Overview

When selecting 3PL partners, it is essential to consider several key factors:

- Their experience and reputation

- Pricing structures

- Shipping capabilities

- Their ability to provide customized solutions

Evaluating these aspects is paramount for ensuring operational efficiency and client satisfaction. Successful partnerships often depend on a provider's proven track record, transparent pricing, reliable shipping, and tailored services that align with specific business needs. By prioritizing these criteria, businesses can forge strong alliances that enhance their logistics capabilities and drive success.

Introduction

Selecting the right third-party logistics (3PL) partner is a pivotal decision that can profoundly impact a company's operational efficiency and customer satisfaction. In today's complex supply chain landscape, grasping the essential factors that foster successful partnerships is crucial. This article explores the key elements to consider when choosing a 3PL provider, including:

- Integrated solutions

- Strategic location

- Pricing structures

- Customer service

How can companies ensure they make the most informed choice amid the expanding array of logistics providers?

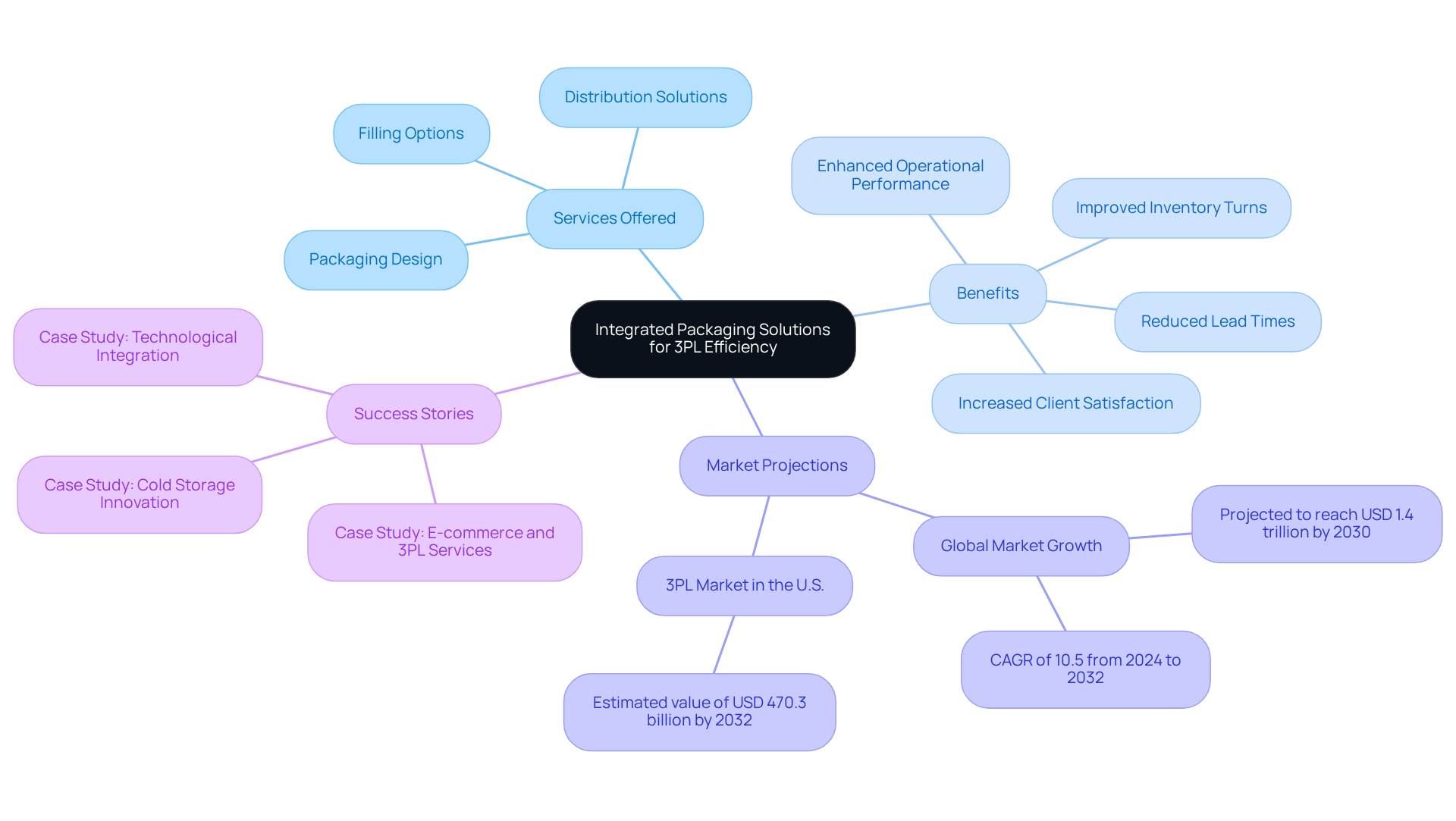

Western Packaging: Integrated Packaging Solutions for 3PL Efficiency

Western Packaging & Distribution distinguishes itself in the 3PL landscape by providing a comprehensive array of services for 3PL partners, including expert packaging design, filling options, and robust distribution solutions. This integrated approach not only streamlines the supply chain but also significantly enhances product appeal and operational efficiency. By merging these services, Western Packaging enables businesses to focus on their core competencies while ensuring their packaging and distribution processes are finely tuned for success.

The benefits of integrated packaging solutions are evident in the growing demand for supply chain efficiency, as the global market driven by 3PL partners is projected to reach USD 1.4 trillion by 2030. Companies that embrace a cohesive strategy for packaging and distribution can anticipate improved inventory turns, as 42% of 3PL partners are expected to integrate predictive tools into their workflows by 2025, leading to a 15-20% boost in efficiency. Furthermore, 90% of Fortune 500 companies now utilize 3PL partners, which highlights the reliance on integrated approaches to meet evolving market demands.

