Overview

This article presents a compelling comparison between flexible packaging and traditional packaging for nutraceuticals, asserting that flexible packaging is increasingly favored due to its cost-effectiveness, sustainability, and superior shelf life. Evidence supports this preference, demonstrating that flexible packaging:

- Utilizes less material

- Aligns with growing consumer demand for eco-friendly options

- Offers enhanced protection for sensitive products

Consequently, it emerges as a strategic choice for manufacturers navigating a competitive market landscape.

Introduction

The ongoing evolution of packaging solutions is fundamentally reshaping the nutraceutical industry. The choice between flexible and traditional packaging is not merely a matter of preference; it can significantly impact product quality and consumer appeal. Flexible packaging, characterized by its lightweight and adaptable materials, is rapidly gaining traction. This trend is driven by its cost-effectiveness and sustainability features, which are increasingly important in today’s market. Conversely, traditional packaging methods, while offering robust protection, often come with higher costs and environmental concerns. As manufacturers navigate this critical decision, one must consider:

- Can flexible packaging truly outperform traditional methods in meeting the demands of both consumers and the environment?

Define Flexible and Traditional Packaging

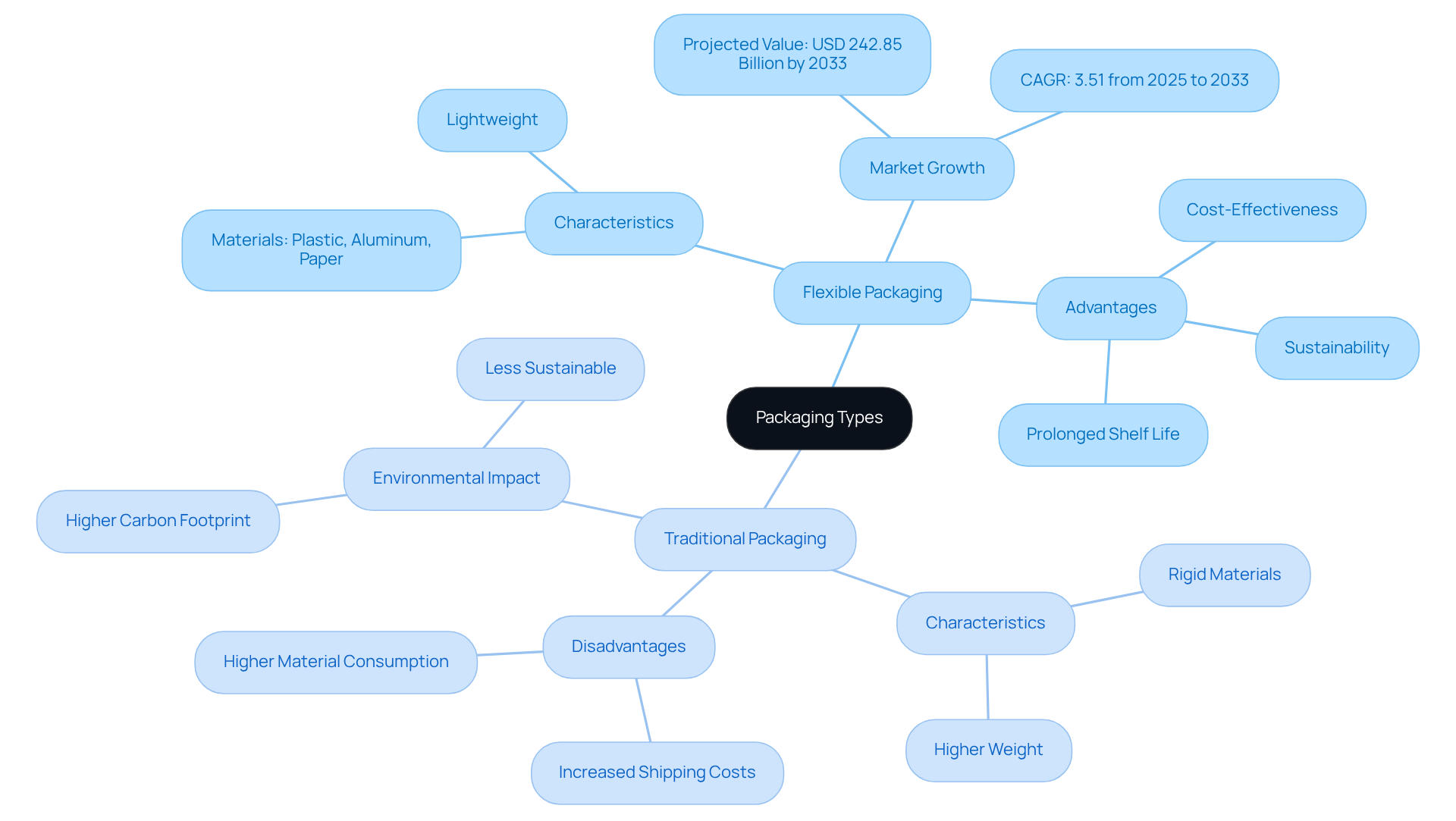

