Overview

The article examines diverse kitting solutions designed to optimize nutraceutical packaging, underscoring the significance of integrated services, automation, and customization. By illustrating how tailored kitting solutions bolster operational efficiency, curtail costs, and enhance product appeal, it positions companies for competitive success in the marketplace. These insights not only highlight the advantages of adopting such solutions but also encourage industry stakeholders to consider their implementation for improved outcomes.

Introduction

In the fast-paced world of nutraceuticals, the efficiency of packaging can indeed make or break a business. Companies are increasingly turning to innovative kitting solutions to streamline their supply chains, reduce lead times, and enhance product delivery. However, as the demand for customized and automated processes grows, one must ask: how can businesses ensure they are leveraging the right strategies to stay competitive? This article explores seven essential kitting solutions that not only optimize packaging operations but also elevate brand presence in a crowded market.

Western Packaging: Integrated Kitting Solutions for Efficient Supply Chains

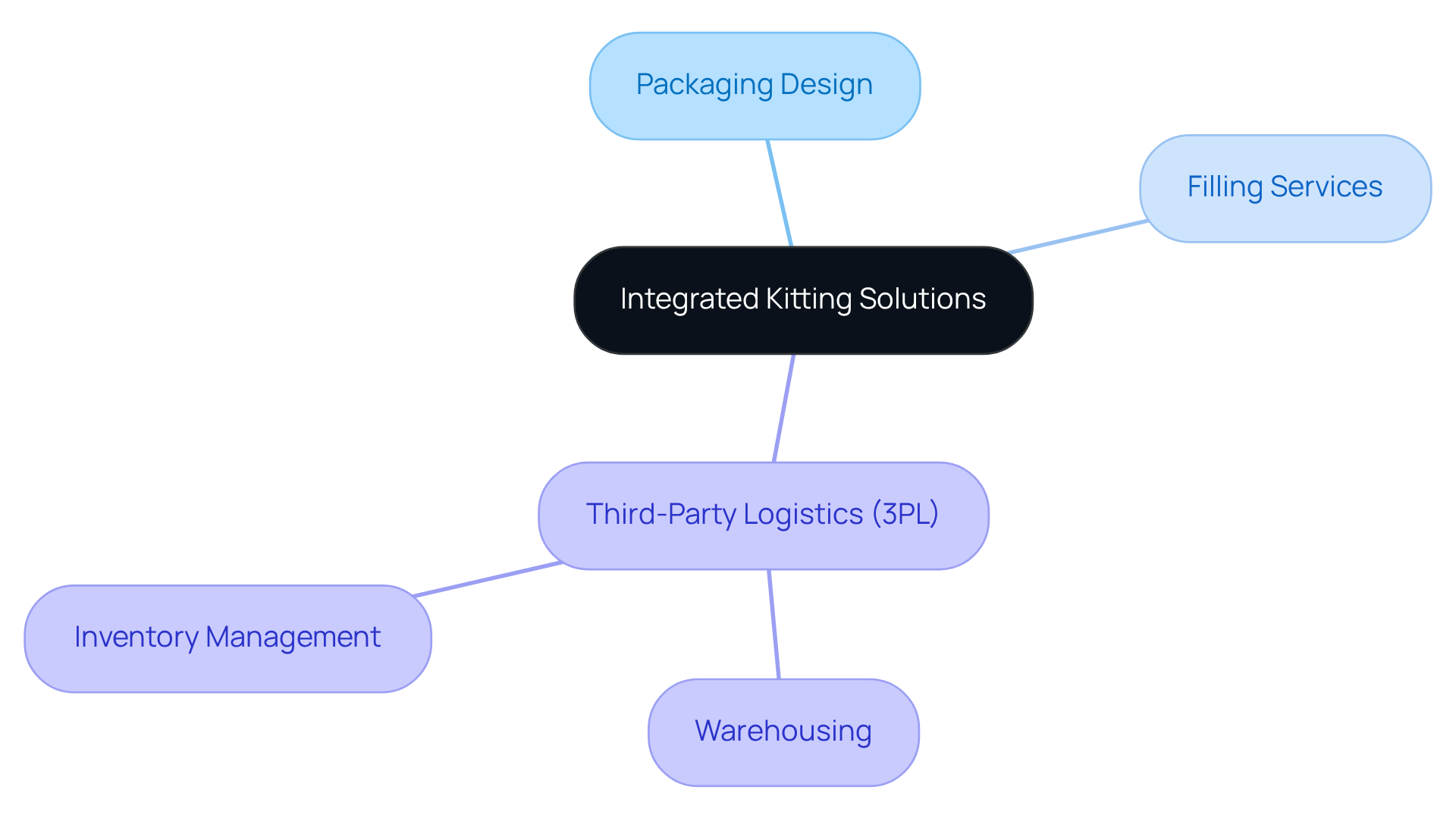

Western Packaging offers an extensive range of kitting solutions designed to enhance supply chains. By merging packaging design, filling services, and third-party logistics (3PL), including warehousing and inventory management, we enable companies to streamline their operations from start to finish. This integrated approach not only reduces lead times but also enhances product delivery, establishing us as a preferred choice for businesses in the nutraceutical sector.

With kitting solutions that are tailored to address specific business needs, Western Packaging empowers nutraceutical producers to focus on their core strengths while benefiting from efficient supply chain management.

To learn more about how our assembly solutions can elevate your operations, contact us today.

