Overview

The article delves into best practices for gummy bottle packaging, underscoring the critical importance of quality, compliance, and innovative design to bolster brand appeal. It articulates essential strategies, including:

- A thorough understanding of regulatory requirements

- The utilization of high-quality materials

- The incorporation of sustainable practices

These elements collectively contribute to maintaining product integrity and attracting consumers in an increasingly competitive market.

Introduction

The booming gummy supplement market presents a significant challenge for manufacturers striving to distinguish themselves in a crowded space. As consumer preferences evolve and regulatory standards tighten, the importance of effective gummy bottle packaging cannot be overstated. This article explores best practices for ensuring quality and compliance, innovative design strategies to enhance brand appeal, and the integration of efficient filling and logistics solutions.

How can manufacturers navigate these complexities to not only meet standards but also captivate consumers?

Prioritize Quality and Compliance in Gummy Bottle Packaging

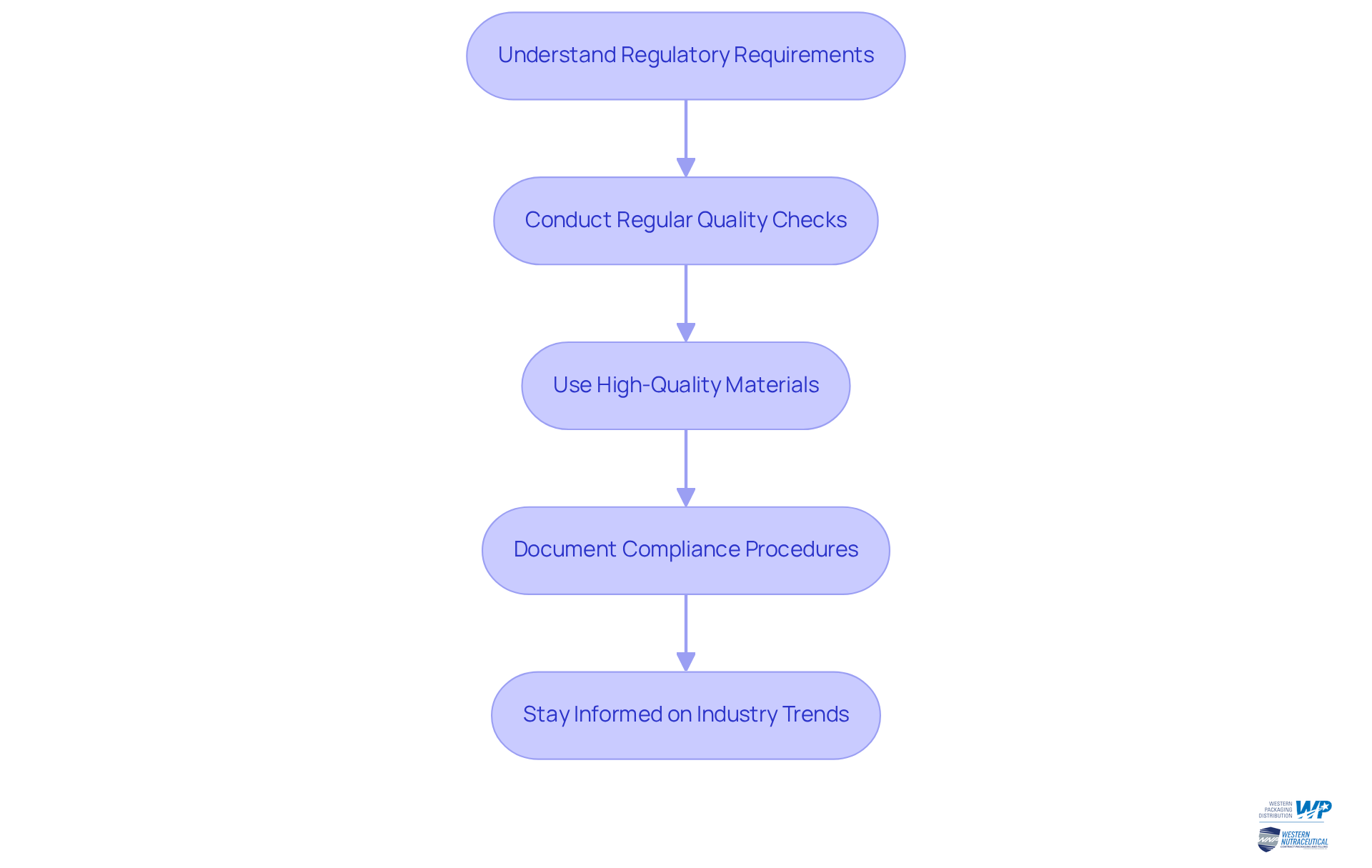

To ensure the highest quality and compliance in gummy bottle packaging, manufacturers must adhere to essential best practices:

