Overview

This article presents a comparative analysis of food supplements contract manufacturing, underscoring how outsourcing production can significantly benefit brands. By leveraging specialized expertise, companies can focus on their core business activities.

Regulatory compliance, production capacity, and customization options emerge as vital criteria for selecting a contract manufacturer. Supported by case studies and market trends, the article illustrates the increasing demand for dietary supplements and the strategic advantages of partnerships within this sector.

As you consider your options, recognize the value of aligning with a reliable contract manufacturer to enhance your brand's success.

Introduction

Outsourcing production has emerged as a strategic lifeline for brands within the rapidly expanding dietary supplement market, projected to reach an impressive USD 402.20 billion by 2034. By engaging in food supplements contract manufacturing, companies can leverage the expertise of specialized producers while concentrating on their core business activities. This approach not only fosters innovation but also enhances responsiveness to market demands.

Yet, with a multitude of manufacturers available, how can brands ensure they select the right partner that meets their unique needs while adhering to stringent regulatory standards? This article explores the comparative landscape of food supplements contract manufacturing, highlighting essential evaluation criteria and providing insights to navigate this complex decision-making process.

Understanding Food Supplements Contract Manufacturing

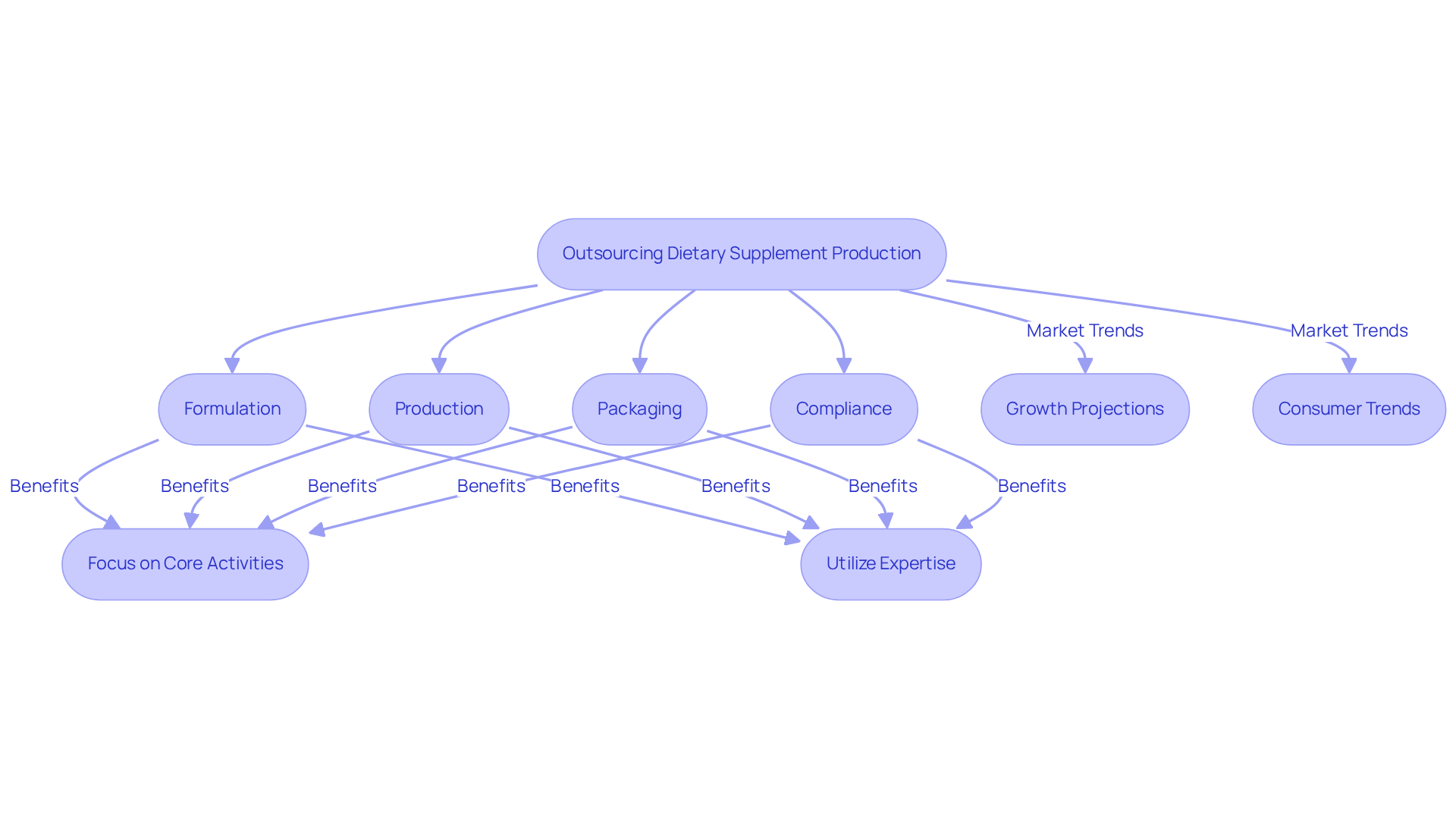

Outsourcing dietary supplement production to specialized producers provides brands a strategic advantage through food supplements contract manufacturing, enabling them to concentrate on core business activities while utilizing the expertise and resources of established entities. Contract manufacturers oversee critical components such as formulation, production, packaging, and compliance with regulatory standards, which is vital in a market defined by stringent compliance requirements. This model is particularly beneficial for companies looking to enter the market quickly without the significant capital investment required for in-house manufacturing facilities.