Automated Kitting Systems: Enhance Efficiency and Accuracy

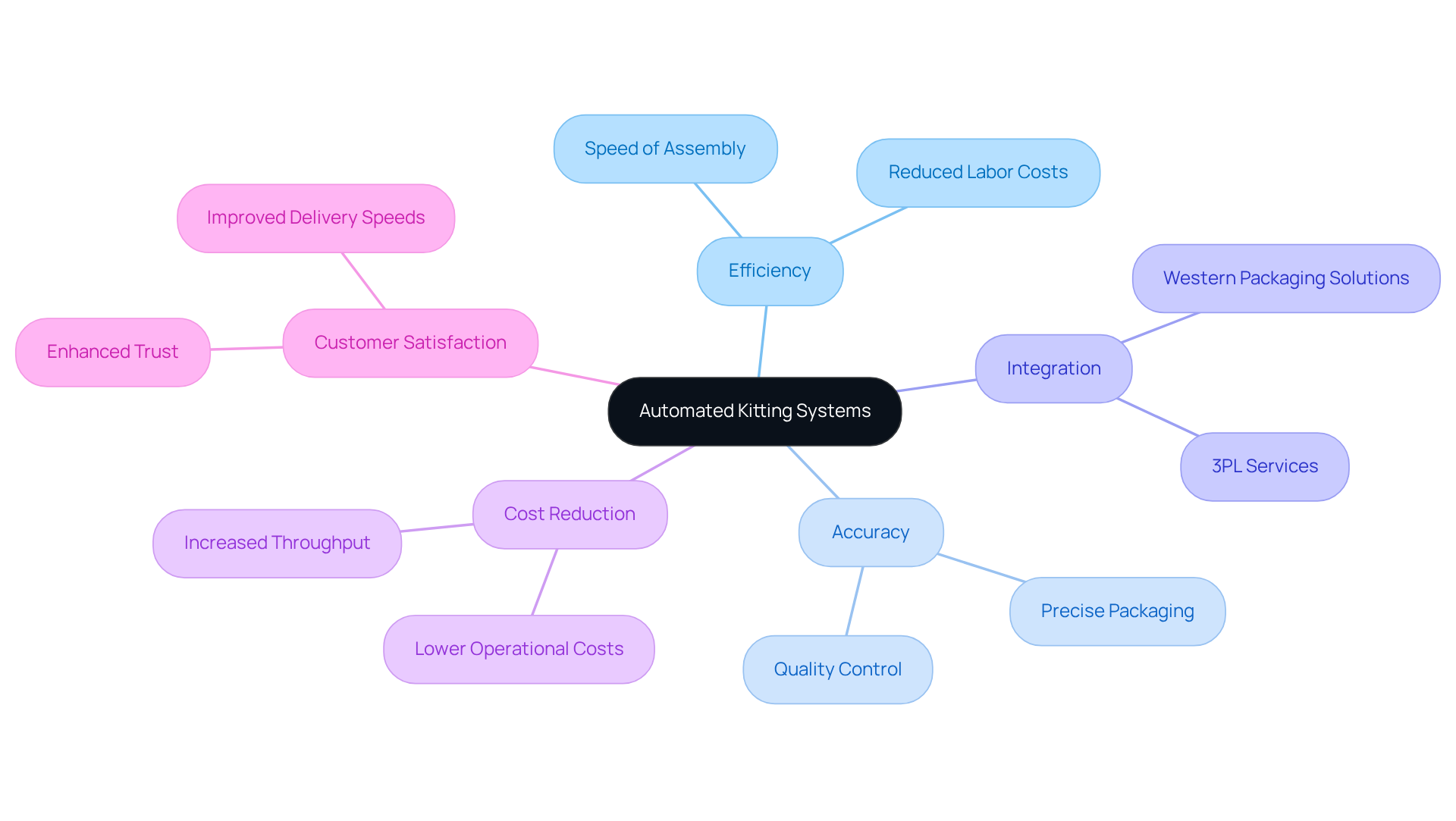

Automated assembly systems are revolutionizing packaging processes by significantly enhancing efficiency and precision. These advanced technologies facilitate the rapid assembly of kitting solutions by leveraging real-time inventory data to promptly meet customer demands and minimize delays. Companies employing automated packaging can achieve assembly speeds that greatly exceed manual methods, reducing human error and boosting overall productivity.

The advantages of automated assembly systems extend well beyond mere speed. They guarantee precise packaging accuracy, a critical factor in industries such as nutraceuticals, where compliance and quality are paramount. By automating the assembly process, companies can uphold consistent quality control, thereby enhancing customer satisfaction and trust.

Western Packaging's integrated filling process seamlessly complements these automated kitting solutions, providing comprehensive solutions that streamline production and optimize supply chain management. With a range of products from powders to gummies and soft-gels, Western Packaging empowers nutraceutical producers to effectively enhance their processing methods.

Experts in the field underscore the vital role of automation in contemporary packaging. As one technology leader noted, the integration of automated systems not only streamlines operations but also enables businesses to concentrate on innovation and growth. This transition towards automation is evident in numerous case studies, where companies have reported significant improvements in operational efficiency and accuracy following the implementation of automated assembly technologies.

For instance, organizations that have adopted automated assembly processes, particularly those utilizing Western Packaging's integrated filling and 3PL services, have witnessed reductions in labor costs and increased throughput, enabling them to expand operations efficiently. By embracing these technologies, companies can enhance their wrapping processes, ensuring they remain competitive in a rapidly evolving market.