Numerous success stories illustrate that many enterprises have experienced enhanced operational performance through comprehensive packaging and logistics solutions. For instance, businesses employing these integrated solutions have reported reductions in lead times and improvements in delivery accuracy, ultimately leading to higher client satisfaction and increased market competitiveness. As the 3PL industry continues to evolve, the focus of 3PL partners on combining packaging and distribution services will remain a pivotal element in driving growth and efficiency.

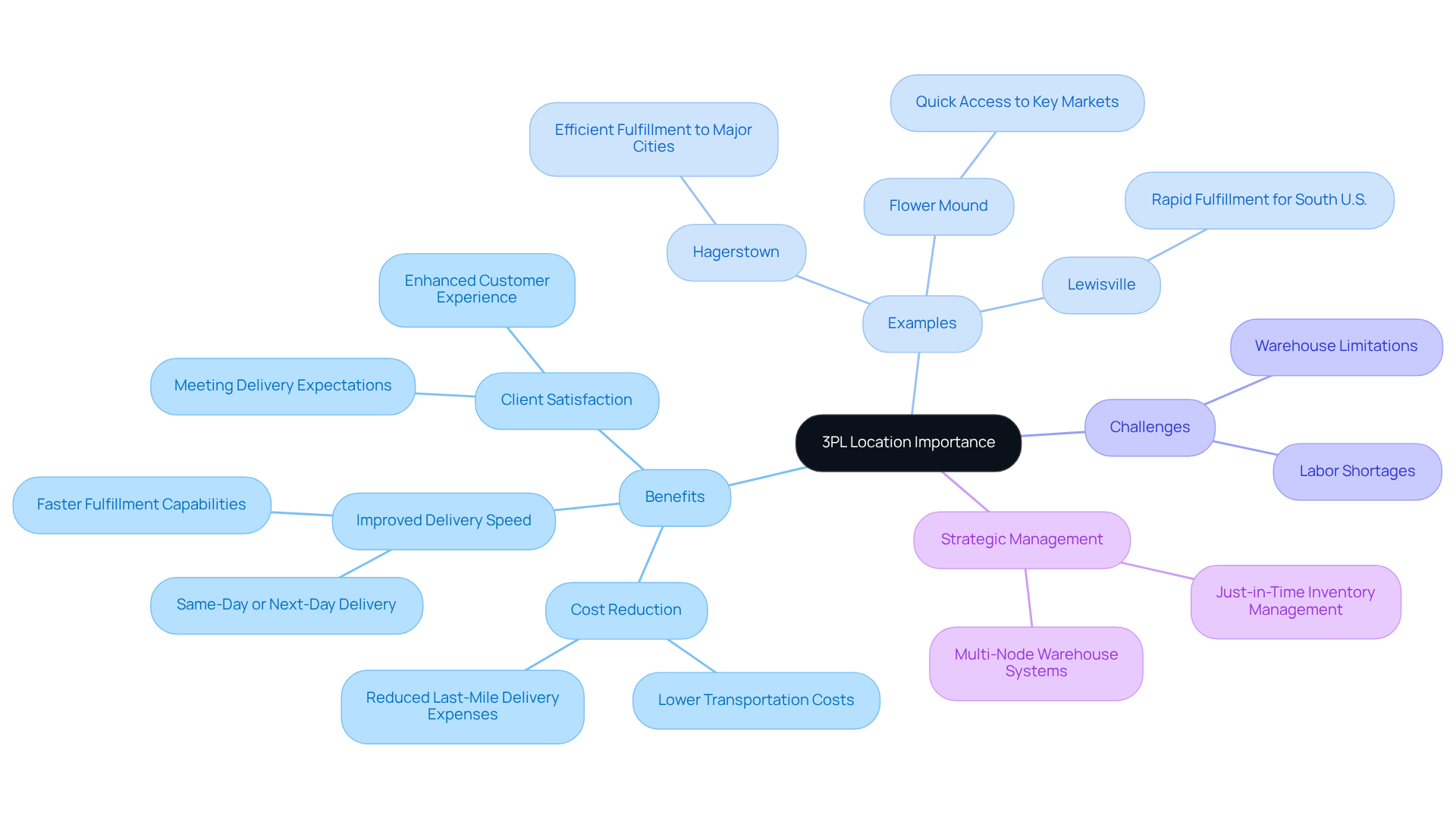

Location: Assessing Proximity to Key Markets and Distribution Channels

When selecting 3PL partners, evaluating their location is essential. A provider situated near major markets can significantly lower transportation expenses and reduce delivery durations, ensuring that products arrive at consumers quickly. This strategic positioning not only enhances operational efficiency but also boosts client satisfaction by meeting delivery expectations. Businesses should assess the 3PL's proximity to suppliers, clients, and transportation centers to optimize logistical efficiency.

Proximity to urban centers is particularly vital, as last-mile delivery constitutes a substantial portion of overall shipping costs. By strategically placing warehouses, companies can minimize these costs and improve delivery speed. For instance, studies indicate that strategic warehouse locations can reduce costs by 20-30%. Furthermore, access to local carriers allows for better shipping rates, enhancing overall supply chain performance.

Logistics experts emphasize that being near high-demand regions enables businesses to respond swiftly to market fluctuations, ensuring timely restocking and fulfillment during peak seasons. This is especially relevant for just-in-time (JIT) inventory management, which allows businesses to stock only what they need when they need it, thereby reducing storage costs and preventing excess stock.

Moreover, particular locations such as Hagerstown, Lewisville, and Flower Mound are recognized for their strategic advantages in supply chain management, offering rapid fulfillment capabilities. However, it is crucial to acknowledge the challenges faced by 3PL partners, including labor shortages and warehouse limitations, which can impact their operational efficiency. By leveraging the benefits of proximity while being mindful of these challenges, companies can streamline their operations and ultimately enhance the client experience.