Flexible packaging signifies containers made from non-rigid materials that can easily change shape, such as pouches, films, and bags. This type of flexible packaging is lightweight and is typically constructed from materials like plastic, aluminum, or paper, which are designed to maximize versatility and efficiency in space and resource utilization. The global flexible containers market is anticipated to reach USD 242.85 billion by 2033, with a compound annual growth rate (CAGR) of 3.51% from 2025 to 2033, underscoring its increasing significance across various sectors, including nutraceuticals.

Conversely, conventional containers are generally made from rigid materials such as glass jars, metal cans, and cardboard boxes. These materials are engineered to offer a robust barrier against environmental influences but often lead to higher material consumption and weight, which can adversely affect shipping and storage efficiency. For instance, while traditional wrapping offers strong protection, it may incur higher shipping costs due to its increased weight.

Moreover, flexible packaging delivers considerable advantages for nutraceuticals, including cost-effectiveness and prolonged shelf life, which are crucial for maintaining product quality. As the industry shifts towards more sustainable practices, the lightweight nature of flexible packaging contributes to reducing carbon footprints, aligning with consumer demands for eco-friendly alternatives. This growing focus on environmental sustainability is driving innovation and acceptance within the flexible packaging market, positioning it as a compelling choice for nutraceutical manufacturers.

