Overview

The article identifies seven key trends shaping vial labeling for nutraceuticals:

- Automation

- Sustainability

- Integration of artificial intelligence

These trends collectively enhance efficiency, accuracy, and compliance in the labeling process. Supported by evidence of industry growth, technological advancements, and consumer preferences for eco-friendly and transparent labeling solutions, companies that adapt to these changes position themselves for competitive advantage in the nutraceutical market.

Introduction

The landscape of vial labeling for nutraceuticals is rapidly evolving, driven by a convergence of technological advancements and shifting consumer expectations. As businesses endeavor to enhance operational efficiency and comply with stringent regulatory standards, grasping the key trends shaping this sector is essential.

What innovative solutions are emerging to tackle the challenges of accuracy, sustainability, and compliance in vial labeling? This exploration investigates the pivotal developments that are not only transforming the industry but also laying the groundwork for future growth and competitiveness.

Western Packaging: Integrated Packaging Solutions for Vial Labeling Efficiency

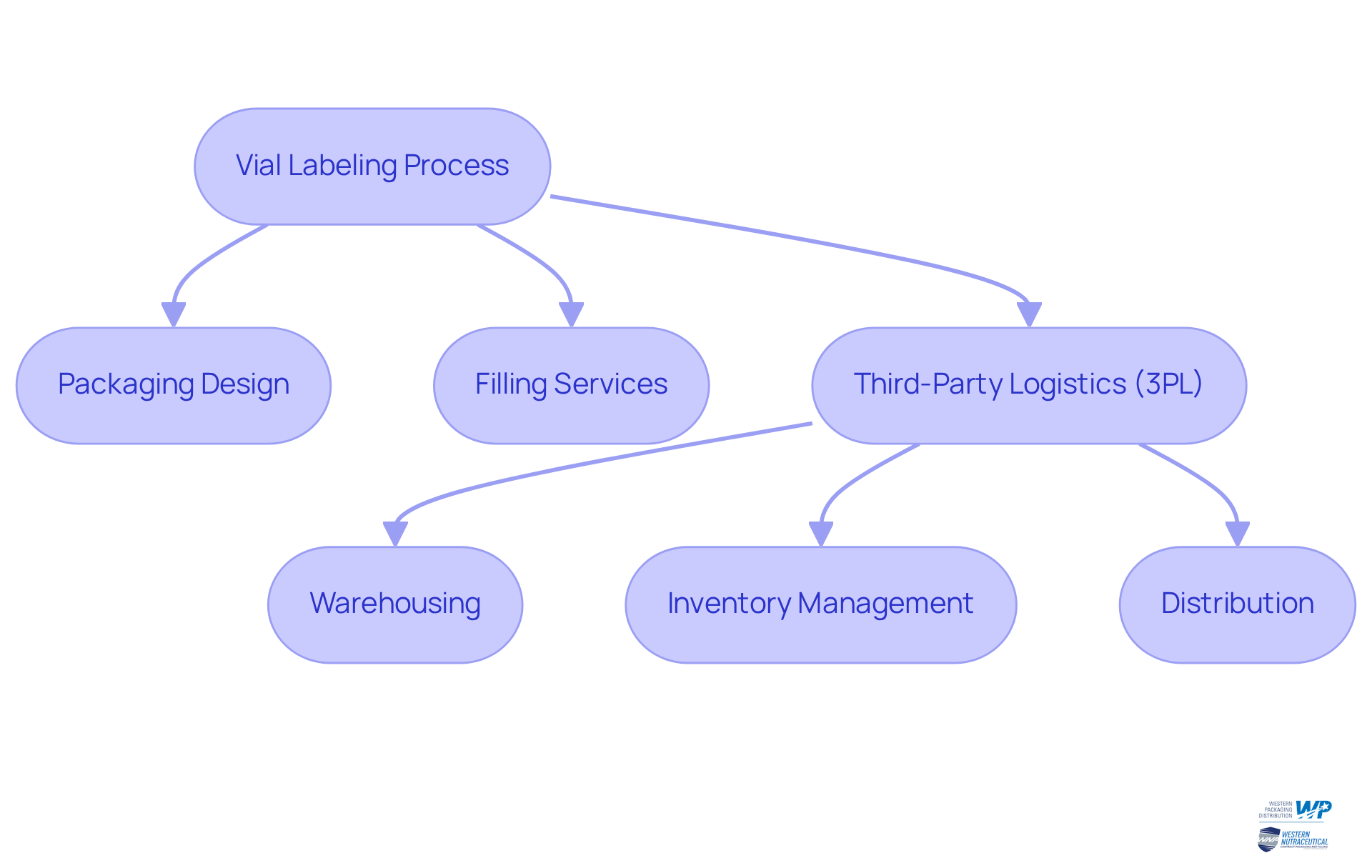

Western Packaging offers a comprehensive suite of services designed to optimize the vial labeling process for nutraceuticals. By seamlessly integrating packaging design, filling services, and third-party logistics (3PL)—which encompasses warehousing, inventory management, and distribution—the organization delivers customized solutions that markedly enhance operational efficiency and minimize lead times. This holistic approach simplifies the supply chain, guaranteeing that products are delivered in a timely and effective manner.

Companies that leverage these integrated 3PL services have reported notable improvements in product delivery timelines and heightened customer satisfaction. The benefits of these packaging solutions extend well beyond mere convenience; they cultivate a more agile supply chain, empowering businesses to swiftly adapt to market demands and consumer preferences.