Inventory Management: Ensuring Efficient Stock Control and Fulfillment

Efficient inventory management is crucial for successful logistics operations, particularly in the context of 3PL partners. A proficient 3PL provider must implement robust inventory control systems that ensure accurate stock levels and timely order fulfillment. Key components of these systems include:

- Real-time tracking, which allows businesses to monitor inventory movements and make informed decisions.

- Demand forecasting, which aids in anticipating client needs and optimizing stock levels.

Automated reordering processes further enhance efficiency by guaranteeing that stock is replenished before depletion, thus minimizing the risk of stockouts. Companies that embrace advanced inventory management techniques can reap significant benefits, such as reducing excess stock and lowering carrying costs—both of which collectively enhance overall supply chain responsiveness. For instance, businesses that utilize 3PL partners report an average improvement in inventory accuracy of 20% to 30%, translating to improved customer satisfaction and operational efficiency.

As the supply chain landscape evolves, the integration of technologies such as RFID and IoT sensors into inventory management systems is becoming increasingly vital. These innovations not only enhance tracking accuracy but also deliver real-time insights essential for maintaining control over inventory levels. In a competitive market, the ability to employ advanced inventory management systems can serve as a game-changer for businesses striving to elevate their operations.

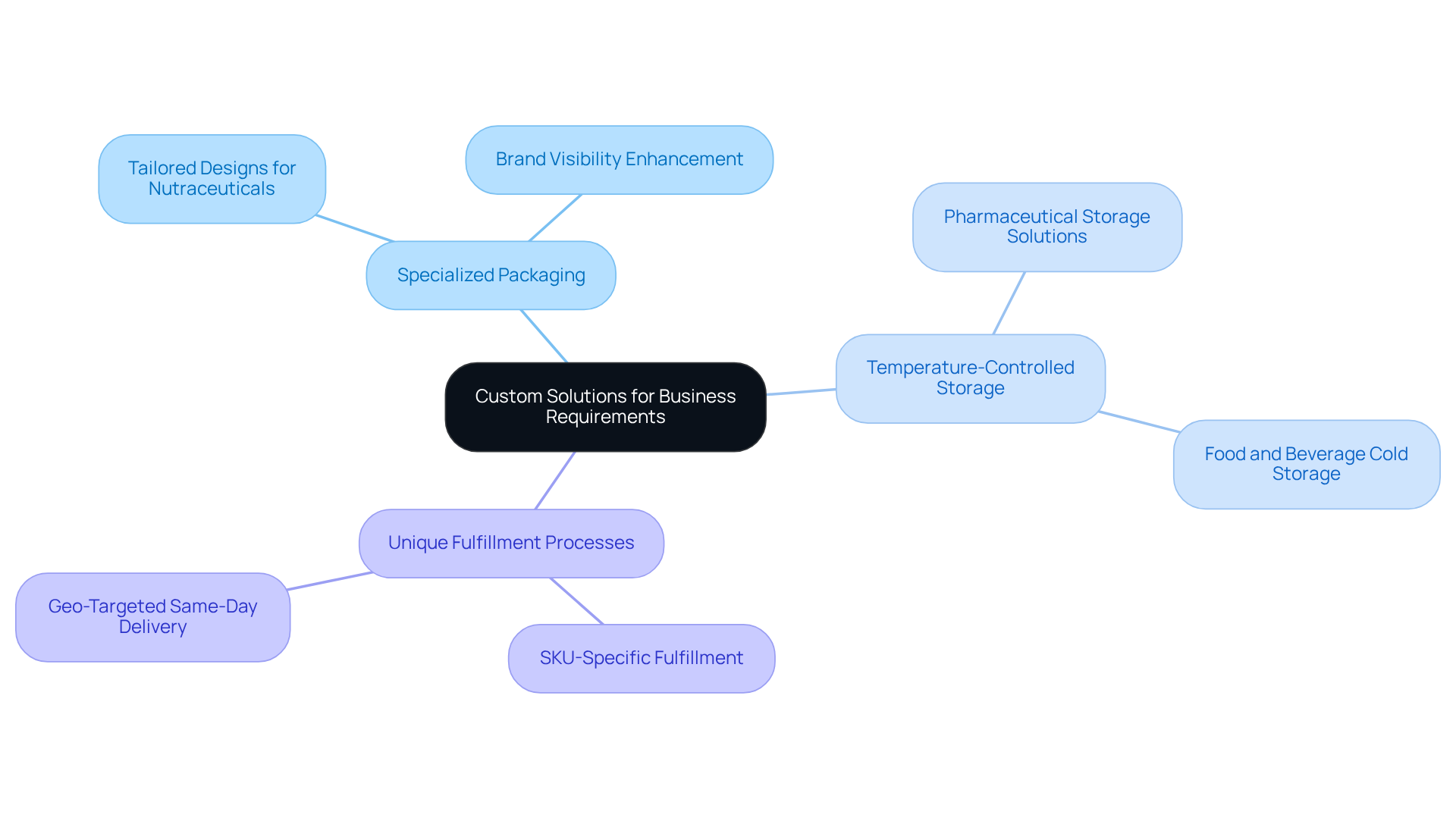

Custom Solutions: Tailoring Services to Meet Unique Business Requirements

Every business has unique logistical requirements, making a one-size-fits-all approach inadequate. A competent 3PL partner must provide customized solutions that address specific needs, including:

- Specialized packaging

- Temperature-controlled storage

- Unique fulfillment processes

For instance, companies in the nutraceutical sector often require tailored packaging designs that not only protect their products but also enhance brand visibility on shelves. By fostering close collaboration with clients, 3PL partners can create bespoke strategies that enhance operational efficiency and align with industry-specific demands. This trend is increasingly recognized; 91% of 3PL users report enhanced customer satisfaction due to the effectiveness of these tailored services. As the supply chain environment evolves, the significance of tailored solutions becomes even more evident, ensuring that businesses can navigate the complexities of contemporary distribution networks effectively.