Explore Advantages of Flexible Packaging for Nutraceuticals

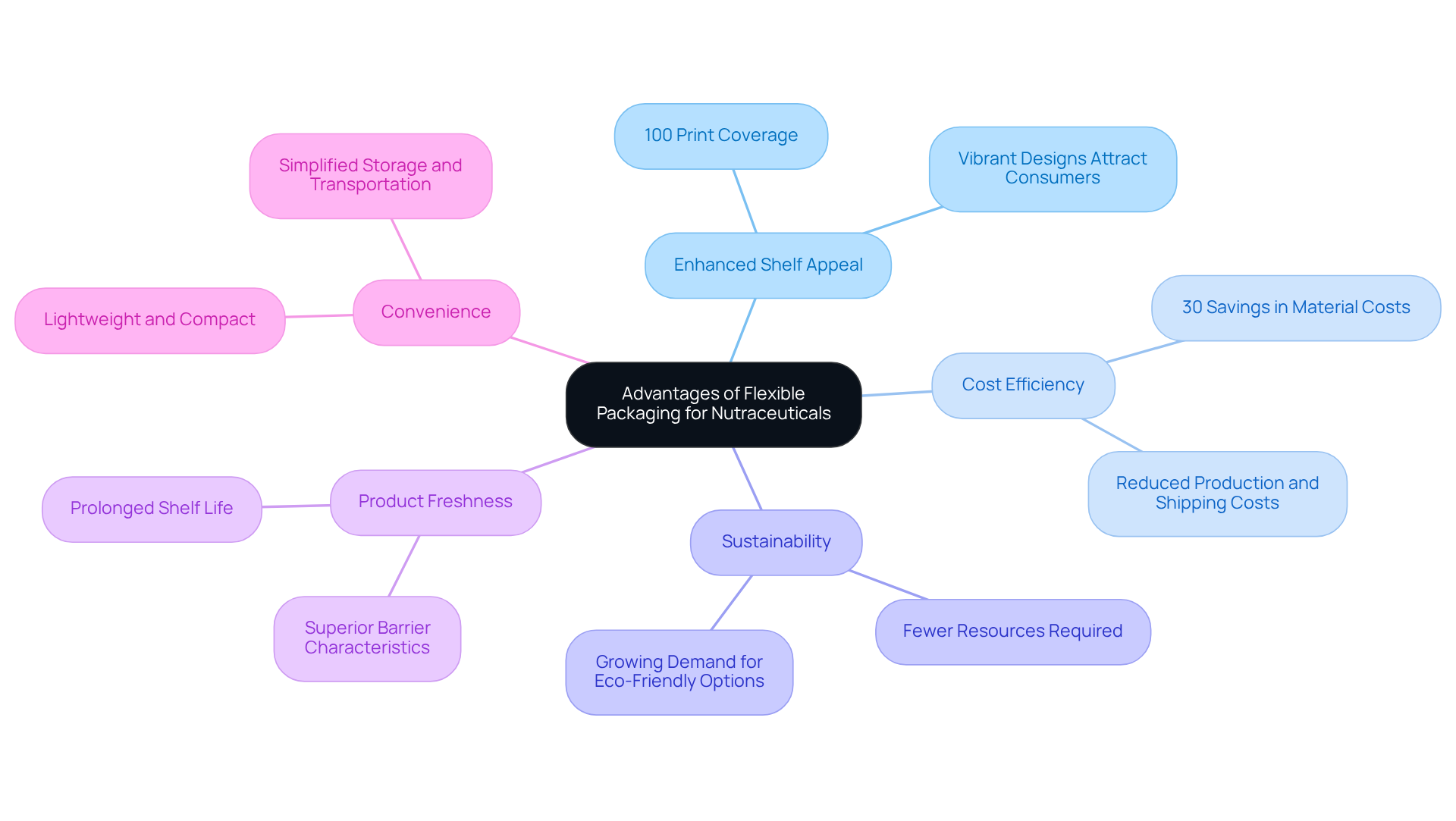

Flexible packaging offers a multitude of advantages for nutraceutical products, establishing itself as a preferred choice within the industry. The key benefits include:

- Enhanced Shelf Appeal: With the capability for 100% print coverage, flexible packaging enables vibrant and eye-catching designs that significantly attract consumers, thereby enhancing brand visibility on shelves.

- Cost Efficiency: This container solution typically utilizes less material compared to conventional options, resulting in reduced production and shipping costs. Companies have reported savings of up to 30% in material costs after transitioning to flexible packaging solutions.

- Sustainability: Flexible packaging materials often require fewer resources to create and produce less waste, which aligns with the growing consumer demand for eco-friendly items. The shift towards recyclable and biodegradable materials is increasingly important in the nutraceutical sector, as consumer preference for sustainable options continues to rise.

- Product Freshness: The superior barrier characteristics of adaptable materials effectively safeguard items from moisture, oxygen, and light, thereby prolonging shelf life and maintaining product quality. This is crucial for ensuring the efficacy of dietary supplements and functional foods.

- Convenience: Lightweight and compact, adaptable wrapping simplifies storage and transportation, contributing to lower carbon footprints. This convenience is particularly appealing in the e-commerce landscape, where efficient shipping is essential.

As the nutraceutical industry continues to advance, the demand for flexible packaging solutions is anticipated to increase notably. The worldwide nutraceutical container market is expected to expand at a CAGR of 6.9% over the next decade. Approximately 74% of adults in the U.S. regularly take dietary supplements, highlighting the market's potential. Businesses that adopt adaptable wrapping not only enhance their operational efficiency but also position themselves advantageously in a competitive market. For instance, Berry Global's launch of lightweight closures and Wonderfeel's biodegradable pouches exemplify effective applications of flexible packaging solutions. By embracing these innovations, companies can meet consumer demands while contributing to sustainability efforts.

