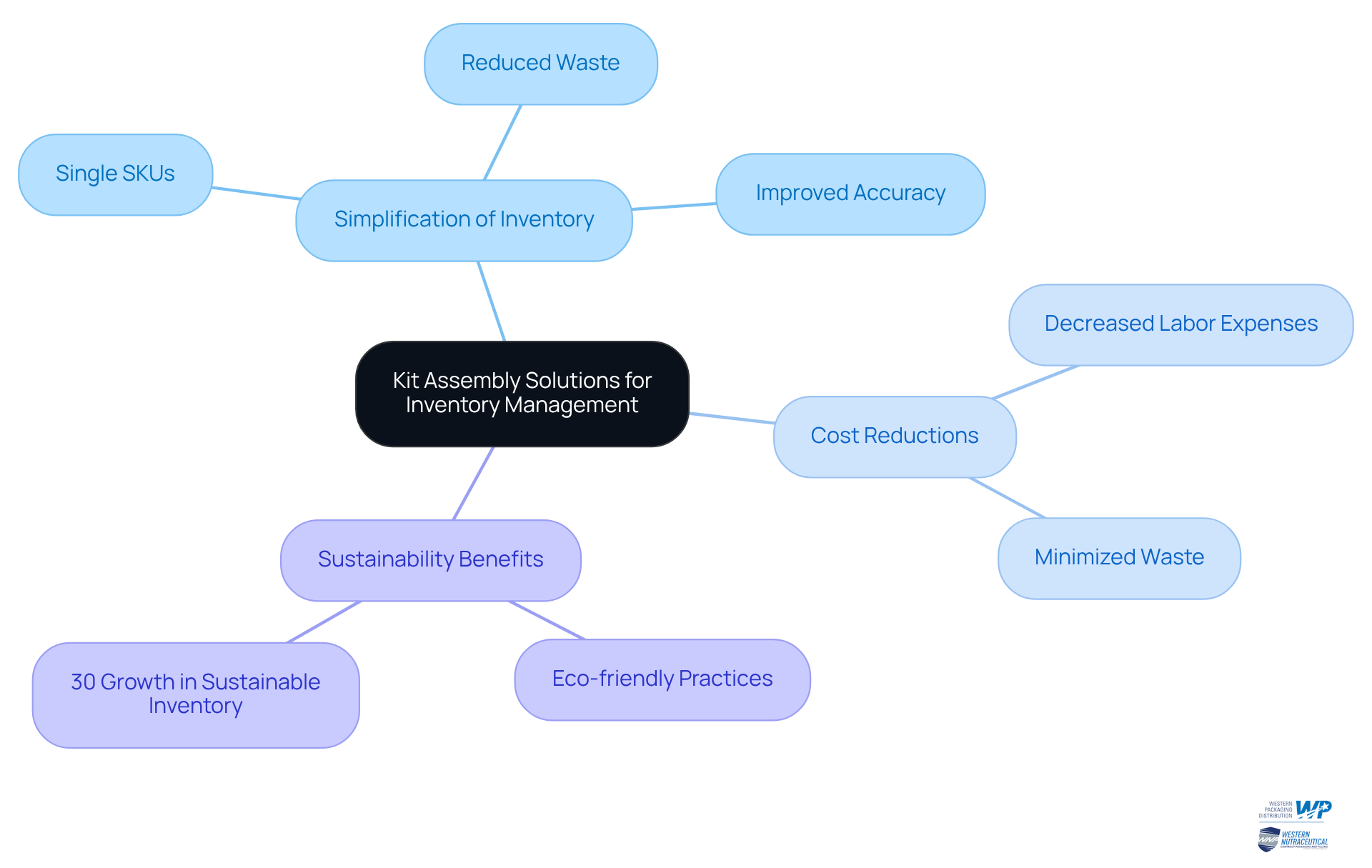

Enhance Inventory Management through Kit Assembly Solutions

Kit assembly solutions significantly enhance inventory management by consolidating multiple components into single SKUs. This simplification minimizes the complexity associated with tracking individual items, resulting in more accurate inventory counts and reduced waste.