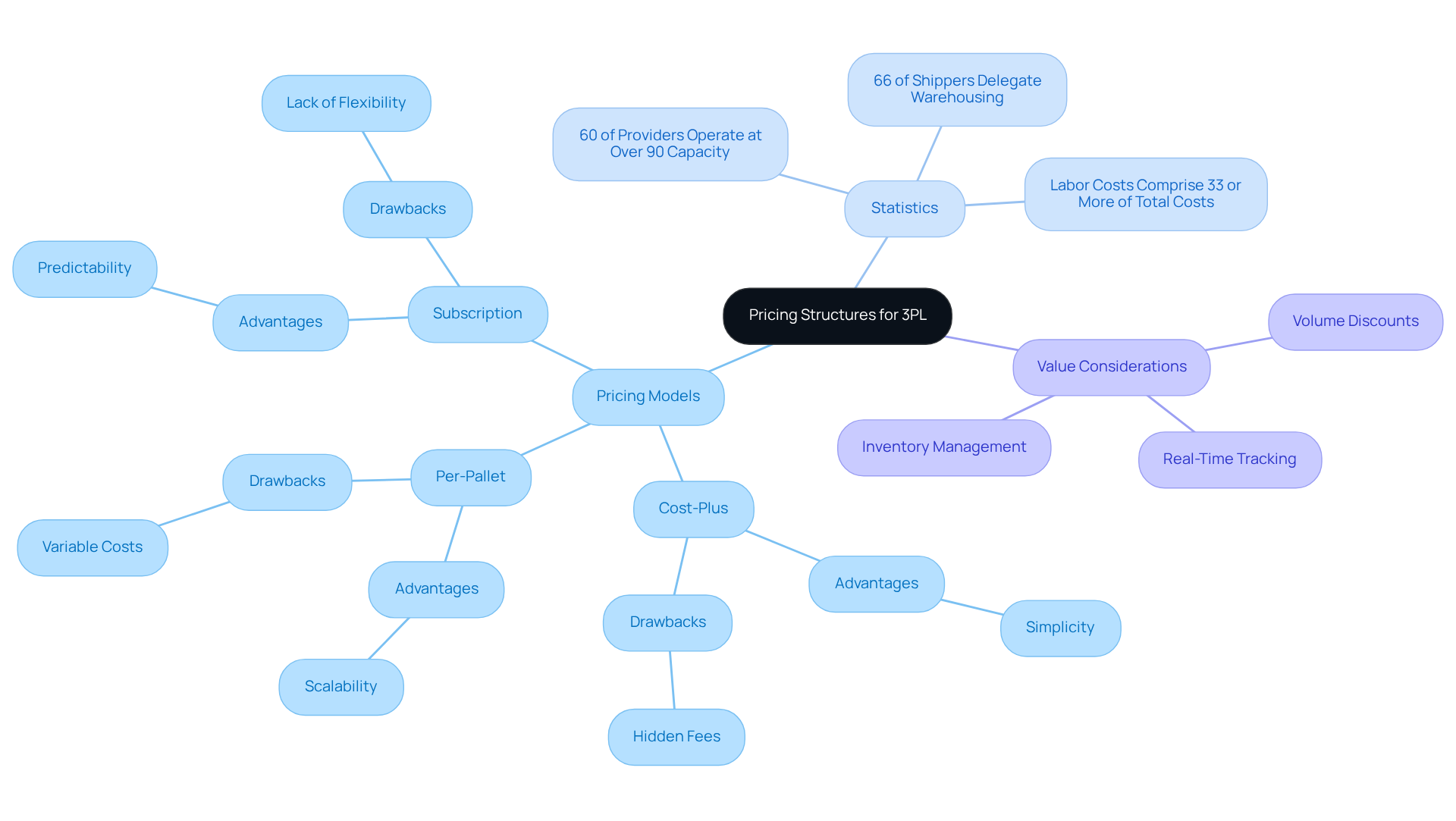

Pricing Structures: Evaluating Cost-Effectiveness and Value

Assessing the pricing frameworks of prospective 3PL partners is crucial for companies seeking to enhance transportation expenses. Providers typically offer a range of models, including cost-plus, per-pallet, and subscription pricing. Each model has its advantages; however, understanding the total cost of ownership is vital. For instance, while a cost-plus model may appear straightforward, hidden fees can inflate overall expenses. Conversely, subscription pricing can provide predictability in budgeting but may lack flexibility for fluctuating demand.

Statistics indicate that 66% of shippers delegate warehousing, emphasizing the increasing dependence on third-party logistics. Furthermore, almost 60% of delivery providers operate at over 90% capacity, which can influence quality levels and pricing. Companies should consider not only base expenses but also the value gained from additional offerings such as real-time tracking and inventory management. Labor costs, which comprise 33% or more of total costs for the majority of 3PL warehouses, must also be factored into the overall pricing assessment.

A transparent pricing model that aligns with business objectives can yield significant cost savings when utilized with 3PL partners. For example, 65% of 3PL warehouses offer discounts on regular pick and pack rates when certain thresholds are met, allowing businesses to leverage volume for better pricing. Furthermore, 91% of 3PL users report heightened customer satisfaction, suggesting that investing in a competent partner can enhance overall supply chain performance.

In conclusion, a comprehensive evaluation of pricing frameworks, coupled with an understanding of the value contributed by 3PL partners, is essential for companies aiming to enhance cost-effectiveness and operational efficiency in their supply chain activities. Additionally, the fact that 50% of 3PL warehouses offer month-to-month terms adds an important layer of flexibility for businesses evaluating their options.

