Overview

The article delineates nine significant benefits of Vertical Form Fill Seal (VFFS) packaging tailored for nutraceutical manufacturers. It underscores the technology's pivotal role in enhancing operational efficiency, flexibility, cost-effectiveness, and sustainability, all while ensuring adherence to regulatory compliance and maintaining product integrity.

These advantages are substantiated by compelling data that illustrates:

- Increased production speeds

- Reduced labor costs

- Heightened market competitiveness

This evidence compellingly demonstrates how VFFS technology adeptly meets the evolving demands of the nutraceutical industry, positioning manufacturers for success in a competitive landscape.

Introduction

The nutraceutical industry is witnessing remarkable growth, with projections highlighting a significant increase in demand for health products and dietary supplements. As manufacturers endeavor to adapt to this evolving market, the integration of Vertical Form Fill Seal (VFFS) packaging technology has emerged as a transformative solution. This innovative approach not only streamlines production processes and enhances efficiency but also delivers a range of advantages, including cost savings and improved sustainability.

What specific benefits does VFFS packaging offer nutraceutical manufacturers, and how can they effectively utilize these solutions to excel in a competitive landscape?

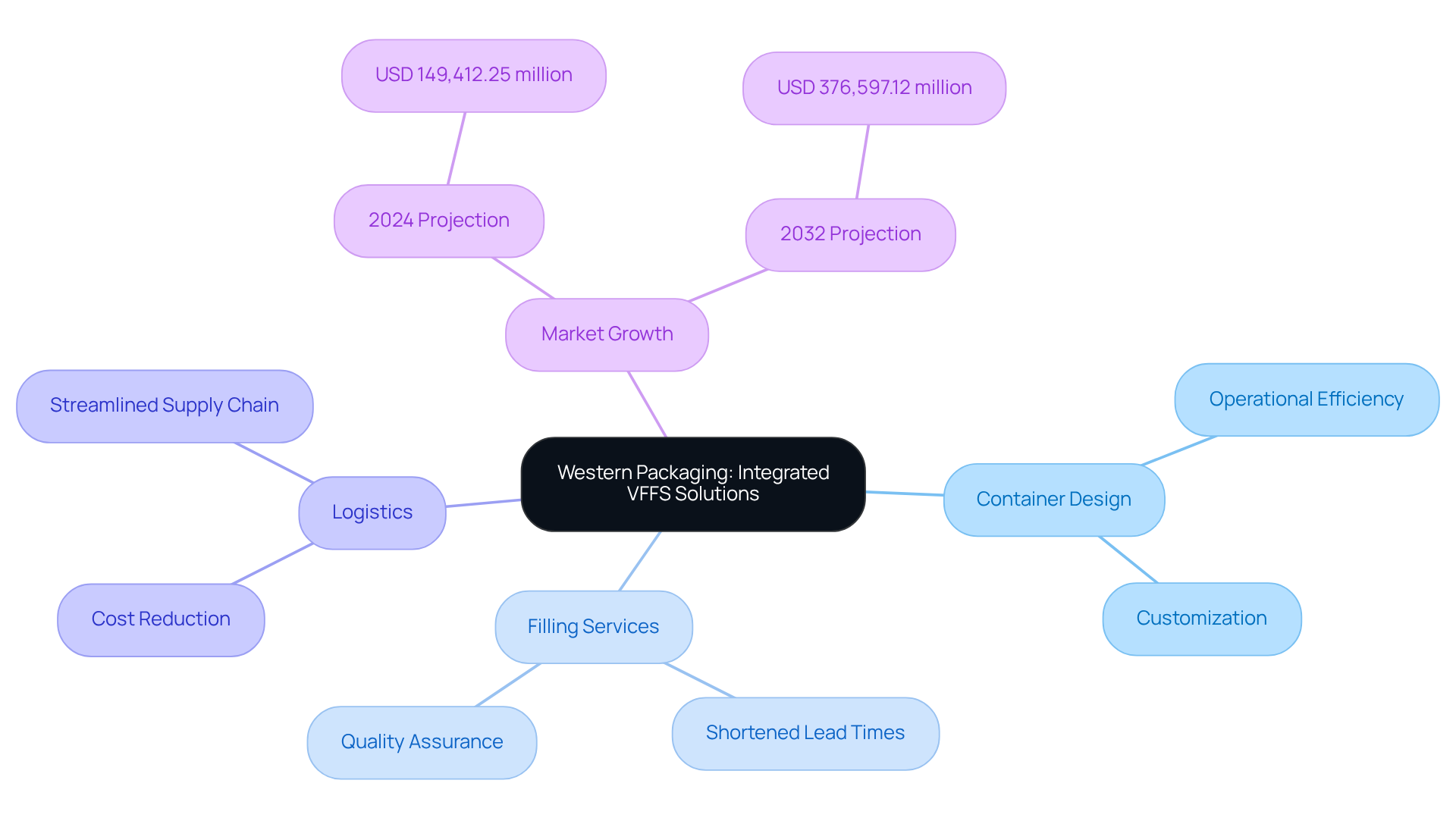

Western Packaging: Integrated VFFS Solutions for Nutraceuticals

Western Packaging specializes in delivering comprehensive vffs packaging solutions tailored for the nutraceutical sector. By seamlessly integrating container design, filling services, and logistics, the company enhances operational efficiency and simplifies the supply chain. This holistic approach allows manufacturers to concentrate on their core competencies while benefiting from customized packaging solutions that cater to their specific needs. The combination of these services not only shortens lead times but also enhances product delivery, facilitating businesses in managing the complexities of the health supplement market.

As the industry continues to grow, forecasts indicate that the health product contract manufacturing market is anticipated to increase from USD 149,412.25 million in 2024 to USD 376,597.12 million by 2032. This underscores the significance of integrated solutions. Businesses utilizing vffs packaging have reported improved productivity and decreased expenses, showcasing the effectiveness of this method in meeting the changing demands of the health supplement industry. Moreover, obtaining an accurate supplement manufacturing quote is crucial for budgeting and upholding quality standards, as emphasized by industry expert Buck Foley. A well-organized Request for Quote (RFQ) can enhance procurement processes, ensuring producers receive precise estimates tailored to their needs.