As the nutraceutical industry evolves, the importance of combined packaging solutions becomes increasingly evident, positioning Western Packaging as an essential partner for businesses aiming to refine their procedures for vial labeling.

Automation in Vial Labeling: Enhancing Efficiency and Accuracy

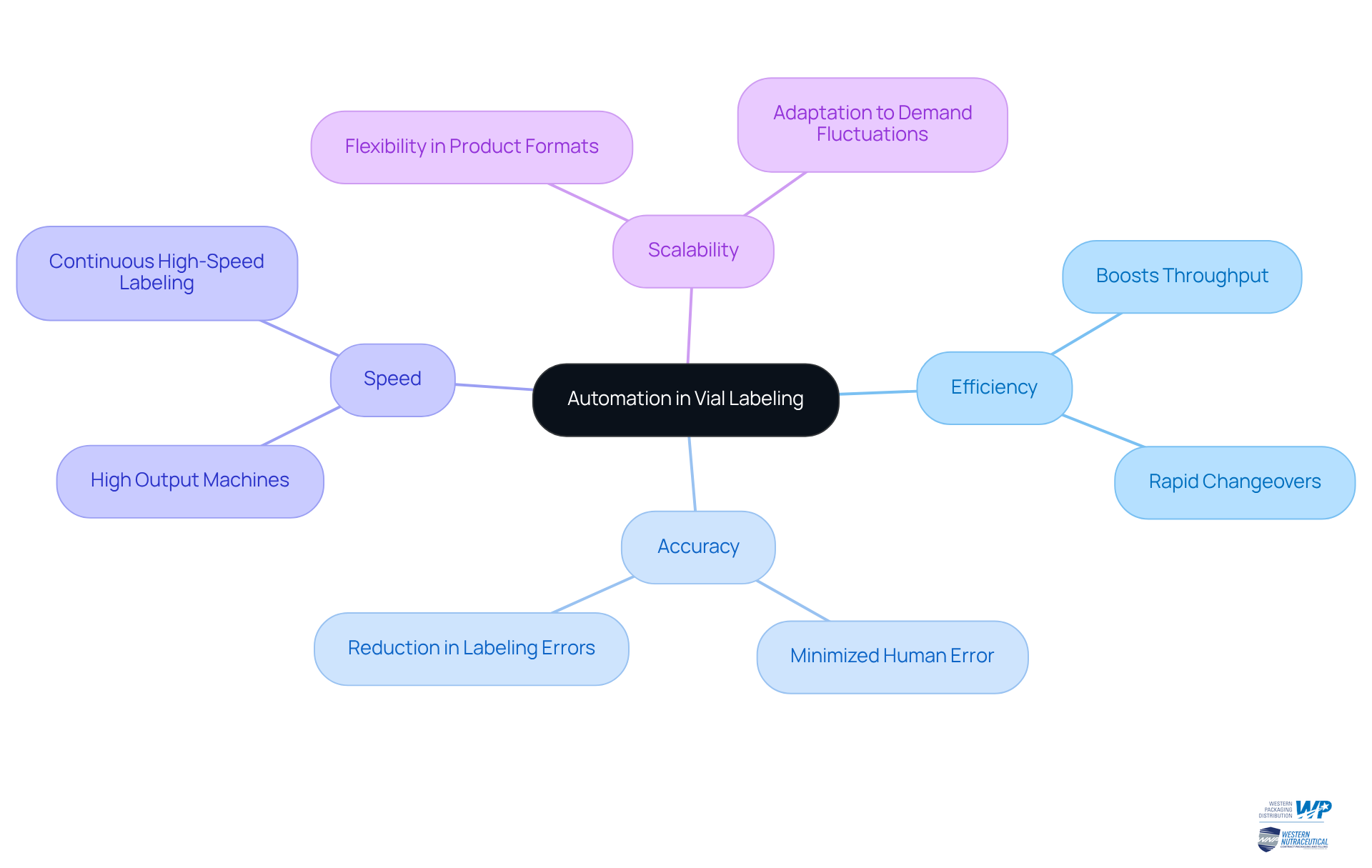

Automation in container marking has significantly transformed the sector, enhancing both pace and precision. Automated tagging machines are capable of applying tags at remarkable speeds, with certain models classified as high output—exceeding 500 containers per hour—while ensuring accurate placement that minimizes the risk of human error. This innovative technology not only boosts throughput but also facilitates rapid changeovers between various container sizes and types. Such capabilities are crucial for businesses aiming to scale their operations effectively.