Western Packaging delivers customized flexible packaging solutions that seamlessly integrate with our comprehensive filling services, accommodating a wide range of products from powders to gummies, soft-gels, and kitting. Our extensive services streamline your production process, enabling you to enhance product appeal and optimize supply chain management. With our integrated 3PL solutions—including warehousing, inventory management, and logistics—we provide the essential support for nutraceutical manufacturers to concentrate on their core competencies while ensuring efficient operations.

The dietary product market is projected to experience significant growth, with a compound annual growth rate (CAGR) of approximately 7.87% from 2025 to 2034, reaching an estimated USD 402.20 billion by 2034. This expansion is fueled by increasing health consciousness, urbanization, and a growing demand for personalized nutrition solutions. Notably, 70% of consumers express interest in personalized dietary products, reflecting a shift toward customized health management.

Successful case studies underscore the advantages of this outsourcing model. For instance, companies like Lonza Group Ltd. have excelled in dietary product manufacturing by adopting advanced technologies and committing to quality and sustainability. Additionally, the COVID-19 pandemic has heightened demand for nutritional products, particularly those that boost immunity, highlighting the importance of flexible production capabilities.

Current trends reveal a rising focus on e-commerce, with online sales of dietary products booming as consumers prioritize convenience and accessibility. This trend is anticipated to persist, further amplifying the market's growth potential. Industry leaders assert that outsourcing not only streamlines production but also empowers brands to innovate and respond swiftly to market demands, ensuring they remain competitive in a rapidly evolving landscape.

In conclusion, food supplements contract manufacturing presents a viable solution for brands seeking to enhance their operations and capitalize on the burgeoning dietary product market. By partnering with skilled producers like Western Packaging, companies can improve product quality, reduce lead times, and ultimately strengthen their market presence.

Key Evaluation Criteria for Contract Manufacturers

When evaluating contract manufacturers for food supplements, several key criteria warrant careful consideration:

- Regulatory Compliance: Ensuring the manufacturer adheres to Good Manufacturing Practices (GMP) and other relevant regulations is paramount. Compliance with these standards is vital for guaranteeing safety and excellence; failure to do so can lead to serious legal repercussions and product recalls.

