Overview

The article provides an authoritative comparison of various film options for in vitro diagnostic (IVD) devices, particularly emphasizing their applications in nutraceuticals.

It underscores the critical importance of selecting suitable film materials, taking into account key factors such as:

- Barrier properties

- Biocompatibility

- Regulatory compliance

Furthermore, it illustrates how advancements like metallocene polyethylene can significantly enhance performance and sustainability in IVD applications, ultimately reinforcing the necessity for informed decision-making in this field.

Introduction

The selection of film materials for in vitro diagnostic (IVD) devices stands as a critical yet frequently overlooked component of medical technology, wielding significant influence over both diagnostic accuracy and environmental sustainability.

With the emergence of innovations in film technology, manufacturers encounter a pivotal opportunity to elevate device performance while adhering to stringent regulatory standards.

Yet, amid a myriad of options—from polyethylene to advanced metallocene polyethylene—how can one ascertain which film type achieves the ideal balance between cost, performance, and ecological impact?

This article embarks on an exploration of the comparative landscape of film options for IVD devices, examining their unique properties and implications for the future of diagnostics.

Understanding IVD Devices and the Role of Film Materials

In vitro testing (IVD) devices serve as essential medical instruments, meticulously analyzing samples from the human body—such as blood or tissue—to identify diseases or conditions. The selection of substances in IVD devices is paramount; these elements function as protective barriers, facilitate sample handling, and preserve the integrity of the testing process. The film for IVD devices must comply with rigorous regulatory standards, ensuring biocompatibility and resilience against various environmental conditions.

Recent advancements in media materials reveal that innovations can significantly enhance device performance. For instance, advanced polymer membranes have been engineered to boost sensitivity and specificity, leading to more dependable diagnostic results. A case study on the application of biodegradable materials in IVD devices underscored their ability to reduce environmental impact while maintaining performance standards, thereby appealing to eco-conscious consumers.

Statistics indicate that the appropriate substance can enhance the overall reliability of IVD devices by as much as 30%, underscoring the importance of material selection in the design process. Industry leaders emphasize that understanding the intended application and user needs is vital for selecting suitable substances, as these elements directly influence the device's efficiency in clinical settings.

As the landscape of IVD technology evolves, the integration of cutting-edge materials in film for IVD devices will remain crucial in advancing testing capabilities and ensuring compliance with regulatory standards.

Exploring Different Film Types for IVD Applications

In the realm of in vitro diagnostics (IVD), various materials, such as film for IVD devices, are employed, each with unique properties tailored for specific applications. Polyethylene sheets are particularly valued for their versatility and moisture barrier capabilities, making them ideal for a range of diagnostic tests. Importantly, the consideration of products made from post-consumer recycled (PCR) materials is essential in aligning with sustainability objectives, as these options can markedly diminish environmental impact.

Conversely, metallocene polyethylene sheets are distinguished by their exceptional strength and clarity, offering a compelling alternative to traditional PVC coverings, which often pose environmental challenges. Premium PE sheets are crafted from high-quality polyethylene resins, ensuring outstanding strength, clarity, and durability. The integration of multi-layer sheets further enhances performance by amalgamating various materials to improve barrier properties while reducing weight, a critical factor for efficient packaging solutions.

Moreover, hydrophilic layers are engineered to optimize fluid management, a vital component in ensuring accurate test results. Each type of material presents unique advantages and disadvantages, necessitating careful selection by manufacturers based on their specific diagnostic requirements. It is also crucial to recognize that premium polyethylene sheets may entail higher initial costs and limitations regarding chemical resistance and aesthetics, factors that manufacturers must weigh in their decision-making processes.

Recent innovations in cinema technology, including multi-layer coextrusion, have significantly improved mechanical properties such as puncture resistance and barrier protection against moisture and oxygen. As the market for metallocene polyethylene products expands, their increasing presence in the diagnostics sector signifies a shift toward materials that deliver both performance and sustainability. Evaluating the performance of polyethylene against metallocene polyethylene materials indicates that the latter often provides enhanced durability and clarity, making it a preferred choice for various film for IVD devices applications.