Sustainability Trends: Eco-Friendly Practices in Vial Labeling

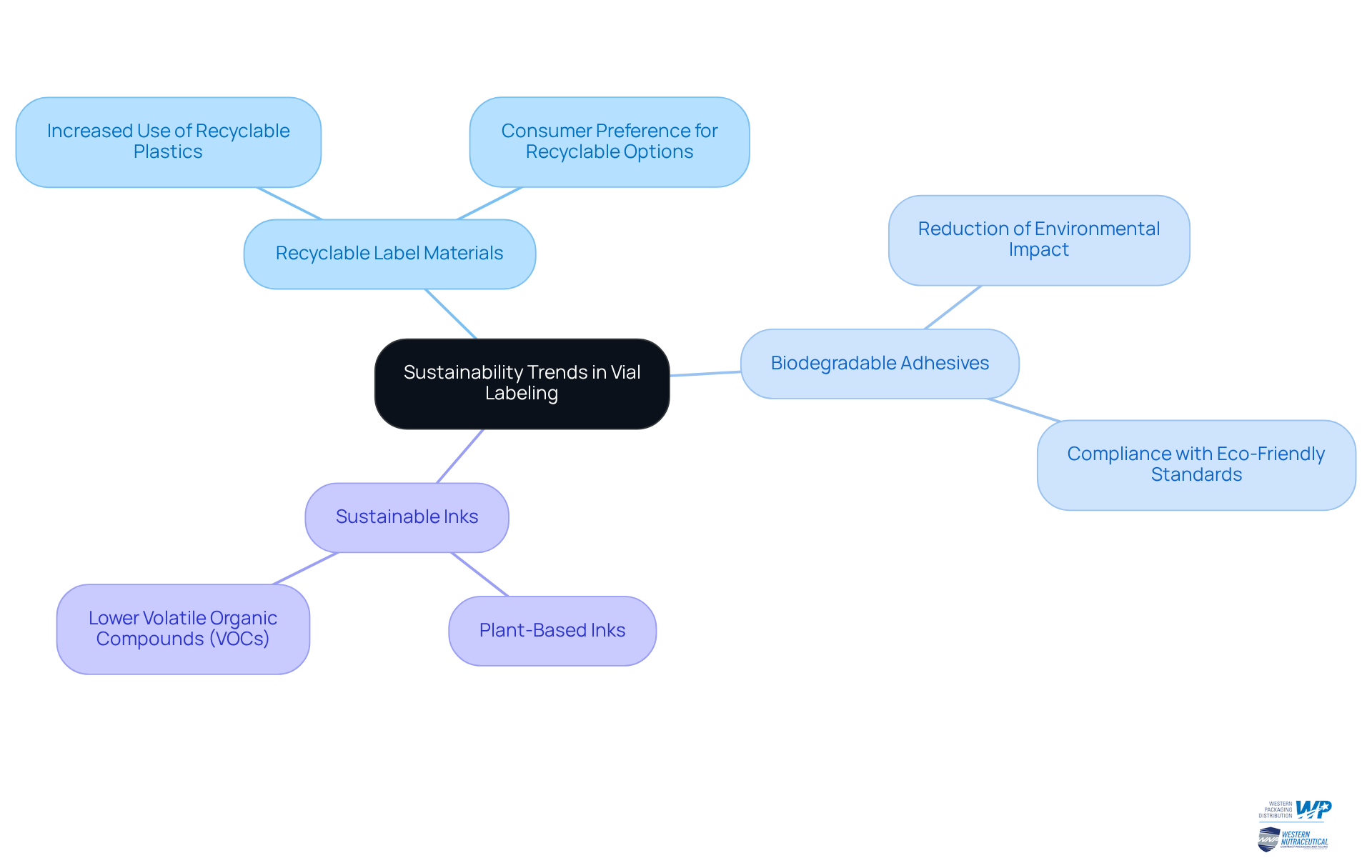

Sustainability trends are significantly reshaping the packaging landscape, as businesses increasingly embrace eco-friendly materials and practices. This transformation encompasses the adoption of:

- Recyclable label materials

- Biodegradable adhesives

- Sustainable inks

All of which are essential for effective vial labeling and minimizing environmental footprints. By prioritizing sustainability, businesses not only mitigate their ecological impact but also respond to a burgeoning consumer base that favors eco-conscious products. For instance, organizations such as Seventh Generation exemplify this commitment by integrating long-term sustainability into their product design and supply chains. Consequently, the share of recyclable materials in container identification is on the rise, reflecting a broader trend toward sustainable consumption and production. This evolution not only enhances brand loyalty but also strategically positions companies in a competitive landscape increasingly influenced by sustainability concerns.