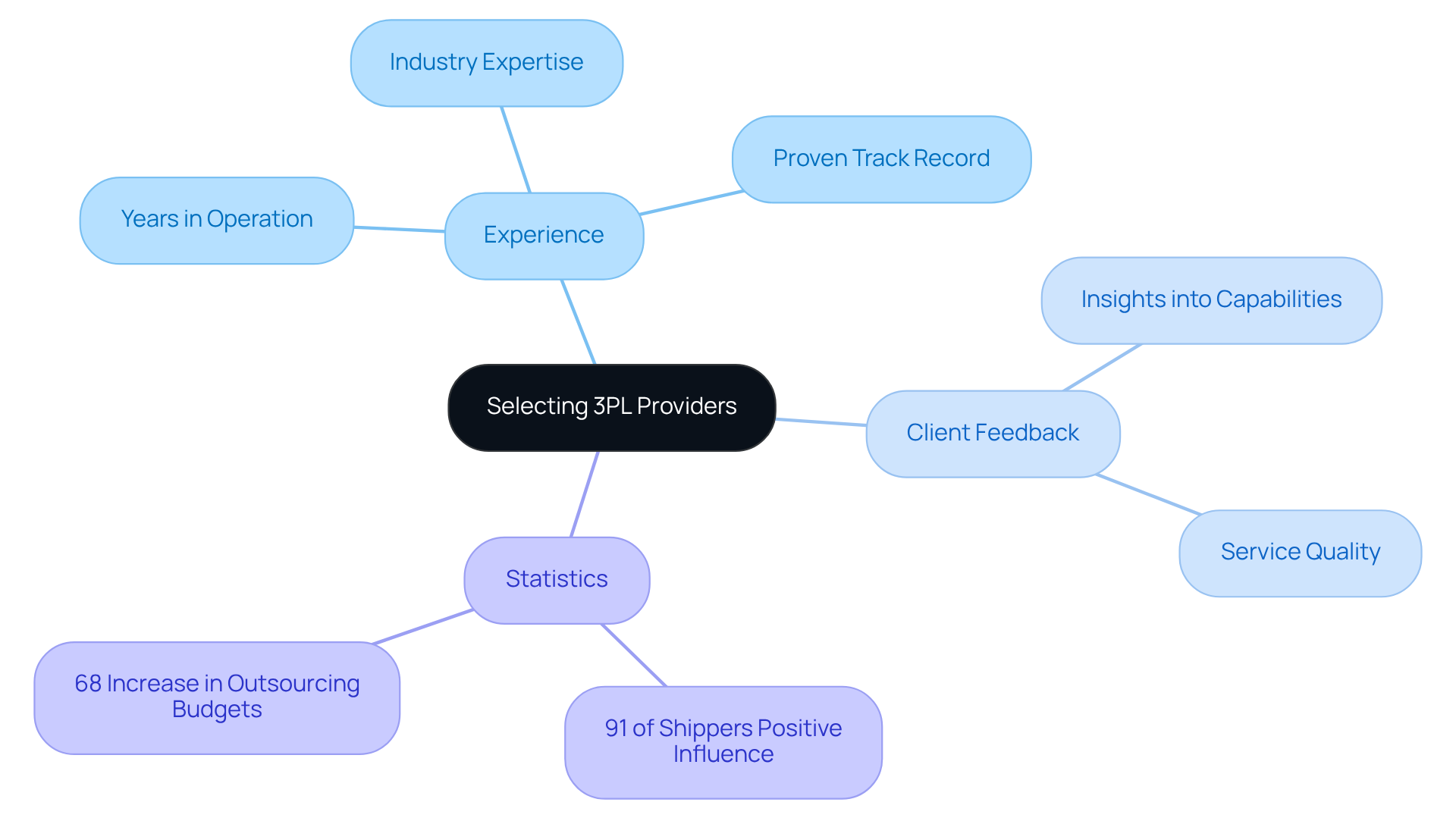

Experience and Reputation: Assessing Track Record and Client Feedback

The experience and reputation of a third-party provider are paramount when selecting a partner. Businesses must thoroughly evaluate a provider's track record, which encompasses their years in operation, industry expertise, and client testimonials. 3PL partners with a proven history of successful collaborations are more likely to deliver dependable offerings and meet performance expectations. Notably, 91% of shippers indicate that outsourcing operations to 3PLs has positively influenced their supply chain effectiveness. This statistic underscores the critical importance of selecting skilled partners.

Furthermore, seeking feedback from current or past clients can yield invaluable insights into a provider's capabilities and service quality. Current trends reveal that 68% of companies intend to increase their outsourcing budgets in supply chain management, reflecting a growing dependence on 3PL partners. As the logistics landscape evolves, recognizing the significance of experience in selecting 3PL partners becomes crucial for companies striving to enhance operational efficiency and client satisfaction.

