Overview

The optimal brand packaging practices for nutraceutical manufacturers hinge on a profound understanding of consumer preferences. By leveraging innovative materials, incorporating essential branding elements, and highlighting key benefits, manufacturers can significantly enhance their market presence.

Furthermore, ensuring regulatory compliance is paramount. These strategies not only elevate product appeal but also resonate with consumer demands for sustainability and transparency. As a result, manufacturers can foster increased customer loyalty and satisfaction, establishing a strong foothold in a competitive landscape.

Introduction

In the competitive realm of nutraceuticals, the importance of effective packaging is paramount. As consumers increasingly gravitate towards products that align with their values—be it sustainability, convenience, or brand identity—manufacturers encounter the pressing challenge of differentiating themselves on crowded shelves.

This article explores best practices in brand packaging that not only captivate consumers but also articulate the unique value of nutraceutical offerings. How can manufacturers harness innovative design, strategic filling services, and compliance measures to bolster their market presence and operational efficiency?

Implement Creative and Precise Packaging Design

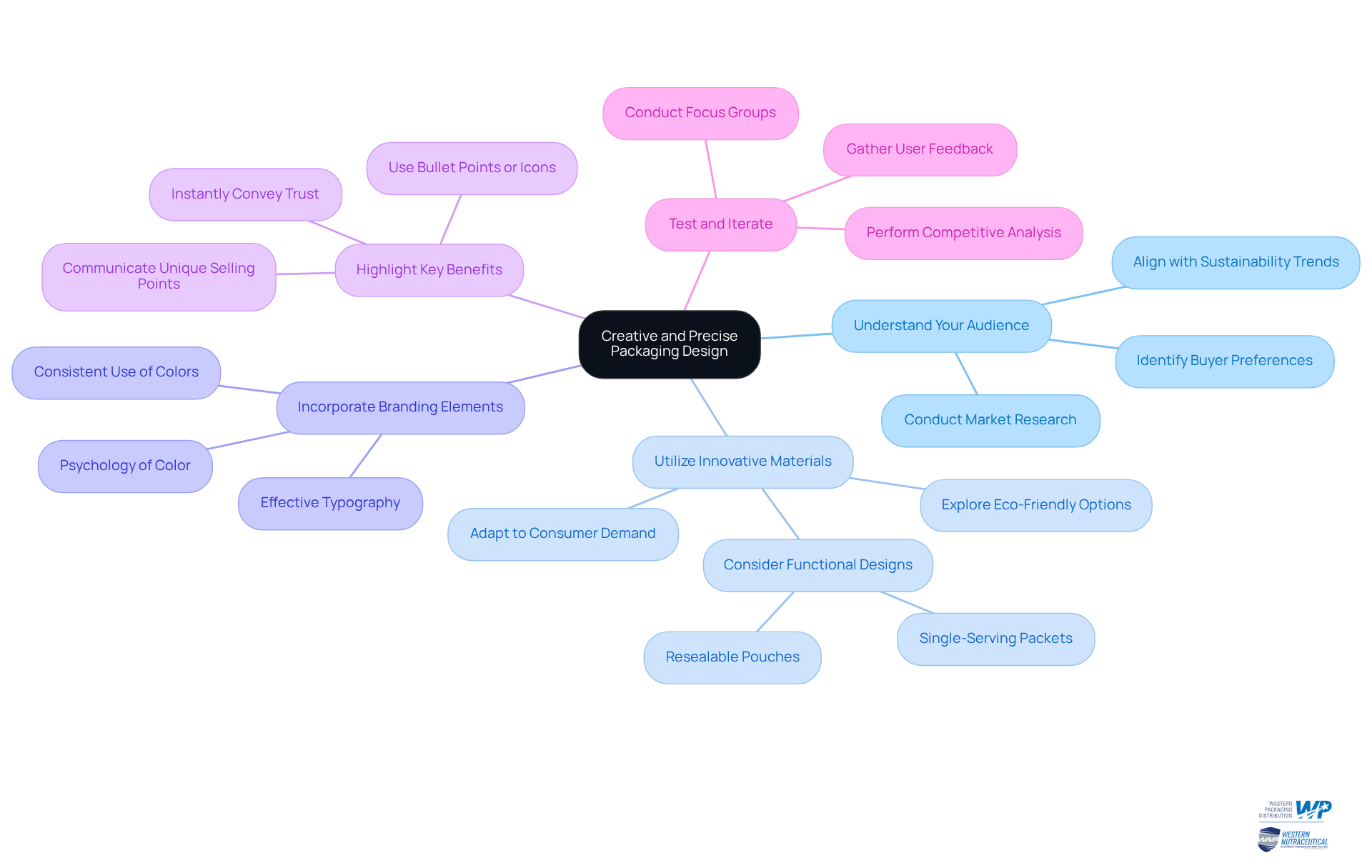

To implement creative and precise packaging design, manufacturers should focus on the following strategies:

-

Understand Your Audience: Conduct thorough market research to identify buyer preferences and emerging trends. Tailor your packaging design to align with the expectations of your target demographic, whether they prioritize sustainability, convenience, or aesthetic appeal. With 45% of individuals expressing interest in brands that prioritize sustainability, understanding these preferences is crucial.

-

Utilize Innovative Materials: Explore eco-friendly materials that appeal to environmentally aware individuals. Consider container choices that are not only visually appealing but also functional, such as resealable pouches or single-serving packets. The adaptable market is experiencing significant growth, driven by consumer demand for practical and user-friendly solutions. Notably, pouch modifications can lead to a 48% increase in purchase preference, making this an important consideration. At Western Packaging, we specialize in discovering optimal flexible solutions tailored to your needs, whether it's large pouches for protein products or stick packs for nutraceuticals.

-

Incorporate Branding Elements: Ensure that your packaging reflects your brand identity. Consistent use of colors, logos, and typography creates a cohesive look that enhances brand recognition. Effective color selections can evoke specific feelings, reinforcing the brand message and nurturing customer loyalty. Understanding the psychology of color is essential, as it can significantly influence consumer behavior. Our creative design solutions at Western Packaging enhance brand visibility and shelf attractiveness, ensuring your items stand out.

-

Highlight Key Benefits: Clearly communicate the product's unique selling points on the packaging. Utilize bullet points or icons to enable individuals to understand the advantages at a glance. Packaging must instantly convey efficacy, format, and trust to avoid being overlooked in a crowded market.

-

Test and Iterate: Before finalizing your design, conduct focus groups or surveys to gather feedback from users. This data-focused method enables enhancement of containers, guaranteeing it fulfills customer expectations and stands out on the shelf. Engaging consumers in the testing process can provide valuable insights into usability and appeal. Furthermore, performing a competitive analysis can assist in recognizing strengths and weaknesses in current container strategies, steering distinct design development. Think about how combined supply services can enhance your wrapping solutions, improving efficiency and item integrity.

By implementing these strategies, nutraceutical manufacturers can create the best brand packaging that not only attracts consumers but also effectively conveys the item's value proposition, ultimately enhancing market presence and operational efficiency.