Artificial Intelligence: Transforming Vial Labeling Processes

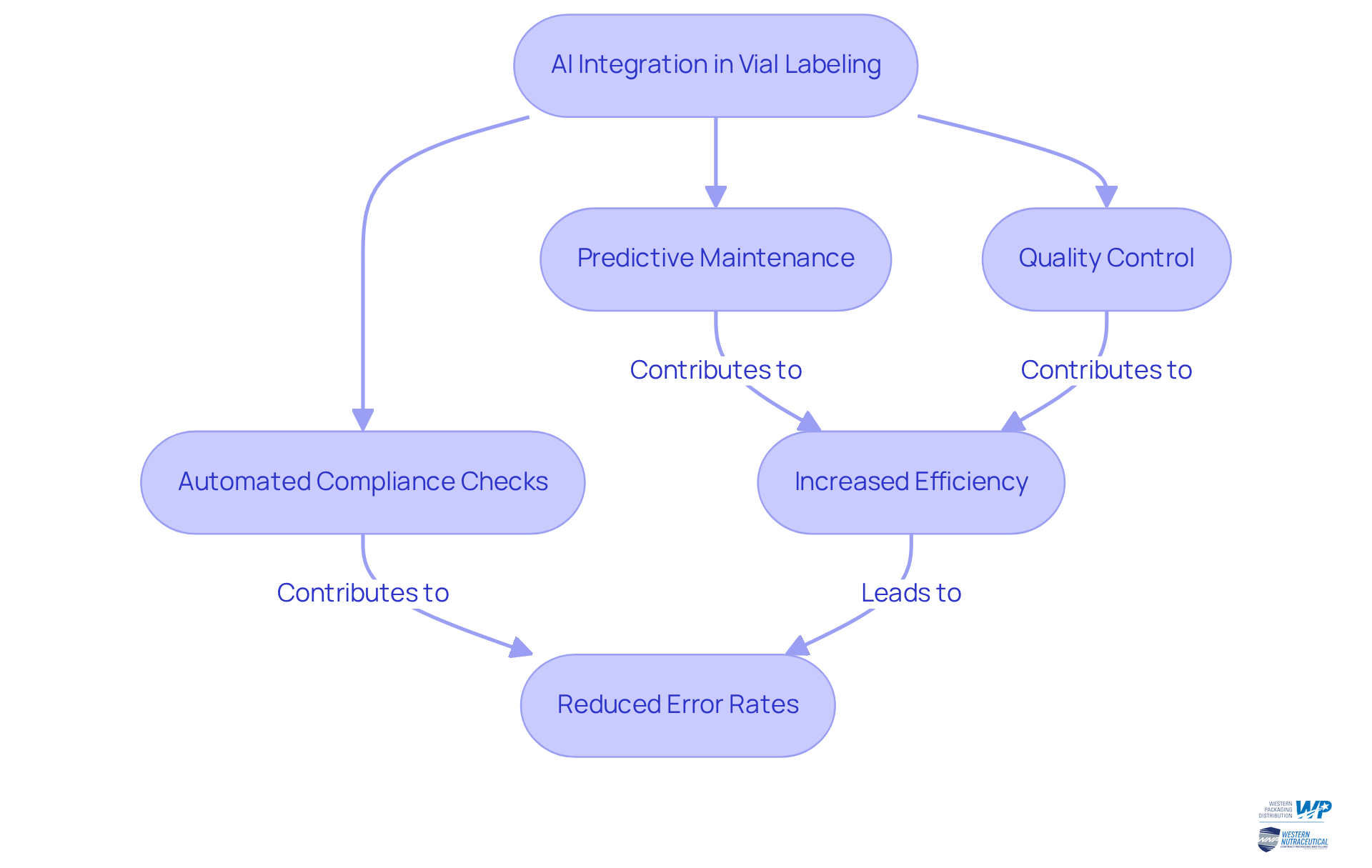

Artificial Intelligence is revolutionizing processes for vial labeling by enhancing predictive maintenance and quality control. AI-driven systems, such as GoVisually, automate compliance checks and analyze data in real-time, ensuring that vial labeling is applied accurately and consistently. This significantly reduces error rates. Companies utilizing AI for label compliance have reported a remarkable 90% faster review process due to these automated workflows. This technology not only boosts operational efficiency but also aids businesses in meeting stringent regulatory standards, ultimately minimizing the risk of costly recalls. In fact, AI adoption typically results in a decrease in Recall Incident Frequency due to enhanced accuracy in compliance checks.

As organizations increasingly embrace AI solutions, they are better equipped to adjust to changing industry demands and sustain a competitive advantage in the nutraceutical sector. Confidence in AI advancement is essential; firms with unreliable AI will find it challenging to thrive in the industry.

As Ginni Rometty, former CEO of IBM, stated, "AI will not replace humans, but those who use AI will replace those who don't.