Custom Kitting Services: Tailored Solutions for Unique Packaging Needs

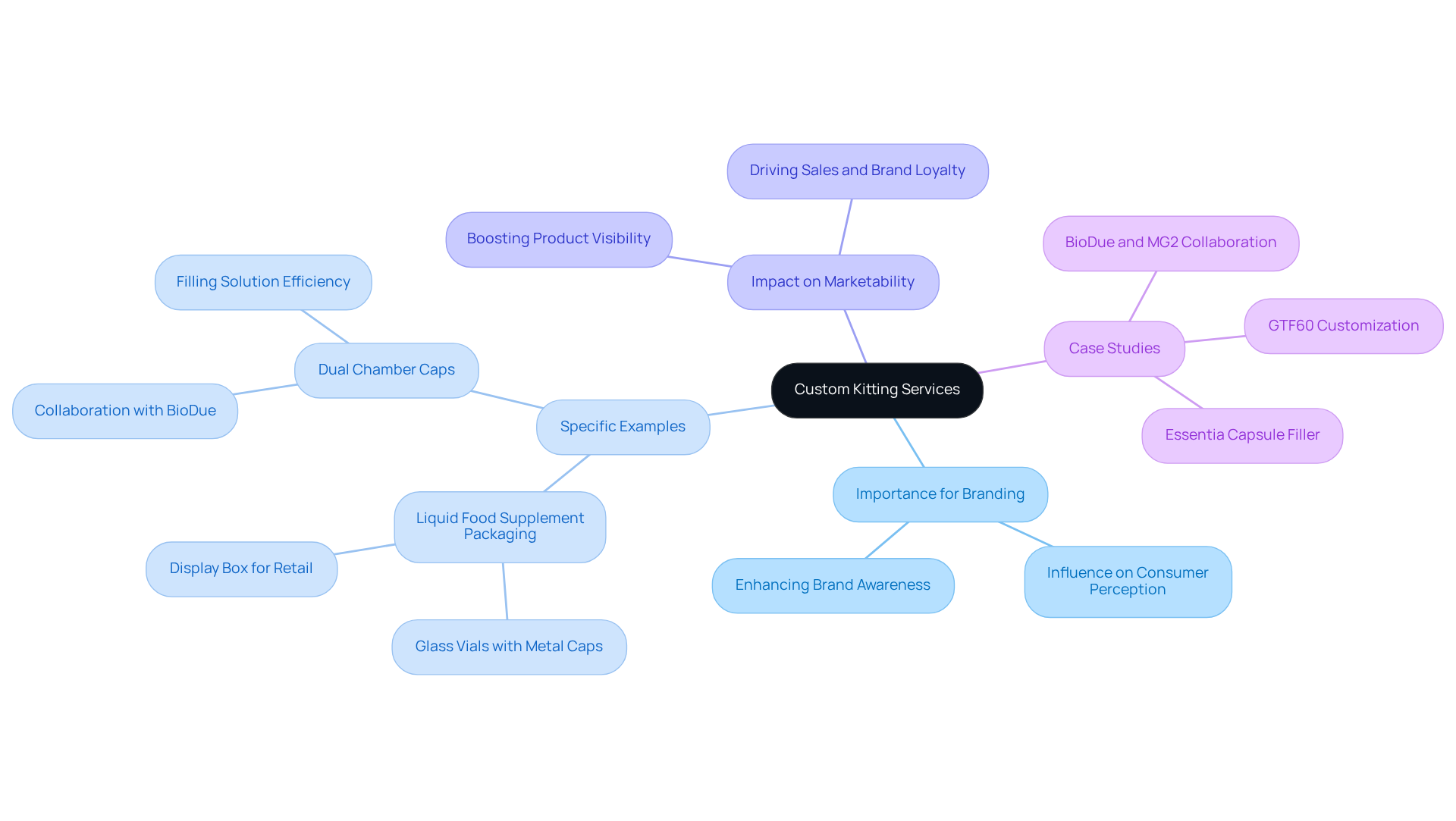

Tailored kitting solutions are essential for companies aiming for unique wrapping options that align with their branding and functional needs. Western Packaging specializes in kitting solutions that are customized to meet specific product requirements, ensuring that each package not only enhances product appeal but also helps businesses stand out in a competitive market. A prime example is the innovative container approach developed for a liquid food supplement in glass vials with metal caps, showcased at a recent trade event. This illustrates how tailored assembly can significantly boost marketability and presentation.

As we look to 2025, the focus on customized kitting solutions for nutraceuticals continues to grow, with brands increasingly recognizing the impact of personalized assembly on brand awareness. Branding experts assert that effective packaging can profoundly influence consumer perception and purchasing decisions. By integrating creativity and precision into their kitting solutions, Western Packaging empowers clients to enhance product visibility and attractiveness, ultimately driving sales and fostering brand loyalty.

The effectiveness of customized kitting solutions is evident in various case studies, such as the partnership between BioDue and MG2, which led to an efficient filling solution for dual chamber caps. This collaboration underscores the importance of personalization in addressing specific industry needs, further solidifying the value of kitting solutions within the nutraceutical sector.

