Overview

Mastering ampoule packaging for nutraceuticals is paramount. Implementing best practices not only ensures product protection but also enhances consumer trust and drives brand loyalty.

- Airtight seals play a significant role in preserving ingredient stability.

- Ergonomic design and tamper-evident features are essential for safety and convenience.

- The growing demand for sustainable packaging solutions cannot be overlooked.

These elements are crucial for success in the competitive nutraceutical market. Embracing these strategies positions brands as leaders, fostering reliability and consumer confidence.

Introduction

In the rapidly evolving nutraceutical industry, the importance of ampoule packaging is paramount. This specialized packaging not only protects sensitive ingredients from environmental factors but also enhances user convenience and fosters trust. As manufacturers navigate a landscape characterized by rising consumer expectations and sustainability trends, the crucial question emerges: how can they implement best practices in ampoule packaging to ensure product integrity and cultivate brand loyalty?

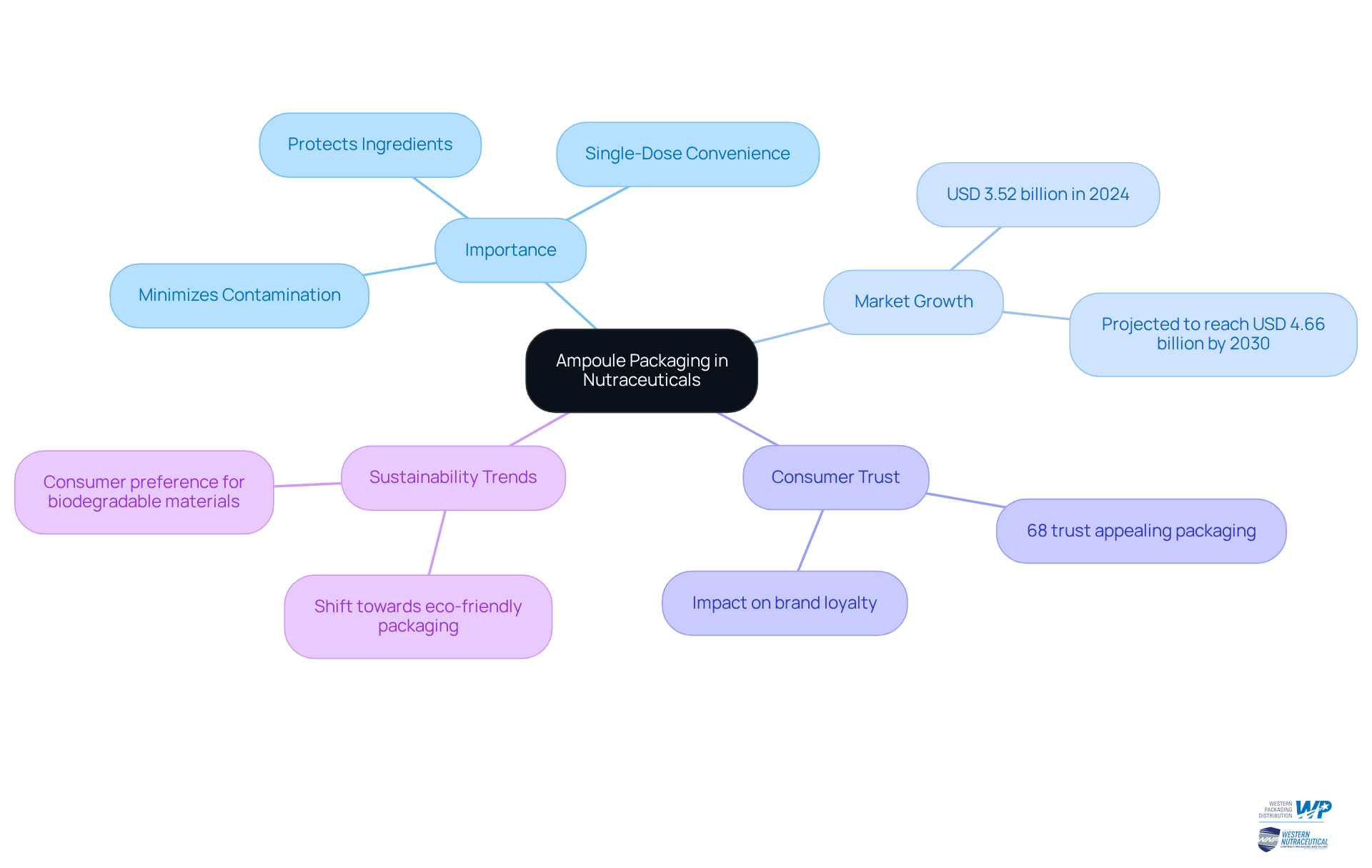

Understand the Importance of Ampoule Packaging in Nutraceuticals

In the nutraceutical industry, ampoule packaging is crucial, especially for products that require protection from environmental factors like light, moisture, and air. The airtight seal of vials guarantees that sensitive ingredients remain stable and effective throughout their shelf life. This is particularly vital for dietary supplements, where the potency of active ingredients can diminish without proper protection. Moreover, vials offer a single-dose option, enhancing user convenience while minimizing the risk of contamination and dosing errors. By employing vial packaging, producers can significantly bolster safety and foster buyer trust, ultimately leading to increased sales and brand loyalty.

Real-world examples underscore this importance:

- Glass ampoules in ampoule packaging for liquid vitamins have demonstrated the ability to sustain product efficacy over extended periods, reinforcing the necessity of selecting appropriate packaging solutions for nutraceuticals.

- The nutraceutical packaging market is projected to expand from USD 3.52 billion in 2024 to USD 4.66 billion by 2030, highlighting the growing demand for effective packaging solutions.

- As sustainability trends gain momentum, producers are increasingly exploring eco-friendly packaging options, aligning with consumer preferences for environmentally responsible products.

- A survey reveals that 68% of consumers trust nutraceutical products with appealing packaging, emphasizing the critical role of packaging in building consumer trust.

- Addressing common pitfalls, such as regulatory challenges and the high costs associated with innovative solutions, will be essential for manufacturers striving to succeed in this competitive landscape.