For health supplement producers, embracing this method can lead to considerable cost reductions, as kit assembly solutions offer substantial savings by decreasing labor expenses and minimizing waste and redoing work. Companies that have implemented single SKU strategies report improved inventory accuracy, with automated systems, particularly barcoding systems, increasing tracking efficiency by up to 85%.

By utilizing Western Packaging's kit preparation services, producers can guarantee they possess the correct components readily available, ultimately enhancing supply chain efficiency and responsiveness to market demands.

This integrated approach not only enhances operational effectiveness but also aligns with sustainability goals; sustainability-focused inventory practices are growing by 30%, reducing excess inventory and waste, and contributing to a more eco-friendly supply chain.

Improve Product Presentation with Customized Kit Assembly

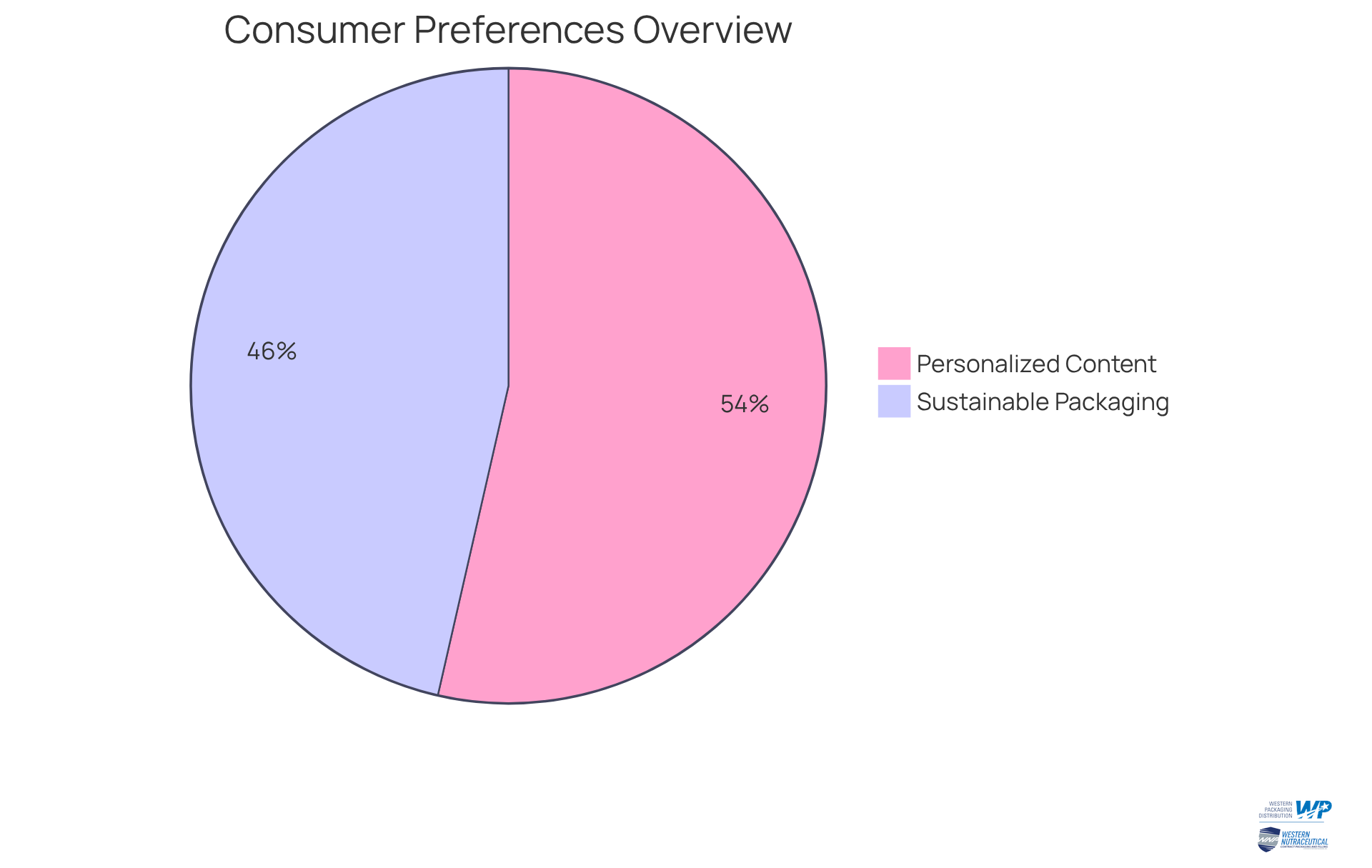

Personalized kit assembly empowers supplement producers to enhance product display, significantly increasing consumer attraction. By aligning packaging and kit assembly with brand identity and consumer preferences, companies can cultivate a more engaging product experience. Research indicates that 75% of consumers are more likely to purchase from brands that offer personalized content, underscoring the critical role of tailored packaging in driving sales.

Western Packaging's expertise in innovative packaging design guarantees that the kit assembly not only meets functional requirements but also captivates the target audience, ultimately enhancing brand loyalty. Our customized flexible packaging solutions, including large pouches for protein products and stick packs for nutraceuticals, elevate product appeal and cater to unique needs.

As brands adapt to the 2025 trend of prioritizing clarity, accessibility, and sustainability, effective packaging emerges as a vital touchpoint in consumer interactions, reinforcing the brand's essence and values. Furthermore, with 60 to 70 percent of US consumers willing to pay more for sustainable packaging when labeled as eco-friendly, integrating sustainability into customized packaging strategies is imperative.

Successful health supplement brands have embraced customized packaging in their kit assembly to boost engagement and drive growth. To implement these strategies effectively, producers should collaborate with Western Packaging, leveraging our tailored solutions and expertise to resonate with their target audience.