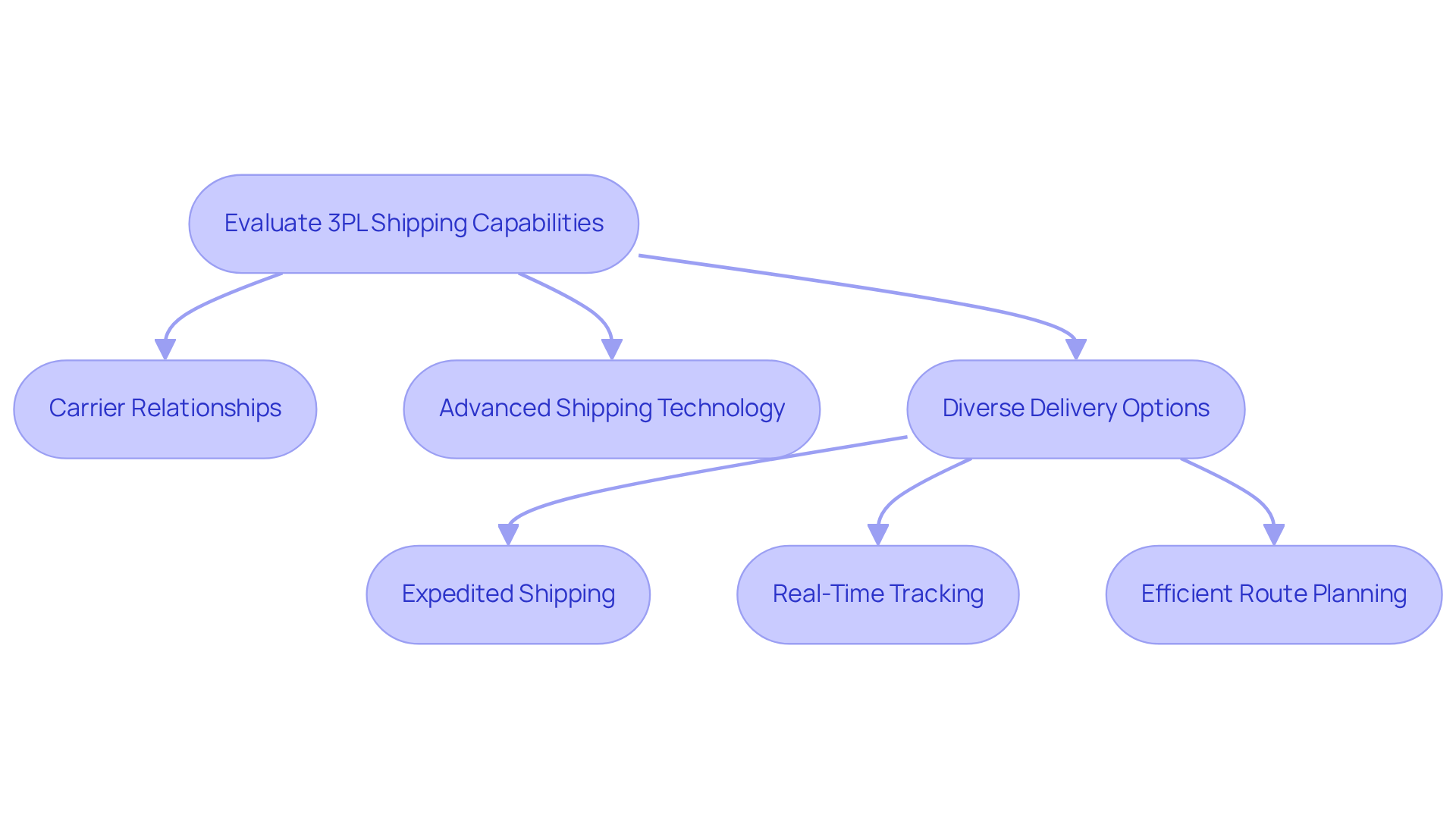

Shipping Capabilities: Ensuring Timely and Reliable Deliveries

Prompt and dependable shipping is essential for sustaining client satisfaction in today's competitive environment. When selecting 3PL partners, businesses must thoroughly evaluate their shipping capabilities, focusing on key aspects such as:

- Carrier relationships

- Advanced shipping technology

- Diverse delivery options

A skilled 3PL provider should offer flexible shipping options that can rapidly adjust to changing needs, ensuring that products consistently arrive to clients punctually. This includes options for:

- Expedited shipping

- Real-time tracking

- Efficient route planning

These are crucial for meeting the expectations of modern consumers.

Same-day delivery has become a standard expectation for over 50% of U.S. retailers, making the ability to meet these demands more important than ever. Furthermore, 93% of shippers agree that data-driven decision-making is vital for supply chain success, and 97% of shippers feel alignment is important to drive the effectiveness of big data initiatives. This underscores the need for 3PL partners to leverage technology in optimizing shipping processes. As sustainability grows more significant in transportation, 3PL partners must adapt their practices to align with these trends.

As supply chain management advances, keeping up with trends in shipping technology will be crucial for improving client satisfaction and preserving a competitive advantage.