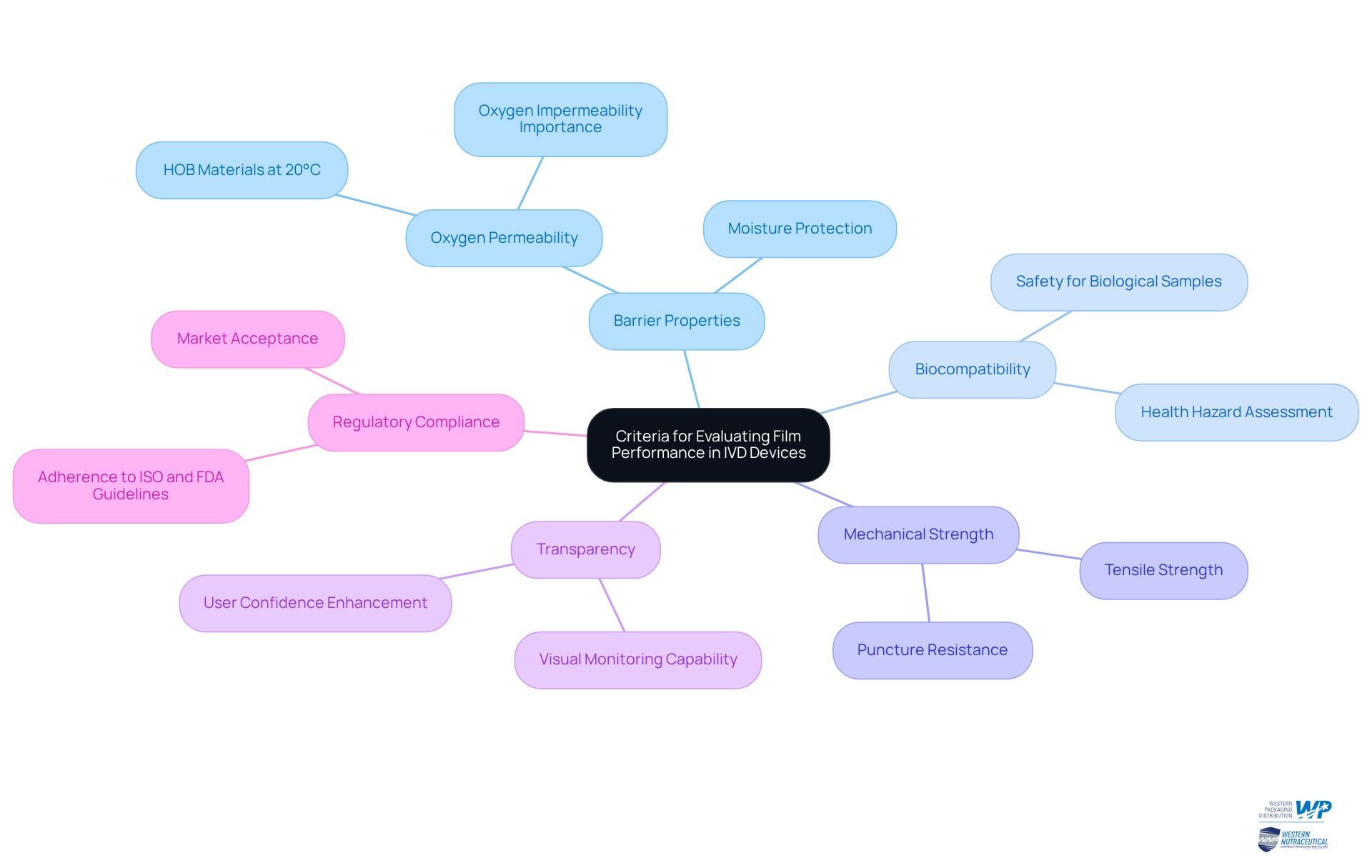

Criteria for Evaluating Film Performance in IVD Devices

When assessing film performance for in vitro diagnostic (IVD) devices, several key criteria must be prioritized:

-

Barrier Properties: Films are required to provide robust protection against moisture, oxygen, and other environmental factors that could jeopardize the integrity of diagnostic samples. Enhanced oxygen impermeability is crucial, as it significantly reduces spoilage and maintains sample stability. For instance, the oxygen permeability of HOB materials at 20°C is 846 cm³/h at 0.1 MPa and 65% RH, demonstrating their effectiveness in preserving sample integrity.

-

Biocompatibility: The substances employed must be safe for interaction with biological samples, ensuring they do not interfere with test outcomes or present any health hazards. Thorough biocompatibility assessment is crucial to verify that the materials fulfill safety criteria for medical purposes.

-

Mechanical Strength: Films should exhibit adequate tensile strength and puncture resistance to endure handling and transportation without tearing or degrading. This is especially important in preserving the integrity of sensitive testing materials during distribution.

-

Transparency: For particular applications, the capability to visualize the sample or test outcomes through the material is essential. High transparency not only aids in monitoring but also enhances user confidence in the diagnostic process.

-

Regulatory Compliance: Films must adhere to relevant industry standards and regulations, such as ISO and FDA guidelines, to ensure safety and efficacy. Compliance with these standards is critical for market acceptance and trust in the product.

By carefully assessing these criteria, manufacturers can choose film for IVD devices that not only meet technical requirements but also improve the overall performance and reliability of their products. As Giorgio Borreani noted, "The primary aim of creating a new biodegradable plastic layer to cover silage is to achieve a material that remains stable against microbial and hydrolysis activities for extended durations exceeding 8 months under natural rain- and sun-exposed conditions, along with a high impermeability to oxygen." This highlights the importance of barrier properties in ensuring the longevity and effectiveness of packaging solutions.