-

Understand Regulatory Requirements: It is crucial to familiarize yourself with local and international regulations governing dietary supplements, including labeling, safety, and presentation standards. This encompasses compliance with FDA guidelines and any specific regulations related to nutraceuticals.

-

Conduct Regular Quality Checks: Establishing a robust quality control system is imperative, incorporating routine evaluations of wrapping materials and processes. This should involve testing for contaminants, ensuring proper sealing, and verifying that the container maintains product integrity.

-

Use High-Quality Materials: Selecting materials for wrapping that are both visually appealing and functional is vital. These materials should protect the gummy bottle from moisture, light, and air, which can compromise the integrity of the gummies. Additionally, consider utilizing child-resistant packaging where necessary to enhance safety.

-

Document Compliance Procedures: Maintaining thorough documentation of compliance protocols and standards checks is essential. This practice not only aids in audits but also builds consumer confidence in your brand.

-

Stay Informed on Industry Trends: Regularly reviewing industry publications and attending relevant conferences is key to remaining aware of changes in regulations and best practices in quality control.

Implement Innovative Packaging Design for Enhanced Brand Appeal

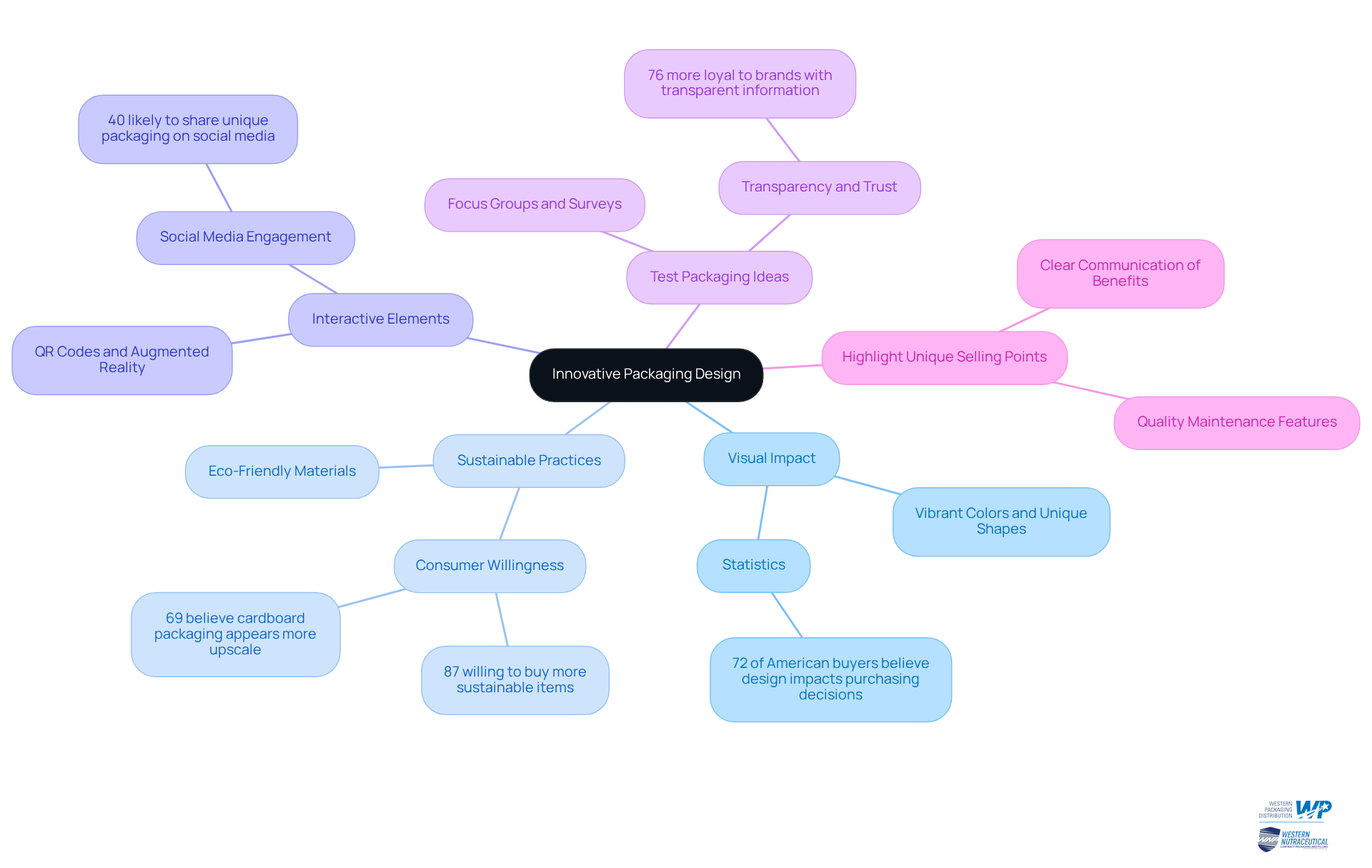

To create innovative packaging designs that enhance brand appeal, consider the following strategies:

-

Focus on Visual Impact: Utilize vibrant colors, unique shapes, and eye-catching graphics that reflect the brand's identity and attract attention on the shelf. Studies show that 72% of American buyers believe that item design greatly impacts their purchasing decisions, underscoring the significance of visual attractiveness in boosting sales. Western Packaging specializes in crafting engaging graphic assets, ensuring a cohesive and captivating brand identity that enhances your item's shelf appeal.

-

