Overview

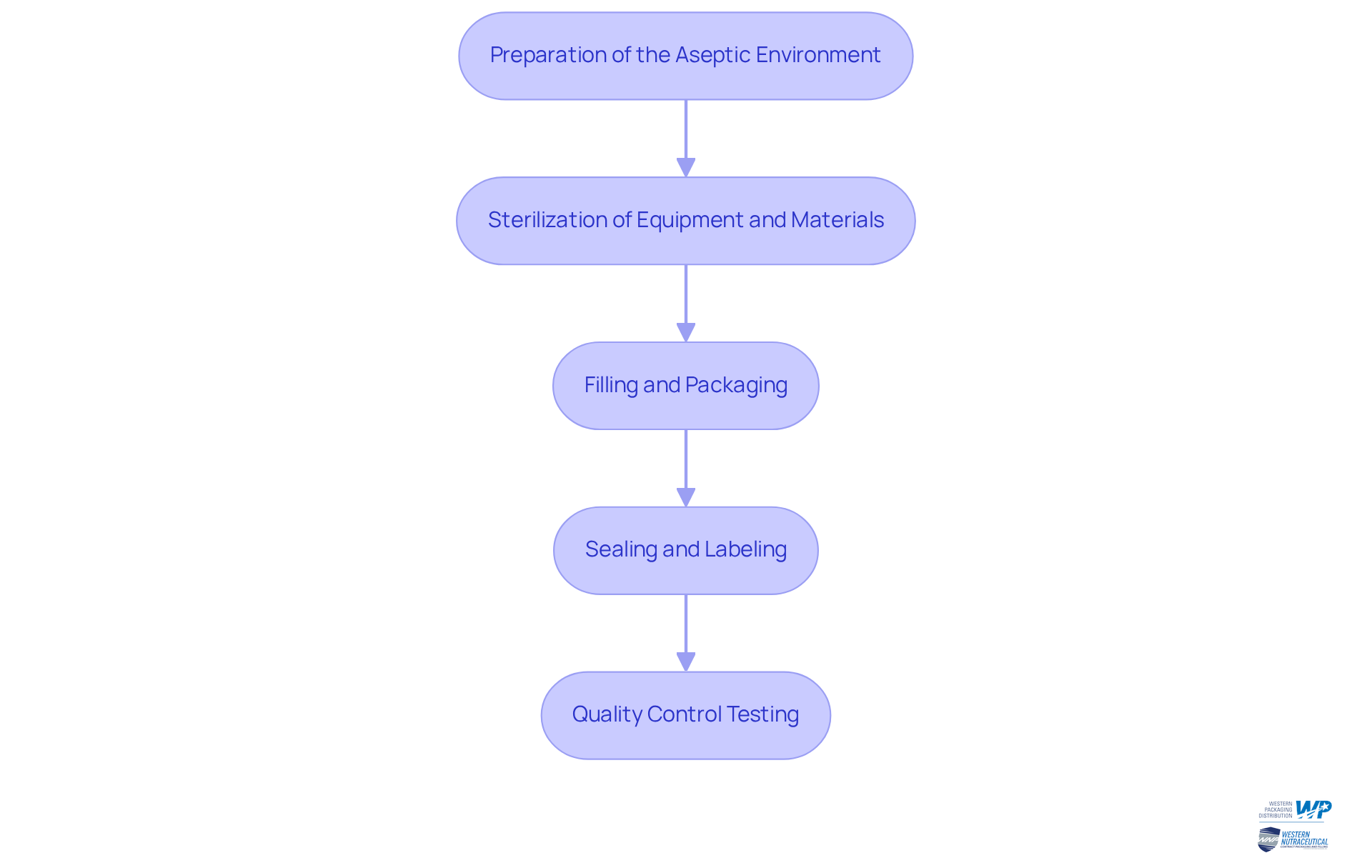

Mastering aseptic manufacturing of pharmaceutical products requires a meticulous approach. The key steps include:

- Preparing a sterile environment

- Sterilizing equipment and materials

- Executing careful filling and packaging

- Sealing and labeling

- Conducting quality control testing

Adhering to these steps is not merely a guideline; it is essential for maintaining product integrity and ensuring regulatory compliance amidst contamination risks. Best practices in training, environmental monitoring, and documentation further reinforce the reliability of the manufacturing process. In the face of stringent industry standards, the commitment to these practices is what distinguishes leaders in the field.