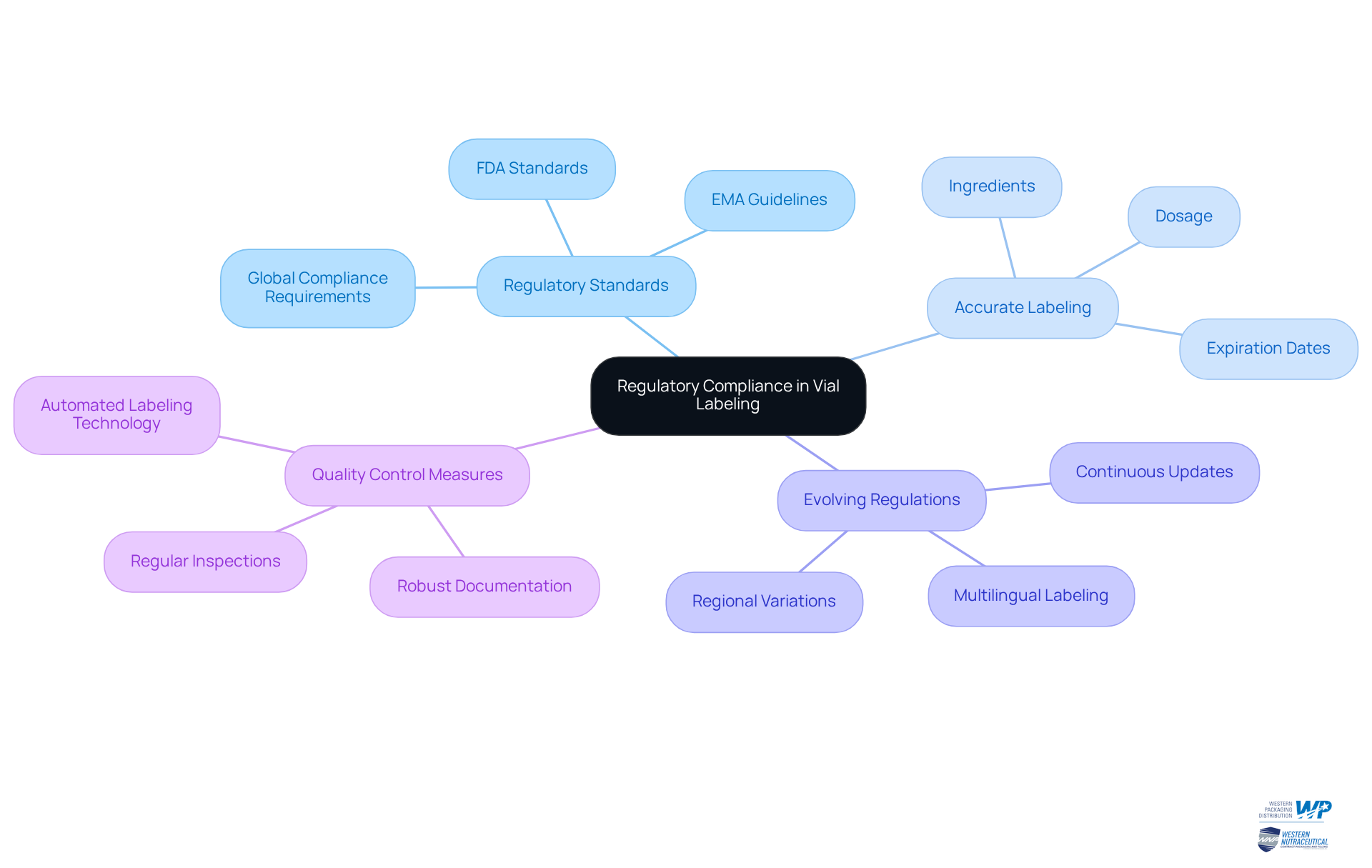

Regulatory Compliance: Navigating Challenges in Vial Labeling

Navigating regulatory adherence in container identification presents significant challenges, particularly due to the stringent standards imposed by agencies such as the FDA. Companies must prioritize the accuracy of vial labeling to ensure they clearly communicate essential information regarding ingredients, dosage, and expiration dates. Staying informed about evolving regulations is not merely advisable; it is imperative. Implementing robust quality control measures is essential for maintaining compliance and mitigating potential legal issues. By prioritizing these practices, businesses can safeguard their operations and enhance their credibility in the marketplace.