Inventory Management Systems: Optimize Kitting Processes

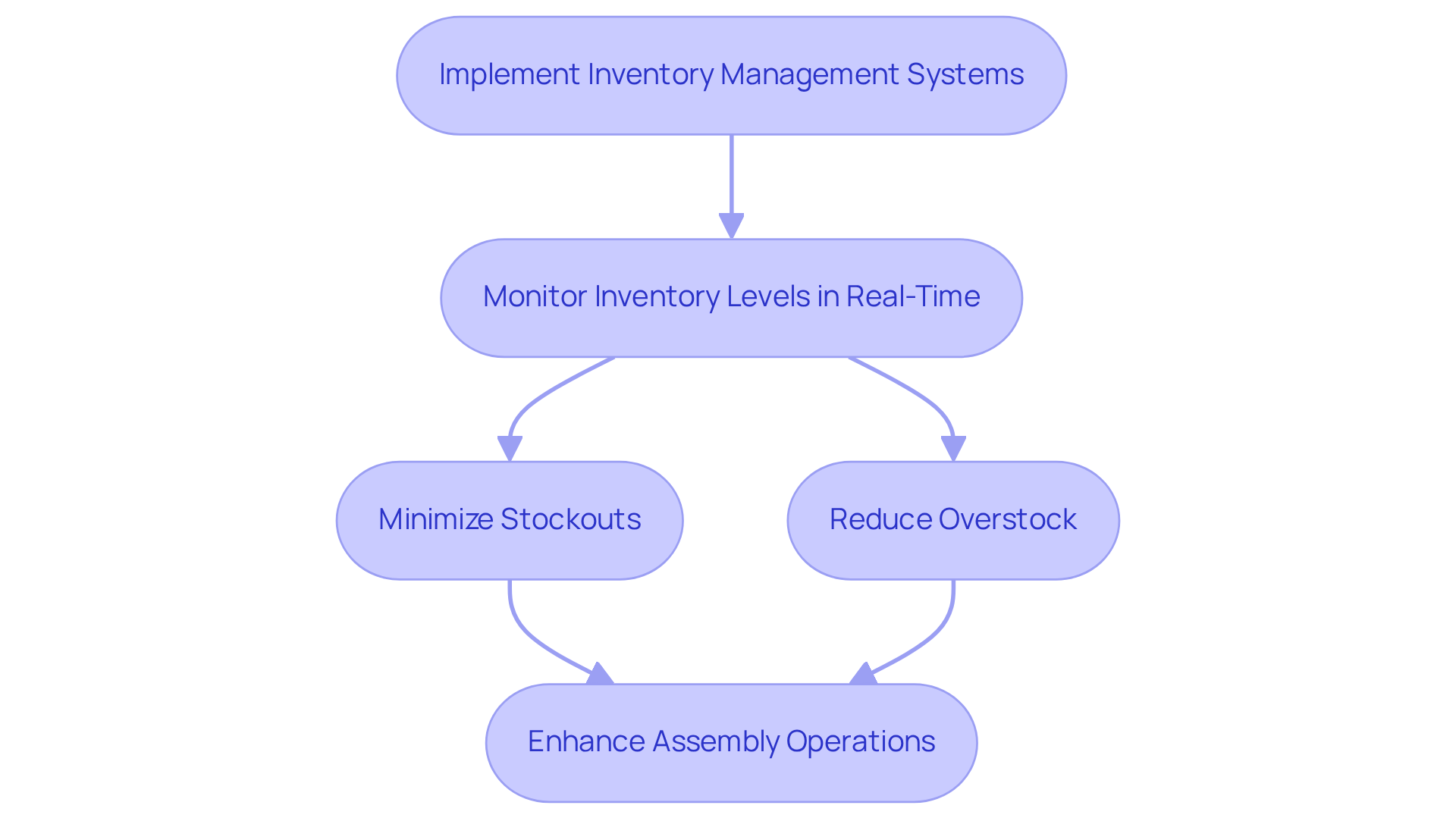

Implementing robust inventory management systems is essential for optimizing assembly processes. These systems empower companies to monitor inventory levels in real-time, ensuring that all components necessary for assembly are readily accessible. By minimizing stockouts and overstock situations, companies can enhance their assembly operations, resulting in quicker fulfillment times and reduced costs. This strategic approach not only streamlines processes but also reinforces the reliability of operations, ultimately driving success in the competitive landscape of logistics and packaging.

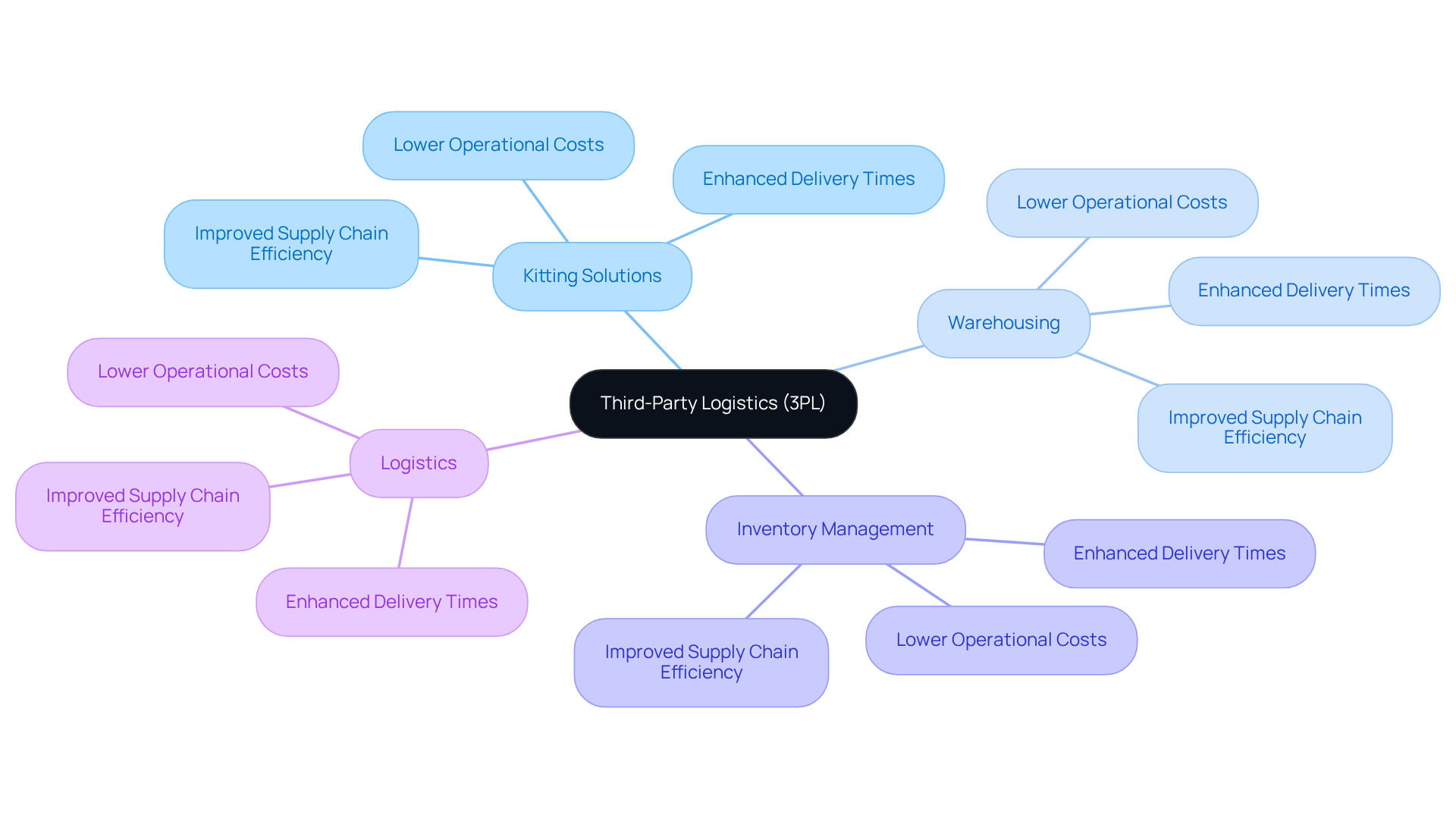

Third-Party Logistics (3PL): Streamline Kitting and Distribution

Leveraging third-party logistics (3PL) services from Western Packaging significantly streamlines assembly and distribution processes. Our extensive 3PL offerings encompass:

- Kitting solutions

- Warehousing

- Inventory management

- Logistics

This empowers companies to outsource these critical functions and benefit from our expertise in efficient assembly and fulfillment. This strategic partnership allows nutraceutical manufacturers to lower operational costs and enhance delivery times, thereby improving overall supply chain efficiency. Concentrate on your core competencies, and allow us to manage the logistics—reach out to Western Packaging today to discover how we can optimize your supply chain.

