Overview

This article delivers comprehensive, step-by-step instructions on the proper method for opening a sterile package, underscoring the critical need to maintain sterility throughout the entire process. It begins by establishing a clean workspace, utilizing sterile gloves, and adhering to specific techniques tailored for various types of packaging. These essential preparation steps are designed to prevent contamination and ensure the safety of the contained products. By following these guidelines, readers can confidently uphold the highest standards of sterility in their operations.

Introduction

Understanding the nuances of sterile packaging is critical in industries where safety and efficacy are paramount. The rise of contamination risks makes it imperative to know how to properly open a sterile package; this is not merely a procedural step—it serves as a safeguard against potential health hazards. However, many individuals encounter challenges when navigating this process.

What are the best practices to ensure that sterility is maintained while opening these packages? How can one effectively troubleshoot common issues that arise? This guide delves into the essential steps and considerations for successfully opening sterile packages while upholding the highest standards of cleanliness.

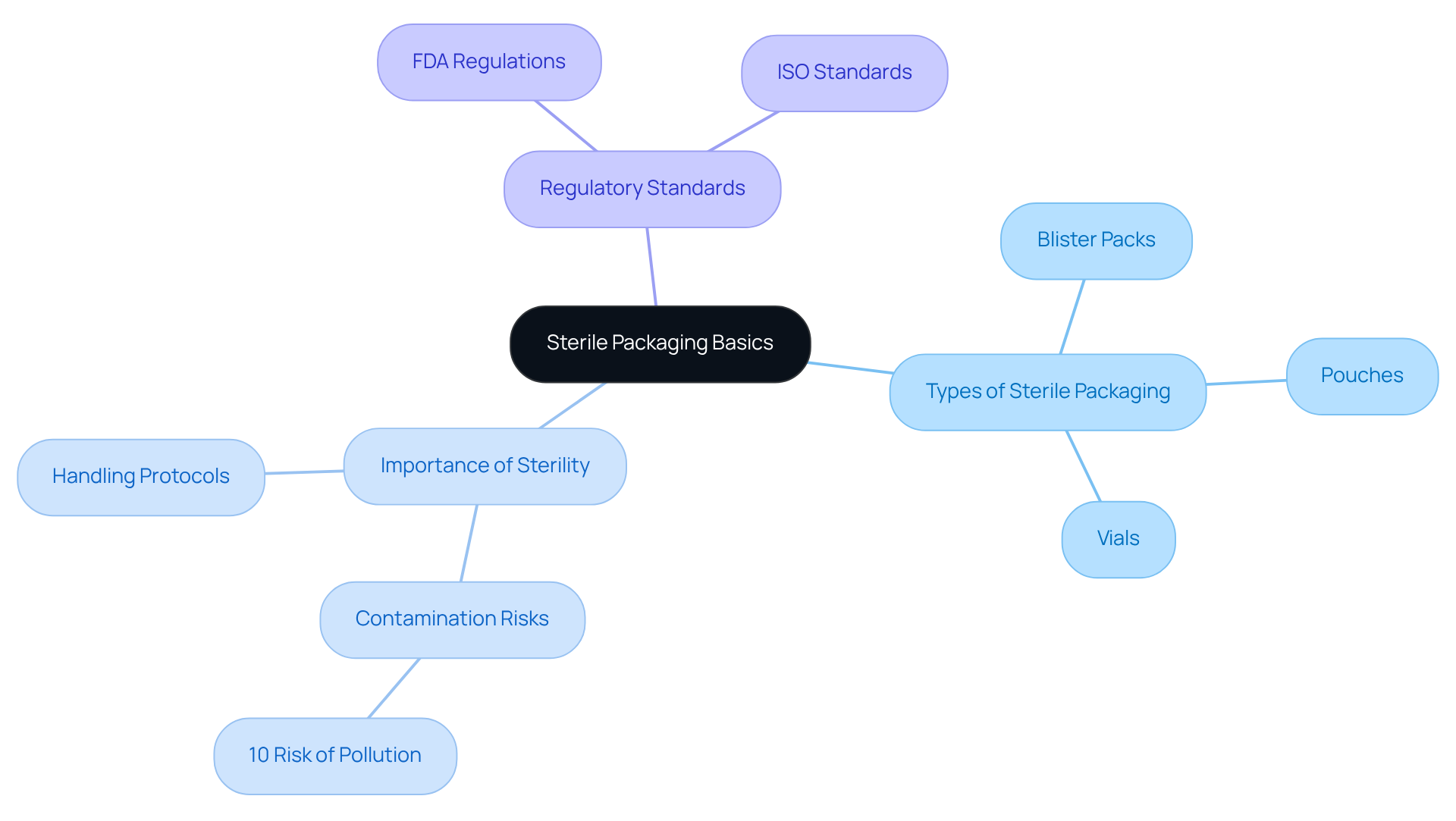

Understand Sterile Packaging Basics

Sterile wrapping is essential for safeguarding products against impurities, ensuring their safety and efficacy in the medical, pharmaceutical, and nutraceutical sectors. Key components of sterile packaging include:

-

