Overview

When selecting the right supplement packaging manufacturers, it is essential to focus on critical criteria. Key factors include:

- Their experience in the nutraceutical sector

- Strict adherence to certifications such as cGMP

- Their capability to provide customized packaging solutions

These elements are not merely recommendations; they are foundational to ensuring quality, compliance with industry standards, and alignment with your brand's unique needs and goals. By prioritizing these criteria, you position your brand for success in a competitive market.

Introduction

Selecting the right supplement packaging manufacturer is pivotal for a brand's success in the fiercely competitive nutraceutical market. With countless options at your disposal, grasping the essential criteria for choosing a partner is vital for ensuring product quality, compliance, and market appeal. Amidst the complexities of customization, sustainability, and regulatory standards, brands must confidently navigate this intricate landscape. The challenge lies in identifying a manufacturer that aligns with their unique needs and goals, ensuring not just compatibility but also a strategic advantage in the marketplace.

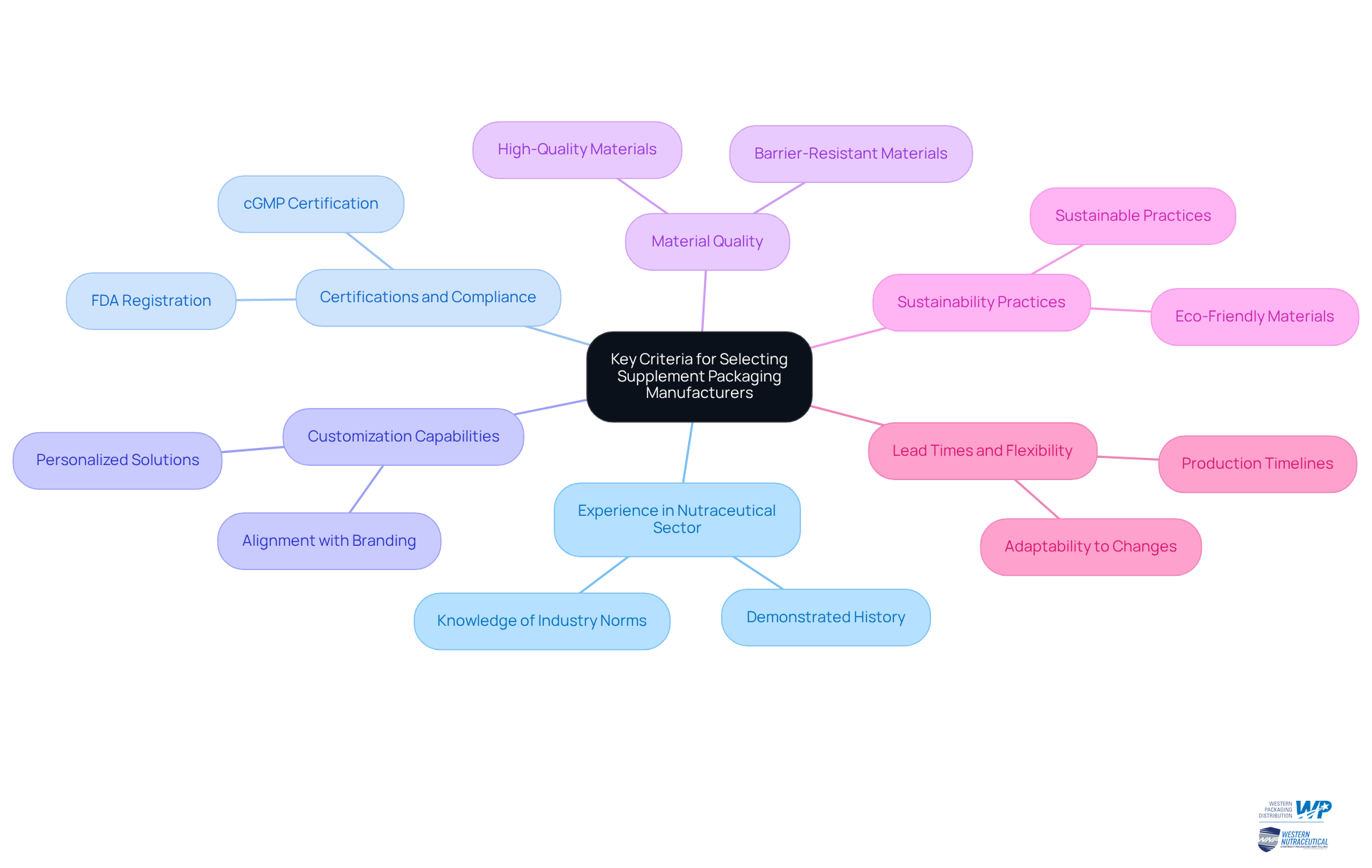

Identify Key Criteria for Selecting Supplement Packaging Manufacturers

To effectively choose a supplement packaging manufacturer, consider the following key criteria:

-

Experience in the Nutraceutical Sector: Seek producers with a demonstrated history in creating packaging for dietary supplements. Their knowledge of industry norms can greatly influence product excellence.