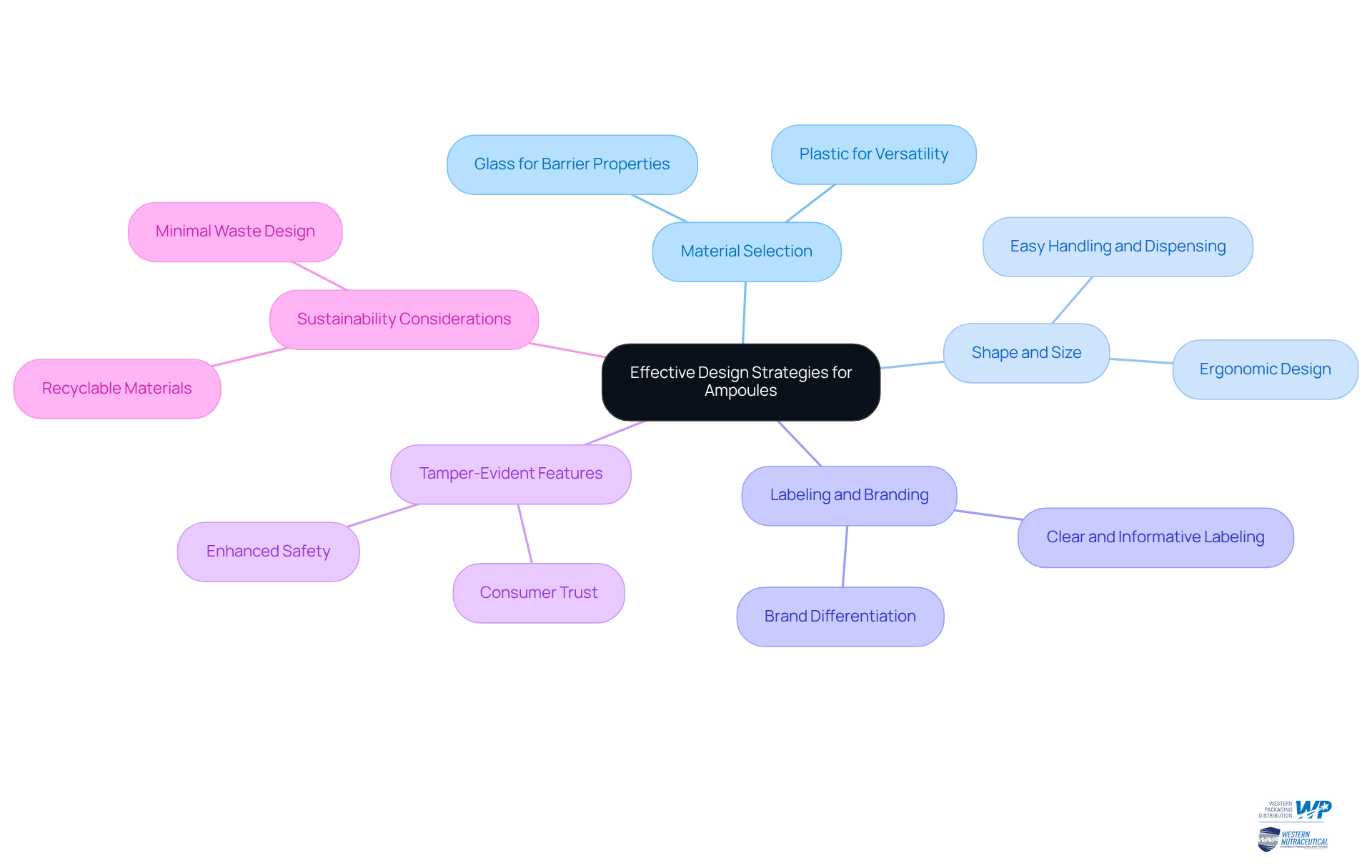

Implement Effective Design Strategies for Ampoules

Designing ampoules requires a meticulous balance between functionality and aesthetics, underscoring the importance of several key strategies:

-

Material Selection: The choice of material is critical. Glass is preferred for its exceptional barrier properties against light and oxygen, safeguarding product integrity. Conversely, plastic offers versatility and reduced weight, catering to diverse customer needs.

-

Shape and Size: Ergonomic design is vital for enhancing user experience. Ampoules must be crafted for easy handling and dispensing, thereby improving convenience for users.

-

Labeling and Branding: Clear and informative labeling is essential for regulatory compliance and public understanding. Integrating branding elements into the ampoule design can effectively differentiate products on retail shelves, fostering brand recognition.

-

Tamper-Evident Features: The inclusion of tamper-evident seals not only enhances safety but also cultivates trust among consumers, a crucial factor in the nutraceutical market.

-

Sustainability Considerations: With an increasing focus on environmental responsibility, employing recyclable materials or designing for minimal waste can significantly elevate brand perception among environmentally conscious individuals.

By implementing these design strategies, producers can create ampoule packaging that not only protects their products but also captivates consumers and bolsters brand loyalty, ultimately driving success in the competitive nutraceutical landscape.