Types of Sterile Packaging: Common formats, such as blister packs, pouches, and vials, are meticulously designed to protect contents from environmental factors, thus preserving their integrity. In 2023, blister packs represented a substantial share of the market, driven by their proven effectiveness in preventing contamination. Notably, the Pharmaceutical & Biologics segment accounted for over 31.5% of the Sterile Medical Container Market, underscoring the critical role these container types play in the industry.

-

Importance of Sterility: The imperative of maintaining sterility cannot be overstated, particularly for items intended for ingestion or application to the body. Contamination can lead to severe health risks, with studies indicating that approximately 10% of items in clean wrapping may be affected by pollution if not handled properly. This highlights the urgent need for rigorous handling protocols. Moreover, chemical sterilization comprised more than 45% of the Sterile Medical Packaging Market in 2023, demonstrating the efficacy of sterilization methods in averting contamination.

-

Regulatory Standards: It is crucial to be well-versed in the regulations governing hygienic encasement, such as those established by the FDA and ISO. Stringent regulatory standards for hygienic packaging solutions guarantee that packaging meets safety and efficacy benchmarks, which is especially vital in the nutraceutical sector where consumer health is of utmost importance.

By comprehending these fundamental elements, one can truly appreciate the significance of employing proper methods when considering how a sterile package is opened, which ultimately enhances the safety and effectiveness of the products contained within.