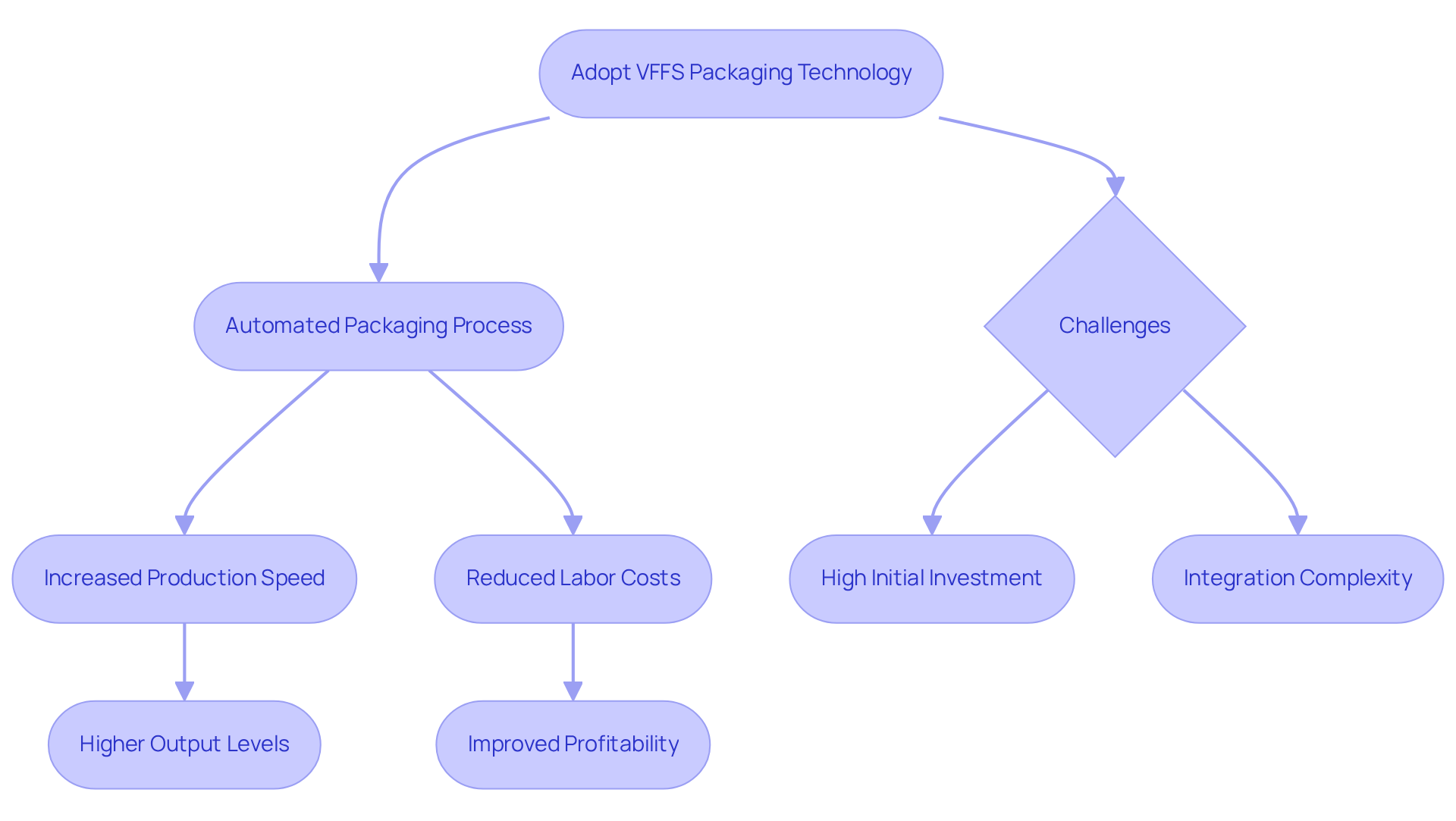

Increased Efficiency: Streamlining Production with VFFS Packaging

VFFS packaging technology is pivotal in enhancing production efficiency for nutraceutical producers by automating the packaging process. This innovative approach facilitates rapid filling and sealing, significantly reducing reliance on manual labor and minimizing potential errors. Consequently, producers can achieve higher output levels, which is essential for meeting growing market demands and maintaining competitive pricing.

For instance, organizations that have adopted VFFS packaging technology report substantial improvements in their operational workflows. A notable example is a nutraceutical producer that integrated VFFS packaging systems, which resulted in a 30% increase in production speed while simultaneously reducing labor costs by 25%. This transition not only optimized their wrapping processes but also allowed for more efficient resource distribution across their operations.

Moreover, the automation of wrapping processes through VFFS packaging technology aligns with the broader trend in the automation market for containers, which is projected to reach USD 77.67 billion by 2025, with a CAGR of 6.9%. This growth is fueled by the increasing demand for efficient and reliable containment solutions across various sectors, including nutraceuticals.

Manufacturers are increasingly acknowledging the value of automation in boosting productivity. As Vishnu Nair, Head of Business Development, remarked, 'Automating our wrapping processes has not only enhanced our output but has also enabled us to focus on innovation and product development.' This perspective resonates with a growing consensus among nutraceutical producers that embracing VFFS packaging automation is vital for staying competitive in a rapidly evolving market.

However, it is crucial to recognize that implementing automated packaging systems can present challenges, such as high initial capital investments and the complexity of integrating new technologies into existing workflows. Addressing these challenges is essential for producers seeking to improve their operations.

In conclusion, VFFS packaging technology not only streamlines production but also empowers health product producers to enhance their operational efficiency, ultimately leading to improved market presence and increased profitability.