- Experience and Expertise: A manufacturer with a proven track record in producing comparable items can significantly enhance production quality and efficiency. Their experience often translates into adept handling of complex formulations and strict adherence to regulatory requirements.

- Standards Control Measures: Evaluating the producer's quality assurance procedures is essential. This includes assessing their testing protocols, certifications, and compliance with industry standards. Robust quality control measures mitigate the risk of contamination and ensure that products meet established safety and efficacy benchmarks. Key measures to consider include ingredient testing, allergen control, sanitation protocols, and accurate labeling.

- Production Capacity: Assessing whether the producer can scale output to meet demand, especially during peak seasons, is crucial. A manufacturer’s ability to adjust production levels can prevent supply chain disruptions and ensure timely delivery.

- Customization Options: Consider the manufacturer’s flexibility regarding formulation and packaging. The ability to tailor offerings to meet specific brand specifications can enhance market appeal and customer satisfaction.

- Technology and Equipment: Investigating the technology and equipment utilized in the manufacturing process is vital. Advanced systems can improve efficiency, reduce production costs, and elevate quality, making them a critical factor in the evaluation process.

- Communication and Support: Effective communication and strong customer support are essential for a successful partnership. Clear communication ensures that any issues are promptly addressed, fostering a collaborative relationship that can yield superior outcomes.

Looking ahead to 2025, the importance of regulatory adherence in contract production will continue to escalate, with an estimated 140 very small dietary product creators at risk of failure due to non-compliance. This statistic underscores the urgency of adhering to GMP standards. Collaborating with skilled service providers can streamline the GMP process and provide essential regulatory support. Therefore, selecting a food supplements contract manufacturing producer that prioritizes these assessment standards is crucial for ensuring quality and maintaining consumer confidence.

Comparative Analysis of Leading Food Supplement Manufacturers

In this comparative analysis, we delve into three prominent food supplement contract manufacturers, each possessing distinct attributes that cater to varying business needs:

-

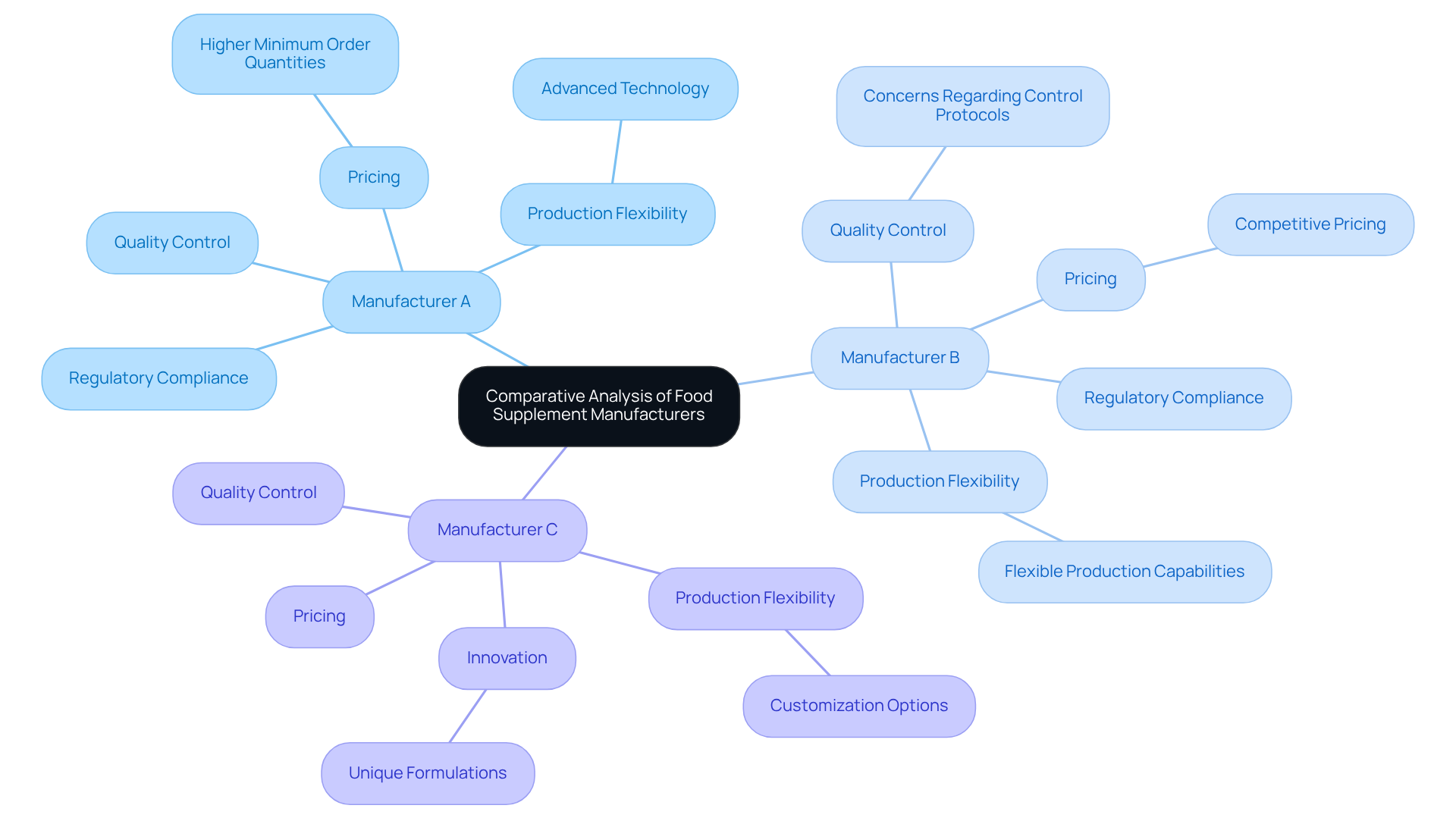

Manufacturer A: Recognized for its comprehensive product range and stringent regulatory compliance, Manufacturer A stands as a leader in quality control. Their investment in advanced technology facilitates efficient production processes. However, they typically impose higher minimum order quantities, which may not align with every client's requirements. As industry expert Trishita Deb asserts, "Quality control is paramount in the dietary supplement industry, especially as the market is projected to reach USD 327.42 billion by 2030."

-

Manufacturer B: This manufacturer appeals to startups due to its competitive pricing and flexible production capabilities. Nevertheless, previous concerns regarding their control protocols could pose risks for brands that prioritize safety and dependability in their offerings. The growth of the dietary supplements market underscores the significance of robust assurance practices.

-

Manufacturer C: Distinguished by its commitment to innovation and customization, Manufacturer C excels in developing unique formulations that resonate with current market trends. Their strong communication and customer support are frequently praised, yet their production capacity may not match that of larger competitors, potentially limiting scalability for some brands. The increasing demand for personalized nutrition plans reflects the growing consumer interest in tailored health solutions, which Manufacturer C effectively addresses.

By evaluating these producers against essential criteria such as product excellence, production adaptability, and regulatory compliance, brands can identify the most suitable partner for food supplements contract manufacturing to meet their operational goals and standards of excellence. Integrating insights from case studies, such as Manufacturer A's strict control measures, can further inform decision-making in this competitive landscape.

