Overview

The article examines nine essential packaging types for nutraceutical manufacturers, underscoring their critical role in product protection, branding, and market competitiveness. It articulates how various packaging solutions, ranging from primary to custom options, not only preserve product integrity and enhance user experience but also align with sustainability trends and consumer preferences. This alignment ultimately drives brand loyalty and operational efficiency, establishing a robust foundation for success in the competitive landscape.

Introduction

The nutraceutical industry is rapidly evolving, driven by an increasing consumer demand for health and wellness products. As manufacturers strive to distinguish themselves in a crowded marketplace, the choice of packaging emerges as a critical factor in product success. This article delves into nine essential packaging types that not only enhance product protection and appeal but also align with current trends in sustainability and consumer engagement.

How can nutraceutical manufacturers leverage these packaging solutions to meet regulatory standards, captivate their audience, and ultimately drive sales?

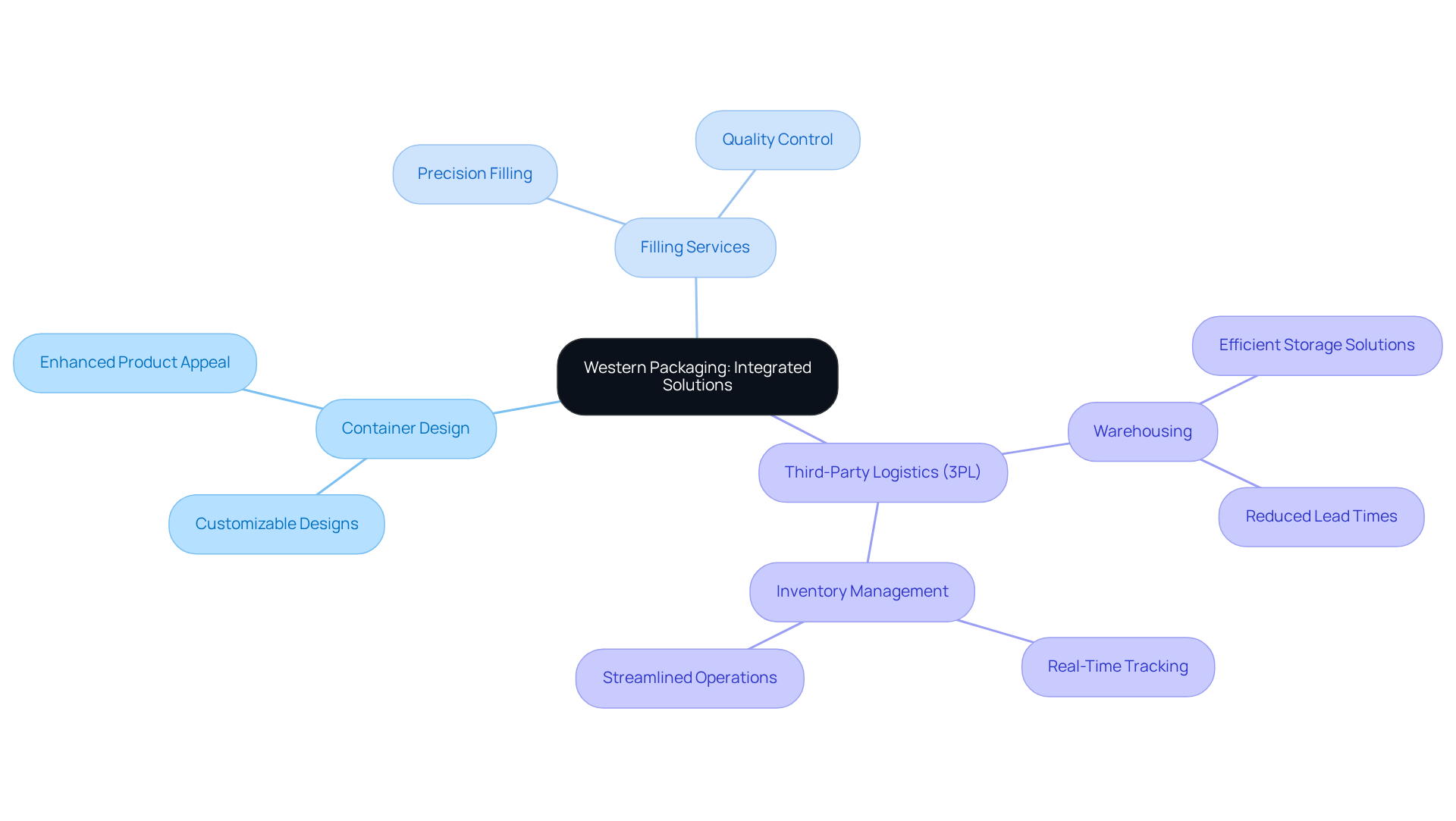

Western Packaging: Integrated Packaging Solutions for Enhanced Efficiency

Western Packaging stands as a leader in providing integrated solutions tailored specifically for nutraceutical manufacturers. By seamlessly combining container design, filling services, and comprehensive third-party logistics (3PL), which includes warehousing and inventory management, the company effectively streamlines the supply chain. This results in reduced lead times and enhanced delivery of goods. Such a cohesive strategy not only elevates product appeal but also enables manufacturers to focus on their core competencies.