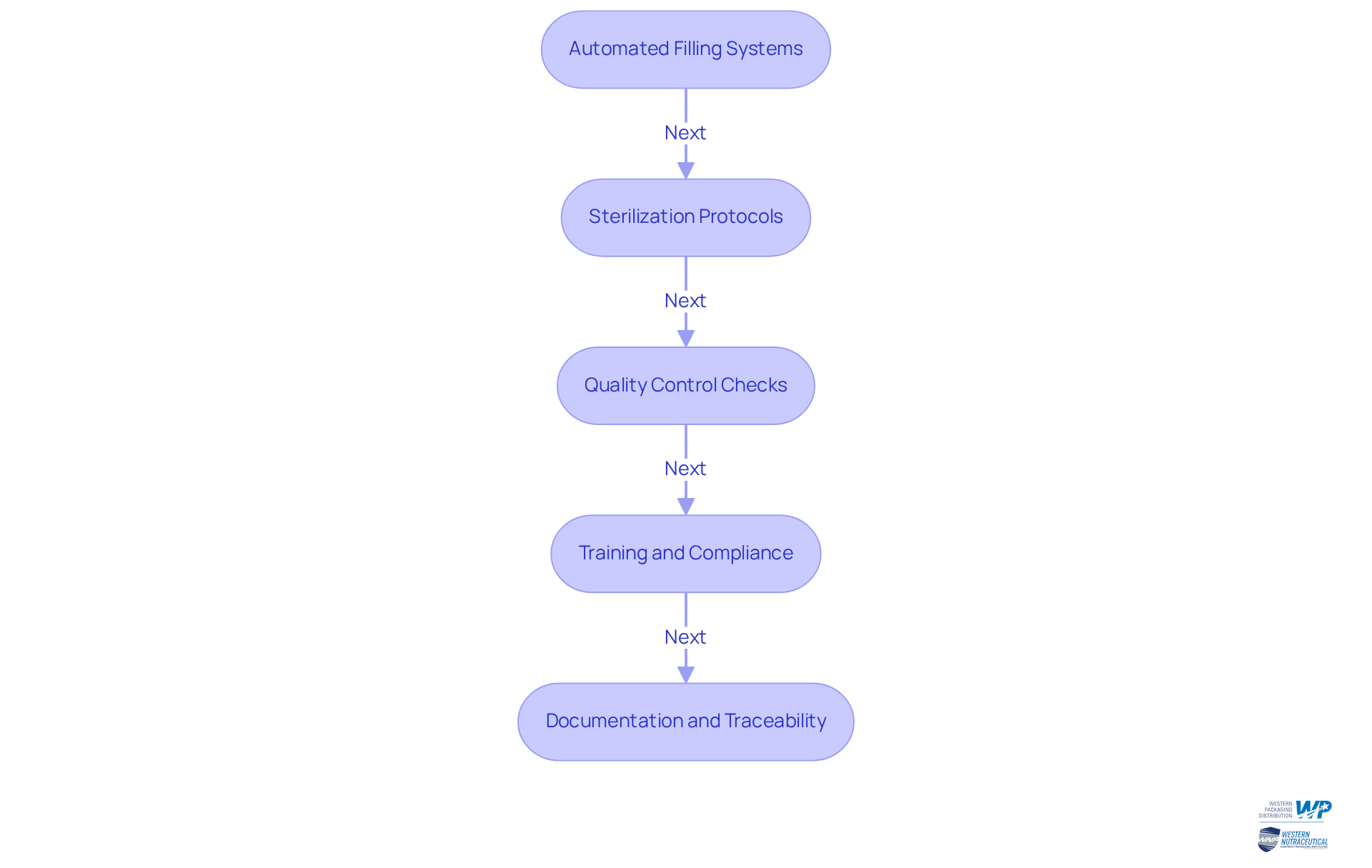

Optimize Filling Processes for Quality Assurance

To ensure the highest quality in ampoule filling processes, manufacturers must adopt best practices that guarantee excellence:

-

Automated Filling Systems: Employing automated filling machines significantly enhances precision and mitigates human error. Regular calibration of these systems is essential to uphold accuracy.

-

Sterilization Protocols: Stringent sterilization protocols for both vials and the filling environment are vital to prevent contamination.

-

Quality Control Checks: Integrating regular quality control checks into the filling process is imperative. This includes examining filled vials for defects and verifying that fill volumes meet specifications.

-

Training and Compliance: Comprehensive training for staff on best practices for filling and handling ampoules is crucial. This training should emphasize the importance of maintaining sterility and adhering to regulatory guidelines.

-

Documentation and Traceability: Maintaining detailed records of the filling process is beneficial for compliance and provides traceability in the event of recalls.

By optimizing these processes, producers can significantly enhance product quality, ensuring that their nutraceuticals are safe and effective for consumers.