Integrate Filling Services for Enhanced Product Appeal

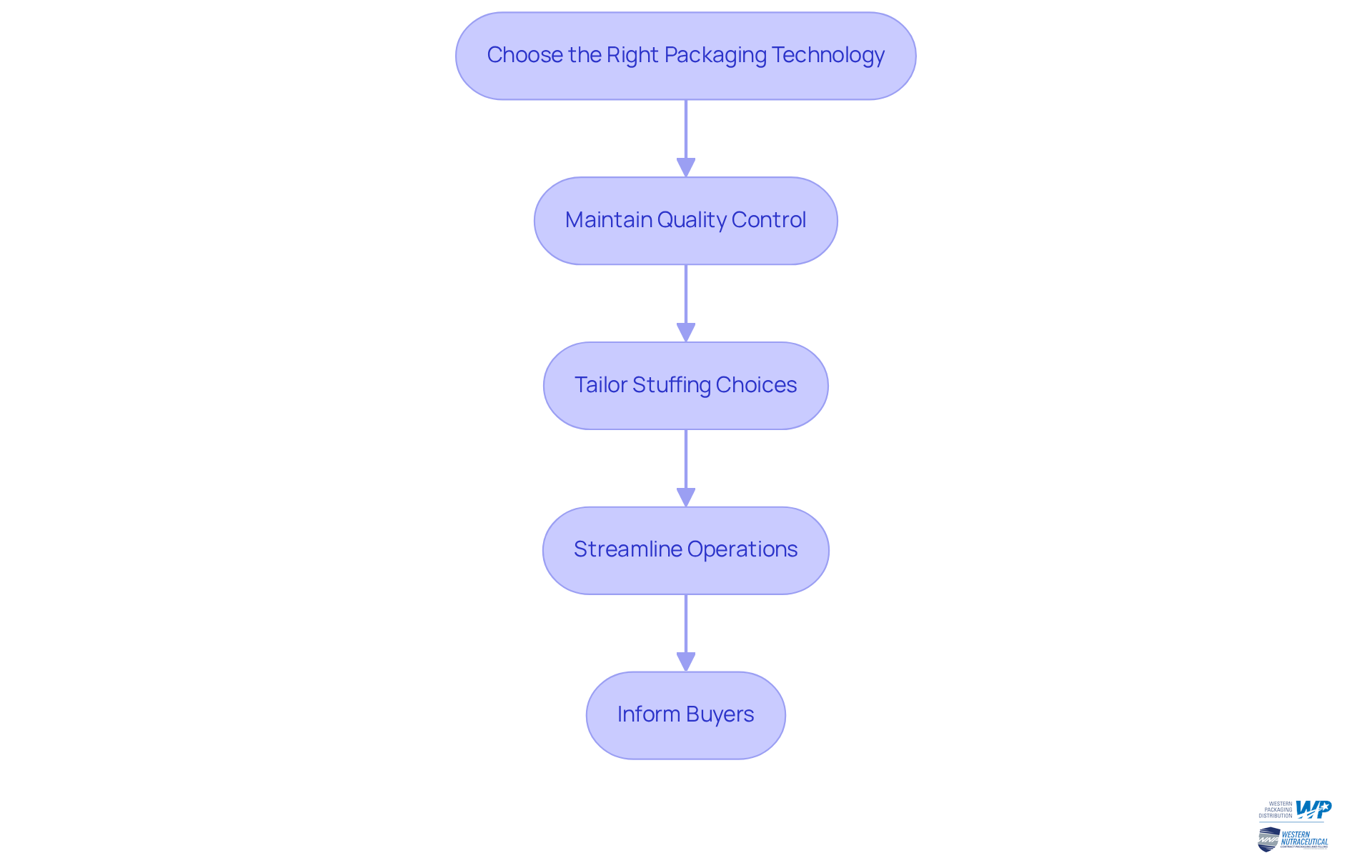

To effectively integrate filling services for enhanced product appeal, consider the following best practices:

-

Choose the Right Packaging Technology: Selecting suitable equipment designed for your item type—whether powders, gummies, or soft gels—is essential. This guarantees precise stuffing and upholds item integrity, which is crucial for customer satisfaction.

-

Maintain Quality Control: Implement rigorous quality assurance measures throughout the packaging process to prevent contamination and ensure consistency. Regular testing of samples is vital to confirm compliance with safety and quality standards. Studies indicate that effective quality control can reduce defects significantly, enhancing overall product reliability. For instance, Six Sigma aims for no more than 3.4 defects per million opportunities, underscoring the importance of stringent quality measures.

-

Tailor Stuffing Choices: Offering a variety of stuffing alternatives, such as single-serving sizes or bulk containers, addresses differing buyer preferences. This flexibility not only boosts customer satisfaction but also drives sales, as tailored solutions resonate more with target markets.

-

Streamline Operations: Merging service solutions with your wrapping line reduces downtime and improves operational efficiency. This approach can lead to faster turnaround times and reduced operational costs, ultimately improving your bottom line.

-

Inform Buyers: Use your packaging to educate buyers about the stuffing process and the advantages of your offering. Openness promotes confidence and can greatly improve brand loyalty, as knowledgeable individuals are more inclined to select items that correspond with their principles.

By concentrating on these practices, nutraceutical manufacturers can effectively boost the attractiveness of their offerings through the strategic incorporation of packaging services. Additionally, it is essential to be aware of common pitfalls, such as inadequate quality monitoring or failure to adapt filling technologies to evolving consumer demands, which can hinder operational success.