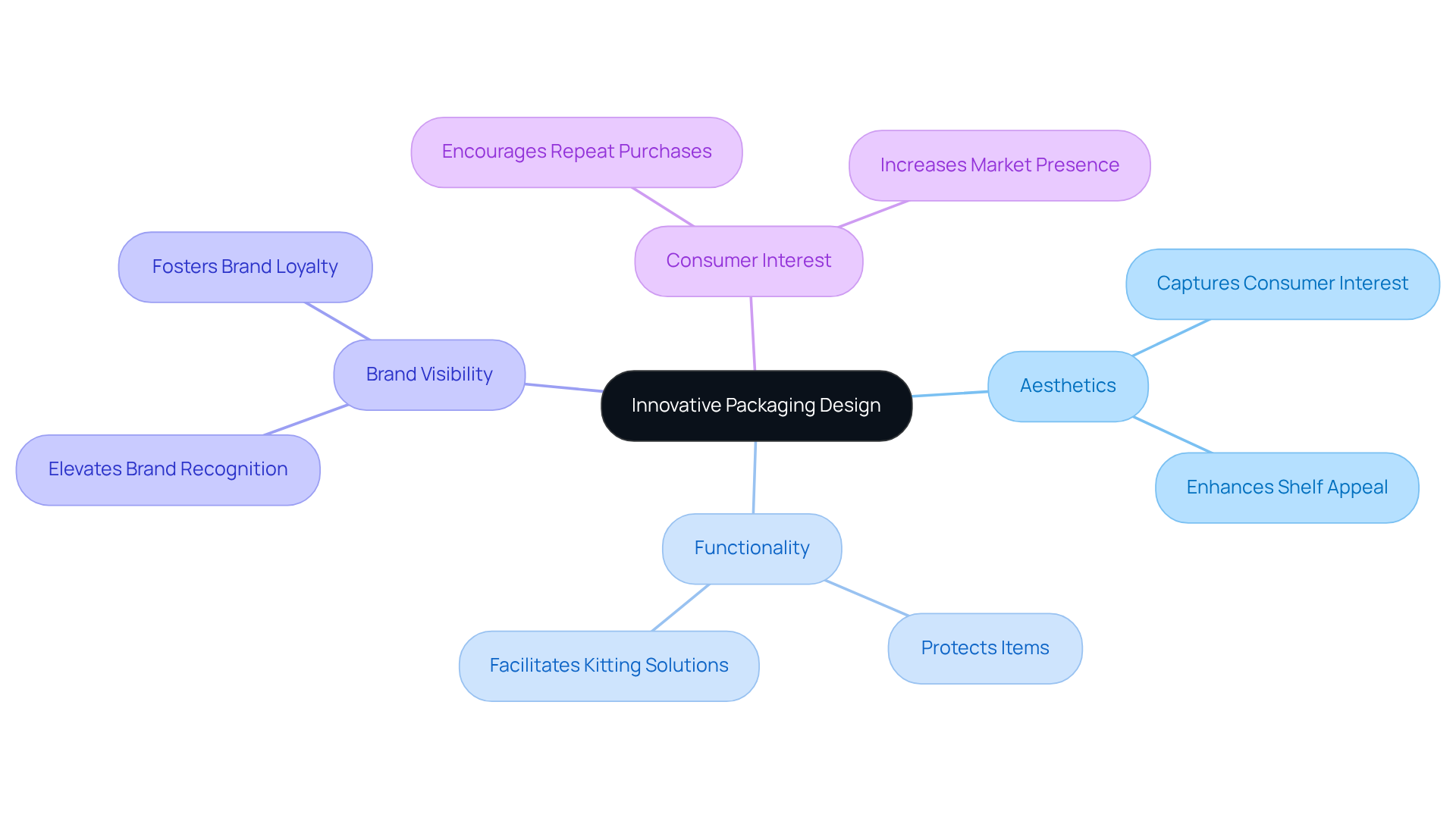

Innovative Packaging Design: Elevate Your Kitting Solutions

Creative container design is pivotal in enhancing kitting solutions. By focusing on both aesthetics and functionality, businesses can develop containers that not only protect items but also elevate brand visibility. At Western Packaging, we specialize in crafting tailored flexible containers that significantly boost your product's shelf appeal and brand recognition. Distinctive designs are instrumental in capturing consumer interest and fostering brand loyalty, making innovative packaging a crucial component of effective kitting solutions. Embrace the power of creative packaging to transform your product's market presence.