Choosing the Right Contract Manufacturer: Insights and Recommendations

Selecting the appropriate food supplements contract manufacturing producer is a crucial decision for any brand in the food supplements sector. To guide your selection process, consider the following insights and recommendations:

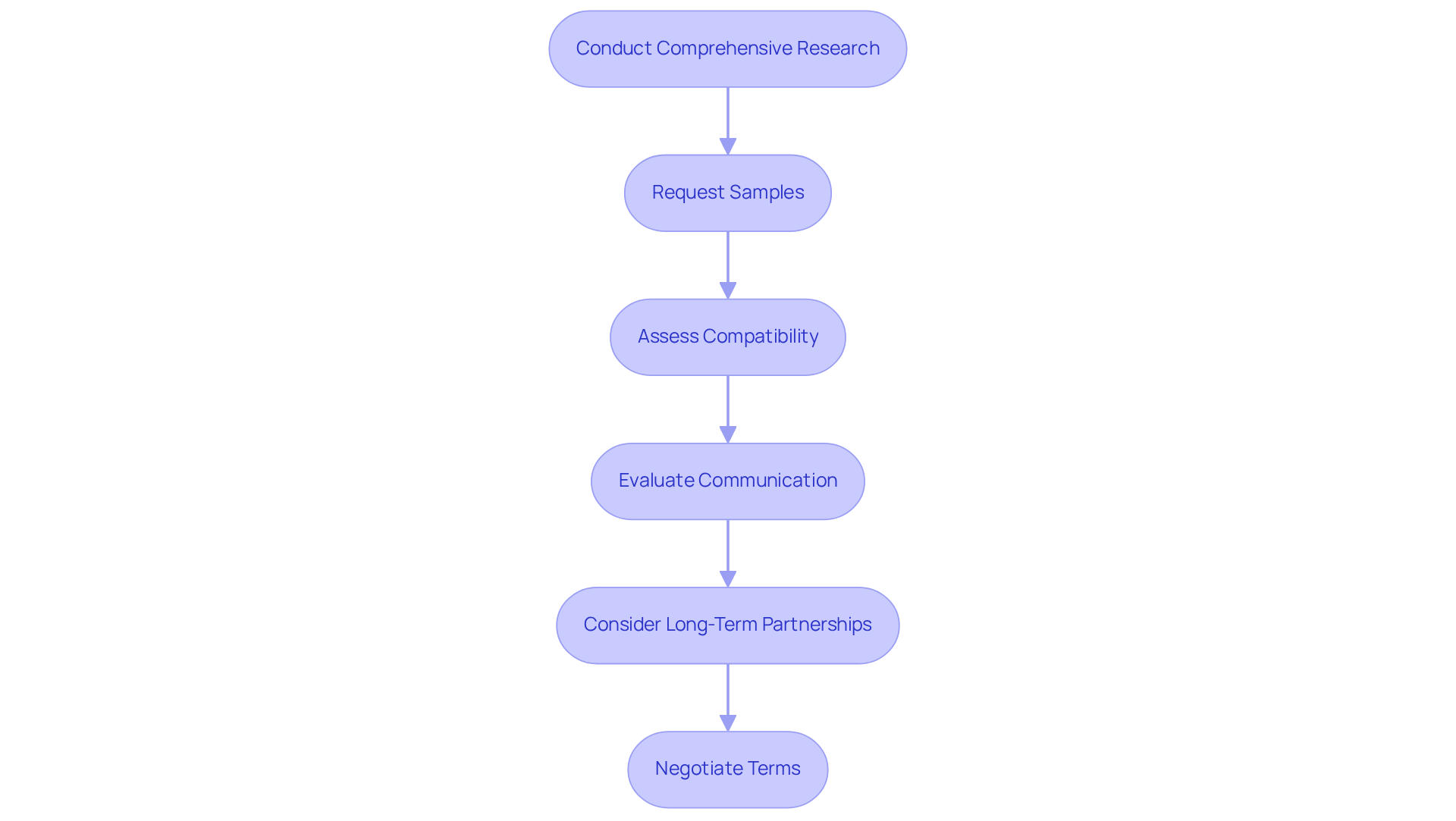

- Conduct Comprehensive Research: Examine potential producers by assessing their certifications, client testimonials, and case studies to evaluate their dependability and standards. This foundational step ensures you are informed about the producers' credibility.