Our tailored solutions are meticulously designed to address the unique needs of each client, ensuring they can navigate the complexities of the nutraceutical market with increased efficiency. By incorporating these services, companies can enhance their supply chain performance, utilizing a single point of contact for their shipping and logistics requirements. This ultimately promotes operational excellence and strengthens market competitiveness.

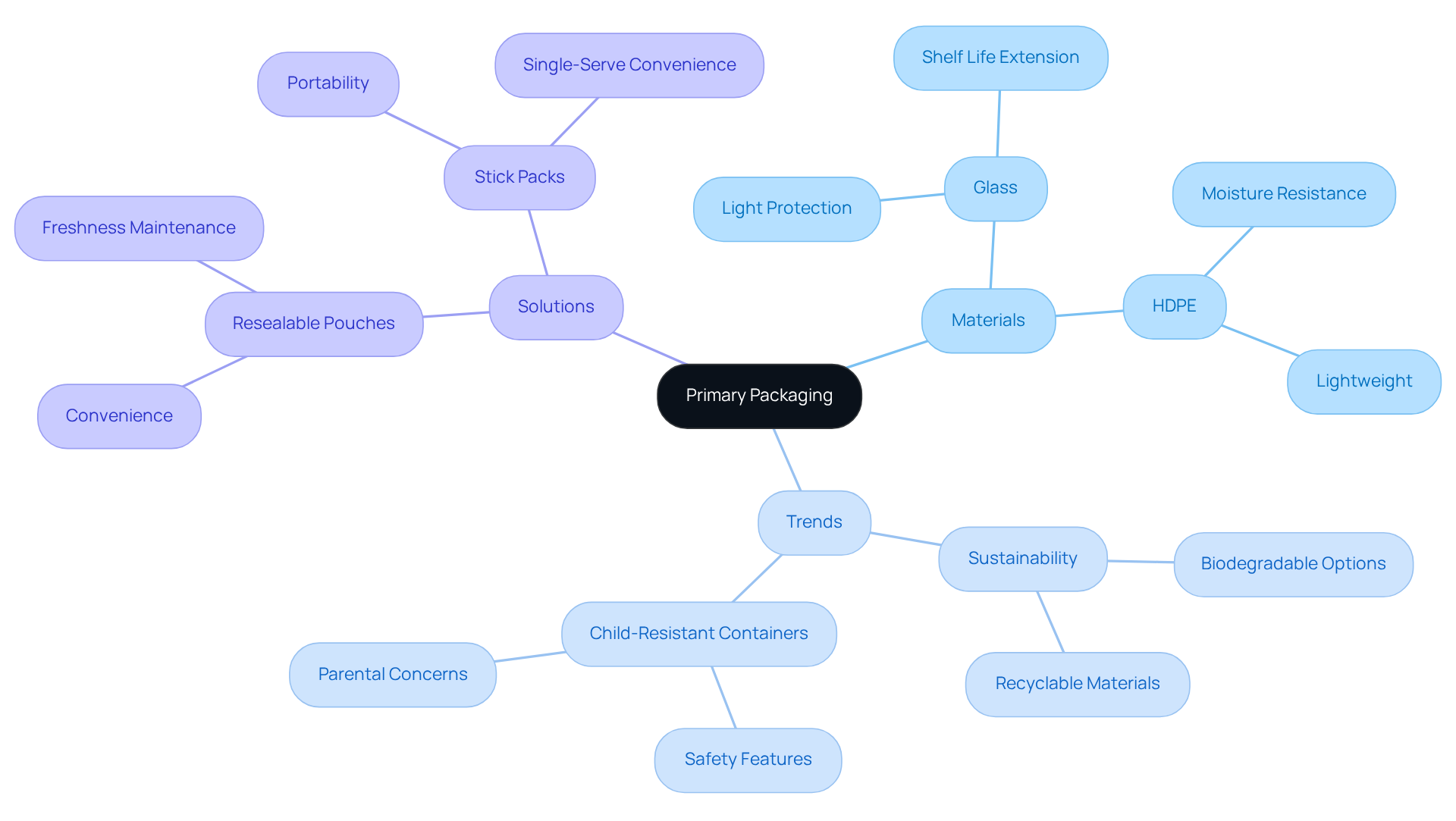

Primary Packaging: Protecting Products at First Contact

Primary containment plays a vital role for nutraceutical items, acting as the essential barrier against moisture, light, and air. Materials such as glass and high-density polyethylene (HDPE) are widely utilized due to their exceptional protective qualities. For instance, glass is particularly effective for light-sensitive products, ensuring product integrity and extending shelf life. Conversely, HDPE provides excellent moisture resistance and is lightweight, making it a practical choice for various formulations.

Recent trends reveal an increasing preference for sustainable materials, with innovations like biodegradable and recyclable options gaining momentum. Additionally, the demand for child-resistant containers is rising, driven by heightened parental concerns regarding safety. Efficient primary containers not only preserve quality but also enhance user experience by being easy to open and reseal, thereby encouraging repeat purchases. Resealable pouches and single-serve bags, for example, are becoming popular for their convenience and ability to maintain freshness.

At Western Packaging, we offer customized flexible solutions, including large pouches for protein items and stick packs for nutraceuticals, that enhance appeal and bolster brand recognition. Ultimately, the choice of packaging types for primary container materials significantly influences quality in the nutraceutical sector. By ensuring optimal protection against external factors, manufacturers can elevate the overall user experience and maintain the effectiveness of their products. Explore our innovative wrapping solutions today to enhance your brand and meet buyer needs.