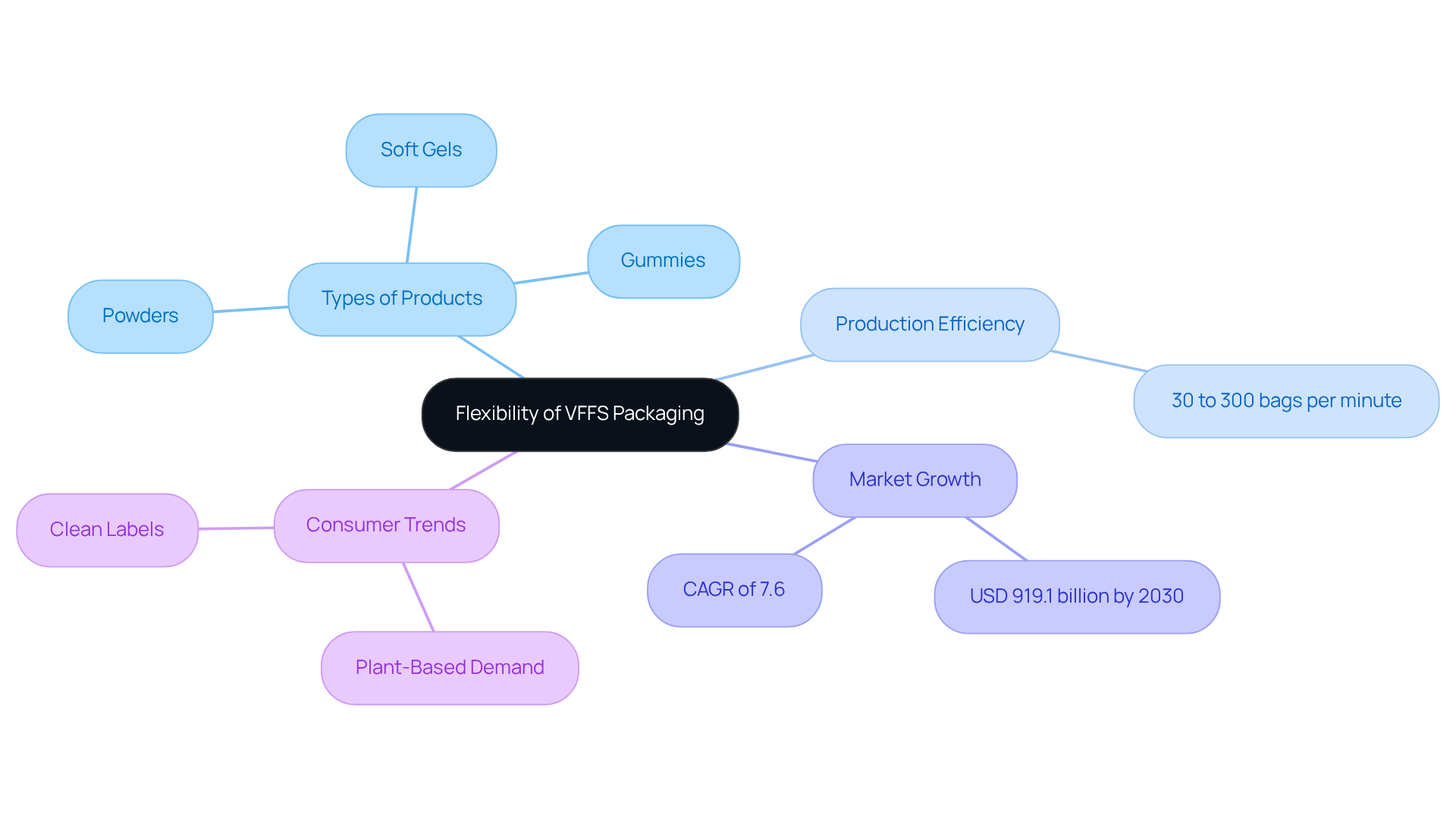

Flexibility: Adapting VFFS Packaging to Diverse Nutraceutical Products

VFFS packaging is renowned for its exceptional versatility, adeptly managing a diverse array of dietary supplement products, including powders, gummies, and soft gels. This adaptability empowers producers to transition seamlessly between various product lines, allowing them to respond swiftly to evolving consumer preferences and market dynamics.

For instance, the capability to fill between 30 and 300 bags per minute markedly reduces downtime and labor costs, ensuring production lines operate efficiently and responsively. As the nutraceutical market continues to expand, projected to reach USD 919.1 billion by 2030 with a compound annual growth rate (CAGR) of 7.6% from 2025 to 2030, producers are increasingly recognizing the importance of VFFS packaging for flexible wrapping solutions.

This capability not only enhances operational efficiency but also positions companies to seize emerging trends, such as the growing demand for plant-based and clean-label products. As highlighted by Grand View Research, consumers are scrutinizing ingredient lists and seeking clean labels, underscoring the necessity for flexible container solutions.

By leveraging flexible packaging technology, producers can effectively meet the demands of a changing market while maintaining high standards of quality and safety.

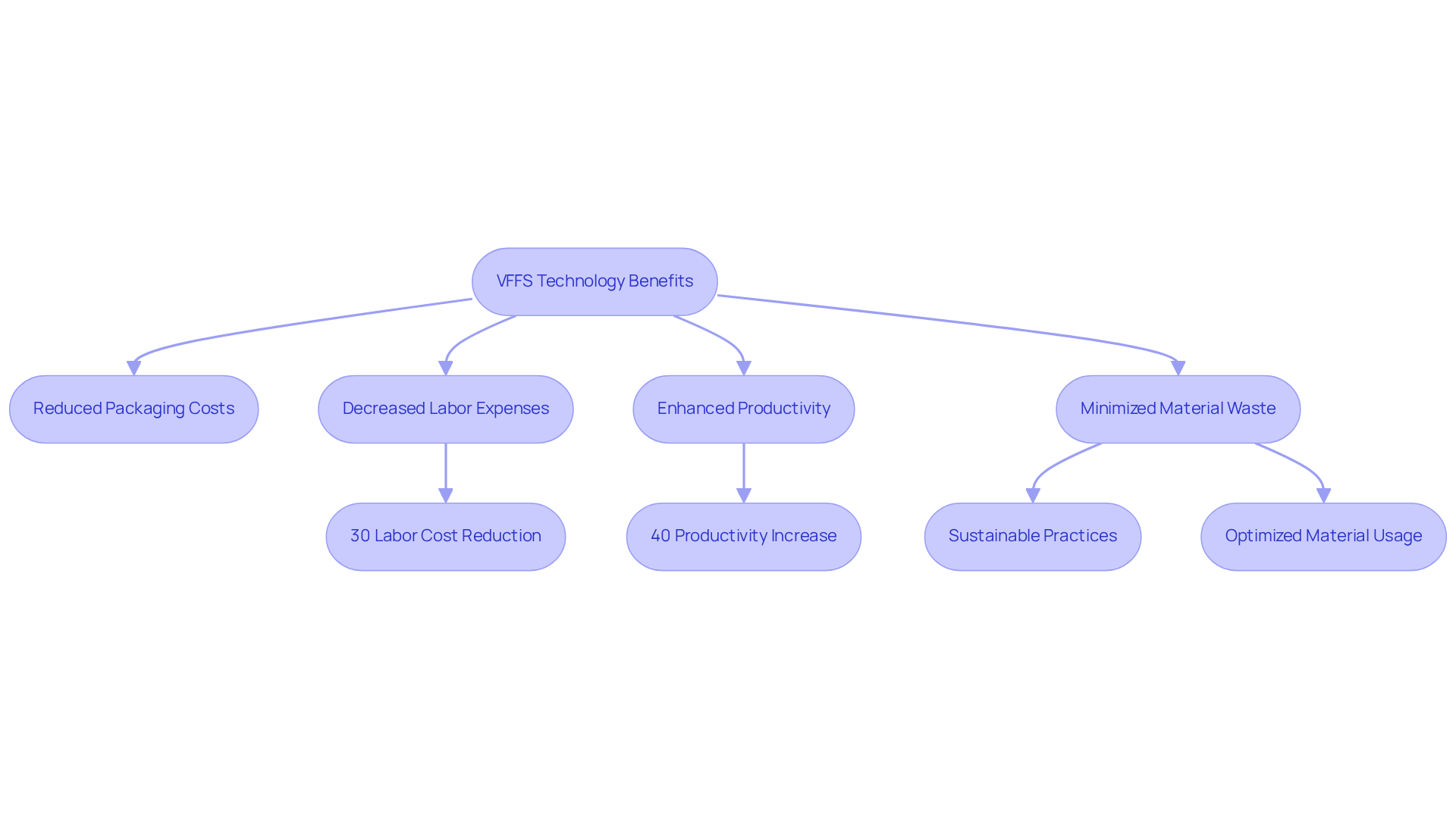

Cost-Effectiveness: Reducing Packaging Expenses with VFFS

This type of packaging stands out for its affordability, enabling producers to significantly reduce packaging costs. By automating processes, this technology can decrease labor expenses by up to 30%, allowing firms to allocate resources more effectively. Moreover, automation can enhance productivity by 40%, directly contributing to improved profitability. The high-speed operation of vertical form-fill-seal systems accelerates production rates, enabling producers to generate more units in less time.