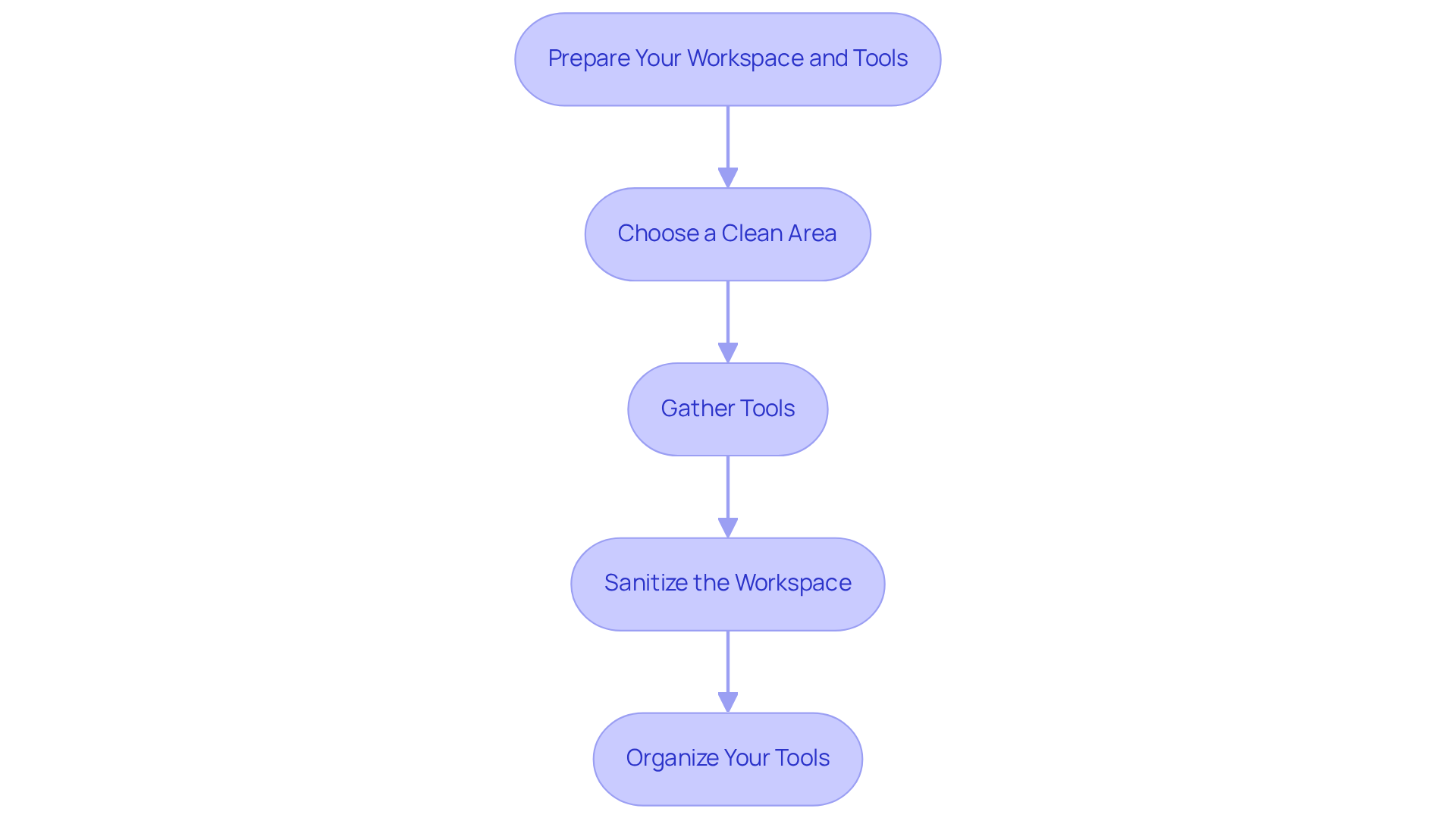

Prepare Your Workspace and Tools

Before opening a clean package, it is crucial to prepare your workspace and gather the necessary tools. Follow these steps to ensure a successful process:

- Choose a Clean Area: Select a flat, clean surface that is free from dust and contaminants. Ideally, this should be a designated area for managing clean products.

- Gather Tools: Collect the following tools:

- Sterile gloves to prevent contamination.

- Scissors or a clean cutting tool, if needed.

- A waste container for disposing of packaging materials.

- Sanitize the Workspace: Wipe down the surface with a suitable disinfectant to ensure it is clean before you begin.

- Organize Your Tools: Arrange your tools within easy reach to minimize movement and potential contamination during the opening process.

By organizing your workspace and tools, you create an environment conducive to learning how a sterile package is opened safely and efficiently.