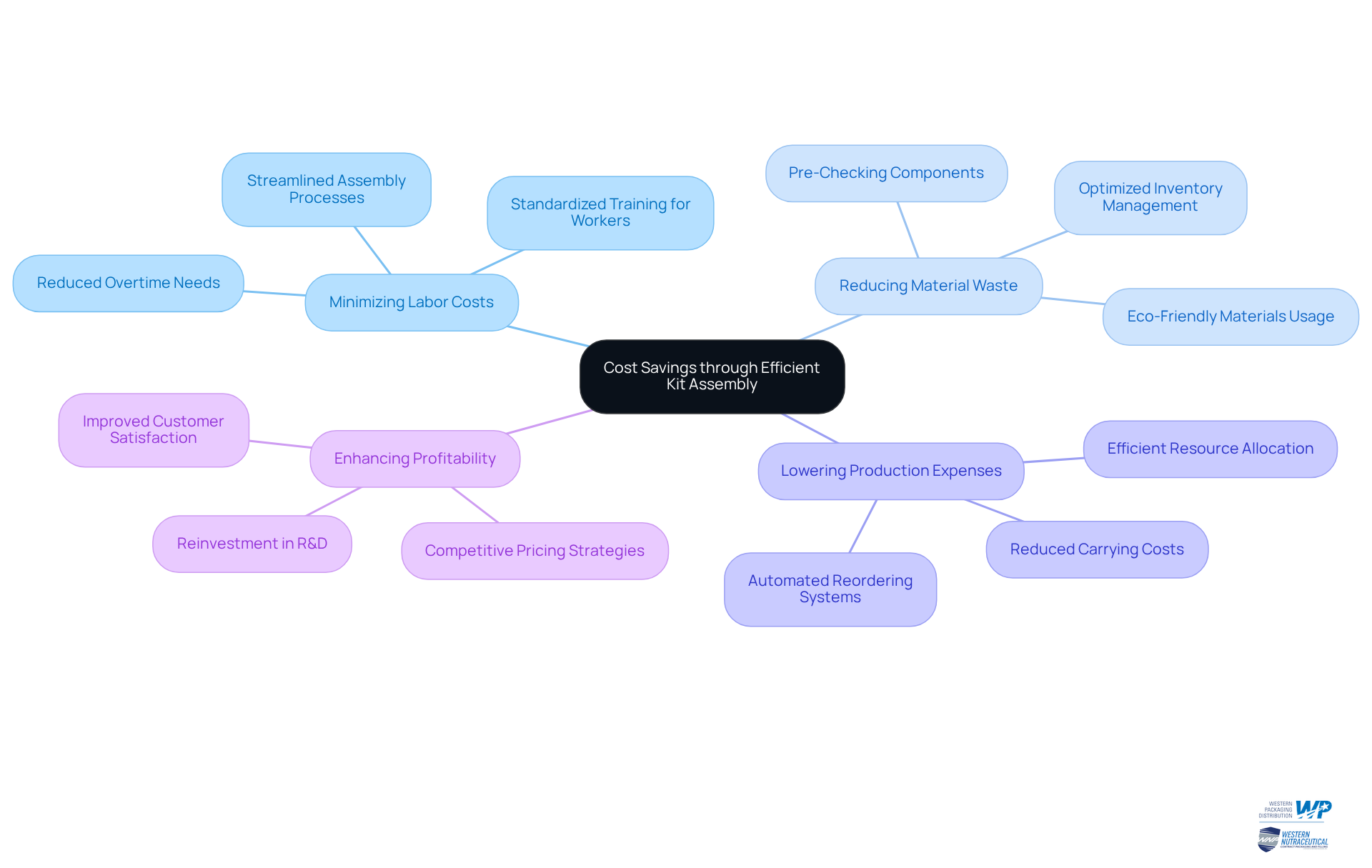

Achieve Cost Savings with Efficient Kit Assembly Practices

Effective kit assembly methods yield significant cost reductions for dietary supplement producers. By minimizing labor costs and reducing material waste in kit assembly, companies can effectively lower their overall production expenses. Western Packaging's efficient production methods ensure that producers can create high-quality packages while avoiding excessive costs. This approach not only enhances profitability but also strengthens their competitive advantage in the market.

Gain Flexibility in Production with Tailored Kit Assembly

Customized kit assembly solutions empower nutraceutical producers to swiftly adapt to evolving market demands. By enabling rapid adjustments in production runs and the creation of tailored packages, companies can effectively respond to shifting consumer preferences and emerging trends.

For instance, producers leveraging kit assembly services can significantly reduce setup time, ensuring that all essential components—such as powders, gummies, and soft-gels—are readily available in pre-packaged kits. This approach not only enhances accuracy in component delivery but also minimizes errors and rework, ultimately elevating product quality and consistency.

Furthermore, kitting services contribute to cost reduction by decreasing the space and labor required for storage and retrieval, making it a financially sound option for producers.

Western Packaging's expertise in flexible production processes, coupled with our integrated filling services and comprehensive 3PL solutions, enables manufacturers to scale operations efficiently, particularly in medium to high-volume production scenarios.

As industry leaders assert, the capability to adapt production in response to market demands is vital for success in the nutraceutical sector. By implementing customized kit assembly and integrating Vendor Managed Inventory (VMI) programs, companies can improve their responsiveness, streamline operations, and better align their offerings with consumer expectations.

Increase Customer Satisfaction with Personalized Kit Assembly

Kit assembly that is personalized is pivotal in enhancing customer satisfaction by providing tailored solutions that align with individual preferences. By offering customizable packages designed specifically for consumer needs, supplement manufacturers can significantly elevate the shopping experience.