Secondary Packaging: Enhancing Brand Presentation and Protection

Secondary wrapping serves as the outer layer that consolidates primary containers, effectively showcasing branding elements such as logos and product information. This packaging type is crucial not only for protecting primary containers during transport but also as a powerful marketing tool that captures shopper attention on retail shelves, highlighting the importance of various packaging types.

Effective secondary wrapping often features tamper-evident seals, which bolster consumer confidence. With 74% of U.S. adults indicating the use of dietary supplements, there exists a substantial market for products that underscore safety and integrity.

Western Packaging offers customized flexible solutions, including large pouches for protein items and stick packs for nutraceuticals, enhancing appeal while aligning with the increasing demand for eco-friendly materials, thereby fostering customer loyalty.

By strategically employing various packaging types, including secondary containers, nutraceutical manufacturers can significantly elevate their brand presentation while ensuring product protection.

Consider partnering with Western Packaging to enhance your design and meet the evolving needs of your consumers.

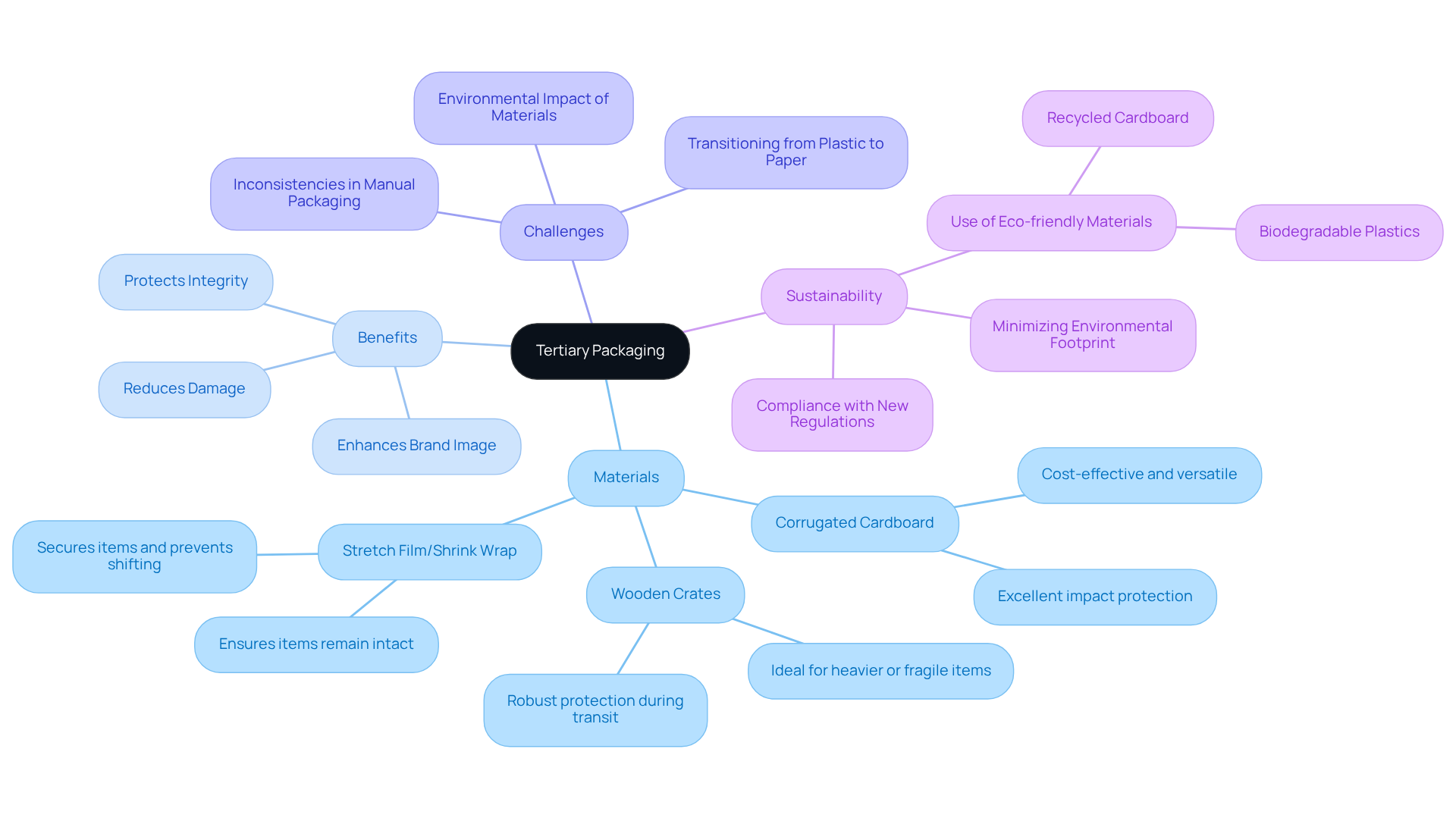

Tertiary Packaging: Ensuring Safe Transportation and Handling

Tertiary containers play a vital role in the safe transport of multiple secondary units, employing robust materials such as corrugated cardboard, wooden crates, and plastic. This layer is essential for maintaining the integrity of the item during shipping and storage. By securely grouping items, tertiary wrapping significantly lowers the risk of harm and loss, which can result in expensive returns and adversely affect customer satisfaction. Damaged products can lead to financial loss and reputational risks for companies, making high-quality tertiary containers essential. For instance, while high-quality tertiary containers can enhance a brand's image as premium, insufficient wrapping may lead to higher damage rates, ultimately harming a company's reputation.