Analyze Limitations of Traditional Packaging

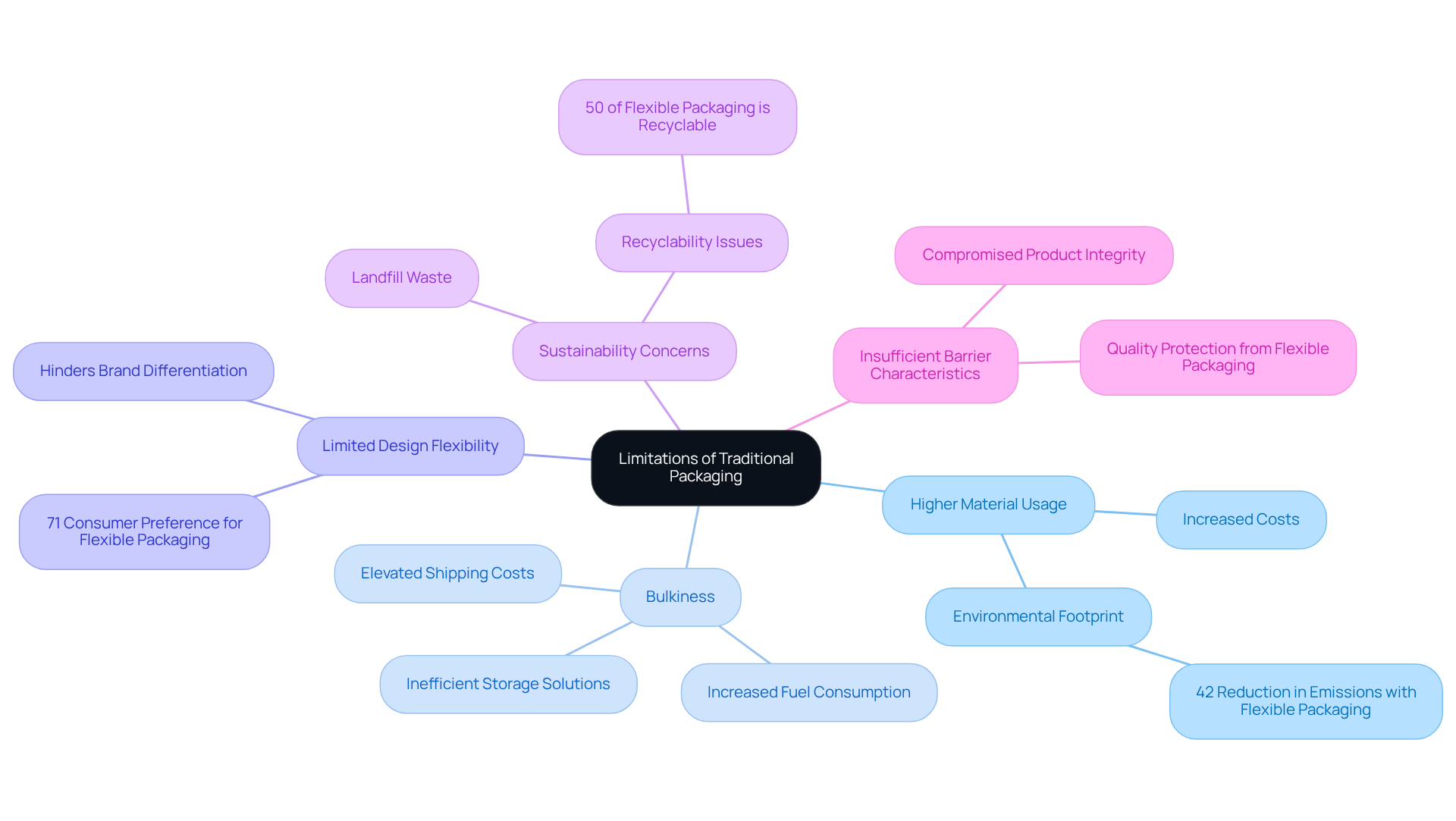

Traditional packaging presents several significant limitations that can adversely affect the effectiveness of nutraceutical products:

- Higher Material Usage: Rigid packaging typically necessitates more material, escalating costs and amplifying its environmental footprint. This increased material usage contributes to higher production costs and greater waste generation. Notably, the shift to flexible packaging can reduce greenhouse gas emissions by as much as 42% during transportation, emphasizing the shortcomings of conventional methods.

- Bulkiness: The inherent bulkiness and weight of conventional containers lead to elevated shipping costs and inefficient storage solutions. This inefficiency strains logistics, particularly for businesses aiming to optimize their supply chains. In contrast, flexible packaging is lighter and allows for more items to be transported per truckload, thereby decreasing fuel consumption and CO2 emissions.

- Limited Design Flexibility: The rigid structure of conventional containers restricts creative design possibilities, hindering brand differentiation in a competitive market. This limitation affects consumer perception and engagement with the product. According to a Harris Poll, 71% of respondents favor flexible packaging over rigid choices, indicating a significant shift in consumer preference.

- Sustainability Concerns: Many traditional containers lack recyclability, resulting in substantial landfill waste and environmental degradation. This issue is increasingly problematic as consumers demand more sustainable options. The Packaging Association observes that approximately 50% of flexible packaging made from pliable plastics is easily recyclable, contrasting sharply with conventional materials.