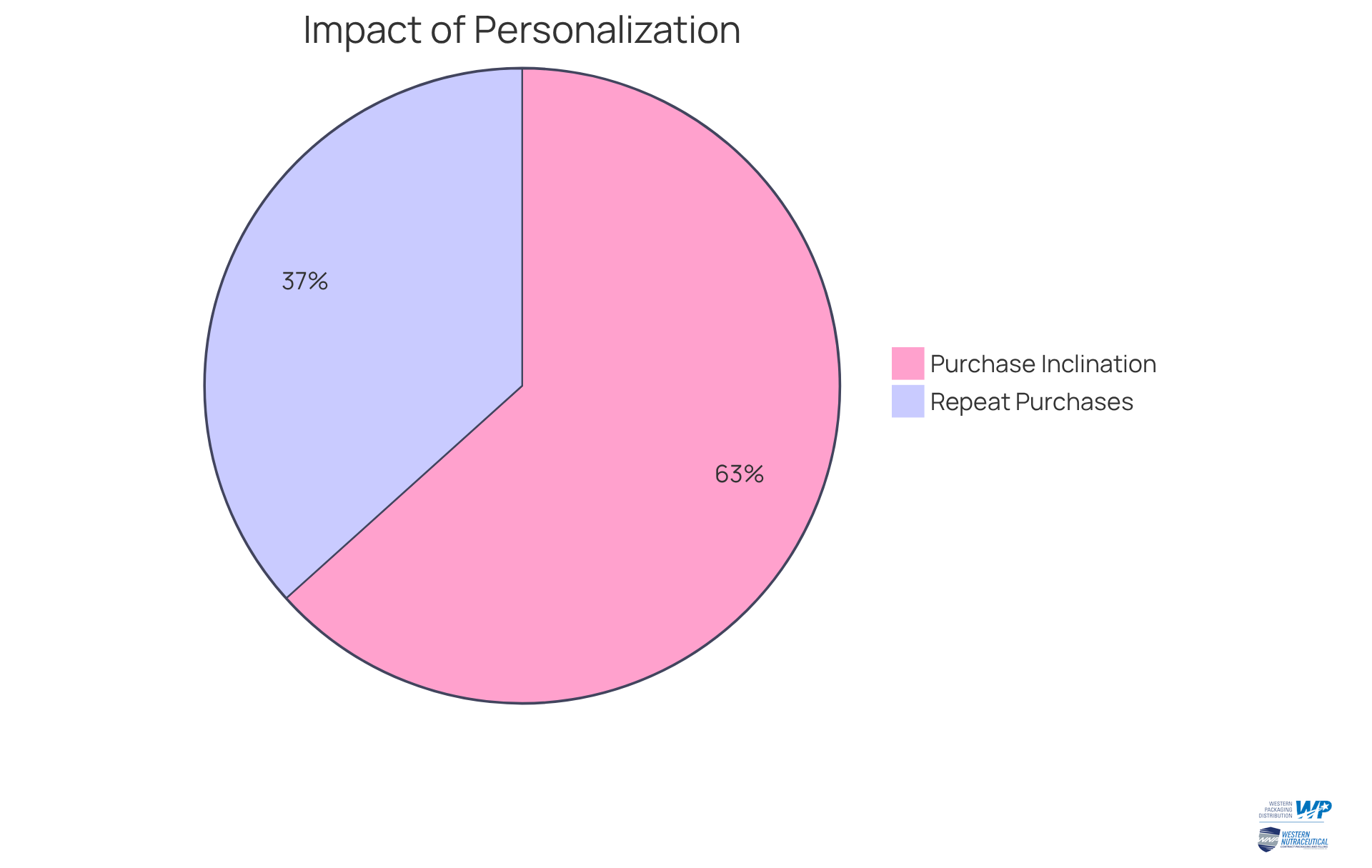

Research reveals that:

- 76% of consumers are more inclined to purchase from brands that deliver personalized experiences, emphasizing the critical role of customization in building loyalty.

- 44% of customers who enjoy good personalized experiences are more likely to make repeat purchases from those brands, underscoring the significance of fostering repeat business.

Western Packaging stands out in the design and assembly of these personalized kits, ensuring customers receive products that resonate with their expectations. This approach not only builds trust but also promotes repeat purchases, as satisfied customers are more likely to advocate for brands that cater to their unique requirements.

As highlighted by consumer behavior experts, the capability to tailor solutions effectively can transform the customer experience, rendering it more engaging and relevant. Successful dietary supplement brands exemplify how personalization can cultivate engaging shopping experiences, thereby reinforcing the importance of tailored kit assembly in nurturing consumer loyalty.

Moreover, the convenience of receiving all essential components in one package amplifies customer satisfaction, streamlining the buying process.