-

Certifications and Compliance: Ensure that the supplement packaging manufacturers hold relevant certifications, such as cGMP (current Good Manufacturing Practices) and FDA registration. These certifications indicate adherence to quality and safety standards.

-

Customization Capabilities: Evaluate if the supplement packaging manufacturers can provide personalized solutions that align with your distinct branding and product needs.

-

Material Quality: Investigate the types of materials used in packaging by supplement packaging manufacturers. High-quality, barrier-resistant materials are crucial for protecting supplements from environmental factors.

-

Sustainability Practices: Consider supplement packaging manufacturers that prioritize eco-friendly materials and practices, as sustainability is increasingly important to consumers.

-

Lead Times and Flexibility: Evaluate the ability of supplement packaging manufacturers to meet your production timelines and adapt to changes in order volume or specifications.

By concentrating on these criteria, you can simplify your search for an appropriate partner for your materials.

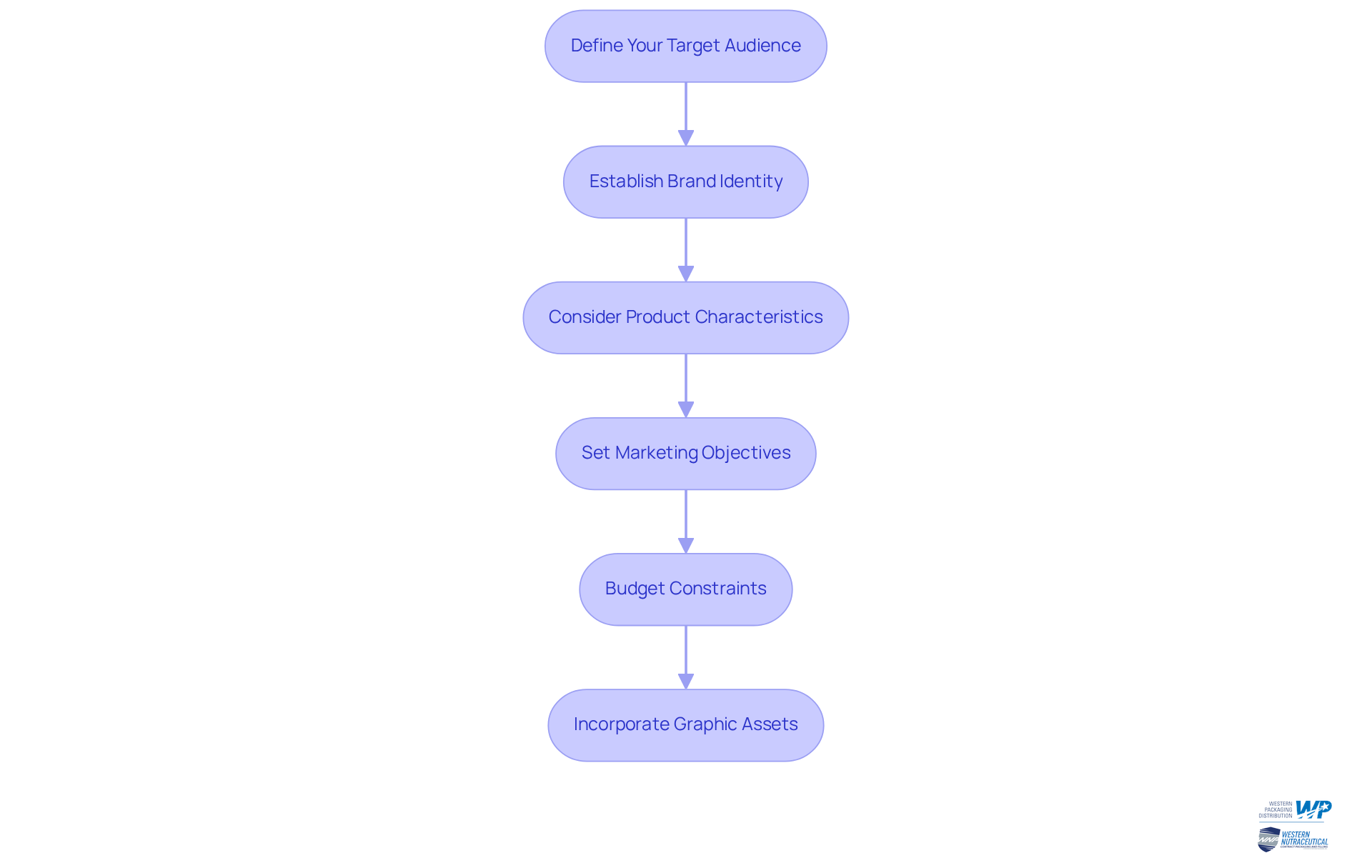

Assess Your Brand's Unique Packaging Needs and Goals

To effectively assess your brand's packaging needs and goals, follow these steps:

-

Define Your Target Audience: Identify your clients and understand their preferences in presentation. This insight will guide your design choices, ensuring alignment with their expectations.

-

Establish Brand Identity: Reflect your brand's personality, values, and mission through your product presentation. Consider color schemes, typography, and overall design aesthetics, which can be enhanced through Western Packaging's innovative design solutions.

-

Consider Product Characteristics: Analyze the specific requirements of your supplements, including dosage forms (capsules, powders, gummies) and any special storage needs (e.g., moisture-sensitive products). Our customized flexible solutions can effectively accommodate these unique characteristics.

-

Set Marketing Objectives: Clearly define your goals for product presentation. This may involve enhancing shelf appeal, improving user experience, or communicating specific health benefits. With Western Packaging's expertise, you can elevate your product's shelf appeal and brand recognition.

-

Budget Constraints: Establish a budget for wrapping that aligns with your overall marketing strategy. Consider both initial expenses and long-term value, ensuring your investment in design yields substantial returns.

-

Incorporate Graphic Assets: Include graphic assets such as labels and brochures in your packaging strategy. These elements are essential for creating a cohesive and captivating brand identity.

By thoroughly evaluating these factors, you can develop a clear plan for your container strategy, ensuring alignment with your brand's objectives while leveraging the innovative solutions provided by supplement packaging manufacturers.