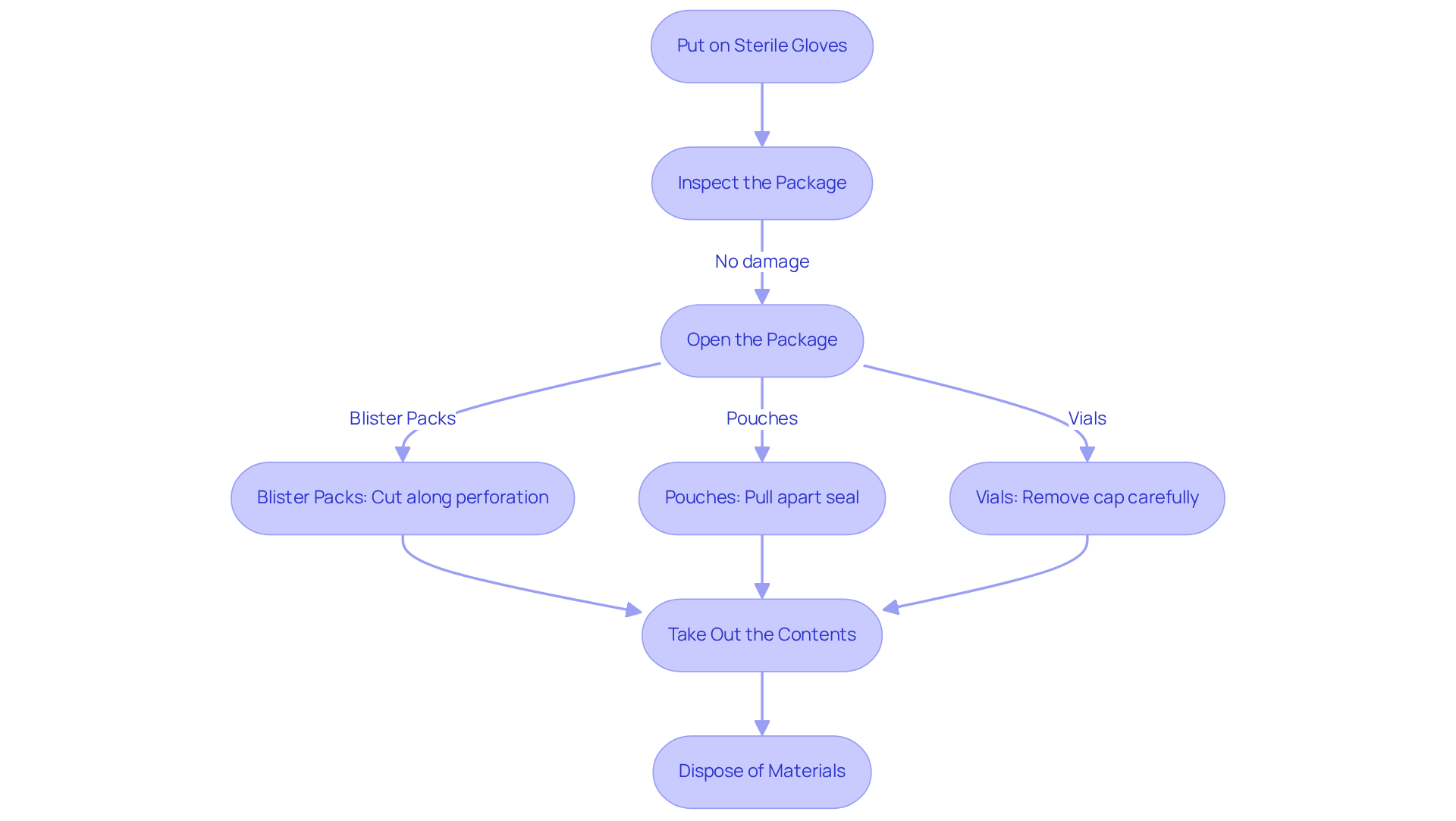

Follow Step-by-Step Instructions to Open the Package

To safely open a sterile package, adhere to the following detailed steps:

- Put on Sterile Gloves: Begin by ensuring your hands are clean and dry before donning sterile gloves. This step is crucial for maintaining a contamination-free environment.

- Inspect the Package: Carefully examine the package for any signs of harm or impurity. If any compromise is found, refrain from using the item, as this could result in impurities.

- Open the Package:

- For blister packs: Use scissors to cut along the designated perforation, taking care not to touch the contents directly.

- For pouches: Hold the pouch by the edges and gently pull apart the seal, ensuring that you do not touch the inside of the pouch.

- For vials: Remove the cap carefully, avoiding contact with the inner surface to maintain sterility.

- Take Out the Contents: After unsealing the package, utilize clean forceps or gloves to carefully extract the item, avoiding direct touch with your hands to prevent pollution.

- Dispose of Materials: Promptly put all wrapping materials in the waste bin to keep a tidy workspace and avoid any risk of pollution.

By following these steps, you can understand how a sterile package is opened to ensure that the sanitized product remains uncontaminated and ready for use. Common mistakes, such as touching the inside of the packaging or failing to inspect for damage, can significantly increase the risk of contamination, underscoring the importance of strict adherence to these best practices.