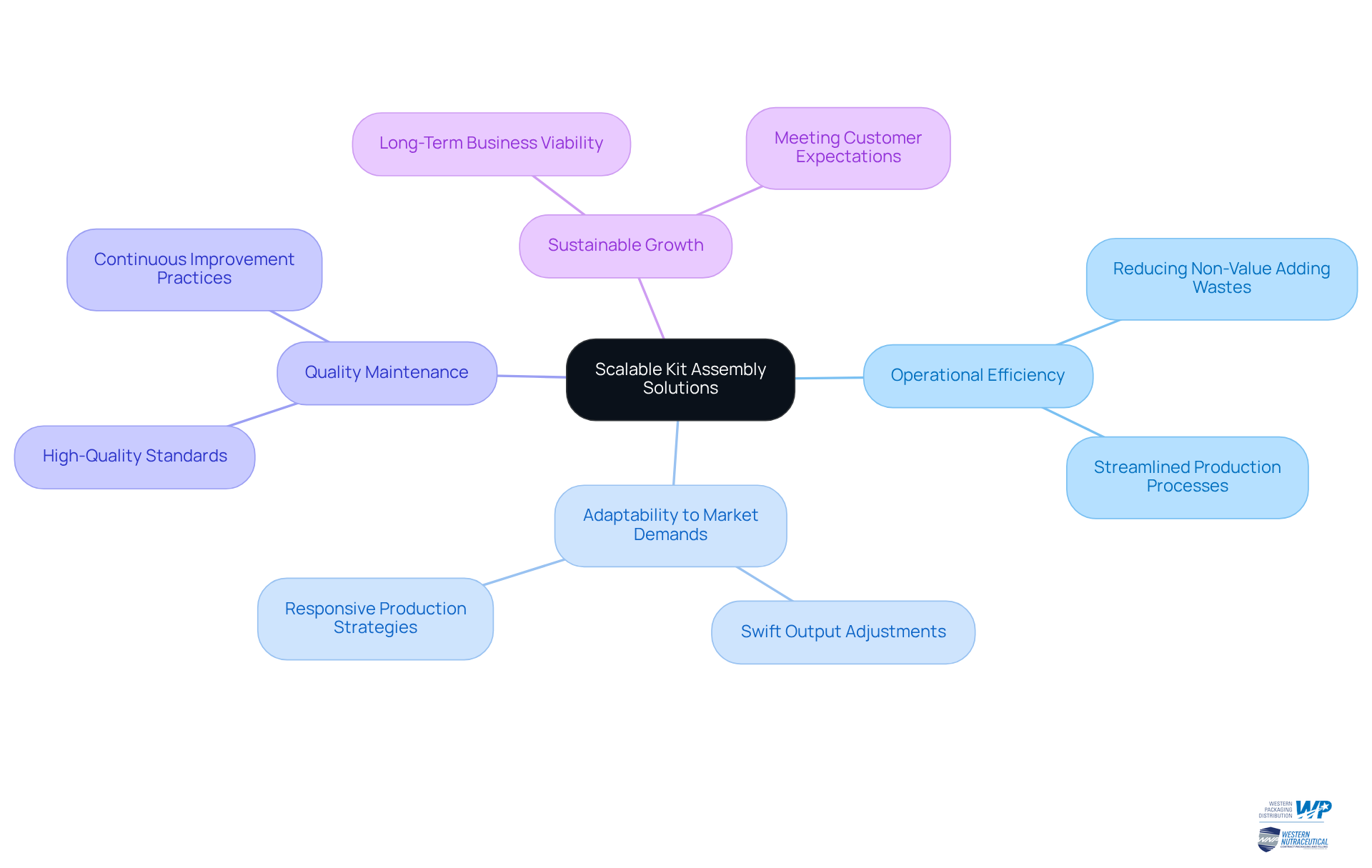

Scale Operations Effectively with Scalable Kit Assembly Solutions

Scalable kit assembly solutions empower nutraceutical producers to expand their operations while maintaining quality and efficiency. These versatile production processes allow businesses to swiftly adjust output levels in response to changing market demands. By leveraging Western Packaging's expertise in scalable solutions, producers can achieve sustainable growth, seamlessly adapting to fluctuations in demand without sacrificing high-quality standards. This strategy not only boosts operational efficiency but also positions companies to excel in a competitive landscape, consistently meeting customer expectations.