Incorporate Sustainable Practices: With growing public awareness of environmental issues, adopting eco-friendly materials and sustainable packaging methods can significantly enhance brand image. Brands that use biodegradable or recyclable materials resonate with eco-conscious consumers, as 87% indicate a willingness to buy more sustainable items if they are readily available. Furthermore, using eco-friendly materials can elevate the overall perception of the brand, with 69% of shoppers believing that items packaged in cardboard or paper appear more upscale.

-

Utilize Interactive Elements: Integrate QR codes or augmented reality features that provide users with additional information about the product, such as sourcing, benefits, or usage tips. This not only engages customers but also fosters a deeper connection with the brand, enhancing customer loyalty. For instance, research reveals that 40% of shoppers are likely to share images of distinctive or labeled containers on social media, thereby increasing brand exposure.

-

Test Packaging Ideas: Conduct focus groups or surveys to gather feedback on design concepts before finalizing them. Understanding buyer preferences can lead to more effective packaging solutions, as brands that prioritize transparency and customer feedback are more likely to cultivate trust and loyalty. Indeed, 76% of buyers are more loyal to brands that offer transparent product information, highlighting the importance of clear labeling.

-

Highlight Unique Selling Points: Ensure that the gummy bottle clearly communicates the unique benefits of the gummies, including organic ingredients, added vitamins, or specific health advantages. Strategic labeling and design features can effectively convey these traits, appealing to buyers' desires for quality and transparency in their purchases. Additionally, incorporating oxygen barriers and moisture safeguards in containers is crucial for maintaining the quality of the gummy bottle items, ensuring they remain fresh and effective for consumers. Western Packaging provides innovative solutions tailored to your needs, including integrated filling services that enhance product appeal and meet unique requirements.