In addition to labor savings, this technology excels in minimizing material waste. These machines are engineered to optimize material usage, ensuring minimal film wastage during changeovers. This efficiency not only reduces costs but also supports sustainable practices by promoting the use of recyclable and biodegradable films.

For instance, producers in the dietary supplement sector have successfully integrated vffs packaging systems to refine their packaging processes, resulting in substantial cost savings. These machines can adapt to various bag sizes and designs, further enhancing operational efficiency and flexibility. Overall, the adoption of vffs packaging technology represents a strategic investment for health supplement producers who aim to boost their profit margins while maintaining high product quality standards.

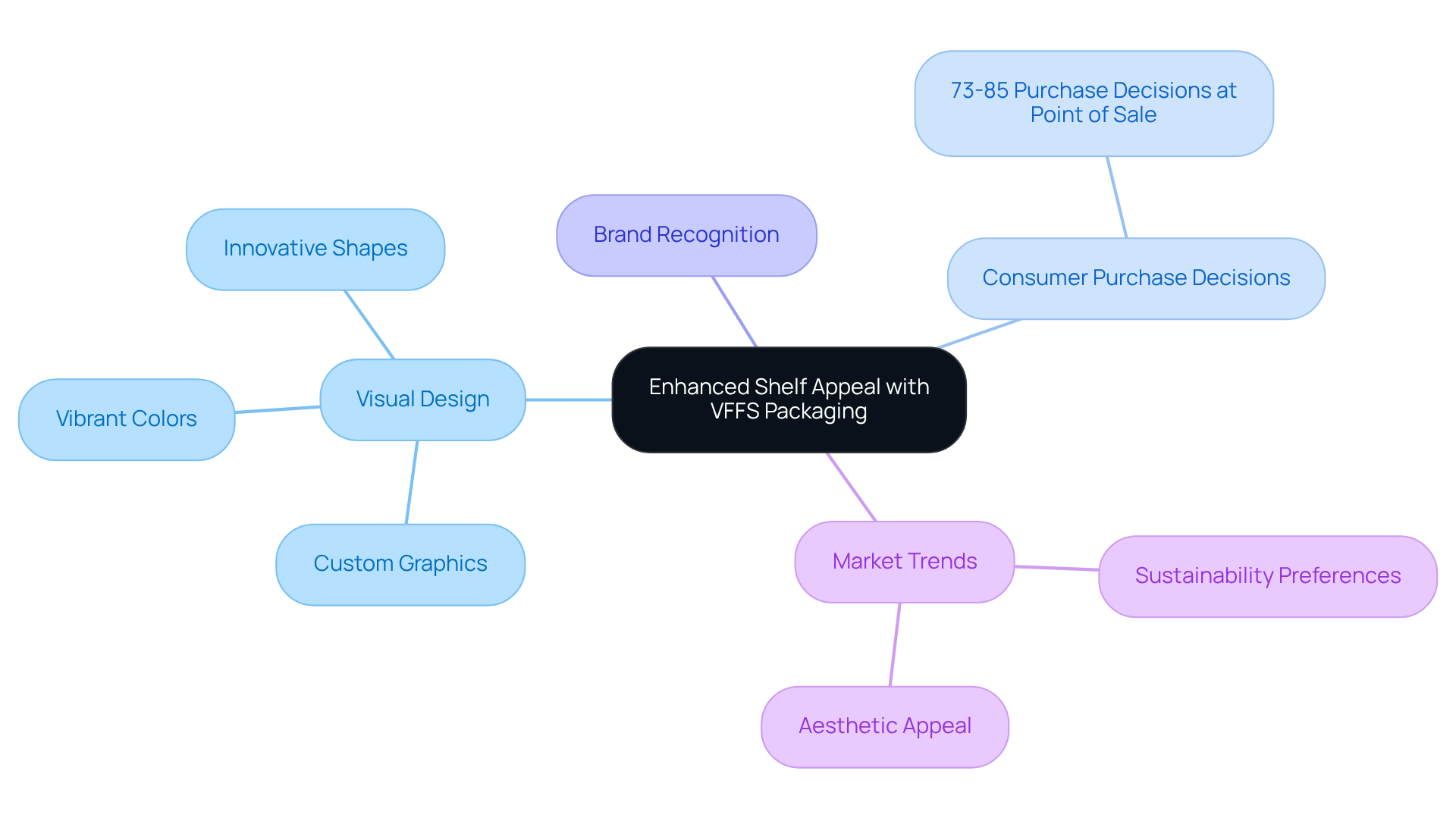

Enhanced Shelf Appeal: Boosting Brand Recognition with VFFS Packaging

Vertical Form Fill Seal solutions present a unique opportunity for supplement producers to create visually striking designs that significantly enhance shelf appeal. By leveraging custom graphics, vibrant colors, and innovative shapes, products can distinctly differentiate themselves in a competitive marketplace.

Research reveals that between 73% to 85% of consumer purchase decisions occur at the point of sale, highlighting the essential role of visual presentation in capturing attention. This increased visibility not only attracts consumers but also strengthens brand recognition, facilitating easier identification and selection of products.

As brands progressively adopt vffs packaging methods, they satisfy consumer preferences for aesthetic appeal while aligning with trends that prioritize sustainability and practicality. Noteworthy examples include leading health supplement brands that employ vffs packaging to create eye-catching container solutions, further solidifying their market presence and fostering customer loyalty.

Additionally, experts emphasize that impactful container design is crucial for enhancing brand perception and driving purchase intentions, making vffs packaging an indispensable strategy for producers aiming to thrive in the nutraceutical industry.