In the context of the industry, the average annual salary for a Certified Sterile Processing Technician is approximately $45,280, with the Bureau of Labor Statistics projecting 66,790 job openings due to an aging workforce and increased demand for equipment preparers in healthcare settings. This emphasizes the vital role of cleanliness processing technicians in preserving sterility and the significance of appropriate training and compliance with best practices to prevent expensive errors.

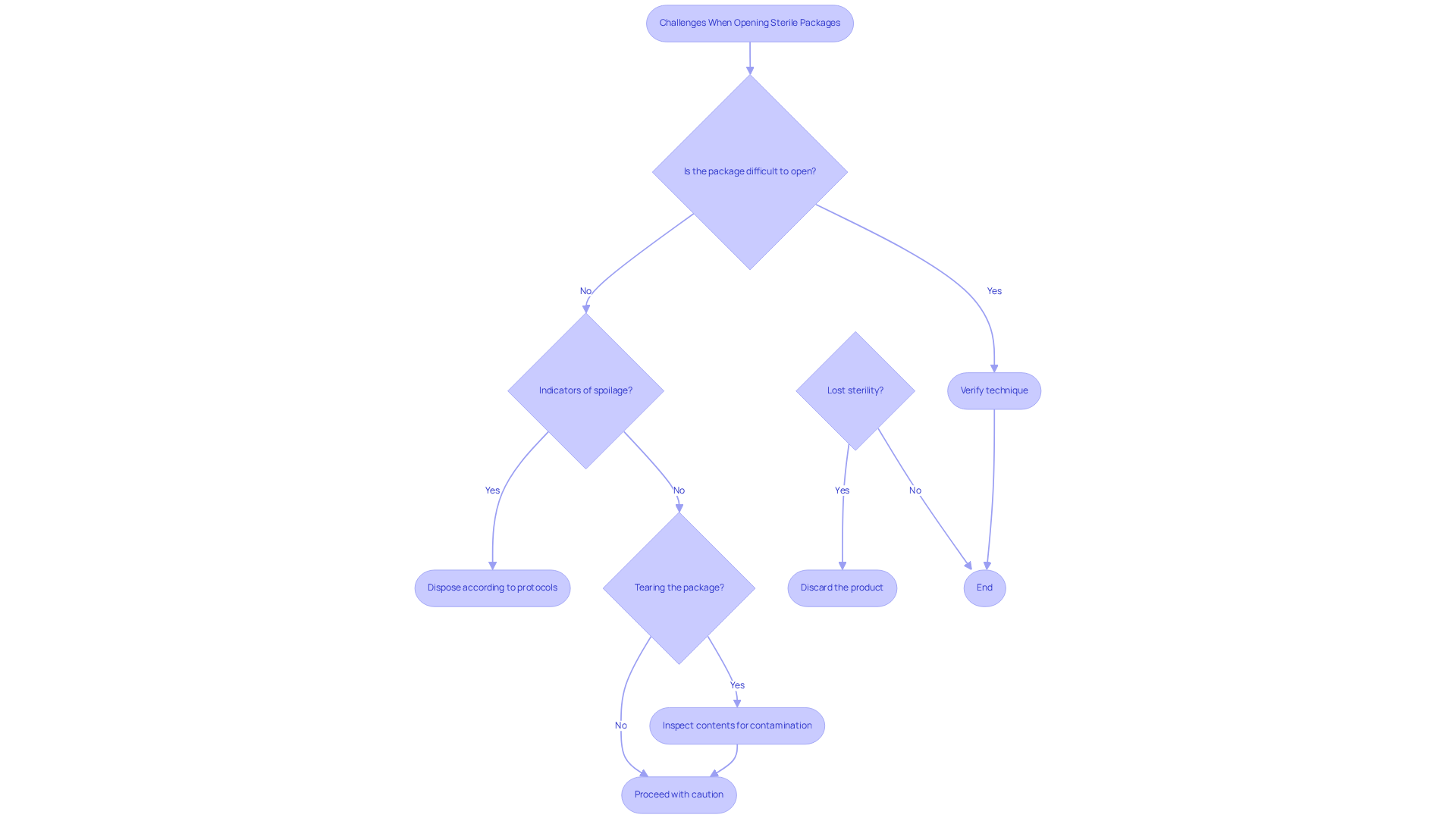

Troubleshoot Common Challenges When Opening Sterile Packages

Despite meticulous preparation, challenges can arise when considering how is a sterile package opened. Understanding these challenges is crucial for maintaining safety and efficiency. Here are some common issues and effective troubleshooting strategies:

- Package is Difficult to Open: If you encounter resistance, verify that you are employing the correct technique. For blister packs, carefully cut along the perforation to avoid damaging the contents.