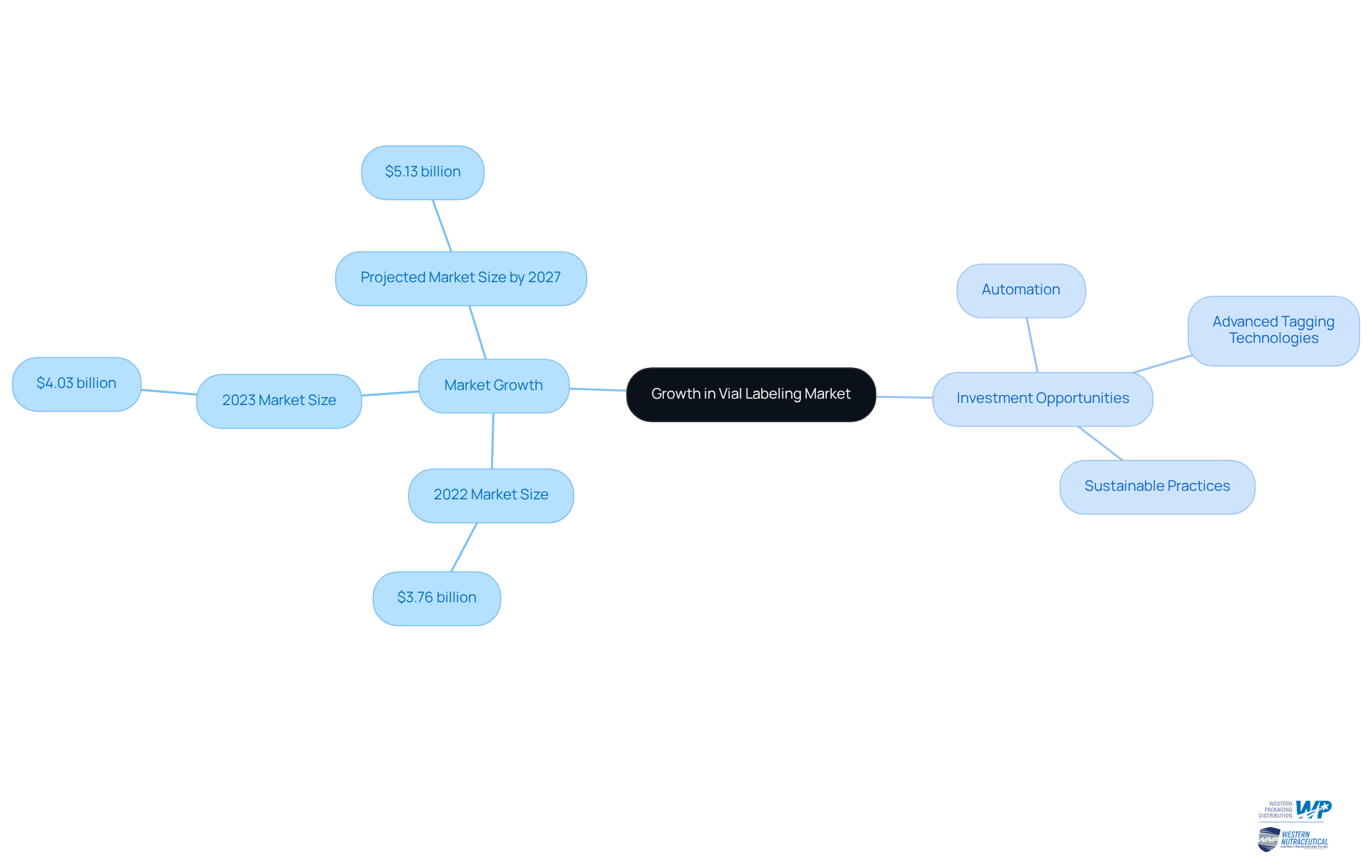

Investment Opportunities: Capitalizing on Growth in Vial Labeling

The container identification sector is poised for remarkable growth, fueled by escalating demand from both the pharmaceutical and nutraceutical industries. The global nutraceutical packaging market is projected to rise from $3.76 billion in 2022 to $4.03 billion in 2023, with expectations to reach $5.13 billion by 2027. This trajectory underscores the substantial potential for technologies related to vial labeling.

Companies aiming to harness this trend must prioritize investments in:

- Advanced tagging technologies

- Automation

- Sustainable practices

By aligning their strategies with consumer needs, businesses can enhance their competitive advantage and secure long-term growth. Notable players in the sector, such as BGR Packaging Solutions and OMNI Systems, are already capitalizing on this momentum, showcasing the effectiveness of innovative packaging solutions in meeting evolving consumer demands.

As Steve Katz emphasizes, performance and durability are non-negotiable in this critical segment of the label industry. As the industry evolves, the focus on these elements in identification will remain vital, ensuring that companies are well-equipped to thrive in this dynamic landscape.

Current Trends: Key Developments in the Vial Labeling Market

Current trends in the vial labeling market are significantly influenced by the adoption of smart tags utilizing technologies such as NFC and RFID, which enhance traceability and product management. These innovations not only improve supply chain transparency but also foster deeper consumer engagement. Notably, the demand for transparency has surged from 69% in 2018 to 76% in 2023, with 82% of consumers likely to scan products or QR codes for additional information. This trend underscores a robust demand for interactive information solutions.

Companies like Fresenius Kabi have successfully integrated RFID technology into their tagging processes, resulting in improved medication inventory management and compliance with stringent regulations. Additionally, the market for sustainable labels is projected to grow at an annual rate of 7.5%, driven by consumer preferences for eco-friendly practices.

As brands prioritize innovative label designs that resonate with consumers, those embracing these trends will be strategically positioned to meet evolving expectations and distinguish themselves in a competitive landscape.