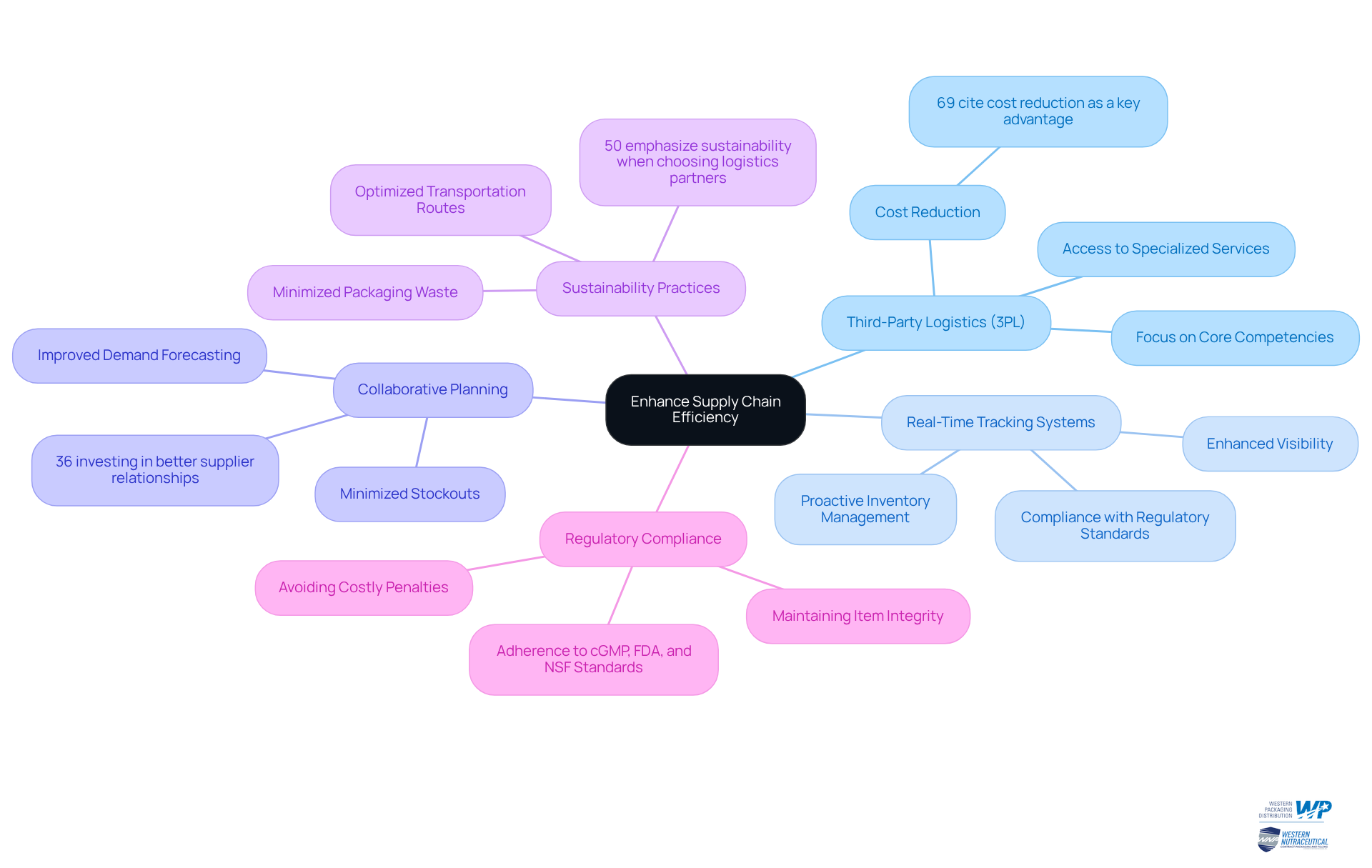

Enhance Supply Chain Efficiency with Integrated Logistics Solutions

To enhance supply chain efficiency, nutraceutical manufacturers should consider integrated logistics solutions that are both effective and strategic:

-

Third-Party Logistics (3PL): Collaborating with a 3PL provider streamlines warehousing, inventory management, and distribution processes. This partnership allows manufacturers to focus on their core competencies while leveraging the expertise and resources of logistics specialists. Research indicates that 69% of logistics professionals cite cost reduction as the leading advantage of integrated logistics, making 3PL an attractive option for many businesses.