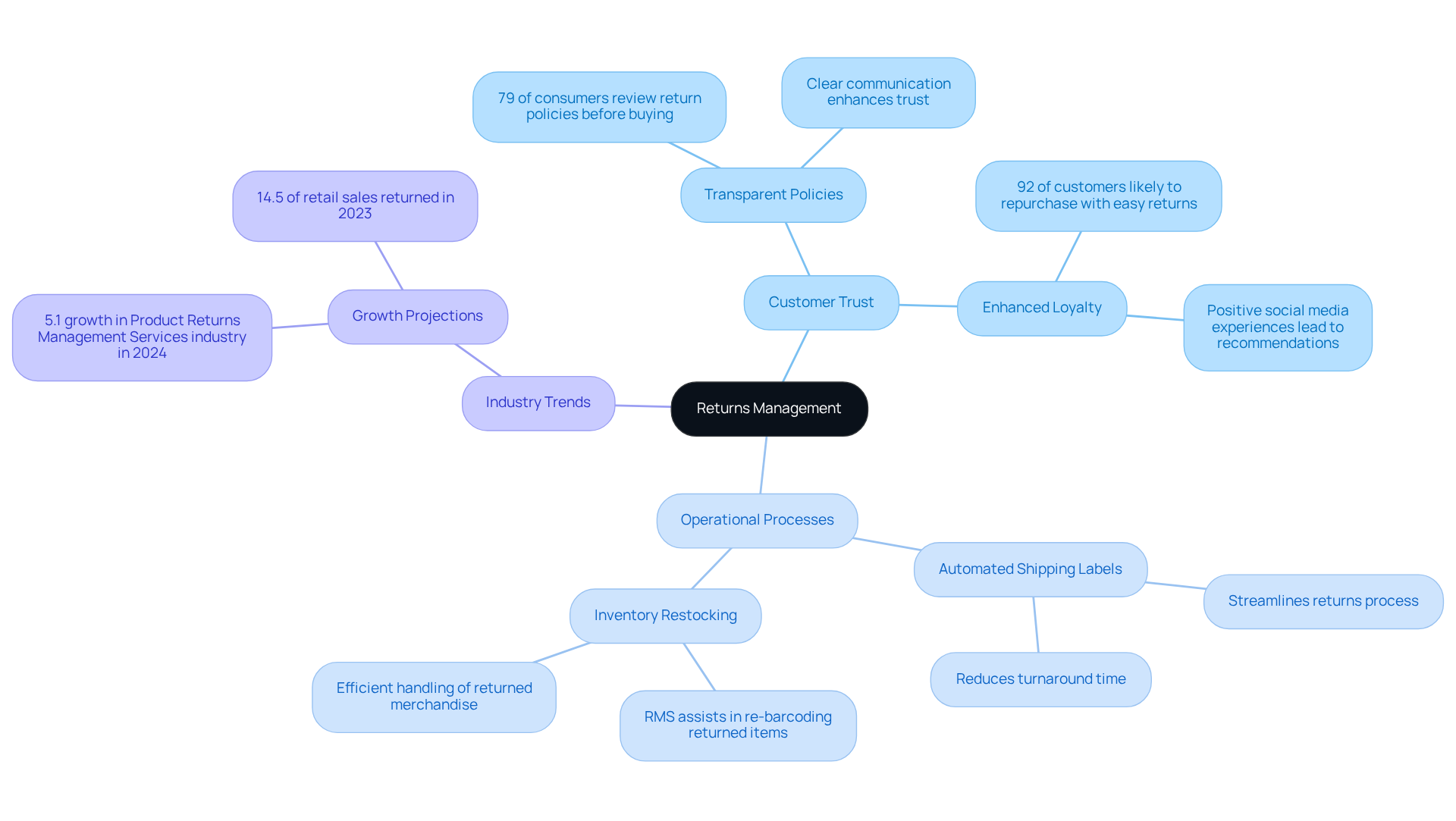

Returns Management: Streamlining Reverse Logistics for Customer Satisfaction

Returns management is a vital yet frequently overlooked element of consumer satisfaction. An effective 3pl partners must implement robust processes for managing returns efficiently. This includes transparent return policies—79% of consumers review return policies prior to buying—highlighting their significance in boosting client trust and satisfaction. Automated return shipping labels and streamlined inventory restocking procedures are essential. By optimizing reverse logistics, businesses can significantly enhance consumer trust and loyalty, which are essential for driving repeat purchases and fostering a positive brand image.

Current trends suggest that companies utilizing advanced Returns Management Systems (RMS) in conjunction with 3pl partners are better equipped to handle the intricacies of returns, ultimately resulting in enhanced operational efficiency and client satisfaction. As highlighted by industry experts, including Terri Luke, a well-designed returns process is not merely about handling returns; it’s about crafting a seamless experience that fosters loyalty and satisfaction. Furthermore, the Product Returns Management Services industry is projected to grow by 5.1% in 2024, underscoring the increasing relevance and investment in returns management solutions. Given the labor-intensive nature of returns processing, effective solutions are crucial for maintaining profitability while addressing the environmental impact of returns management.