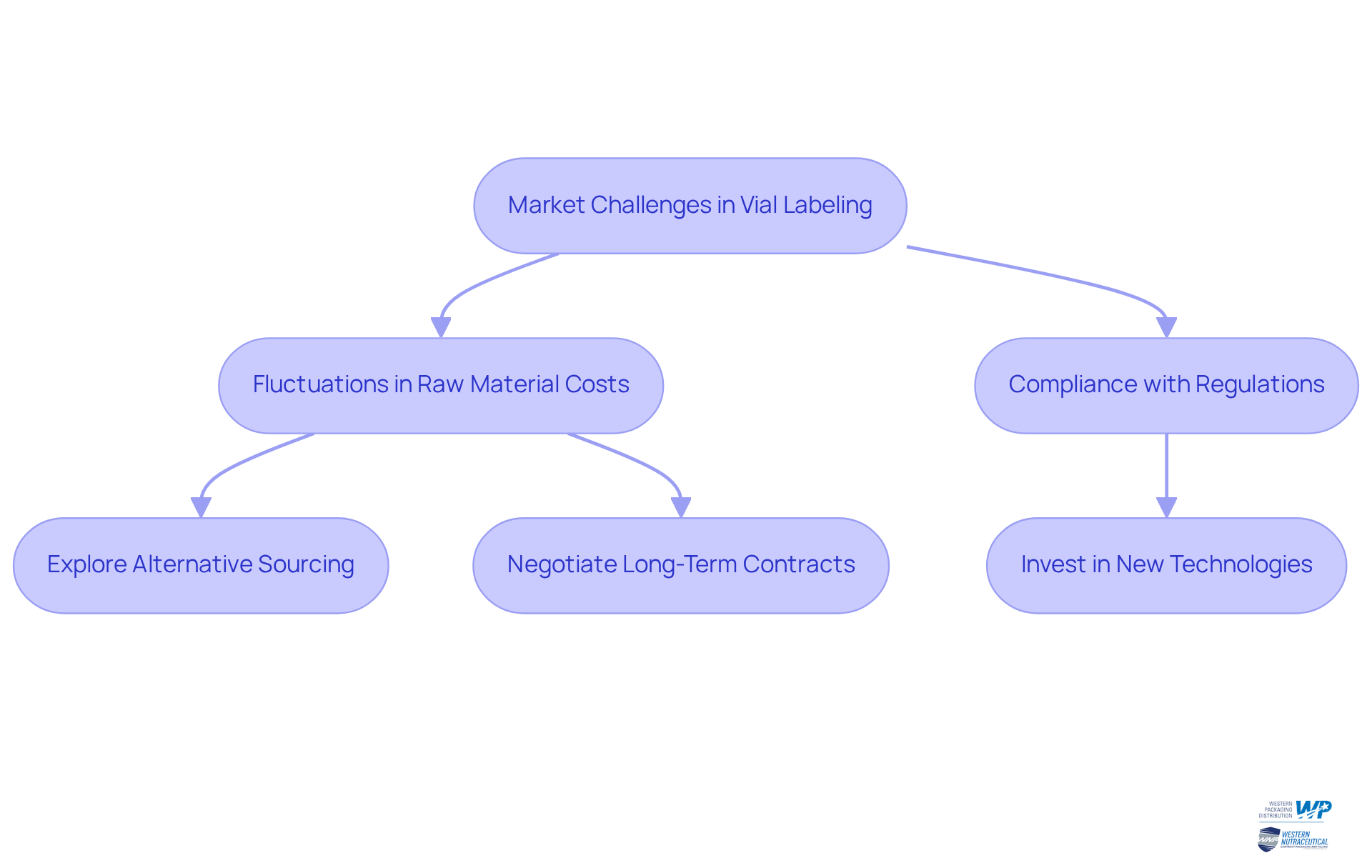

Market Challenges: Addressing Obstacles in Vial Labeling

The container marking market is currently confronting significant challenges, notably the fluctuations in raw material costs and the necessity for compliance with stringent regulations. Variations in raw material prices for vial marking can directly impact production expenses for manufacturers, making it imperative for companies to adopt proactive strategies to mitigate these effects. For example, organizations may consider exploring alternative sourcing options or negotiating long-term contracts to stabilize costs.

Furthermore, the integration of new labeling technologies into existing systems introduces its own complexities. Companies that have adeptly navigated these challenges, as illustrated in the case study titled 'Challenges in the Vial Labeling,' underscore the importance of strategic planning and investment in innovative solutions. By cultivating a culture of adaptability and continuous improvement, businesses can enhance operational efficiency while ensuring compliance with evolving standards.

As the industry progresses, organizations must remain vigilant and adaptable to these challenges, leveraging technology to optimize processes and maintain competitiveness in the nutraceutical sector. Agility is emerging as a sustainable competitive advantage, enabling companies to respond swiftly to changes and flourish in a volatile environment.