-

Real-Time Tracking Systems: Implementing advanced real-time tracking systems significantly enhances visibility across the supply chain. These systems enable proactive inventory management and shipment tracking, thereby reducing shrinkage and preventing spoilage. Nutraceutical firms that employ such technologies can effectively manage lot numbers and expiration dates, ensuring compliance with regulatory standards and maintaining item integrity.

-

Collaborative Planning: Engaging in collaborative planning with suppliers and distributors fosters improved demand forecasting and inventory management. This approach minimizes stockouts and excess inventory, ultimately leading to more efficient operations. Companies that prioritize collaboration often see enhanced service levels and customer satisfaction. Notably, 36% of respondents are investing in better supplier relationships due to poor supplier communication, underscoring the importance of collaboration.

-

Sustainability Practices: Incorporating sustainable logistics practices—such as optimizing transportation routes and minimizing packaging waste—not only improves operational efficiency but also enhances brand reputation. As more than 50% of surveyed professionals emphasize sustainability when choosing logistics partners, implementing eco-friendly practices can attract environmentally conscious buyers.

-

Regulatory Compliance: Ensuring that logistics operations adhere to industry regulations is vital for maintaining item integrity and avoiding costly penalties. By aligning logistics processes with cGMP, FDA, and NSF standards, nutraceutical producers can safeguard their products and build trust with consumers.

By embracing these integrated logistics solutions, manufacturers can significantly enhance their supply chain efficiency, leading to improved service levels and increased customer satisfaction.

Conclusion

In the realm of nutraceuticals, mastering ampoule packaging is a pivotal factor that significantly influences product integrity, consumer trust, and overall market success. Effective packaging safeguards sensitive ingredients, enhances user convenience, and fosters brand loyalty. By understanding the critical role of ampoule packaging, manufacturers can ensure their products maintain potency and appeal to health-conscious consumers.

Key insights highlight the importance of:

- Selecting appropriate materials

- Optimizing design strategies

- Adhering to rigorous quality assurance practices

From the choice of glass or plastic to the incorporation of tamper-evident features, each element of ampoule design contributes to an enhanced user experience and reinforces product safety. Furthermore, streamlining filling processes and integrating logistics solutions are essential for maintaining high quality and operational efficiency in a competitive landscape.

Ultimately, embracing best practices in ampoule packaging addresses current market trends and positions nutraceutical companies for long-term success. By prioritizing sustainability, consumer trust, and compliance, manufacturers can meet the evolving demands of the market while cultivating a loyal customer base. The journey towards excellence in ampoule packaging is not merely a choice; it is a necessity for those committed to delivering safe and effective nutraceutical products.

Frequently Asked Questions

Why is ampoule packaging important in the nutraceutical industry?

Ampoule packaging is crucial in the nutraceutical industry because it protects products from environmental factors like light, moisture, and air, ensuring that sensitive ingredients remain stable and effective throughout their shelf life.

How does ampoule packaging enhance user convenience?

Ampoule packaging offers a single-dose option, which enhances user convenience by minimizing the risk of contamination and dosing errors.

What benefits do vials provide to producers in the nutraceutical market?

By using vial packaging, producers can significantly improve safety, foster buyer trust, and ultimately increase sales and brand loyalty.

Can you provide an example of effective ampoule packaging in nutraceuticals?

Glass ampoules used for liquid vitamins have shown the ability to maintain product efficacy over extended periods, demonstrating the importance of selecting appropriate packaging solutions.

What is the projected growth of the nutraceutical packaging market?

The nutraceutical packaging market is projected to grow from USD 3.52 billion in 2024 to USD 4.66 billion by 2030, indicating a rising demand for effective packaging solutions.

How are sustainability trends affecting packaging choices in the nutraceutical industry?

As sustainability trends gain momentum, producers are increasingly exploring eco-friendly packaging options to align with consumer preferences for environmentally responsible products.

What role does packaging play in consumer trust for nutraceutical products?

A survey indicates that 68% of consumers trust nutraceutical products with appealing packaging, highlighting the critical role of packaging in building consumer trust.

What challenges do manufacturers face in the nutraceutical packaging landscape?

Manufacturers must address common pitfalls such as regulatory challenges and the high costs associated with innovative packaging solutions to succeed in the competitive market.