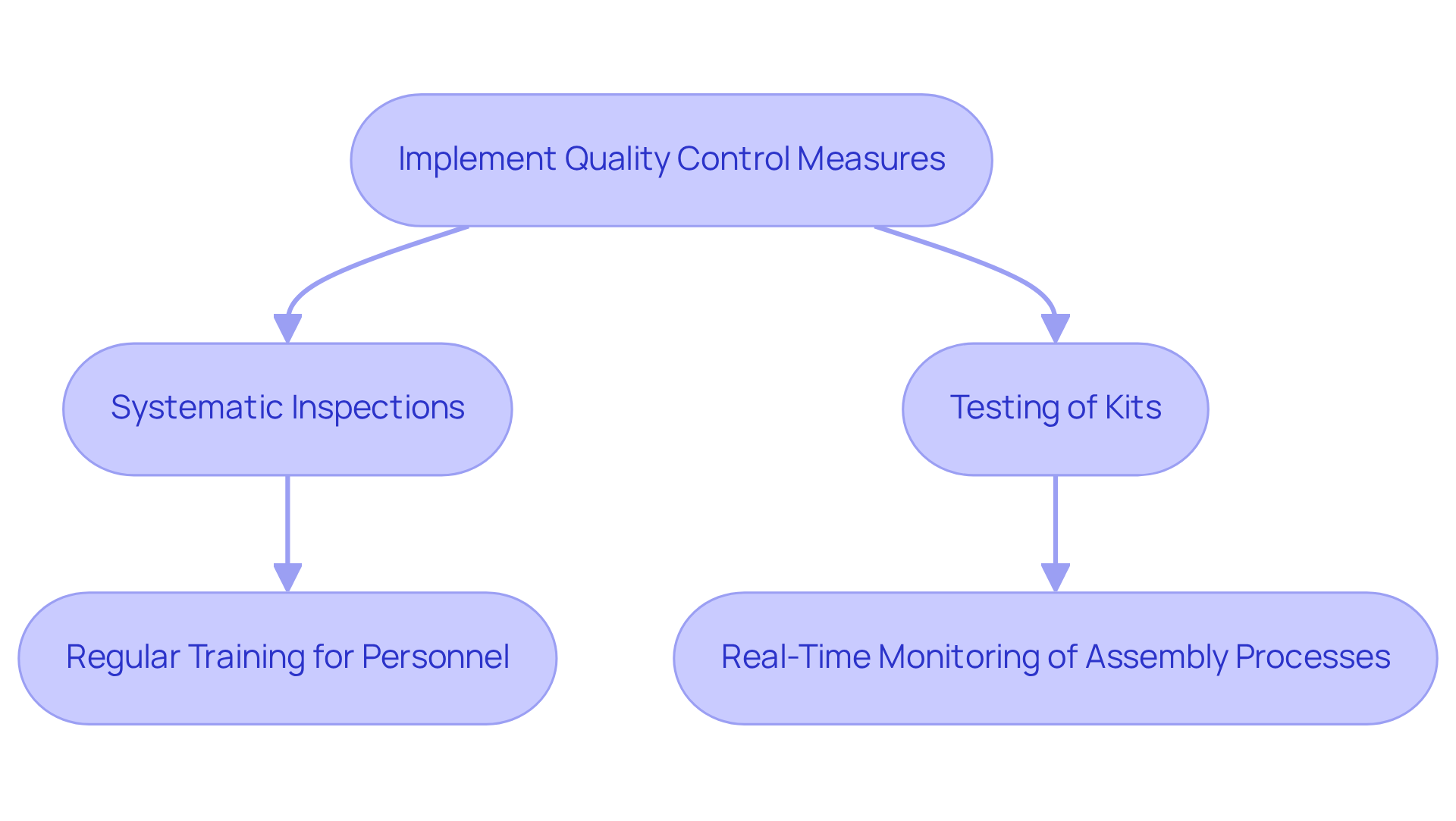

Quality Control Measures: Ensure Compliance in Kitting Solutions

Implementing rigorous quality control measures is essential for ensuring compliance in the nutraceutical sector's kitting solutions. This process encompasses systematic inspections and testing of kits to confirm that all components meet established standards. By upholding high-quality standards, companies not only safeguard their brand reputation but also enhance customer satisfaction—an indispensable factor in the nutraceutical industry. Effective quality control can significantly mitigate the risk of product recalls and regulatory issues, ultimately fostering trust and loyalty among consumers.

As emphasized by JohnsByrne, "We utilize high-quality materials and cutting-edge printing technologies to guarantee that your containers are durable, secure, and visually impressive," highlighting the critical role of quality in presentation. As the market evolves, the maintenance of these standards becomes increasingly vital for companies striving to excel in a competitive landscape.

To further enhance adherence, organizations should consider:

- Implementing regular training for personnel on quality control protocols

- Leveraging technology for real-time monitoring of assembly processes

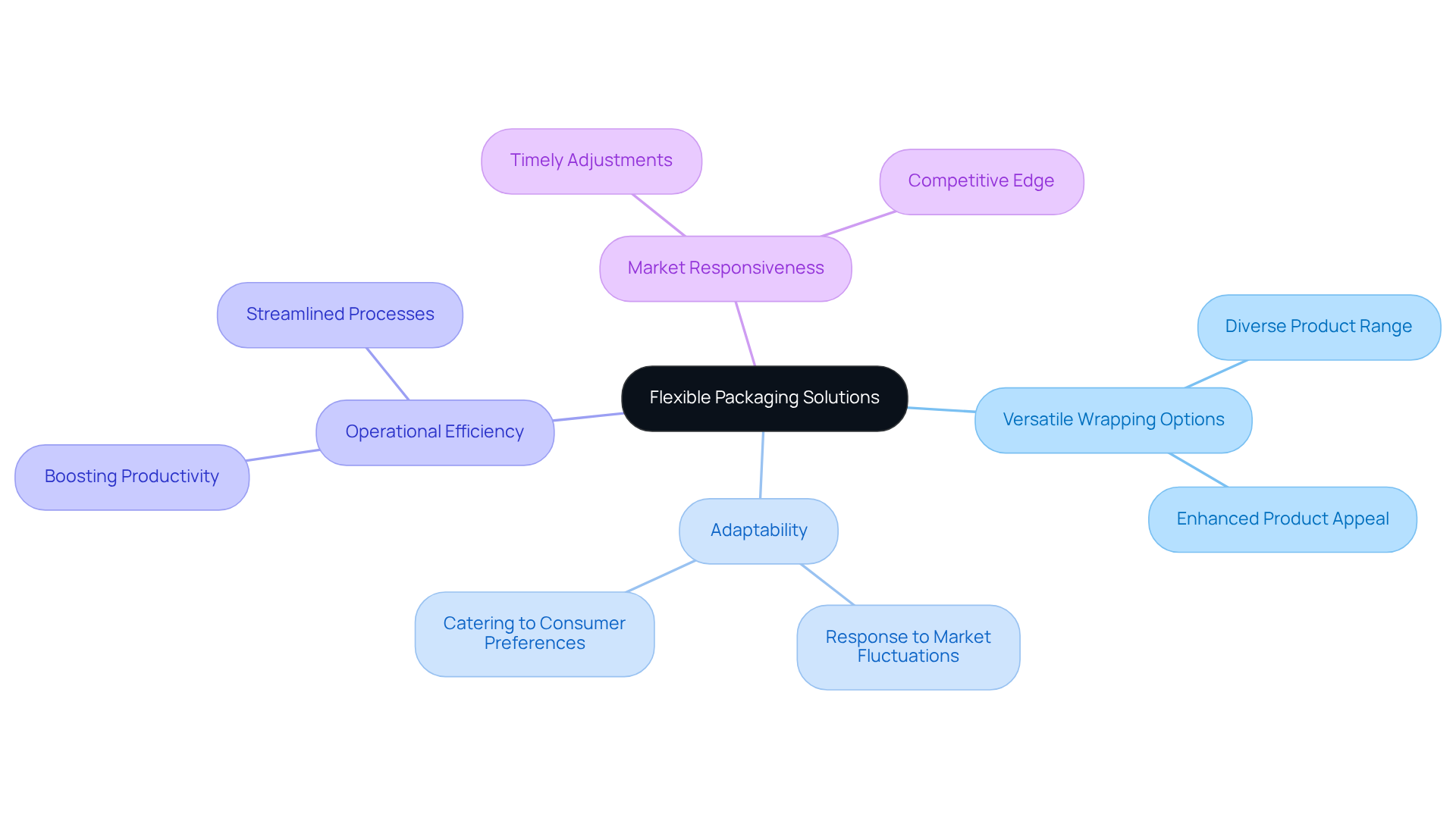

Flexible Packaging Solutions: Adaptable Kitting for Diverse Products

Versatile wrapping options are crucial for implementing flexible assembly methods, empowering companies to cater to a diverse range of products. This adaptability enables businesses to respond promptly to market fluctuations and consumer preferences, thereby ensuring that their assembly solutions remain relevant and efficient. By leveraging flexible packaging, organizations can significantly boost their operational efficiency and enhance product appeal. Embracing these innovative solutions is essential for maintaining a competitive edge in the ever-evolving marketplace.