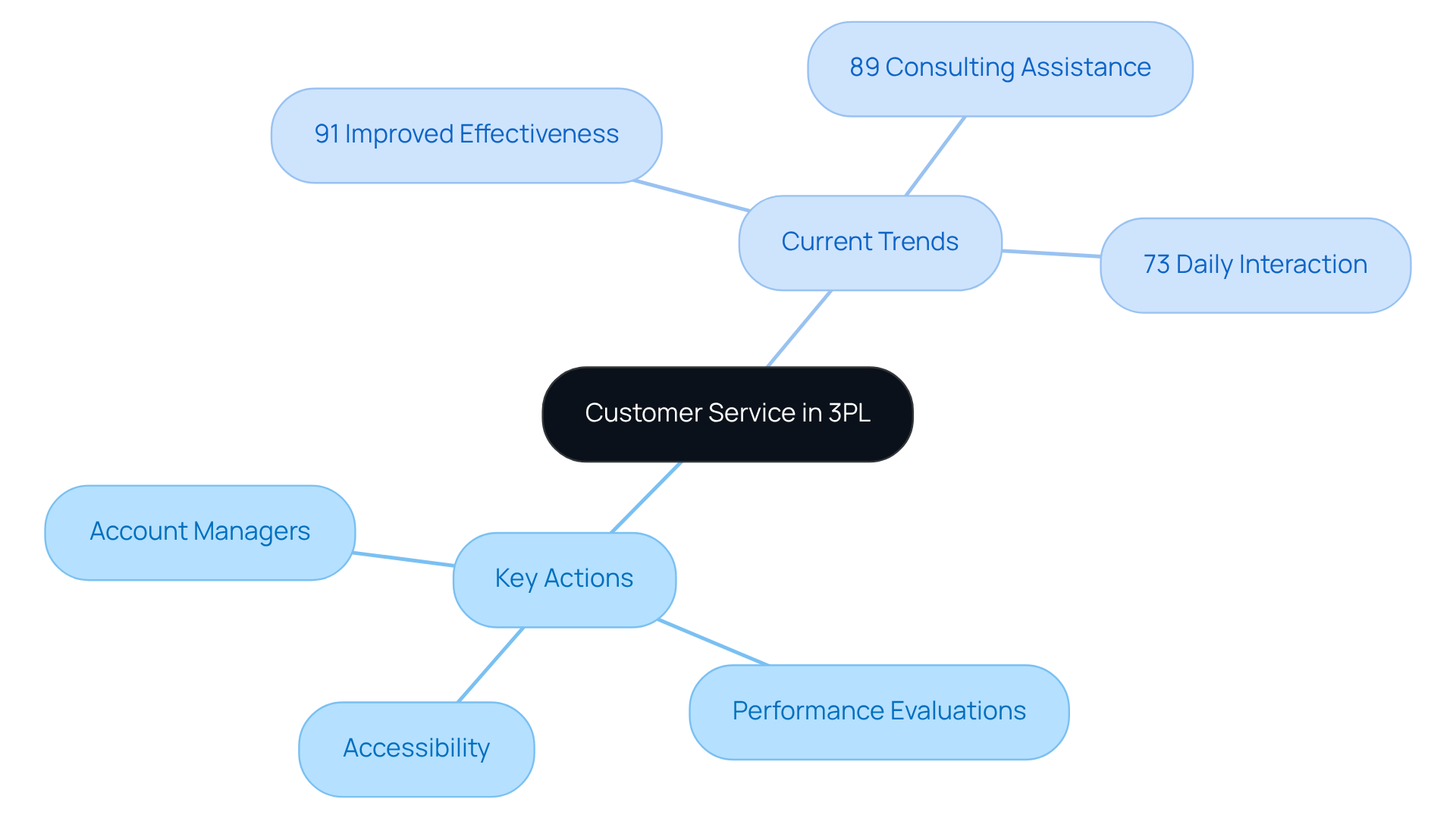

Customer Service: Ensuring Responsive Support and Communication

Customer support is crucial in establishing a successful partnership with a third-party provider. Businesses must prioritize 3PL partners that provide responsive support and maintain clear communication channels. This includes:

- Designating specific account managers who can provide tailored attention.

- Conducting regular performance evaluations to assess service quality.

- Ensuring that service representatives are easily accessible.

A 3PL that values client relationships and proactively resolves issues fosters a collaborative environment, significantly enhancing supply chain performance.

Current trends indicate that:

- 91% of shippers report improved supply chain effectiveness and client satisfaction when outsourcing to 3PL partners, underscoring the necessity of robust support systems.

- 89% of 3PL partners now provide consulting assistance for supply chain operations, reflecting a shift towards more engaged and responsive customer support practices.

As the logistics landscape continues to evolve, effective communication remains a vital component, with 73% of shippers interacting with their 3PL partners daily or even hourly. This level of engagement not only streamlines operations but also builds trust, ultimately resulting in superior service outcomes.

Conclusion

Selecting the right third-party logistics (3PL) partner is pivotal for businesses aiming to enhance operational efficiency and customer satisfaction. A comprehensive evaluation of various factors—including:

- Integrated packaging solutions

- Location

- Inventory management

- Custom services

- Pricing structures

- Experience

- Shipping capabilities

- Returns management

- Customer service

is essential for ensuring a successful partnership. By understanding these key components, companies can make informed decisions that align with their specific logistical needs.

The integration of services, strategic location, and tailored solutions significantly contribute to a 3PL partner's effectiveness. Robust inventory management and transparent pricing are crucial, as both play a vital role in maintaining cost-effectiveness and operational efficiency. Furthermore, reliable shipping capabilities and superior customer service highlight the growing expectations in today's logistics environment.

Ultimately, the choice of a 3PL partner can profoundly impact a business's supply chain performance and overall success. Embracing these considerations not only facilitates seamless operations but also fosters long-term relationships that drive growth and adaptability in an ever-evolving market. Companies are encouraged to prioritize these factors to secure a logistics partner that not only meets their current needs but also supports their future objectives.

Frequently Asked Questions

What services does Western Packaging & Distribution offer to 3PL partners?

Western Packaging & Distribution provides expert packaging design, filling options, and robust distribution solutions, creating an integrated approach that enhances supply chain efficiency and product appeal.

How does the integrated approach of Western Packaging benefit businesses?

The integrated approach allows businesses to focus on their core competencies while ensuring their packaging and distribution processes are optimized for success, leading to improved operational efficiency.

What is the projected growth of the 3PL market by 2030?

The global market driven by 3PL partners is projected to reach USD 1.4 trillion by 2030.

How can companies improve their inventory turns with 3PL partners?

Companies that adopt a cohesive strategy for packaging and distribution can expect improved inventory turns, with 42% of 3PL partners expected to integrate predictive tools into their workflows by 2025, resulting in a 15-20% boost in efficiency.

What percentage of Fortune 500 companies utilize 3PL partners?

90% of Fortune 500 companies currently use 3PL partners, highlighting the importance of integrated approaches in meeting market demands.

What advantages do strategic warehouse locations provide?

Strategic warehouse locations near major markets can significantly lower transportation expenses, reduce delivery durations, and enhance operational efficiency, ultimately boosting client satisfaction.

How does proximity to urban centers affect shipping costs?

Proximity to urban centers is crucial as last-mile delivery constitutes a large portion of shipping costs. Strategic warehouse placements can reduce these costs by 20-30%.

What is just-in-time (JIT) inventory management?

Just-in-time (JIT) inventory management allows businesses to stock only what they need when they need it, reducing storage costs and preventing excess stock.

What challenges do 3PL partners face that can impact operational efficiency?

3PL partners face challenges such as labor shortages and warehouse limitations, which can affect their operational efficiency despite the benefits of proximity to key markets.

What are key components of robust inventory management systems?

Key components include real-time tracking, demand forecasting, and automated reordering processes, all of which contribute to accurate stock levels and timely order fulfillment.

How can advanced inventory management techniques benefit businesses?

Advanced inventory management techniques can reduce excess stock and lower carrying costs, improving overall supply chain responsiveness and enhancing customer satisfaction.

What technological innovations are becoming vital in inventory management?

Technologies such as RFID and IoT sensors are increasingly important for enhancing tracking accuracy and providing real-time insights for maintaining control over inventory levels.