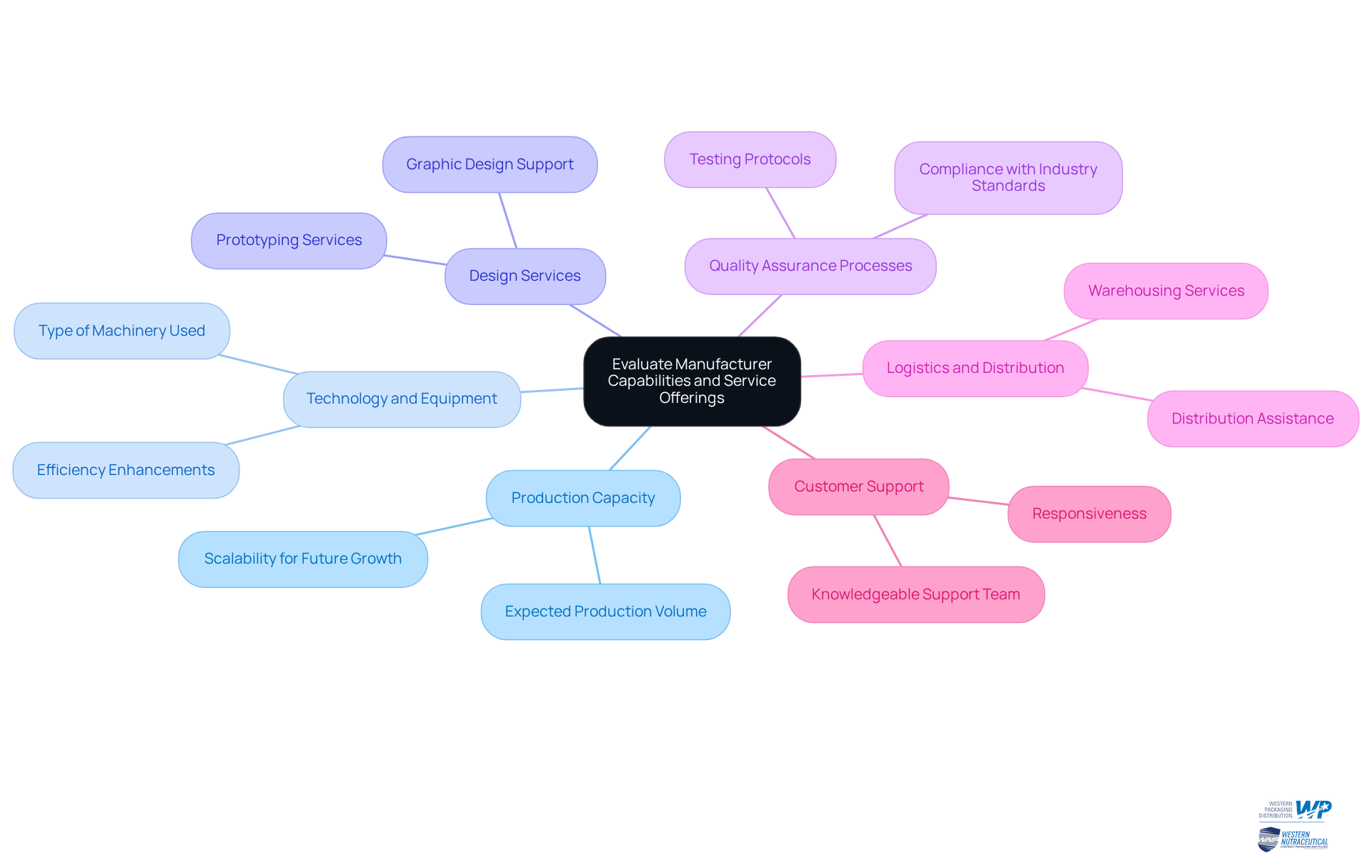

Evaluate Manufacturer Capabilities and Service Offerings

When evaluating potential supplement packaging manufacturers, it is crucial to consider the following capabilities and services:

-

Production Capacity: Assess whether the manufacturer can handle your expected production volume, including scalability for future growth.

-

Technology and Equipment: Inquire about the technology and machinery utilized in the wrapping process. Advanced equipment can significantly enhance efficiency and standards.

-

Design Services: Determine if the producer offers design support, including graphic design and prototyping, to help bring your packaging vision to life.

-

Quality Assurance Processes: Examine the producer's quality control measures, which should include rigorous testing protocols and compliance with industry standards.

-

Logistics and Distribution: Assess if the producer provides logistics assistance, such as warehousing and distribution services, to optimize your supply chain.

-

Customer Support: Consider the level of customer service offered. A responsive and knowledgeable support team can facilitate a smoother collaboration process.

By thoroughly evaluating these factors, you can ensure that the supplement packaging manufacturers you choose are well-equipped to meet your packaging needs.