Sustainability: Eco-Friendly Practices in VFFS Packaging

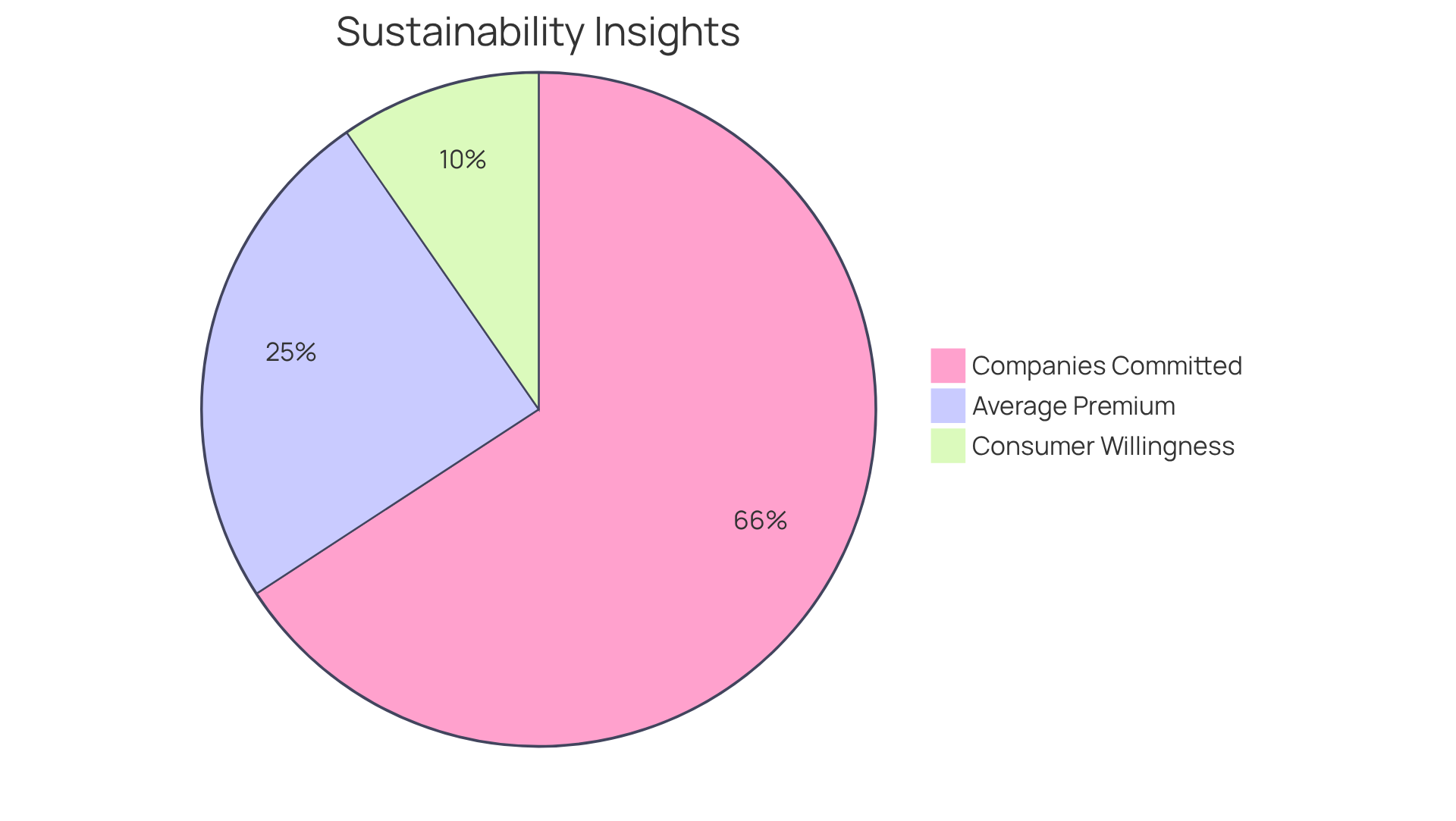

VFFS packaging solutions increasingly emphasize sustainability, enabling producers to choose biodegradable or recyclable materials that significantly reduce their environmental impact. By adopting eco-friendly practices, companies not only meet the growing demand from environmentally conscious consumers but also play a crucial role in promoting a sustainable future.

Numerous producers are currently utilizing post-consumer recycled (PCR) content in their containers, diverting waste from landfills and lessening reliance on virgin materials. This transition aligns with consumer preferences; studies indicate that U.S. consumers are willing to pay an 11% premium for eco-friendly products, with the actual premium averaging 28%.

Furthermore, brands that implement innovative, sustainable container solutions can enhance their market appeal and differentiate themselves from competitors. As highlighted by industry specialists, approximately 75 percent of organizations have made explicit sustainable commitments, demonstrating that the shift to eco-friendly solutions is not merely a trend but a strategic necessity for brands aiming to meet consumer expectations and align with global sustainability objectives.