Common materials utilized in tertiary packaging for nutraceuticals include:

- Corrugated cardboard: Cost-effective and versatile, it provides excellent impact protection.

- Wooden crates: Ideal for heavier or fragile items, offering robust protection during transit.

- Stretch film and shrink wrap: These materials secure items and prevent shifting, ensuring they remain intact throughout the shipping process.

Optimal methods in tertiary containers for nutraceutical producers involve choosing appropriate packaging types that address the particular requirements of the items, taking into account factors such as size, weight, and fragility. Custom tertiary containers can assist in fulfilling any specific requirements a company has, optimizing space, reducing shipping expenses, and improving supply chain efficiency. As the industry shifts towards sustainability, many companies are exploring eco-friendly materials, such as recycled cardboard and biodegradable plastics, to minimize their environmental impact while ensuring product safety during transit. This shift is particularly relevant due to new Plastic Packaging Tax Regulations, prompting many businesses to transition from plastic to paper materials for sustainability.

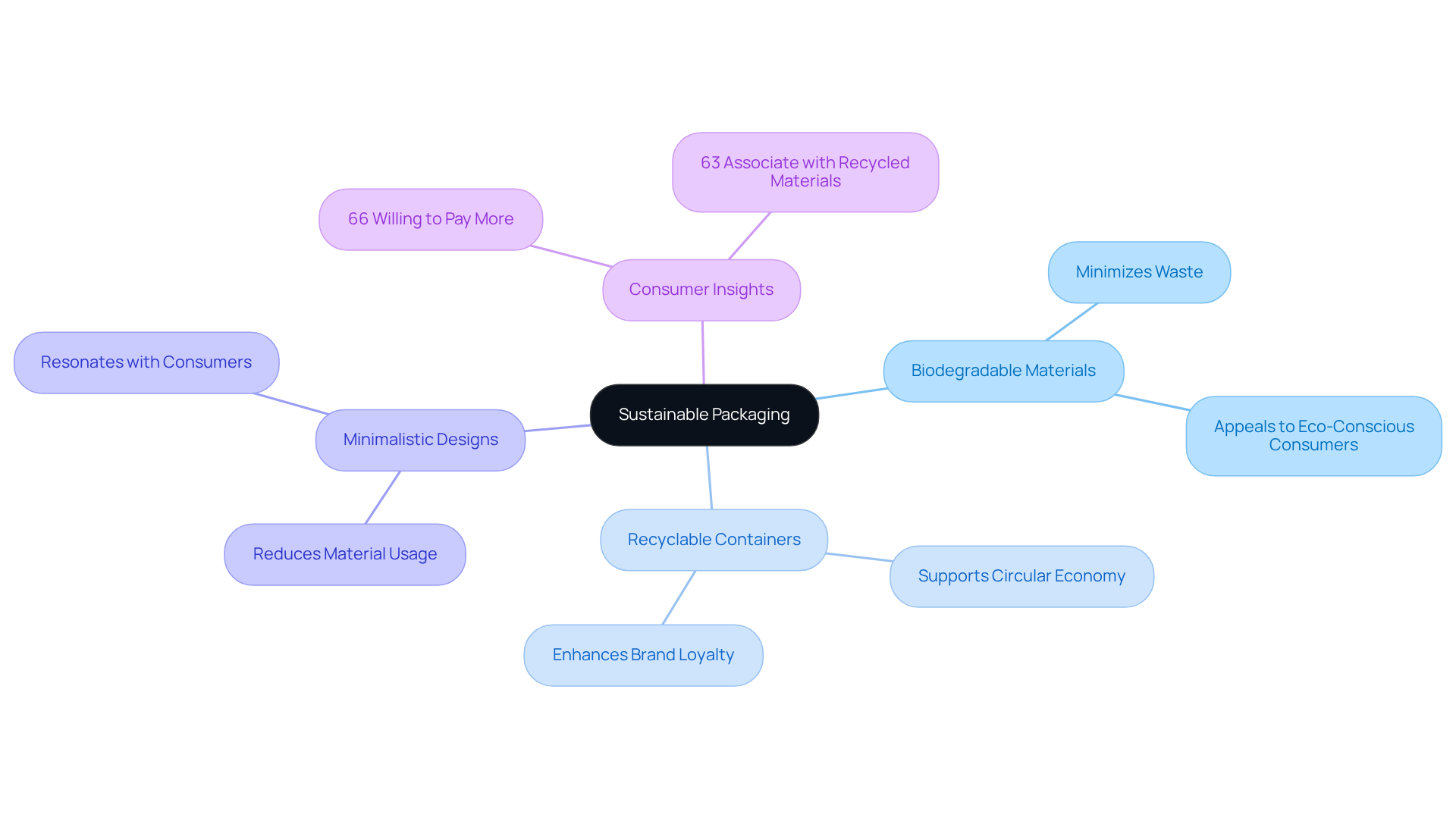

Sustainable Packaging: Meeting Environmental Standards

Sustainable solutions for containment are increasingly essential in the nutraceutical sector, as companies strive to comply with environmental regulations and meet public expectations. Packaging types such as:

- Biodegradable materials

- Recyclable containers

- Minimalistic designs

not only help minimize waste but also resonate with environmentally conscious consumers. By integrating innovative container designs and tailored flexible solutions, nutraceutical producers can enhance market appeal and brand recognition while embracing sustainable practices. Notably, statistics reveal that:

- 66% of U.S. shoppers are willing to pay more for sustainable products, indicating a strong market demand for eco-friendly containers.