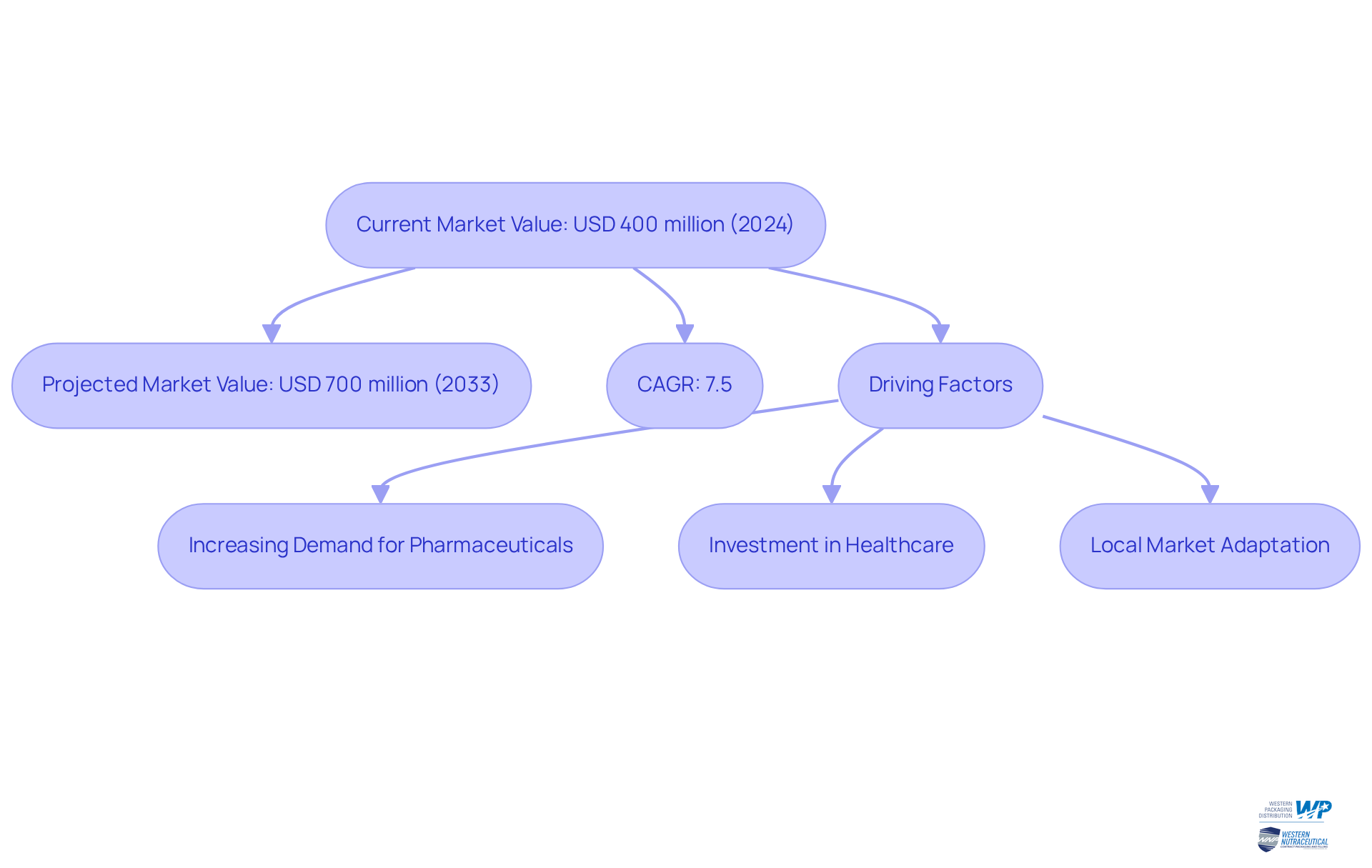

Emerging Markets: Growth Potential in Vial Labeling

Developing economies, particularly in Asia-Pacific and Latin America, are poised for significant expansion in the container identification sector. The market for vial labeling machines was valued at USD 400 million in 2024 and is projected to grow at a CAGR of 7.5%, reaching USD 700 million by 2033. This growth is fueled by the escalating demand for pharmaceutical and nutraceutical products in these regions, creating fertile ground for companies eager to establish an early presence.

Firms that tailor their products and services to meet local demand will find themselves at a competitive advantage. Furthermore, the increasing investment in the pharmaceutical and healthcare industries in these areas is driving the demand for advanced marking technologies such as vial labeling. This trend underscores the importance of strategic planning and local adaptation for businesses striving to thrive in these dynamic environments.

Growth Drivers: Factors Fueling the Vial Labeling Market

The vial labeling industry is experiencing significant growth, driven by several critical factors, notably the increasing demand for personalized medicine and the expansion of e-commerce within the pharmaceutical sector. As personalized medicine evolves, it necessitates accurate and adaptable identification solutions that can meet specific product specifications and regulatory standards. This trend is underscored by the projection that the global personalized medicine market will grow at a compound annual growth rate of 7.21% from 2023 to 2032, highlighting the escalating need for customized packaging methods in the nutraceutical domain.

Furthermore, innovations in tagging technology and automation are improving operational efficiency, allowing companies to optimize their processes and better satisfy consumer needs. For example, automated tagging machines can diminish human error by up to 85% when compared to manual operations, significantly boosting compliance and productivity—especially in the nutraceutical sector, where accuracy is critical. This precision is particularly essential, given that over 70% of sterile injectable products globally are housed in containers and ampoules, which require exact and tamper-proof vial labeling solutions.

Organizations that adeptly harness these growth drivers are strategically positioned to thrive in an ever-evolving marketplace. The adoption of intelligent packaging technologies, such as QR codes and RFID tags, is becoming more prevalent, enhancing traceability and consumer interaction. Additionally, the growing demand for eco-friendly ampoules and vials, driven by sustainability trends in the pharmaceutical industry, further accentuates the necessity for innovative and efficient vial labeling solutions. Western Packaging provides customized flexible packaging solutions, including large pouches for protein products and stick packs for nutraceuticals, addressing the distinct requirements of both nutraceuticals and pharmaceuticals, ultimately enhancing brand recognition and shelf appeal.

Conclusion

The evolution of vial labeling in the nutraceutical sector is being shaped by several transformative trends that emphasize efficiency, sustainability, and technological advancement. As businesses navigate the complexities of this landscape, the integration of innovative packaging solutions, automation, and artificial intelligence emerges as critical components in enhancing operational effectiveness and meeting consumer demands.

Key insights from the article highlight:

- The importance of automated systems for improved accuracy and speed

- The shift towards sustainable practices that resonate with eco-conscious consumers

- The necessity of regulatory compliance in maintaining market credibility

Additionally, the growth potential in emerging markets and the increasing investment in advanced labeling technologies signal a robust future for the industry, driven by both consumer preferences and technological innovations.

In light of these developments, organizations within the nutraceutical space are encouraged to embrace these trends actively. By prioritizing investment in automation, sustainability, and compliance technologies, businesses can not only enhance their operational efficiency but also position themselves favorably in a competitive market. Adapting to these changes is not just beneficial; it is essential for thriving in a dynamic environment where consumer expectations and regulatory requirements are continually evolving.

Frequently Asked Questions

What services does Western Packaging offer for vial labeling?

Western Packaging provides integrated packaging solutions that include packaging design, filling services, and third-party logistics (3PL) such as warehousing, inventory management, and distribution to optimize the vial labeling process for nutraceuticals.

How do Western Packaging's solutions impact operational efficiency?

Their holistic approach enhances operational efficiency by simplifying the supply chain, reducing lead times, and ensuring timely and effective product delivery, which leads to notable improvements in product delivery timelines and increased customer satisfaction.

Why is automation important in vial labeling?

Automation enhances efficiency and accuracy in container marking by allowing automated tagging machines to apply labels at high speeds (over 500 containers per hour) while minimizing human error. This technology also enables rapid changeovers between different container sizes and types, facilitating scalability for businesses.

What sustainability practices are being adopted in vial labeling?

Businesses are increasingly using eco-friendly materials and practices, including recyclable label materials, biodegradable adhesives, and sustainable inks, to minimize their environmental impact and cater to a growing consumer preference for eco-conscious products.

How does prioritizing sustainability benefit businesses in the vial labeling industry?

By embracing sustainable practices, businesses can reduce their ecological footprint, enhance brand loyalty, and strategically position themselves in a competitive market that is increasingly influenced by sustainability concerns.