Optimize Supply Chain with Third-Party Logistics (3PL)

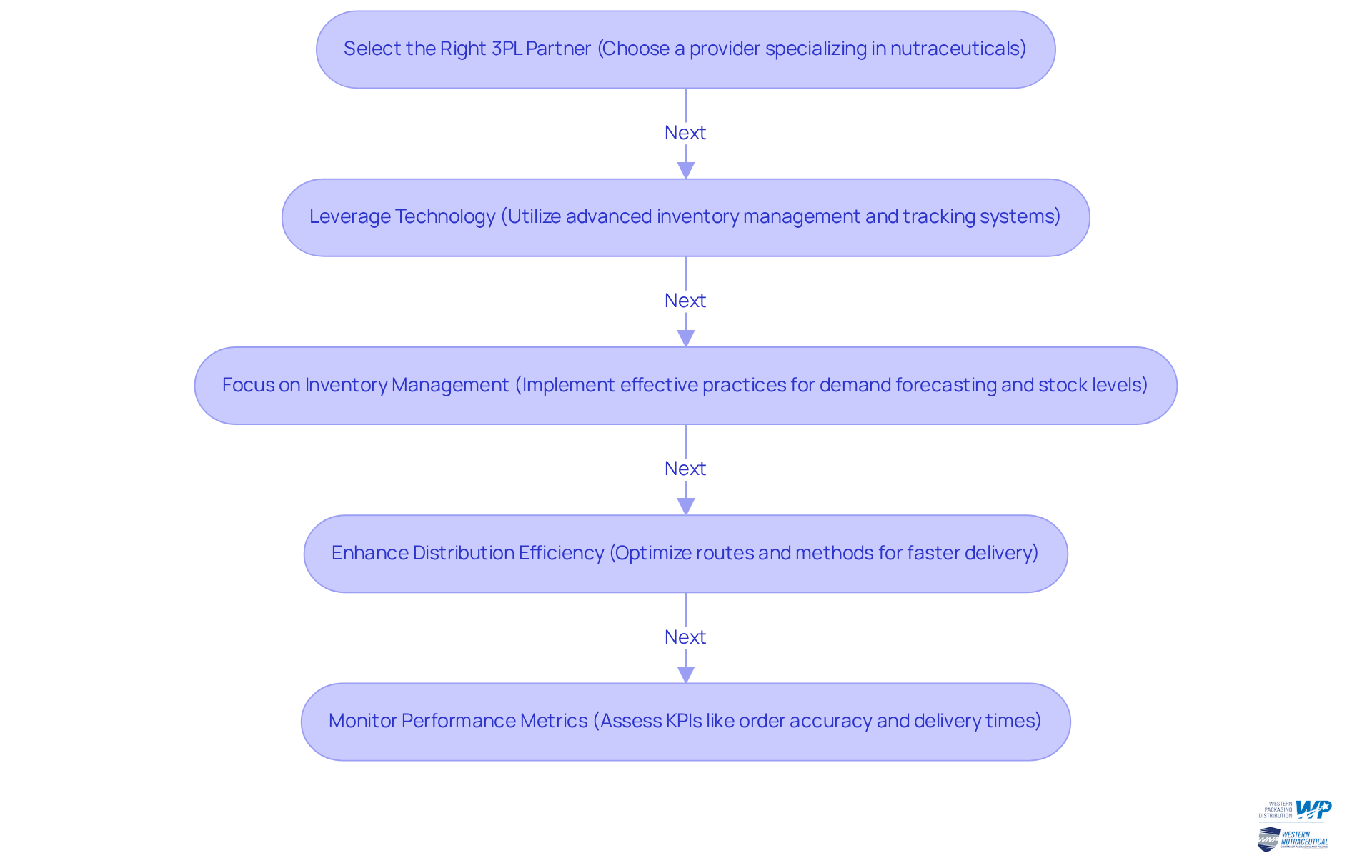

To optimize your supply chain with third-party logistics, consider implementing the following strategies:

-

Select the Right 3PL Partner: It is crucial to choose a 3PL provider that specializes in nutraceuticals and comprehends the unique challenges of the industry. Seek collaborators with a proven history and the capability to grow alongside your enterprise, ensuring they can manage the intricacies of compliance and service integrity. Adherence to regulations, such as California's updated Proposition 65, is essential for preserving integrity and avoiding costly penalties.

-

Leverage Technology: Utilize the advanced technology solutions offered by your 3PL provider, including inventory management systems and real-time tracking. These tools enhance visibility across your supply chain, facilitating better decision-making and streamlined operations—critical components in a market projected to experience significant growth. For instance, effective inventory management can lead to a 95% on-time delivery rate, a benchmark vital for customer satisfaction.

-

Focus on Inventory Management: Collaborate with your 3PL partner to implement effective inventory management practices. This encompasses accurate demand forecasting, managing stock levels, and reducing excess inventory to minimize costs. High return rates may indicate underlying issues in fulfillment operations, making effective inventory control essential. According to industry experts, maintaining high order accuracy is crucial to prevent customer dissatisfaction and returns.