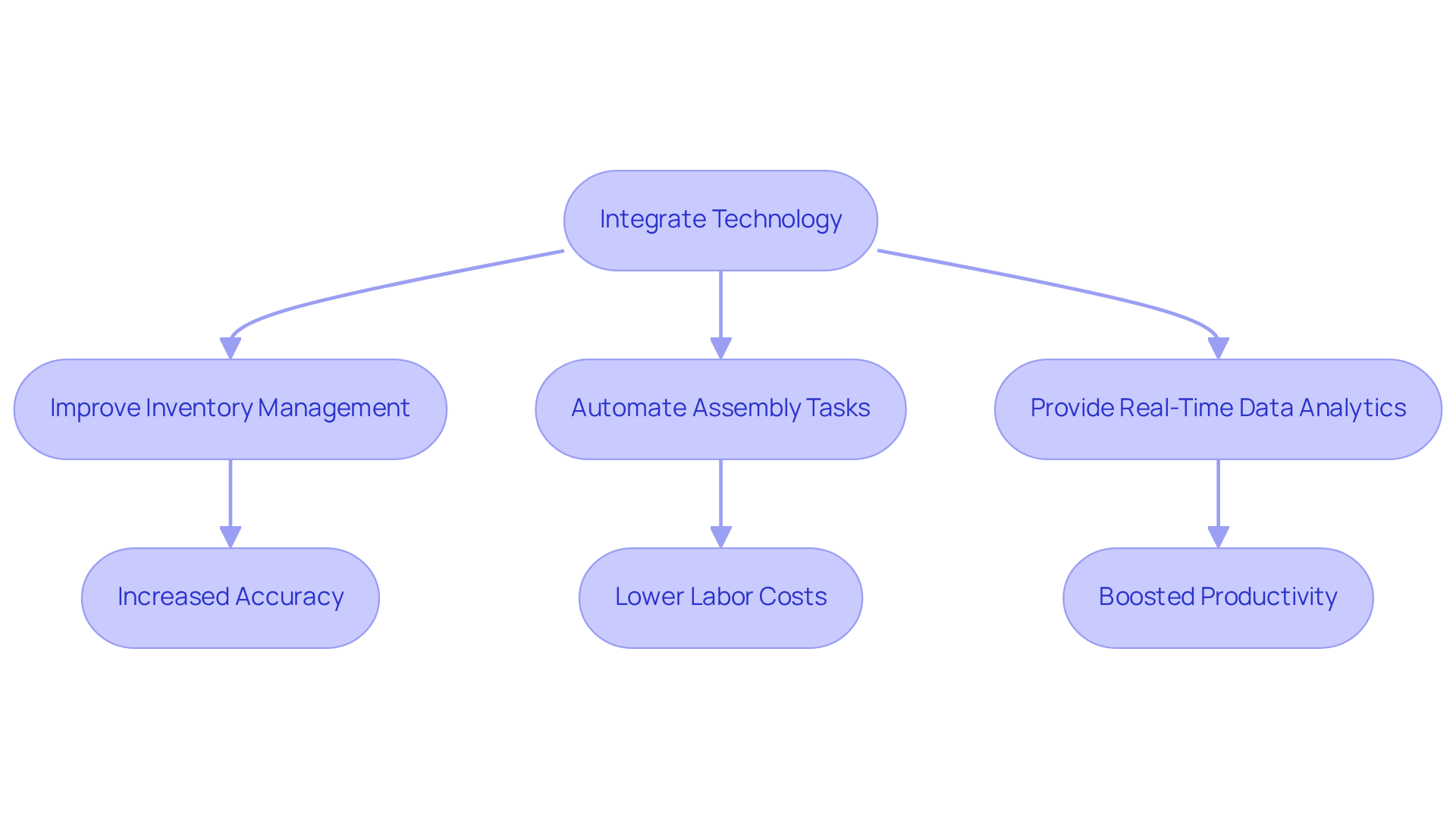

Technology Integration: Modernize Your Kitting Operations

Incorporating technology into assembly operations is not just beneficial; it is essential for modernizing processes and enhancing efficiency. Advanced software applications significantly improve inventory management, automate assembly tasks, and provide real-time data analytics. By embracing these technologies, companies can achieve remarkable accuracy, lower labor costs, and boost overall productivity in their assembly operations.

The integration of such innovations positions businesses as leaders in the industry, ready to meet the demands of a competitive market. It is time to act—adopt these technological advancements and transform your assembly operations into a model of efficiency and effectiveness.