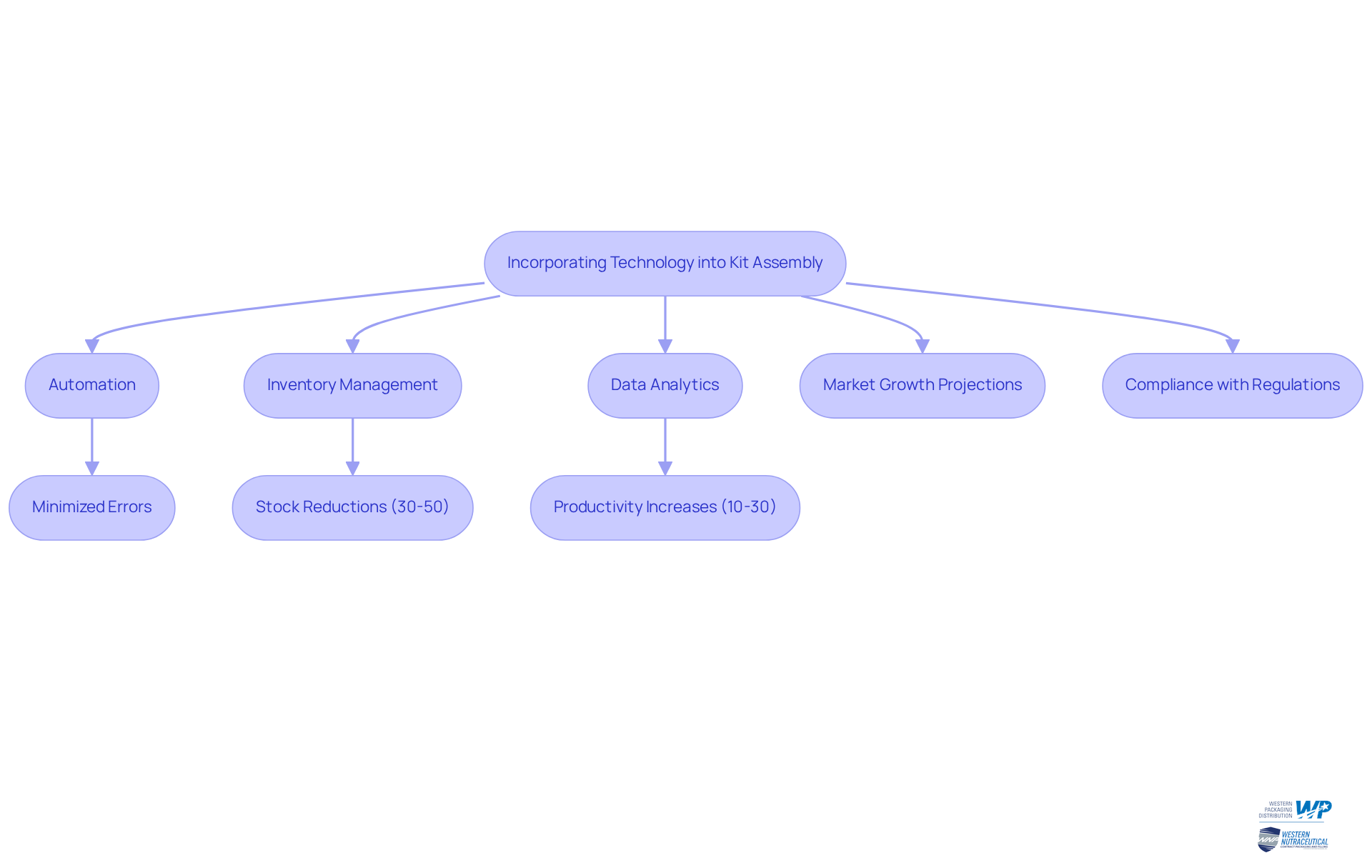

Leverage Technology for Accurate and Efficient Kit Assembly

Incorporating technology into kit assembly processes significantly enhances both precision and productivity for nutraceutical producers. By employing advanced automation, sophisticated inventory management systems, and robust data analytics, companies can streamline their assembly operations, thereby minimizing the risk of errors. For instance, producers utilizing Just-in-Time (JIT) practices have reported stock reductions of 30-50% alongside productivity increases of 10-30%. This level of efficiency is essential in a market projected to grow at a 5.09% CAGR, reaching USD 657.84 billion by 2030. Furthermore, the Asia-Pacific region is expected to achieve a remarkable 7.90% CAGR from 2025-2030, underscoring the significant growth potential across various markets.