- Insufficient Barrier Characteristics: Although conventional wrapping provides a certain degree of protection, it frequently underperforms in barrier effectiveness compared to adaptable options. This inadequacy can compromise the integrity of items, particularly for sensitive nutraceuticals that require optimal protection from moisture, light, and oxygen. Quality flexible packaging materials provide excellent barrier protection against heat, odors, oxygen, and light, minimizing spoilage and food waste.

Compare Suitability of Packaging Types for Nutraceutical Products

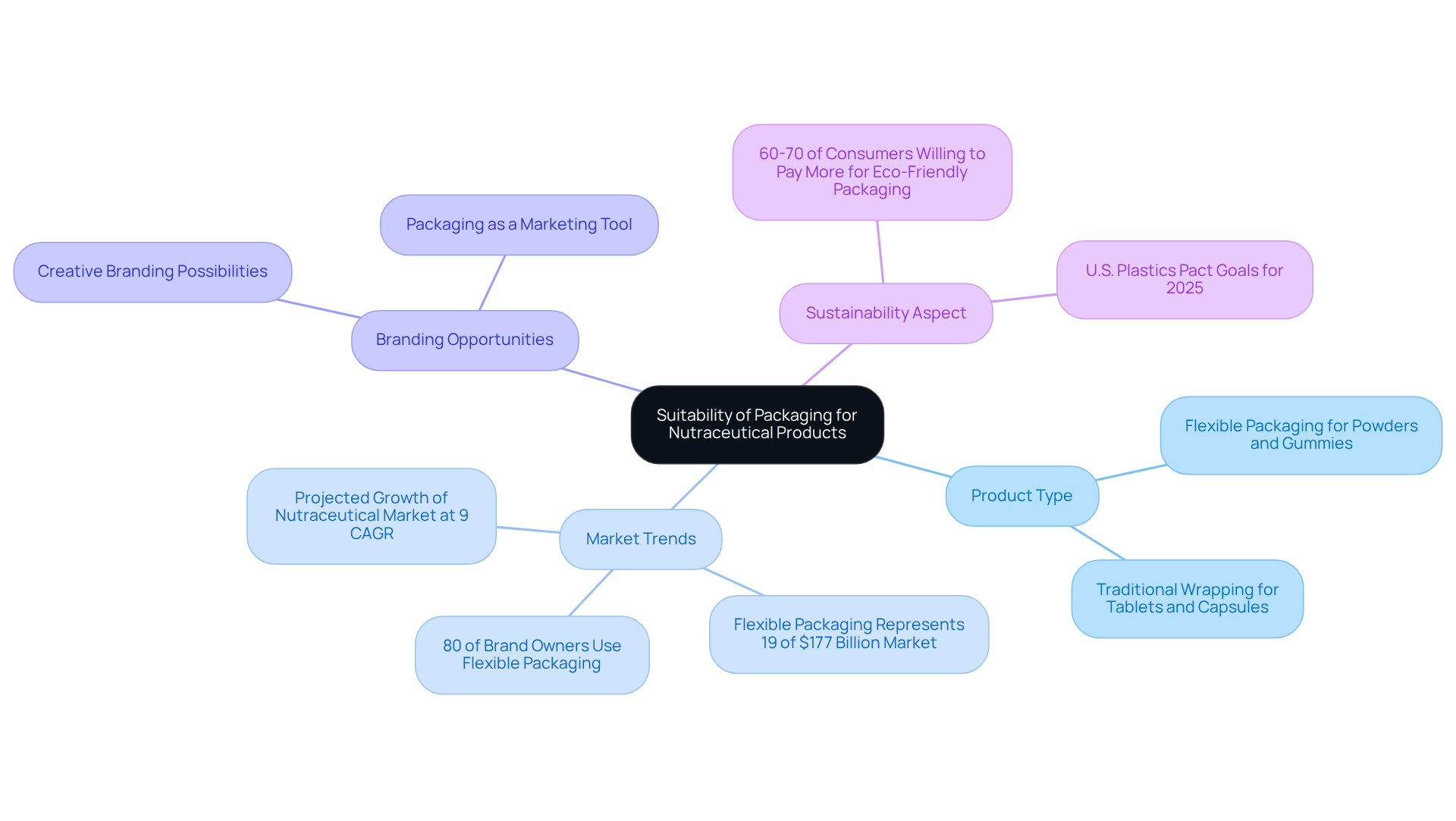

When evaluating the suitability of packaging types for nutraceutical products, several critical factors emerge:

- Product Type: Flexible packaging excels for powders, gummies, and soft gels, as it can be customized to safeguard sensitive ingredients effectively. In contrast, traditional wrapping is often more suitable for solid forms like tablets or capsules that necessitate sturdier containment.