Introduction

Aseptic manufacturing stands as a cornerstone in the pharmaceutical industry, where the stakes are undeniably high and the margin for error is exceedingly slim. As the demand for sterile products escalates, a comprehensive understanding of the intricate processes and best practices inherent in aseptic manufacturing becomes imperative. How can manufacturers guarantee that their products are not only safe but also compliant with the rigorous regulatory standards? This article explores the essential steps and techniques of aseptic manufacturing, providing insights that can significantly enhance product quality and ensure patient safety.

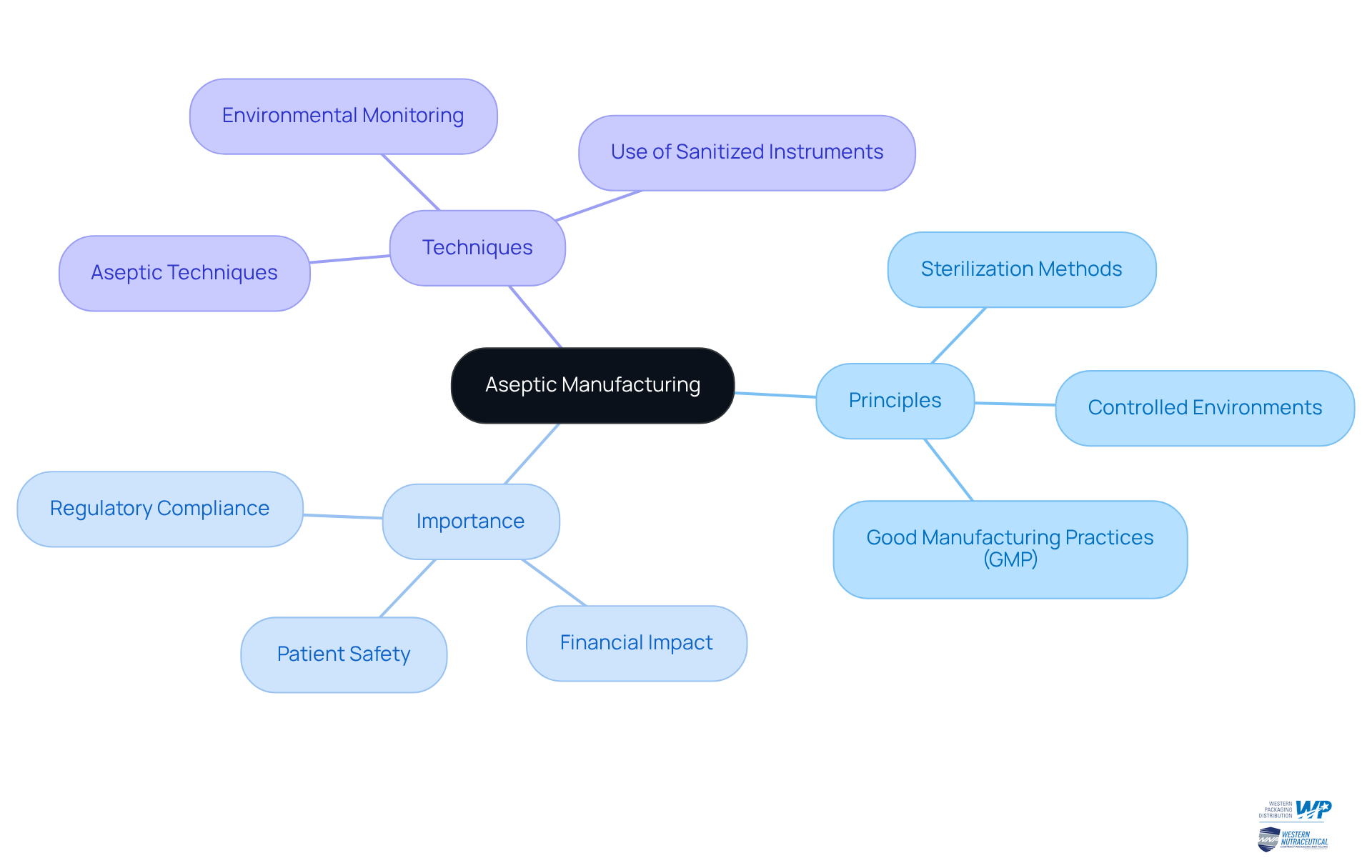

Understand Aseptic Manufacturing: Principles and Importance

Aseptic manufacturing of pharmaceutical products stands as a cornerstone in the production of items, particularly those vulnerable to contamination, such as injectables and biologics. The essence of aseptic manufacturing of pharmaceutical products lies in creating a hygienic environment where products can be filled and packaged without exposure to harmful microorganisms. This is accomplished through a blend of stringent sterilization methods, controlled environments, and unwavering adherence to Good Manufacturing Practices (GMP).

The importance of sterile production is paramount. Contamination can lead to product recalls, jeopardize patient safety, and incur significant financial losses. Therefore, understanding the fundamentals of sterile techniques, including the use of sanitized instruments, cleanroom protocols, and environmental monitoring, is essential for anyone involved in the aseptic manufacturing of pharmaceutical products. By mastering these principles, manufacturers can uphold the integrity of their products and ensure compliance with regulatory standards.

Explore the Aseptic Manufacturing Process: Key Stages and Techniques

The aseptic manufacturing of pharmaceutical products represents a meticulous sequence of stages designed to uphold sterility and product quality. These stages encompass:

-