Western Packaging exemplifies this commitment to innovation by integrating cutting-edge technology into its services, enabling producers to optimize performance and maintain a competitive edge. As industry leaders such as Ginni Rometty emphasize, technology enhances human capabilities rather than replacing them, making it imperative for producers to adopt automation in their production processes. Additionally, the implementation of automated stock management systems can alert personnel when supply levels dip below critical thresholds, ensuring uninterrupted production and timely responses to market demands.

The impact of automation extends beyond mere efficiency; it also significantly enhances accuracy in assembly processes. By leveraging technology, dietary supplement manufacturers can achieve higher order accuracy and reduced fulfillment times in their kit assembly processes, which are vital for satisfying the growing consumer demand for health-enhancing products. As the nutraceutical landscape evolves, those who invest in automation will be strategically positioned to navigate the complexities of the market and deliver quality products that align with consumer expectations. Compliance with regulations such as cGMP is equally crucial, as it fosters consumer trust and guarantees product safety.

Conclusion

The advantages of kit assembly for nutraceutical manufacturers are multifaceted, providing a strategic edge in a competitive market. By integrating packaging design, production, and logistics, companies can streamline operations, enhance compliance with regulations, and ultimately boost customer satisfaction. This holistic approach not only improves efficiency but also strengthens brand loyalty through personalized packaging solutions that resonate with consumer preferences.

Key insights from the discussion highlight the importance of effective kit assembly in enhancing operational efficiency, ensuring regulatory compliance, and improving inventory management. Evidence shows that companies leveraging these services can achieve significant cost savings, adapt swiftly to market demands, and elevate the overall consumer experience. As the nutraceutical industry continues to grow, embracing these innovative solutions becomes essential for maintaining a competitive advantage and meeting the evolving needs of customers.

In conclusion, the significance of kit assembly in the nutraceutical sector cannot be overstated. By investing in tailored assembly solutions and leveraging technology, manufacturers can optimize their production processes while aligning their offerings with consumer expectations. The call to action is clear: nutraceutical producers should consider integrating advanced kit assembly services to enhance operational capabilities, foster customer loyalty, and position themselves for sustained growth in an increasingly dynamic market.

Frequently Asked Questions

What services does Western Packaging provide for the health supplement sector?

Western Packaging specializes in integrated kit assembly services, packaging design, filling services for powders, gummies, and soft-gels, and logistics tailored for the health supplement sector.

How do integrated packaging and logistics solutions impact lead times for companies?

Companies implementing integrated packaging and logistics solutions experience a notable reduction in lead times, enhancing operational efficiency and improving product delivery timelines.

What is the influence of packaging design on consumer purchasing choices?

Studies indicate that 70% of customers are influenced by packaging design in their purchasing decisions.

How does effective kit assembly help nutraceutical producers comply with industry regulations?

Effective kit assembly includes all necessary components, which streamlines compliance processes, reduces the risk of errors, and helps meet labeling and safety standards established by regulatory agencies like the FDA and cGMP.

What advantages do companies gain from using Western Packaging's services?

Companies benefit from enhanced market presence, operational effectiveness, and protection from potential legal repercussions due to compliance with stringent industry standards.

What is the projected growth of the biodegradable packaging market by 2030?

The worldwide biodegradable paper and plastic packaging market is projected to reach $23.4 billion by 2030.

How does streamlined kit assembly improve operational efficiency for nutraceutical producers?

Streamlined kit assembly organizes components, drastically reduces production time, minimizes errors, and enables faster turnaround times, ultimately improving productivity.

What types of products does Western Packaging cater to with its kit assembly services?

Western Packaging provides kit assembly services for a diverse range of products, including powders, gummies, and soft-gels.

What is the importance of quality and accuracy in kit assembly according to Western Packaging?

Quality and accuracy in kit assembly are essential for navigating compliance with safety regulations, enhancing product safety, and fostering consumer confidence in the health supplement sector.