- 63% of individuals associate eco-friendly containers with the use of recycled materials, underscoring the importance of adopting such practices.

Successful brands, including Zing Zang®, have transitioned to packaging types such as lightweight plastic made from 25% post-consumer recycled material, illustrating how sustainable containers can enhance brand loyalty and differentiate offerings in a competitive landscape. By adopting sustainable practices alongside innovative design solutions, nutraceutical manufacturers can significantly elevate their market presence and cultivate deeper connections with environmentally aware consumers.

Flexible Packaging: Versatile Solutions for Diverse Products

Flexible wraps emerge as a highly adaptable solution among various packaging types for a diverse array of nutraceutical items, including powders, gummies, and soft gels. This packaging type is one of the packaging types that predominantly employs advanced materials such as laminates and films, recognized for their exceptional barrier properties against moisture and oxygen. These characteristics are crucial for preserving item integrity and extending shelf life, particularly in the nutraceutical market, where stability is paramount.

Moreover, among the various packaging types, flexible wrapping facilitates significant cost reductions by minimizing material usage and optimizing transportation efficiency. As a result, manufacturers are increasingly choosing adaptable packaging types to enhance operational efficiency while meeting consumer demands for high-quality, durable products.

Western Packaging is dedicated to developing customized flexible solutions, such as large pouches for protein items and stick packs for nutraceuticals, that enhance product appeal and identity. Recent innovations in this sector have also prioritized sustainability, with numerous companies exploring eco-friendly materials that resonate with rising environmental concerns. This trend not only addresses regulatory pressures but also aligns with consumers seeking responsible product options.

Additionally, we offer a comprehensive range of graphic materials, from labels to brochures, ensuring a cohesive and captivating brand identity.