Comparative Analysis of Top Film Options for IVD Devices

In comparing the top film options for IVD devices, several factors come into play:

-

Polyethylene Films: Known for their flexibility and moisture resistance, these films are cost-effective but may lack the strength required for more demanding applications. According to Kalorama Information, while polyethylene materials are widely utilized, they may not satisfy the stringent requirements of high-performance environments.

-

Metallocene Polyethylene Sheets: These materials provide exceptional strength and clarity, rendering them perfect for high-performance applications. Although they typically come at a higher cost compared to standard polyethylene, their enhanced properties justify the investment for many IVD manufacturers. Case studies have demonstrated that metallocene polyethylene materials significantly enhance diagnostic capabilities, particularly in settings demanding strict regulatory compliance.

-

Multi-layer Sheets: Merging different substances, these sheets offer improved barrier characteristics and decreased weight, rendering them appropriate for a broad spectrum of IVD applications. However, their complexity can lead to higher manufacturing costs, which may be a consideration for budget-conscious projects. The integration of multiple materials can also enhance the overall performance metrics, as noted in recent industry reports.

-

Hydrophilic Membranes: Crafted for optimal fluid management, these materials are essential for applications requiring precise sample handling. They excel in performance, but their specialized nature may limit availability in the market. As emphasized in recent progress in laboratory automation, hydrophilic coatings are becoming increasingly significant in diagnostics.

-

PVC Sheets: Although historically favored, PVC sheets encounter examination due to ecological issues. They offer good performance but may not align with sustainability goals. The shift towards more sustainable materials is becoming a priority for many manufacturers, as noted in industry discussions.

Each category of media presents unique advantages and challenges, and the choice ultimately depends on the specific requirements of the IVD application, including performance, cost, and regulatory compliance. For instance, metallocene polyethylene film for IVD devices has been highlighted in case studies for its effectiveness, showcasing its potential to enhance diagnostic capabilities while meeting stringent regulatory demands.

Conclusion

The exploration of film materials for in vitro diagnostic (IVD) devices underscores the critical role these substances play in ensuring accurate and reliable test results. Selecting the appropriate film transcends a mere technical decision; it significantly influences the efficiency and effectiveness of diagnostic processes. As advancements continue to shape the landscape of IVD technology, understanding the nuances of different film types becomes essential for manufacturers striving to meet both performance and regulatory standards.

Key insights from the comparative analysis reveal the strengths and weaknesses of various film materials, including:

- polyethylene

- metallocene polyethylene

- multi-layer sheets

- hydrophilic membranes

- traditional PVC

Each option offers unique advantages tailored to specific applications, whether it’s flexibility, moisture resistance, or optimal fluid management. It is evident that advancements in material science are not only enhancing the performance metrics of IVD devices but also aligning with sustainability goals—a crucial consideration for modern manufacturers.

Ultimately, the choice of film materials for IVD devices must be approached with careful consideration of specific diagnostic requirements, cost implications, and regulatory compliance. As the industry progresses, embracing innovative materials will be vital for improving diagnostic capabilities and ensuring the safety and efficacy of medical testing. Stakeholders are encouraged to stay informed about emerging trends and technologies to make well-informed decisions that will shape the future of in vitro diagnostics.

Frequently Asked Questions

What are IVD devices and their purpose?

In vitro testing (IVD) devices are medical instruments that analyze samples from the human body, such as blood or tissue, to identify diseases or conditions.

Why is the selection of substances in IVD devices important?

The selection of substances is crucial as they serve as protective barriers, facilitate sample handling, and preserve the integrity of the testing process.

What regulatory standards must the film for IVD devices meet?

The film for IVD devices must comply with rigorous regulatory standards, ensuring biocompatibility and resilience against various environmental conditions.

How have advancements in media materials impacted IVD devices?

Recent advancements, such as engineered advanced polymer membranes, have improved sensitivity and specificity, leading to more dependable diagnostic results.

What is the significance of biodegradable materials in IVD devices?

Biodegradable materials can reduce environmental impact while maintaining performance standards, making them appealing to eco-conscious consumers.

How much can the appropriate substance enhance the reliability of IVD devices?

The appropriate substance can enhance the overall reliability of IVD devices by as much as 30%.

What factors should be considered when selecting substances for IVD devices?

Understanding the intended application and user needs is vital for selecting suitable substances, as these directly influence the device's efficiency in clinical settings.

Why is the integration of cutting-edge materials important in IVD technology?

The integration of advanced materials in film for IVD devices is crucial for advancing testing capabilities and ensuring compliance with regulatory standards.