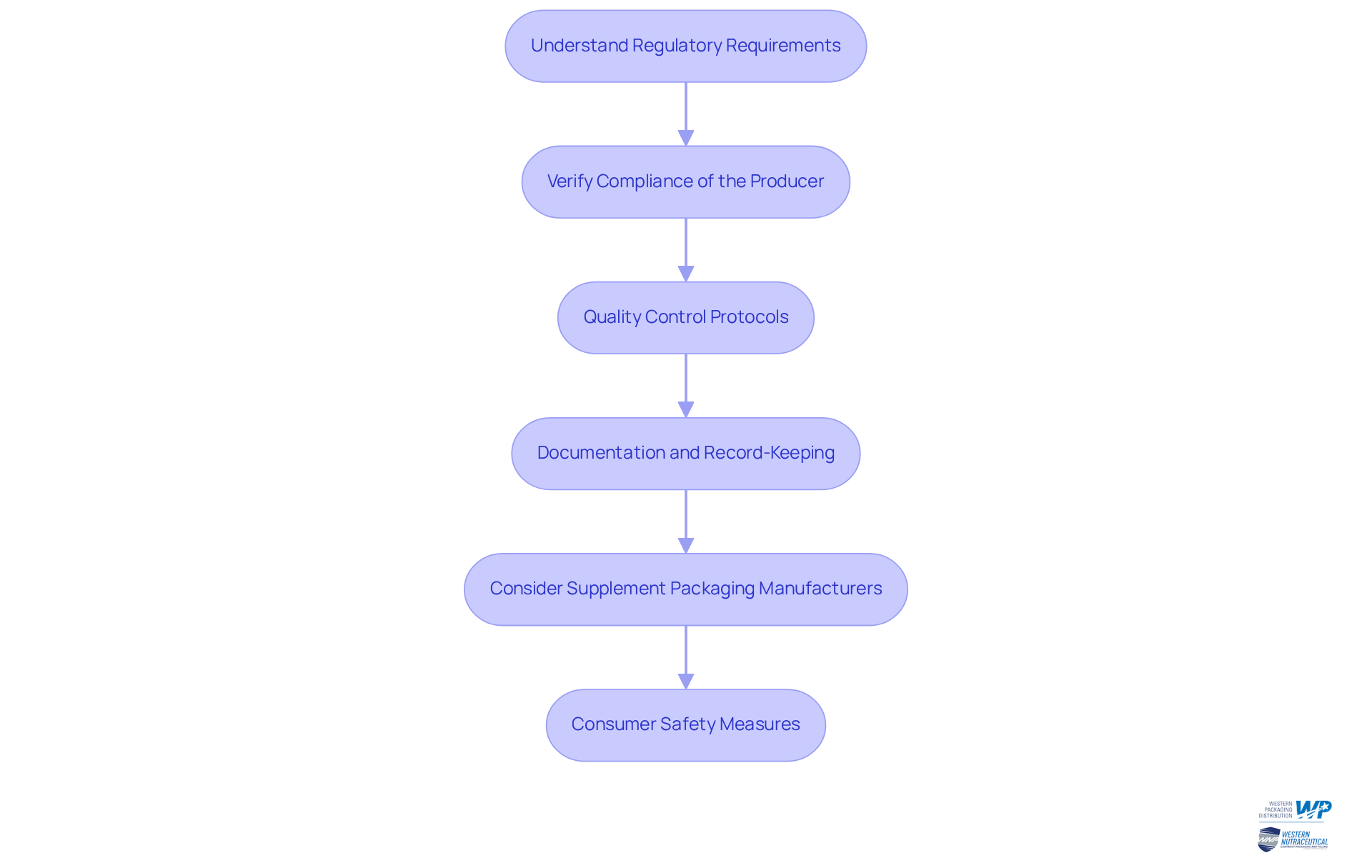

Ensure Compliance with Regulatory Standards and Quality Control

To ensure compliance with regulatory standards and maintain quality control, adhere to the following guidelines:

-

Understand Regulatory Requirements: Familiarize yourself with the regulations governing dietary supplements, including labeling requirements and safety standards set by the FDA.

-

Verify Compliance of the Producer: Confirm that the producer adheres to cGMP guidelines and possesses the necessary certifications to operate legally in the nutraceutical space.

-

Quality Control Protocols: Inquire about the producer's quality control processes, including ingredient sourcing, testing, and batch tracking.

-

Documentation and Record-Keeping: Ensure that the producer maintains thorough documentation of their processes, which is essential for compliance and traceability.

-

Consider supplement packaging manufacturers that undergo regular audits and inspections to verify compliance with industry standards.

-

Consumer Safety Measures: Assess the measures in place to ensure consumer safety, such as allergen management and contamination prevention.

By prioritizing compliance and quality control, you safeguard your brand's reputation while ensuring the safety of your products.

Conclusion

Choosing the right supplement packaging manufacturer is a critical decision that can significantly impact a brand's success. By focusing on essential criteria such as experience in the nutraceutical sector, compliance with regulatory standards, and customization capabilities, brands can ensure they partner with manufacturers that align with their specific needs and goals.

Key points throughout the article highlight the importance of evaluating a manufacturer's production capacity, technology, design services, and quality assurance processes. Understanding a brand's unique packaging needs, including target audience and marketing objectives, is crucial for developing an effective packaging strategy. The emphasis on sustainability and compliance with industry regulations further underscores the necessity of selecting a responsible and capable partner.