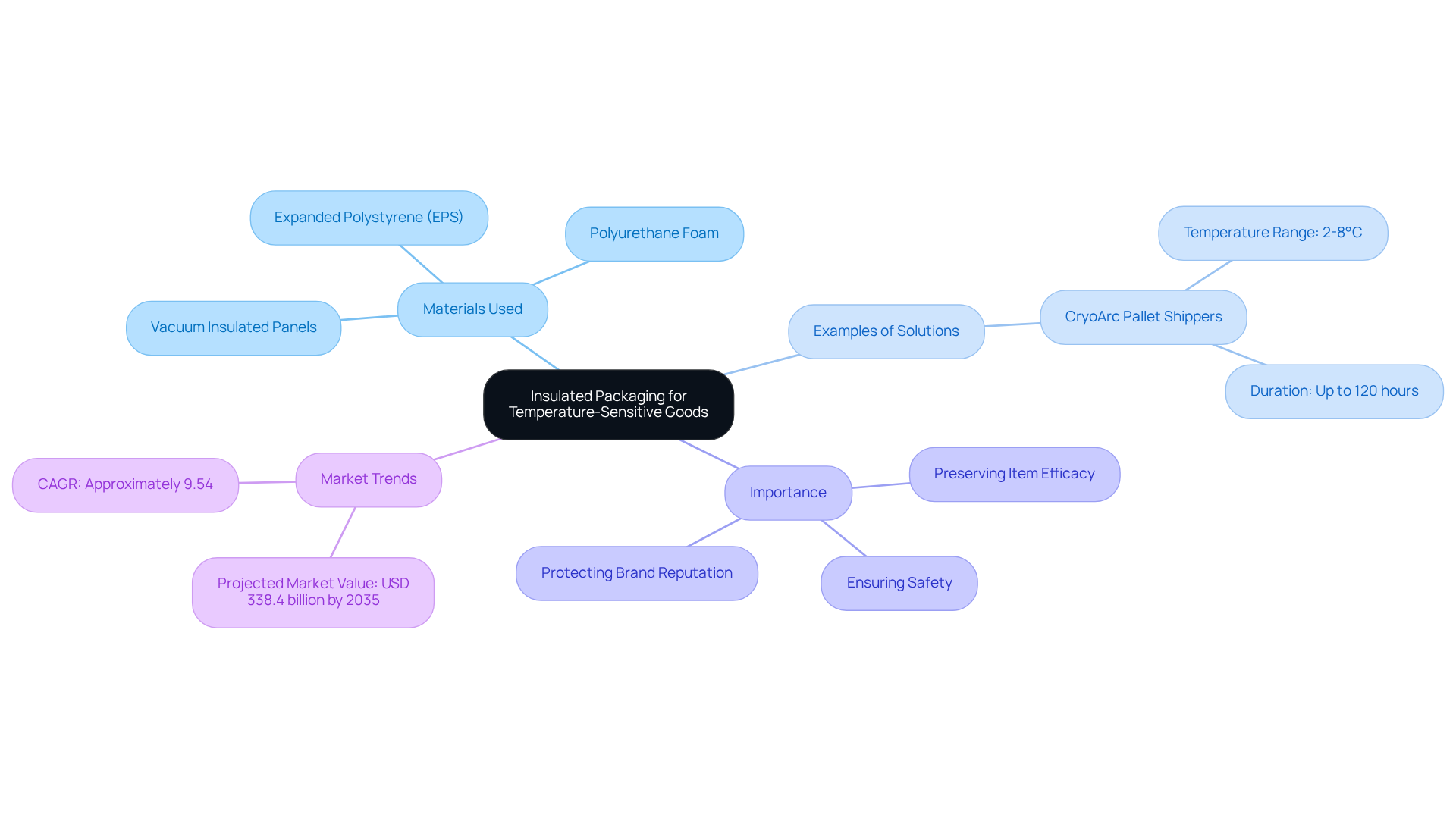

Insulated Packaging: Protecting Temperature-Sensitive Goods

Insulated shipping solutions are critical for the secure transport of temperature-sensitive nutraceutical items, such as probiotics and specific vitamins. These packages employ advanced materials, including Expanded Polystyrene (EPS), polyurethane foam, and vacuum insulated panels, to effectively maintain the necessary temperature during transit. By ensuring that items remain within designated temperature ranges, insulated containers not only preserve item efficacy and safety but also protect consumer health and uphold the brand's reputation.

For example, CryoArc pallet shippers provide reliable shipping within a temperature range of 2-8°C for up to 120 hours, showcasing the effectiveness of insulated solutions in preserving item integrity. As demand for temperature-sensitive containers continues to rise, particularly in the nutraceutical sector, the adoption of innovative materials and designs becomes essential for enhancing stability and compliance with regulatory standards.

The thermal insulation materials market is projected to reach USD 338.4 billion by 2035, with a CAGR of approximately 9.54%, underscoring the growing significance of these solutions in the industry.

Protective Packaging: Safeguarding Fragile Products

Protective wrapping plays a crucial role in safeguarding fragile nutraceutical products during transportation. Utilizing materials such as bubble wrap, foam inserts, and custom-fit boxes, these solutions effectively absorb shocks and vibrations, minimizing the risk of damage.

For instance, bubble wrap can lessen impact damage by up to 60% compared to non-cushioned materials, establishing it as a staple in effective shipping strategies. The global protective wrapping market was valued at USD 37.86 billion in 2024, underscoring the industry's significance.

By investing in high-quality protective materials, manufacturers not only reduce the likelihood of product returns but also significantly improve customer satisfaction, as consumers receive their orders in pristine condition. When protective wrapping performs well, it reassures the customer that the brand is reliable, fostering trust and loyalty, ultimately benefiting the brand's reputation in a competitive market.

Furthermore, with 20% of individuals indicating damaged delicate items as their primary moving worry, effective protective wrapping becomes even more essential. However, it is important to consider the environmental impact, as 85% of bubble wrap ends up in landfills, prompting a need for sustainable wrapping solutions.