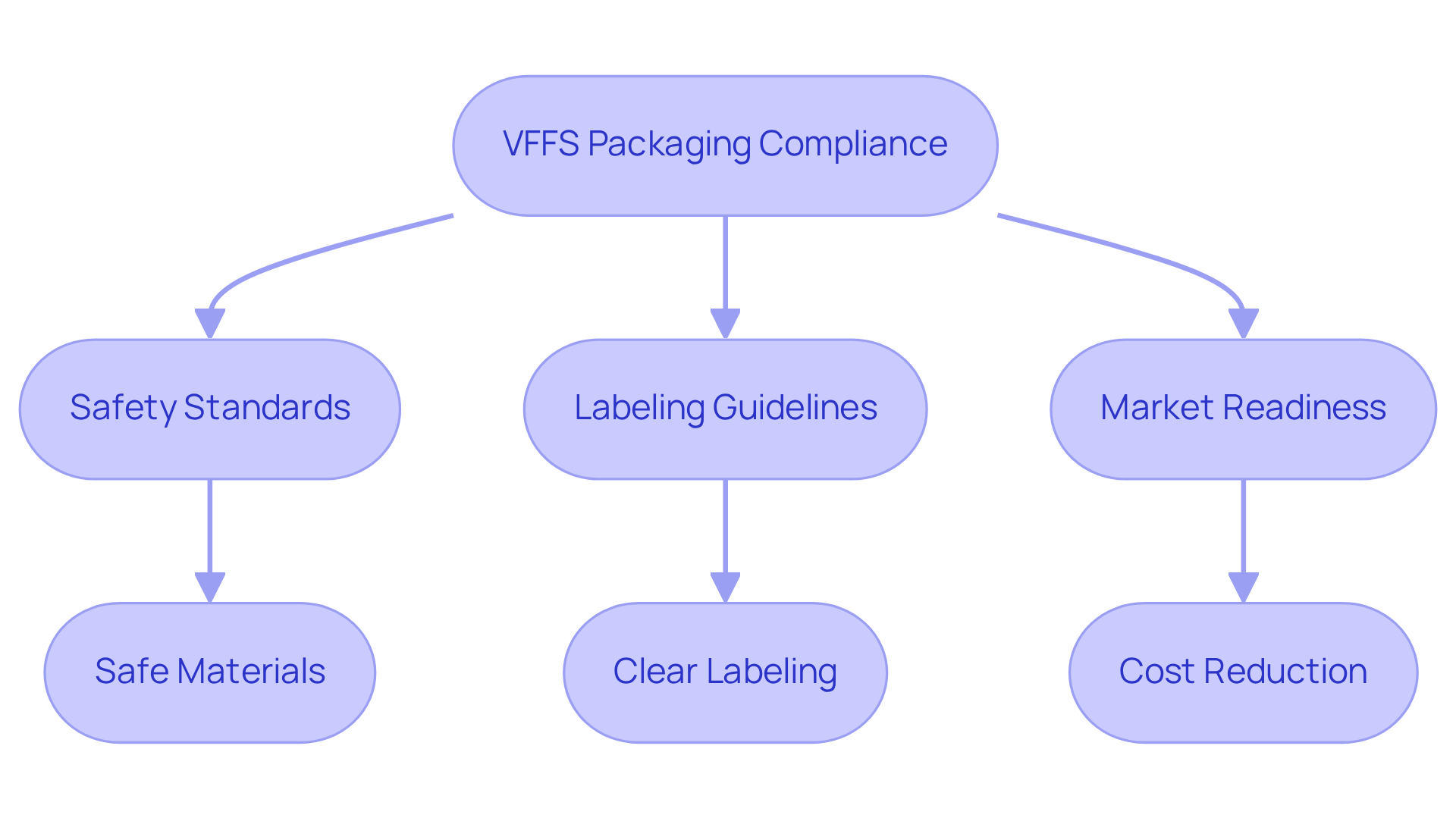

Regulatory Compliance: Meeting Standards with VFFS Packaging

Vertical Form Fill Seal (VFFS) systems are meticulously designed to meet the stringent regulatory standards of the nutraceutical sector. These systems ensure that container materials are safe for food contact, adhering to safety standards that protect consumer health. Compliance with labeling guidelines is equally critical, as accurate and clear labeling fosters consumer trust and ensures regulatory adherence. By adopting compliant VFFS packaging solutions, manufacturers can significantly reduce the risk of costly fines and prepare their products for market entry.

For instance, companies like Amcor and Berry Global have successfully integrated VFFS packaging technology to meet industry standards, thereby enhancing both safety and efficiency in their operations. Amcor, which commands a substantial market share, has concentrated on innovations in PET and HDPE container designs to guarantee compliance with safety regulations. This approach not only streamlines production but also underscores the importance of maintaining high-quality containers that align with evolving consumer expectations. As Ismail Sutaria, a Principal Consultant, remarked, "The market is driven by a growing global emphasis on health and wellness, with consumers increasingly seeking dietary supplements, functional foods, and fortified beverages to address health concerns."

As the nutraceutical market continues to grow, projected to reach approximately USD 5.30 billion by 2025 due to increasing health awareness and demand for dietary supplements, the significance of compliant container solutions becomes even more paramount in ensuring product integrity and consumer safety.

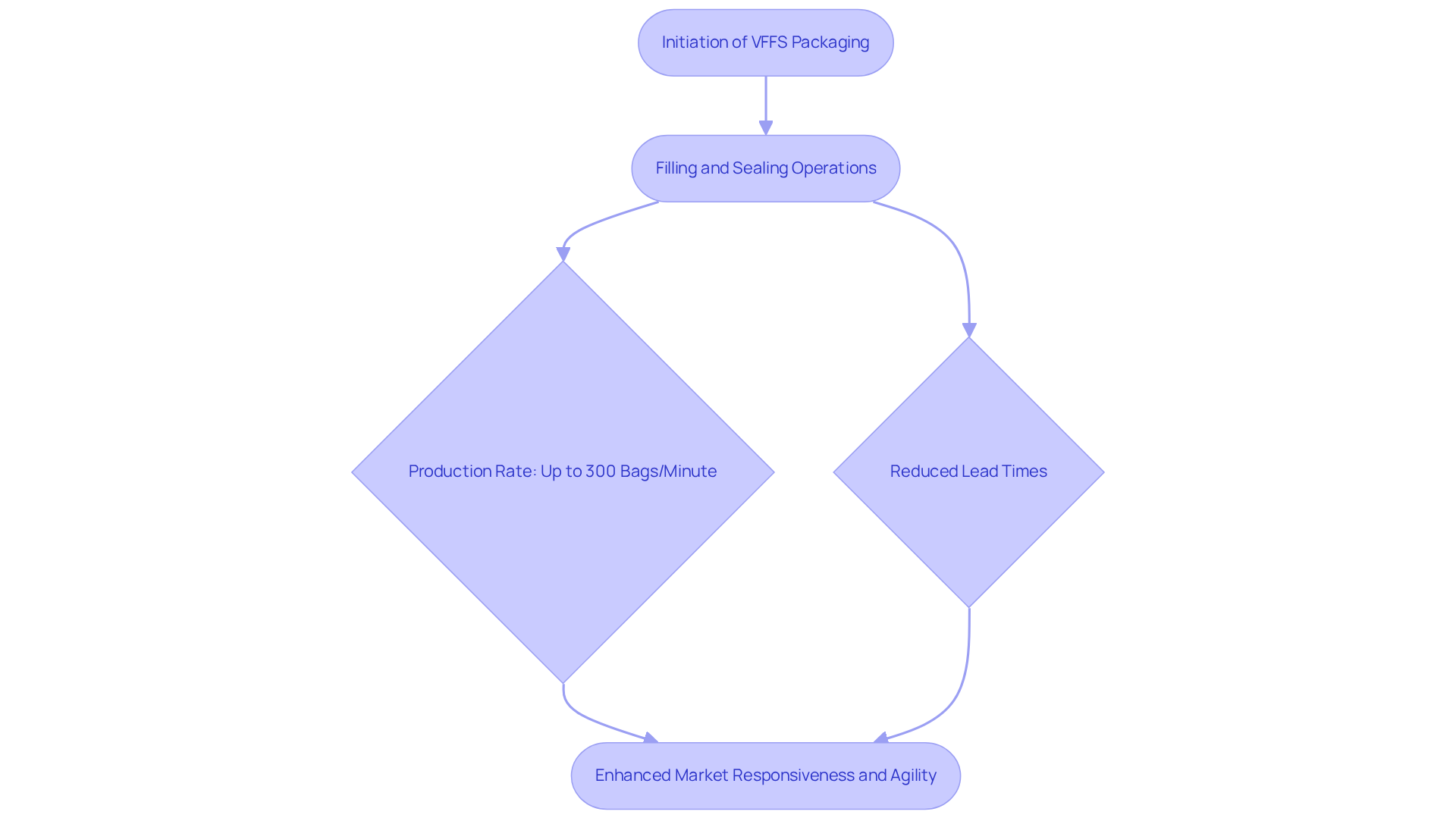

Speed: Accelerating Production with VFFS Packaging

Vffs packaging systems are engineered for rapid production cycles, empowering producers to enhance their filling and sealing operations. This automation dramatically reduces packaging time, enabling companies to respond swiftly to consumer demand and introduce new products with remarkable agility.