- Indicators of Spoilage: If you notice any indicators of spoilage, refrain from using the item. Dispose of it according to your facility's established protocols to prevent infection risks.

- Tearing the Package: In the event of an unexpected tear, inspect the contents for contamination. If the item appears undisturbed, proceed with caution while wearing clean gloves to ensure safety.

- Lost Sterility: If you inadvertently touch the inside of the package, discard the product immediately to uphold safety standards.

Awareness of these challenges and knowing how is a sterile package opened can ensure a safe and efficient opening process for sterile packages. Ongoing observation of wrapping practices is crucial, as studies indicate that mistakes linked to visualization account for 88.6% of all surgical instrument errors, with over 50% of both inpatient and outpatient cases experiencing delays due to such errors. As Peter Nichol MD/PhD emphasizes, "Identification and correction of these errors are important for improving surgical quality and safety." Furthermore, a case study titled "Factors Associated with Deficiencies in Packaging of Surgical Instruments" highlights significant factors contributing to packaging defects, underscoring the importance of addressing these challenges. Additionally, research shows that larger pouches had significantly higher contamination rates (14.7% for large pouches compared to 6.0% for small pouches), illustrating how pouch size impacts contamination risk during aseptic presentation.

Conclusion

Understanding how to properly open a sterile package is paramount for maintaining the integrity and safety of medical, pharmaceutical, and nutraceutical products. The meticulous process of unwrapping these packages transcends mere convenience; it is a critical step in safeguarding against contamination that could compromise health and efficacy.

Throughout this discussion, essential points have been highlighted, including:

- The importance of sterile packaging types

- The necessity of a clean workspace

- Step-by-step instructions for opening packages without introducing impurities

Common challenges that may arise during the process have also been addressed, emphasizing the need for awareness and adherence to best practices to mitigate risks. Furthermore, the role of compliance with regulatory standards and the significant impact of training in sterile processing have been underscored, reinforcing the importance of these practices in healthcare settings.

Ultimately, the significance of mastering the technique of opening sterile packages cannot be overstated. It is crucial not only for individual safety but also for the broader implications it holds for public health. By implementing the outlined steps and remaining vigilant against potential challenges, individuals can contribute to a safer healthcare environment. Embracing these best practices ensures that the integrity of sterile products is preserved, thereby enhancing their effectiveness and protecting those who rely on them.

Frequently Asked Questions

What is the purpose of sterile packaging?

Sterile packaging is essential for safeguarding products against impurities, ensuring their safety and efficacy in the medical, pharmaceutical, and nutraceutical sectors.

What are the common types of sterile packaging?

Common formats of sterile packaging include blister packs, pouches, and vials, which are designed to protect contents from environmental factors and preserve their integrity.

Why is sterility important in packaging?

Maintaining sterility is crucial, especially for items intended for ingestion or application to the body, as contamination can lead to severe health risks. Studies show that approximately 10% of items in clean wrapping may be affected by pollution if not handled properly.

What role does chemical sterilization play in sterile packaging?

Chemical sterilization accounted for more than 45% of the Sterile Medical Packaging Market in 2023, highlighting its effectiveness in preventing contamination.

What regulatory standards should be considered for sterile packaging?

It is important to be familiar with regulations established by organizations such as the FDA and ISO, which ensure that hygienic packaging solutions meet safety and efficacy benchmarks, particularly in the nutraceutical sector.

How does understanding sterile packaging contribute to product safety?

By comprehending the fundamental elements of sterile packaging, one can appreciate the significance of proper methods for opening sterile packages, ultimately enhancing the safety and effectiveness of the products contained within.