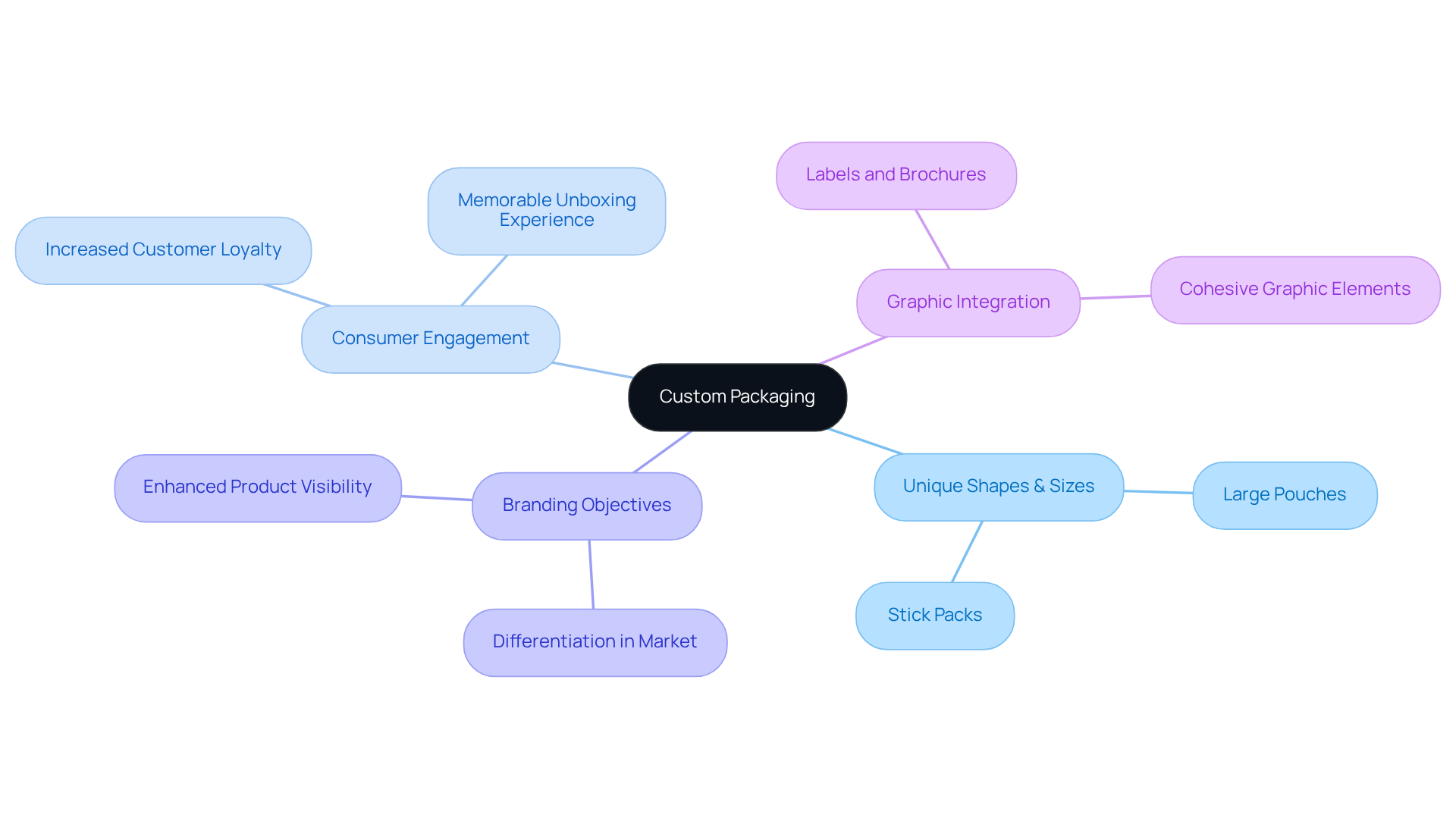

Custom Packaging: Tailoring Solutions for Unique Products

Custom packaging types empower nutraceutical manufacturers to develop packaging that meets specific requirements and branding objectives. This approach often features unique shapes, sizes, and materials, significantly enhancing product visibility and attracting customers. Research indicates that 92% of individuals consider dietary supplements vital for health, underscoring the need for differentiation in a competitive market.

By investing in personalized containers from Western Packaging, companies can create a memorable unboxing experience that resonates with consumers, fostering loyalty and encouraging repeat purchases. Our customized adaptable packaging types, such as large pouches for protein products and stick packs for nutraceuticals, not only draw attention on retail shelves but also elevate the overall perception of product quality.

Moreover, integrating graphic assets like labels and brochures can further strengthen corporate identity. Firms that adopt innovative container designs report a notable increase in customer engagement and sales, establishing it as a crucial element in the marketing strategy for nutraceuticals.

To maximize impact, consider harmonizing your packaging design with cohesive graphic elements that embody your brand's values.