For instance, producers utilizing vffs packaging technology can achieve production rates of up to 300 bags per minute, as highlighted by Syntegon, a critical factor in the fast-evolving health supplement market. Statistics reveal that companies embracing these systems have experienced a significant reduction in lead times, bolstering their competitive advantage.

As one producer articulated, 'The incorporation of vffs packaging technology has revolutionized our production abilities, allowing us to launch products to market more quickly than ever before.' This efficiency not only addresses current consumer needs but also positions businesses for future growth in an increasingly dynamic industry.

Furthermore, these machines are versatile, capable of using vffs packaging to wrap a wide variety of products, further underscoring their importance in the nutraceutical sector.

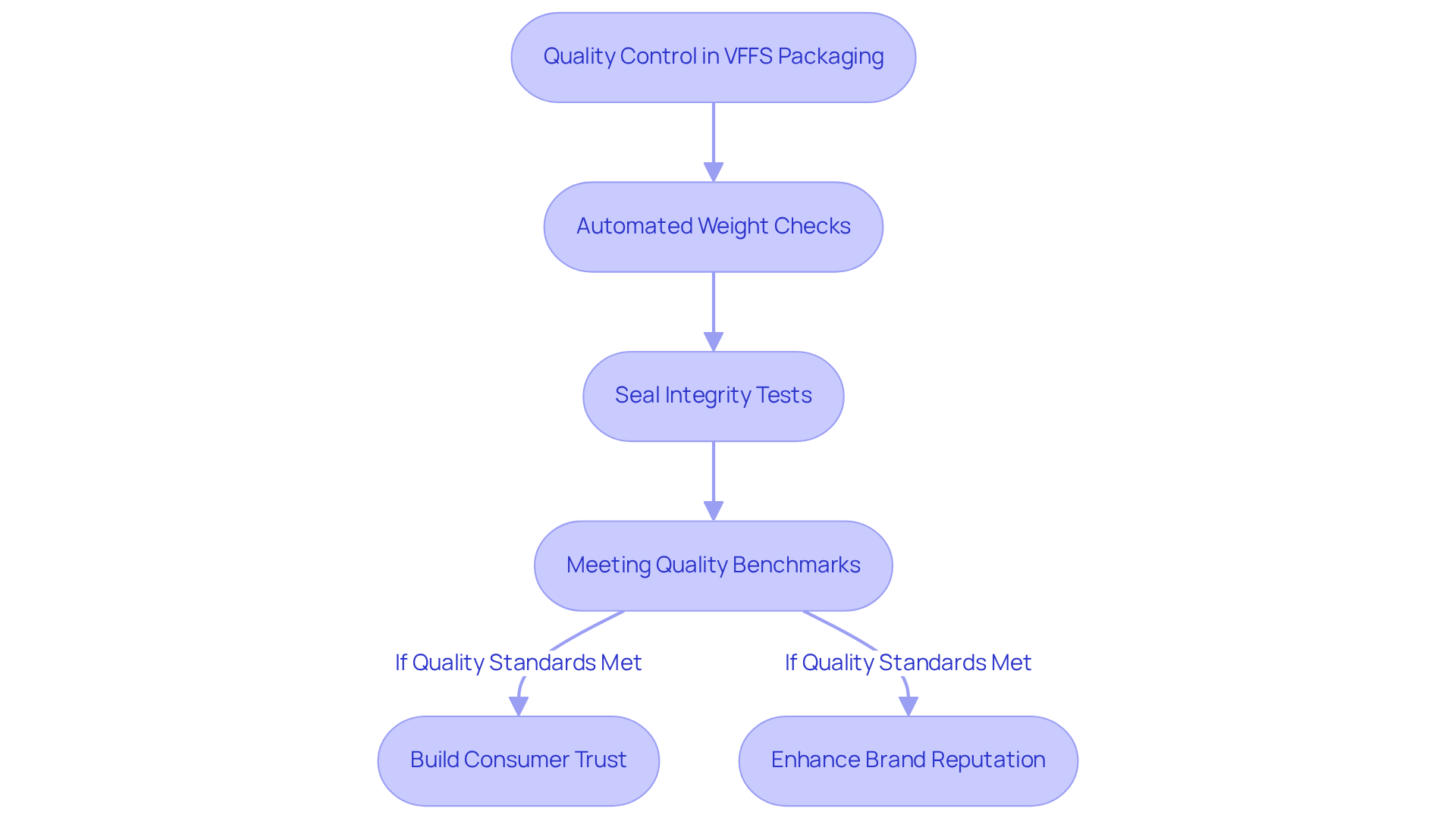

Quality Control: Ensuring Product Integrity with VFFS Packaging

Vertical Form Fill Seal systems exemplify sophisticated quality assurance practices that ensure product integrity. With features such as automated weight checks and seal integrity tests, producers can uphold high standards in packaging. By guaranteeing that each package meets stringent quality benchmarks, companies not only build consumer trust but also enhance their brand reputation. This commitment to quality is essential for businesses aiming to lead in the competitive VFFS packaging and logistics industry.