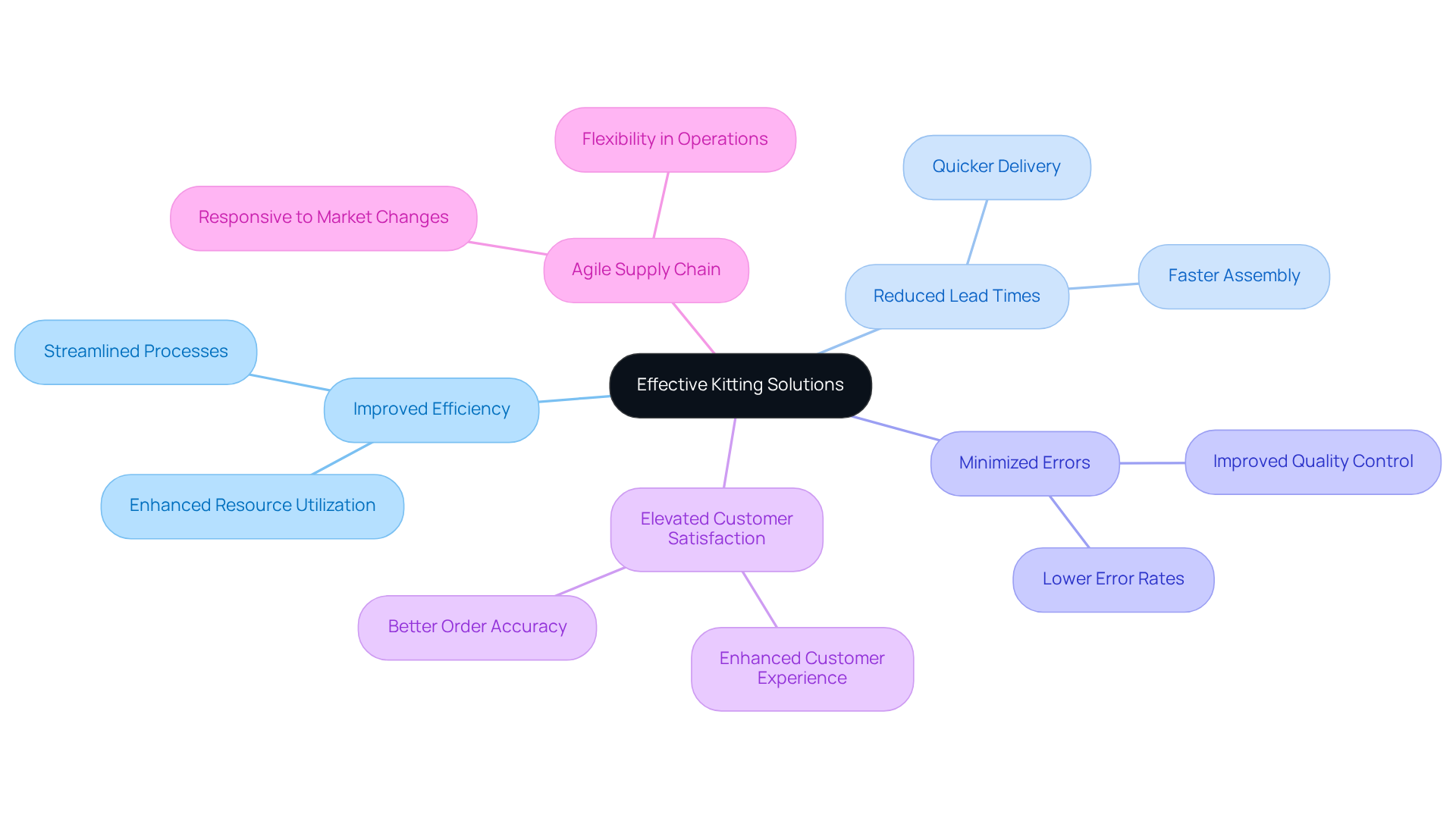

Supply Chain Efficiency: The Impact of Effective Kitting Solutions

Effective kitting solutions greatly improve the efficiency of the supply chain. By streamlining assembly and packaging processes, businesses can effectively reduce lead times, minimize errors, and elevate customer satisfaction. This optimization not only bolsters operational performance but also fosters a more agile and responsive supply chain. Consequently, companies are strategically positioned for success in an increasingly competitive market. Embracing kitting solutions is not just a choice; it is a necessity for those aiming to thrive.

Conclusion

Effective kitting solutions are essential for enhancing the efficiency of nutraceutical packaging. By integrating services such as automated assembly, custom kitting, and robust inventory management, businesses can streamline operations and achieve significant improvements in productivity and customer satisfaction. The focus on tailored solutions enables companies to meet their unique packaging needs while distinguishing themselves in a competitive marketplace.

Key insights throughout this article highlight the benefits of adopting automated systems, the critical importance of quality control, and the advantages of partnering with third-party logistics providers. Each of these elements contributes to a more agile supply chain, ensuring accurate and efficient product delivery. Moreover, innovative packaging design and flexible solutions are vital for responding to evolving consumer preferences and market trends.

Ultimately, embracing these kitting strategies is not just a choice; it is a necessity for companies aiming to thrive in the nutraceutical sector. By investing in advanced technologies and customized services, businesses can position themselves as leaders in the industry, ready to meet the demands of a fast-paced market. Taking action now to implement these solutions will enhance operational efficiency and foster long-term success and growth.

Frequently Asked Questions

What kitting solutions does Western Packaging offer?

Western Packaging offers an extensive range of kitting solutions that merge packaging design, filling services, and third-party logistics (3PL), including warehousing and inventory management, to streamline operations in supply chains.

How do Western Packaging's kitting solutions benefit nutraceutical producers?

The kitting solutions are tailored to address specific business needs, allowing nutraceutical producers to focus on their core strengths while benefiting from efficient supply chain management, which reduces lead times and enhances product delivery.

What role do automated kitting systems play in packaging processes?

Automated kitting systems enhance efficiency and accuracy by facilitating rapid assembly of kitting solutions, leveraging real-time inventory data to meet customer demands promptly, and minimizing delays.

What are the advantages of using automated assembly systems?

Advantages include significantly increased assembly speeds compared to manual methods, reduced human error, improved packaging accuracy, consistent quality control, and enhanced customer satisfaction.

How does Western Packaging's integrated filling process complement automated kitting solutions?

The integrated filling process works seamlessly with automated kitting solutions to streamline production and optimize supply chain management, benefiting nutraceutical producers with a range of products from powders to gummies and soft-gels.

What is the importance of customized kitting solutions?

Customized kitting solutions are essential for companies seeking unique wrapping options that align with their branding and functional needs, helping them stand out in a competitive market.

Can you provide an example of a successful customized kitting solution?

An example is the innovative container approach developed for a liquid food supplement in glass vials with metal caps, which illustrates how tailored assembly can enhance marketability and presentation.

How does effective packaging influence consumer behavior?

Effective packaging can significantly influence consumer perception and purchasing decisions, driving brand awareness and loyalty.

What is the significance of the partnership between BioDue and MG2?

The partnership illustrates the effectiveness of personalized kitting solutions in addressing specific industry needs, leading to an efficient filling solution for dual chamber caps in the nutraceutical sector.