Ultimately, informed decisions in selecting supplement packaging manufacturers not only enhance product presentation but also safeguard consumer safety and brand reputation. Prioritizing these considerations fosters a successful partnership that meets both current and future packaging demands. Assessing and aligning with the right manufacturer will lead to a more cohesive brand identity and a competitive edge in the marketplace.

Frequently Asked Questions

What is the first key criterion for selecting a supplement packaging manufacturer?

The first key criterion is the manufacturer's experience in the nutraceutical sector, which includes a demonstrated history in creating packaging for dietary supplements.

Why are certifications important when choosing a supplement packaging manufacturer?

Certifications, such as cGMP (current Good Manufacturing Practices) and FDA registration, are important as they indicate adherence to quality and safety standards.

What should I consider regarding customization capabilities of packaging manufacturers?

It is essential to evaluate if the manufacturers can provide personalized solutions that align with your distinct branding and product needs.

How does material quality impact supplement packaging?

High-quality, barrier-resistant materials are crucial for protecting supplements from environmental factors, making material quality an important consideration.

Why should sustainability practices be considered when selecting a manufacturer?

Sustainability practices are increasingly important to consumers, so considering manufacturers that prioritize eco-friendly materials and practices can be beneficial.

What role do lead times and flexibility play in the selection process?

Evaluating the ability of manufacturers to meet production timelines and adapt to changes in order volume or specifications is important for ensuring a smooth partnership.