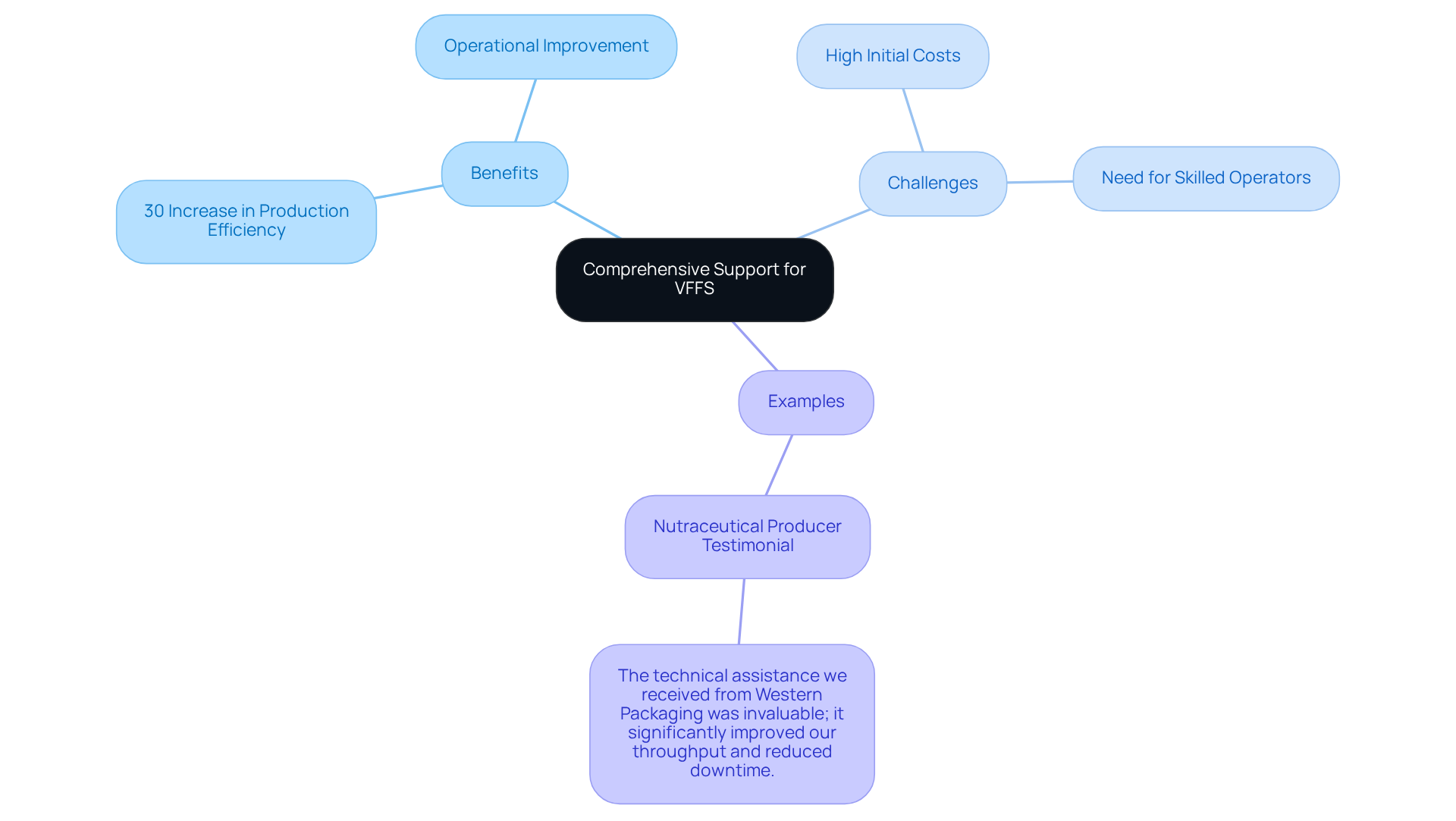

Comprehensive Support: Maximizing VFFS Packaging Efficiency with Western Packaging

Western Packaging offers comprehensive support for producers utilizing VFFS systems, ensuring the optimization of this technology's advantages. From initial design consultations to ongoing technical assistance, their expert team empowers clients to enhance packaging efficiency and effectively address operational challenges.

Industry research indicates that producers receiving technical assistance can achieve up to a 30% increase in production efficiency. For instance, a nutraceutical producer noted, "The technical assistance we received from Western Packaging was invaluable; it significantly improved our throughput and reduced downtime."

By facilitating the seamless integration of vertical form fill seal systems, Western Packaging not only enhances operations but also empowers producers to thrive in a competitive market. However, it is crucial to recognize that some manufacturers may encounter challenges, such as:

- High initial costs

- The necessity for skilled operators when implementing VFFS technology.

Conclusion

The advantages of Vertical Form Fill Seal (VFFS) packaging for nutraceutical manufacturers are substantial, offering a transformative approach to production and market engagement. This technology streamlines operations while enhancing flexibility, cost-effectiveness, and sustainability, making it an essential tool for businesses aiming to thrive in a competitive landscape.

Key benefits of VFFS packaging include:

- Increased efficiency through automation

- Adaptability to diverse product types

- Significant cost reductions

- Enhanced shelf appeal that drives consumer engagement

Furthermore, the focus on sustainability and regulatory compliance illustrates how VFFS solutions align with modern consumer expectations and industry standards. Collectively, these factors position VFFS packaging as a strategic investment for nutraceutical producers.

In a rapidly evolving market, embracing VFFS packaging technology is not merely an operational upgrade; it is a vital step toward long-term success. By leveraging the benefits of this innovative packaging solution, nutraceutical manufacturers can enhance their production capabilities, meet consumer demands more effectively, and strengthen their market presence. The future of the nutraceutical industry shines bright for those who harness the power of VFFS packaging to optimize their processes and product offerings.

Frequently Asked Questions

What is Western Packaging's specialization in the nutraceutical sector?

Western Packaging specializes in delivering integrated VFFS (Vertical Form Fill Seal) packaging solutions tailored for the nutraceutical sector, enhancing operational efficiency and simplifying the supply chain.

How does Western Packaging's approach benefit manufacturers?

Their holistic approach allows manufacturers to focus on their core competencies while benefiting from customized packaging solutions that cater to their specific needs, ultimately shortening lead times and enhancing product delivery.

What is the projected growth of the health product contract manufacturing market?

The health product contract manufacturing market is anticipated to grow from USD 149,412.25 million in 2024 to USD 376,597.12 million by 2032.

What advantages do businesses experience by utilizing VFFS packaging?

Businesses utilizing VFFS packaging report improved productivity and decreased expenses, demonstrating its effectiveness in meeting the changing demands of the health supplement industry.

Why is obtaining an accurate supplement manufacturing quote important?

An accurate supplement manufacturing quote is crucial for budgeting and maintaining quality standards, and a well-organized Request for Quote (RFQ) can enhance procurement processes for precise estimates.

How does VFFS packaging technology improve production efficiency?

VFFS packaging technology automates the packaging process, facilitating rapid filling and sealing, which reduces reliance on manual labor and minimizes errors, leading to higher output levels.

Can you provide an example of improved efficiency through VFFS packaging?

A nutraceutical producer that integrated VFFS packaging systems reported a 30% increase in production speed and a 25% reduction in labor costs, optimizing their wrapping processes.

What is the projected growth of the automation market for containers?

The automation market for containers is projected to reach USD 77.67 billion by 2025, with a compound annual growth rate (CAGR) of 6.9%.

What challenges might producers face when implementing automated packaging systems?

Producers may encounter challenges such as high initial capital investments and the complexity of integrating new technologies into existing workflows.

What types of nutraceutical products can VFFS packaging accommodate?

VFFS packaging can manage a diverse array of dietary supplement products, including powders, gummies, and soft gels.

How does VFFS packaging contribute to operational flexibility?

VFFS packaging allows producers to fill between 30 and 300 bags per minute, reducing downtime and labor costs, and enabling efficient transitions between various product lines.

What market trend is influencing the demand for flexible packaging solutions?

The growing consumer demand for plant-based and clean-label products is driving the necessity for flexible container solutions in the nutraceutical market.