Integrate Filling Services for Customized Packaging Solutions

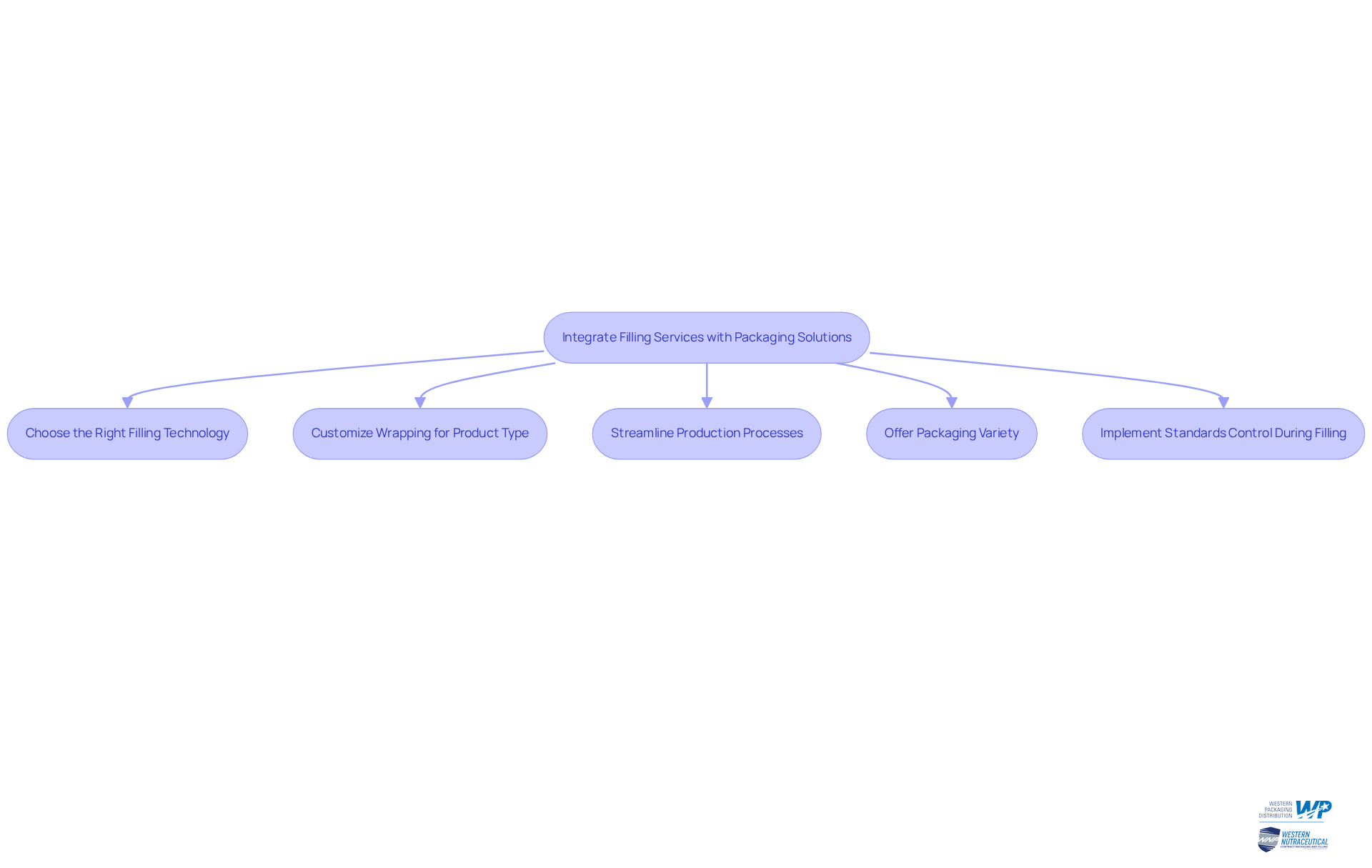

To effectively integrate filling services with packaging solutions, consider the following best practices:

-

Choose the Right Filling Technology: Selecting filling equipment that aligns with the gummy formulation and type of container is crucial. This compatibility enhances efficiency and minimizes waste, ensuring a smooth production process. For instance, reducing product size can cut down the quantity of raw materials utilized and waste produced, emphasizing the importance of this choice.

-

Customize the wrapping for product type by designing containers, such as a gummy bottle, that reflect the unique characteristics of the gummies, including size, shape, and texture. Utilizing gummy bottles with tamper-evident seals can enhance safety and consumer confidence. As remarked by PMI KYOTO, custom solutions are crucial for addressing specific container requirements.

-

Streamline Production Processes: Collaborate closely with filling service providers to optimize production workflows. This includes coordinating schedules, maximizing equipment usage, and integrating quality checks throughout the filling process to maintain high standards. Addressing common pitfalls, such as misalignment between filling technology and container solutions, can prevent inefficiencies.

-

Offering variety in packaging options, such as different sizes and shapes of gummy bottles, can cater to diverse market demands and consumer preferences, enhancing item appeal.