-

Enhance Distribution Efficiency: Work closely with your 3PL provider to optimize distribution routes and methods. This collaboration can yield faster delivery times and reduced shipping costs, which are vital for sustaining customer satisfaction in a competitive market. Case studies have demonstrated that companies optimizing their distribution strategies can significantly enhance their operational efficiency.

-

Monitor Performance Metrics: Regularly assess your 3PL partner's performance using key performance indicators (KPIs) such as order accuracy, delivery times, and customer satisfaction. Utilizing analytics can help identify common themes or recurring issues, enabling informed decisions and continuous improvements. As noted by industry leaders, monitoring these metrics is essential for ensuring that your logistics operations align with your business goals.

By optimizing your supply chain with 3PL services, nutraceutical manufacturers can enhance operational efficiency, reduce logistics costs, and focus on product development and marketing, ultimately improving their market presence.

Ensure Regulatory Compliance in Packaging Practices

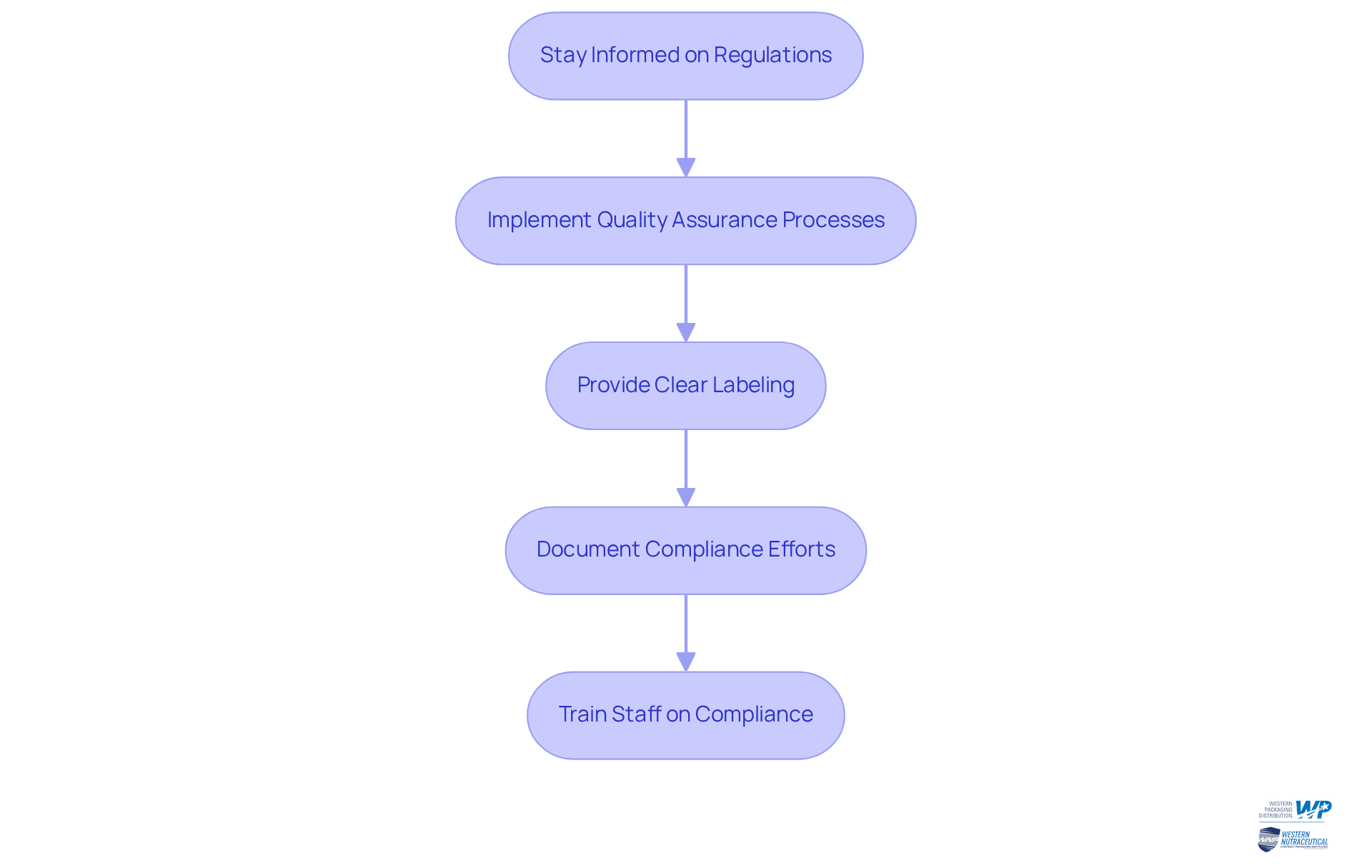

To ensure regulatory compliance in packaging practices, manufacturers must adhere to the following best practices:

-

Stay Informed on Regulations: Regularly review and stay updated on relevant regulations governing nutraceutical containers, including labeling requirements and safety standards. This proactive approach is essential for maintaining compliance in a dynamic regulatory environment.

-

Implement Quality Assurance Processes: Establish robust quality assurance protocols to guarantee that all materials and processes align with regulatory standards. This includes rigorous testing for safety and efficacy, ensuring that products meet consumer expectations.

-

Provide Clear Labeling: It is imperative that all product labels are clear, accurate, and compliant with regulations. Essential information such as ingredients, dosage, and health claims must be included to foster consumer trust and transparency.

-

Document Compliance Efforts: Maintain comprehensive documentation of compliance efforts, including testing results and quality control measures. This thorough record-keeping is crucial in the event of audits or regulatory inquiries, demonstrating commitment to compliance.

-

Train Staff on Compliance: Provide targeted training for personnel involved in wrapping and labeling, ensuring they fully understand regulatory requirements and the importance of adherence. This investment in staff education reinforces a culture of compliance within the organization.

By diligently following these practices, nutraceutical manufacturers can ensure regulatory compliance in their best brand packaging, thereby safeguarding their brand reputation and protecting consumers.

Conclusion

The effective packaging of nutraceuticals is crucial for attracting consumers and establishing brand loyalty. By focusing on creative design, innovative materials, and clear communication of product benefits, manufacturers can significantly enhance their market presence and operational efficiency. The integration of filling services and strategic partnerships with third-party logistics further streamlines operations, ensuring that products meet consumer expectations and comply with regulatory standards.

Key strategies include:

- Understanding target demographics

- Utilizing eco-friendly materials

- Incorporating branding elements

- Maintaining rigorous quality control throughout the packaging process

These practices enhance product appeal and foster trust and transparency with consumers. Moreover, optimizing supply chain management through effective inventory practices and performance monitoring can lead to improved efficiency and reduced costs.

Ultimately, the significance of thoughtful packaging in the nutraceutical industry cannot be overstated. As consumer preferences evolve, manufacturers must stay informed about trends and regulations, ensuring their packaging stands out on the shelf and reflects their commitment to quality and compliance. Embracing these best practices will bolster brand reputation and position nutraceutical manufacturers for sustained success in a competitive market.

Frequently Asked Questions

What are the key strategies for implementing creative and precise packaging design?

The key strategies include understanding your audience, utilizing innovative materials, incorporating branding elements, highlighting key benefits, and testing and iterating the design.

Why is understanding the audience important in packaging design?

Understanding the audience is crucial because it helps manufacturers tailor their packaging to align with buyer preferences and emerging trends, such as sustainability, convenience, or aesthetic appeal. This alignment can significantly influence purchasing decisions.

What types of materials should manufacturers consider for eco-friendly packaging?

Manufacturers should explore eco-friendly materials and consider functional container choices, such as resealable pouches or single-serving packets, that appeal to environmentally aware consumers.

How can branding elements affect packaging design?

Incorporating consistent branding elements like colors, logos, and typography enhances brand recognition and can evoke specific feelings, reinforcing the brand message and nurturing customer loyalty.

What should be highlighted on the packaging to attract consumers?

Packaging should clearly communicate the product's unique selling points using bullet points or icons, allowing consumers to quickly understand the advantages and trust the product.

How can manufacturers ensure their packaging design meets customer expectations?

Manufacturers can conduct focus groups or surveys to gather user feedback before finalizing the design. This data-focused method helps enhance usability and appeal, ensuring the packaging stands out on the shelf.

What role does competitive analysis play in packaging design?

Competitive analysis helps identify strengths and weaknesses in current container strategies, guiding the development of distinct and effective packaging designs.

How does effective packaging design impact market presence and operational efficiency?

By implementing effective packaging strategies, manufacturers can create attractive packaging that conveys the product's value proposition, ultimately enhancing market presence and improving operational efficiency.