- Request Samples: Before committing, request samples of the items to evaluate the quality and formulation of their offerings. This allows you to make an informed judgment about their products.

- Assess Compatibility: Ensure that the producer's capabilities align with your product vision, including formulation, packaging, and branding needs. Compatibility is key to a successful partnership.

- Evaluate Communication: Select a producer that prioritizes clear communication and is responsive to your inquiries, as this will facilitate a smoother partnership. Effective communication is essential for collaboration.

- Consider Long-Term Partnerships: Look for manufacturers that can grow with your brand, offering scalability and adaptability as your business evolves. A long-term partnership can provide stability and support.

- Negotiate Terms: Don’t hesitate to negotiate terms that work for both parties, including pricing, lead times, and minimum order quantities. A mutually beneficial agreement sets the stage for success.

By following these recommendations, brands can make informed decisions that enhance their chances of success in the competitive market for food supplements contract manufacturing.

Conclusion

Outsourcing food supplements production through contract manufacturing presents brands with a strategic pathway to enhance operational efficiency and market competitiveness. By leveraging the expertise of specialized manufacturers, companies can focus on their core business while ensuring high-quality production, compliance with regulations, and rapid market entry.

Critical factors for evaluating potential contract manufacturers include:

- Regulatory compliance

- Experience

- Quality control measures

- Production capacity

- Customization options

Successful case studies illustrate how strategic partnerships can lead to innovative products that meet the growing consumer demand for personalized nutrition. Furthermore, the projected growth of the dietary supplements market underscores the urgency for brands to select the right manufacturing partner to navigate this evolving landscape effectively.

In light of these insights, it is essential for brands to approach the selection of food supplements contract manufacturers with a comprehensive strategy. Conducting thorough research, assessing compatibility, and fostering long-term partnerships will position companies for success in a competitive market. Embracing these best practices not only enhances product quality but also cultivates consumer trust, ultimately driving growth in the burgeoning dietary supplement industry.

Frequently Asked Questions

What is food supplements contract manufacturing?

Food supplements contract manufacturing involves outsourcing dietary supplement production to specialized producers, allowing brands to focus on their core business activities while leveraging the expertise and resources of established manufacturers.

What are the main responsibilities of contract manufacturers?

Contract manufacturers manage critical components such as formulation, production, packaging, and compliance with regulatory standards, which are essential in a market with stringent compliance requirements.

Why might a company choose to use contract manufacturing?

Companies may opt for contract manufacturing to enter the market quickly without the significant capital investment needed for in-house manufacturing facilities.

What services does Western Packaging offer?

Western Packaging provides customized flexible packaging solutions, comprehensive filling services, and integrated 3PL solutions, including warehousing, inventory management, and logistics, to support nutraceutical manufacturers.

What is the projected growth of the dietary product market?

The dietary product market is projected to grow at a compound annual growth rate (CAGR) of approximately 7.87% from 2025 to 2034, reaching an estimated USD 402.20 billion by 2034.

What factors are driving the growth of the dietary product market?

The growth is driven by increasing health consciousness, urbanization, and a growing demand for personalized nutrition solutions, with 70% of consumers showing interest in personalized dietary products.

Can you provide examples of successful companies in dietary product manufacturing?

Companies like Lonza Group Ltd. have excelled in dietary product manufacturing by adopting advanced technologies and committing to quality and sustainability.

How has the COVID-19 pandemic impacted the demand for nutritional products?

The pandemic has increased demand for nutritional products, particularly those that boost immunity, emphasizing the need for flexible production capabilities.

What current trends are influencing the dietary product market?

There is a rising focus on e-commerce, with online sales of dietary products increasing as consumers prioritize convenience and accessibility, a trend expected to continue.

How does outsourcing benefit brands in the dietary product market?

Outsourcing streamlines production, allowing brands to innovate and respond quickly to market demands, helping them remain competitive in a rapidly evolving landscape.