- Market Trends: The nutraceutical sector is experiencing a notable transition towards sustainability, with adaptable containers harmonizing effortlessly with these consumer needs. In fact, over 80% of brand owners currently employ adaptable materials, and 31% intend to enhance its usage in the upcoming years, reflecting a wider industry trend. Significantly, adaptable wrapping accounts for 19% of the $177 billion US container market, highlighting its increasing significance. Cost considerations show that for manufacturers aiming to optimize costs, flexible packaging typically presents a more economical solution, particularly for high-volume products. This cost-effectiveness is crucial as the global nutraceutical market, valued at $454 billion in 2021, is projected to grow at a CAGR of 9% through 2030.

- Branding Opportunities: Flexible packaging provides improved creative branding possibilities, enabling brands to differentiate themselves on shelves and connect with consumers more effectively. This is especially crucial since the wrapping acts not only as a protective barrier but also as a strong marketing instrument that can affect buying choices.

- Sustainability Aspect: With 60-70% of US consumers willing to pay more for eco-friendly materials, the adaptability of these options' alignment with these preferences is a significant advantage. Moreover, the U.S. Plastics Pact targets 100% of plastic containers to be reusable, recyclable, or compostable by 2025, highlighting the significance of sustainability in selection choices.

In summary, the nutraceutical sector increasingly favors flexible packaging because of its adaptability, cost efficiency, and alignment with sustainability trends, making it a compelling choice for manufacturers aiming to enhance their product offerings.

Conclusion

Flexible packaging has emerged as a transformative force in the nutraceutical industry, offering advantages that traditional packaging cannot match. By prioritizing adaptability, cost-effectiveness, and sustainability, flexible packaging positions itself as the preferred choice for manufacturers seeking to meet evolving consumer demands and enhance product quality.

Key insights reveal that flexible packaging not only enhances shelf appeal and product freshness but also significantly reduces material usage and shipping costs. The shift towards eco-friendly practices is reinforced by the growing consumer preference for sustainable options, highlighting the limitations of traditional packaging, which often incurs higher material consumption and environmental impact. Additionally, the versatility of flexible packaging allows for innovative branding opportunities, enabling brands to stand out in a competitive marketplace.

As the nutraceutical sector evolves, embracing flexible packaging is essential for companies aiming to thrive in an increasingly sustainability-conscious environment. By recognizing the benefits of flexible packaging and the challenges posed by traditional methods, manufacturers can make informed decisions that enhance operational efficiency and contribute positively to the planet. Transitioning to flexible packaging is a crucial step towards aligning with consumer preferences and ensuring long-term success in the nutraceutical market.

Frequently Asked Questions

What is flexible packaging?

Flexible packaging refers to containers made from non-rigid materials that can easily change shape, such as pouches, films, and bags. It is lightweight and typically constructed from materials like plastic, aluminum, or paper.

What are the benefits of flexible packaging?

Flexible packaging offers advantages such as cost-effectiveness, prolonged shelf life, and reduced carbon footprints, making it appealing for industries like nutraceuticals.

How does the flexible packaging market project to grow?

The global flexible containers market is expected to reach USD 242.85 billion by 2033, with a compound annual growth rate (CAGR) of 3.51% from 2025 to 2033.

What is traditional packaging?

Traditional packaging generally consists of rigid materials such as glass jars, metal cans, and cardboard boxes, which provide strong barriers against environmental influences but often result in higher material consumption and weight.

What are the drawbacks of traditional packaging?

Traditional packaging can lead to higher shipping costs due to its increased weight and may not be as efficient in space and resource utilization compared to flexible packaging.

Why is flexible packaging becoming more popular among nutraceutical manufacturers?

Flexible packaging is gaining popularity among nutraceutical manufacturers due to its cost-effectiveness, ability to maintain product quality through prolonged shelf life, and alignment with the industry's shift toward sustainable practices.