-

Implement Standards Control During Filling: Establishing robust standards control measures during the filling process is essential. Routine inspections for fill levels, seal integrity, and labeling accuracy guarantee that each bottle meets the necessary standards, protecting quality and adherence. Case studies, such as Makat's NutraGummyFactory Recognition, illustrate the effectiveness of these practices in real-world applications.

Leverage 3PL Services for Efficient Supply Chain Management

To effectively leverage 3PL services for streamlined supply chain management, consider the following strategies:

-

Select a Reliable 3PL Partner: Opt for a 3PL provider like Western Packaging, recognized for its comprehensive services tailored to the nutraceutical sector. Seek partners that offer a wide range of services, including warehousing, inventory management, and distribution, ensuring they understand the unique requirements of gummy bottle products. As noted by Nutraceutical Publishing, "Choosing the right 3PL provider is crucial for the success of your nutraceutical business."

-

Optimize Inventory Management: Collaborate with your 3PL provider to implement advanced inventory management systems that provide real-time tracking of stock levels. This proactive strategy helps mitigate stockouts and overstock situations, ensuring availability aligns with demand. With the nutraceutical industry projected to exceed $700 billion by 2025, effective inventory management is essential for capitalizing on this growth.

-

Enhance Distribution Efficiency: Work closely with Western Packaging to refine distribution routes and methods. Streamlining these processes can lead to reduced shipping costs and improved delivery times, ultimately enhancing customer satisfaction. Major logistics centers for nutraceutical items, such as Phoenix, AZ, Raleigh-Durham, NC, and Los Angeles, CA, can be leveraged to optimize distribution strategies.

-

Utilize Technology for Transparency: Adopt technology solutions that enhance visibility throughout the supply chain. Tracking systems that allow clients to monitor shipments and inventory levels in real-time can significantly improve operational efficiency.

-

Focus on Scalability: Choose a 3PL provider capable of scaling operations in response to your business needs. This flexibility is crucial for adapting to market fluctuations and the increasing demand for gummy bottles. Additionally, consider potential tax advantages and incentives for businesses utilizing 3PL services, which can further enhance the benefits of selecting a reliable partner.

Conclusion

Prioritizing quality and innovative design in gummy bottle packaging is essential for manufacturers aiming to establish a strong market presence. By adhering to regulatory requirements, conducting thorough quality checks, and employing high-quality materials, brands can ensure that their products not only meet safety standards but also resonate with consumers seeking transparency and quality.

The article highlights several key strategies, including:

- The importance of visual impact in packaging design

- The integration of sustainable practices

- The utilization of interactive elements to engage customers

Furthermore, the seamless integration of filling services and effective supply chain management through reliable 3PL partners can significantly enhance operational efficiency and product appeal. These practices collectively contribute to a robust brand image and customer loyalty.

In a competitive landscape, embracing these best practices is not just beneficial—it is imperative. As the gummy packaging market continues to evolve, staying informed about trends and consumer preferences will empower brands to innovate and adapt. By focusing on quality, compliance, and creative design, manufacturers can position themselves for success and meet the growing demand for gummy products in the marketplace.

Frequently Asked Questions

What are the essential best practices for gummy bottle packaging?

The essential best practices include understanding regulatory requirements, conducting regular quality checks, using high-quality materials, documenting compliance procedures, and staying informed on industry trends.

Why is it important to understand regulatory requirements in gummy bottle packaging?

Understanding regulatory requirements is crucial to comply with local and international regulations governing dietary supplements, including labeling, safety, and presentation standards, such as FDA guidelines.

What should be included in regular quality checks for gummy packaging?

Regular quality checks should include routine evaluations of wrapping materials and processes, testing for contaminants, ensuring proper sealing, and verifying that the container maintains product integrity.

What qualities should materials used for gummy bottle packaging have?

Materials should be visually appealing, functional, and protective against moisture, light, and air, which can compromise the integrity of the gummies. Child-resistant packaging should also be considered for safety.

Why is documentation of compliance procedures important?

Thorough documentation of compliance protocols and standards checks is essential for audits and helps build consumer confidence in the brand.

How can manufacturers stay informed about industry trends?

Manufacturers can stay informed by regularly reviewing industry publications and attending relevant conferences to keep up with changes in regulations and best practices in quality control.