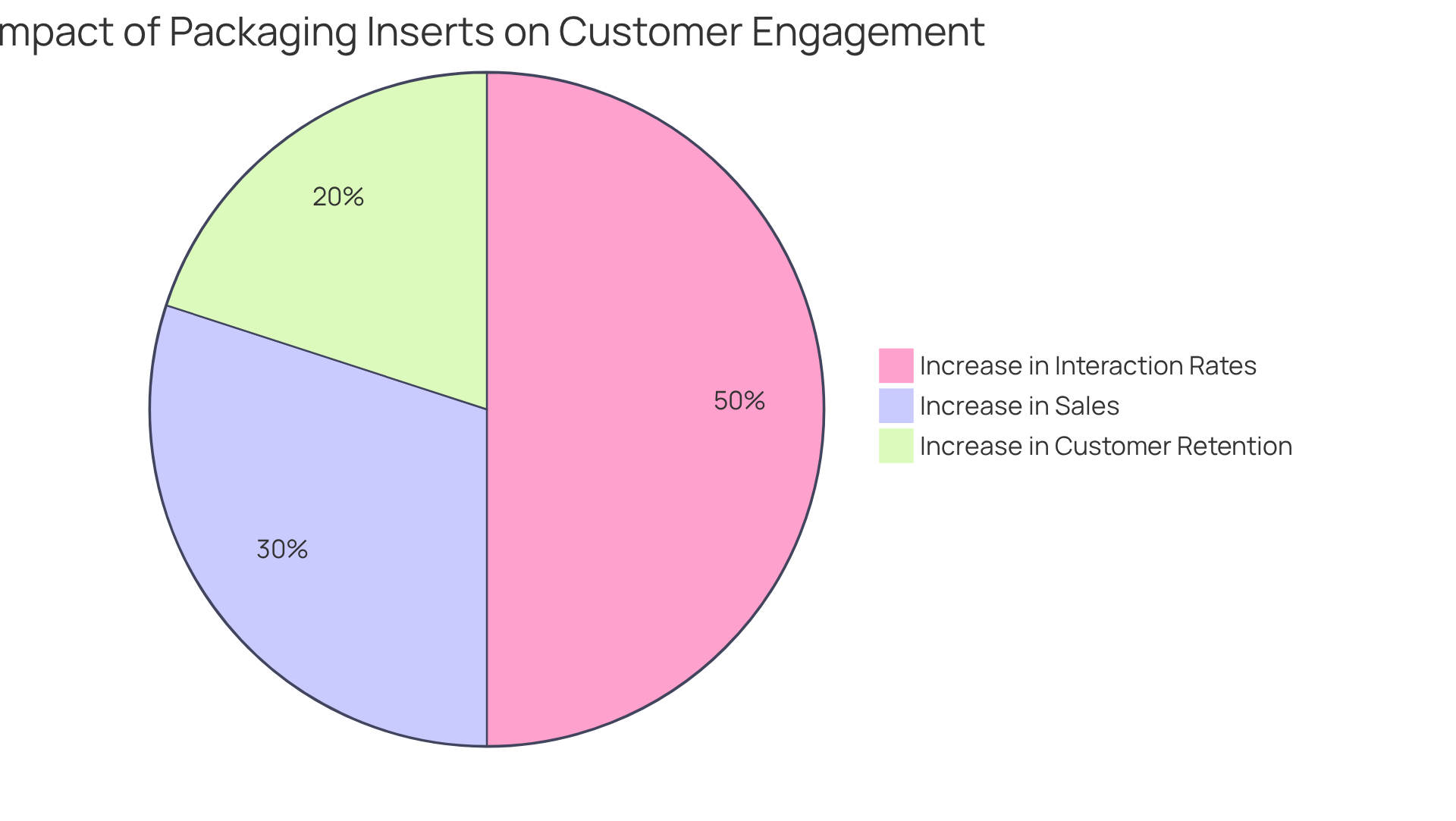

Packaging Inserts: Enhancing Customer Engagement and Information

Packaging inserts serve as a powerful resource for enhancing customer interaction and providing essential information about nutraceutical products. These inserts can encompass a variety of content, including promotional materials, detailed usage instructions, and educational resources that underscore the benefits of the product. Brands that have effectively utilized product inserts have reported significant increases in customer engagement, with some experiencing a 25% boost in interaction rates, a 15% increase in sales, and a 10% rise in customer retention from successful campaigns.

Statistics reveal that:

- 72% of American shoppers believe that the design of the container influences their buying choices, highlighting the importance of thoughtfully designed inserts.

- 63% of online buyers are swayed by presentation when making purchasing decisions, further emphasizing the impact of presentation on consumer behavior.

- 94% of consumers are more likely to remain loyal to brands that provide transparency through clear and precise labeling.

This demonstrates that well-crafted inserts not only inform but also build trust, fostering stronger connections with customers and encouraging repeat business.

For nutraceutical items, it is crucial to include specific packaging types of information in inserts. This should detail the product's health benefits, provide dosage recommendations, and feature testimonials or case studies that reinforce the product's efficacy. By aligning the content of inserts with customer preferences for transparency and education, companies can significantly enhance their market presence and loyalty.

Incorporating personalized messaging and tailored offers within these inserts can further elevate the customer experience, leading to increased sales and retention rates. Furthermore, integrating intelligent wrapping technologies, such as QR codes and NFC tags, can enhance customer interaction by offering engaging experiences. As the nutraceutical market continues to evolve, leveraging different packaging types effectively will be key to meeting consumer expectations and driving brand success.

Conclusion

The diverse packaging types explored in the nutraceutical industry are not merely functional; they are pivotal in shaping product integrity, brand identity, and consumer trust. Each packaging layer—primary, secondary, tertiary, and beyond—plays a distinct role in protecting products, enhancing market appeal, and ensuring safe transportation. By understanding and implementing the right packaging solutions, nutraceutical manufacturers can significantly boost their operational efficiency and market presence.

Throughout this article, key insights have been presented regarding the importance of tailored packaging solutions. From primary containers that safeguard product quality to secondary wraps that elevate brand visibility, each type contributes to a holistic approach that addresses both consumer needs and environmental considerations. Innovations in sustainable packaging, flexible solutions, and custom designs further demonstrate the industry's commitment to adapting to evolving market demands.

In a competitive landscape where consumer preferences are shifting towards sustainability and transparency, embracing effective packaging strategies is essential. Companies are encouraged to invest in innovative packaging solutions that not only meet regulatory standards but also resonate with environmentally conscious consumers. By prioritizing quality and creativity in packaging, nutraceutical manufacturers can enhance customer engagement, foster loyalty, and ultimately drive sales in an ever-evolving market.

Frequently Asked Questions

What integrated solutions does Western Packaging provide for nutraceutical manufacturers?

Western Packaging offers integrated solutions that include container design, filling services, and comprehensive third-party logistics (3PL), such as warehousing and inventory management, to streamline the supply chain for nutraceutical manufacturers.

How do Western Packaging's solutions benefit nutraceutical manufacturers?

Their solutions reduce lead times, enhance delivery of goods, elevate product appeal, and allow manufacturers to focus on their core competencies, ultimately promoting operational excellence and strengthening market competitiveness.

What role does primary packaging play in the nutraceutical industry?

Primary packaging acts as a barrier against moisture, light, and air, preserving product integrity and extending shelf life. Materials like glass and high-density polyethylene (HDPE) are commonly used for their protective qualities.

What trends are emerging in primary packaging for nutraceuticals?

There is an increasing preference for sustainable materials, such as biodegradable and recyclable options. Additionally, the demand for child-resistant containers is rising due to safety concerns among parents.

What are some examples of effective primary container types offered by Western Packaging?

Western Packaging provides customized flexible solutions like large pouches for protein items and stick packs for nutraceuticals, which enhance appeal and bolster brand recognition.

What is the function of secondary packaging in the nutraceutical sector?

Secondary packaging serves as the outer layer that consolidates primary containers, protecting them during transport while also showcasing branding elements and product information to attract shoppers.

How does secondary packaging enhance consumer confidence?

Effective secondary wrapping often includes tamper-evident seals, which help to bolster consumer confidence in the safety and integrity of the products.

What are the advantages of partnering with Western Packaging for nutraceutical manufacturers?

By partnering with Western Packaging, nutraceutical manufacturers can enhance their design and packaging strategies, meet evolving consumer needs, and improve brand presentation while ensuring product protection.