Preparation of the Aseptic Environment: Establishing cleanrooms that adhere to stringent cleanliness standards is paramount. This involves ensuring that all surfaces and equipment are thoroughly sterilized prior to use, with ISO 5 areas requiring less than one colony-forming unit per cubic meter of air—ideally zero. Typical air change rates are 240 air changes per hour (ACH) for ISO 5 and 30-60 ACH for ISO 7/8, essential for maintaining air quality and preventing impurities.

-

Sterilization of Equipment and Materials: All tools, containers, and raw materials must undergo thorough sterilization methods. Common methods include autoclaving and gamma irradiation, which are crucial for eliminating microbial contamination. The expectation for successful media fills is zero contaminated units out of thousands filled, underscoring the importance of effective sterilization. Regular qualification tests, such as media-fill simulations, are vital for validating the aseptic manufacturing of pharmaceutical products and ensuring ongoing compliance with sterility standards.

-

Filling and Packaging: The filling of products occurs within a controlled environment. Operators are required to wear sterile gowns and utilize laminar flow hoods to avoid pollution. Modern filling lines often operate inside sealed isolators, which are bio-decontaminated with vaporized hydrogen peroxide, significantly reducing the risk of human-borne contamination. The FDA emphasizes the importance of robust environmental monitoring programs in the aseptic manufacturing of pharmaceutical products to ensure cleanliness and sterility.

-

Sealing and Labeling: After filling, items are sealed in sterile packaging to maintain sterility until they reach the end consumer. Proper labeling is essential for compliance and traceability, ensuring that all items meet regulatory standards.

-

Quality Control Testing: Throughout the manufacturing phase, samples are taken for microbiological testing to confirm that no contamination has occurred. This encompasses environmental observation and item testing, which are essential for preserving the integrity of the sterile process. Routine qualification assessments, like media-fill simulations, are conducted to confirm the sterile environment.

By comprehensively understanding these stages, manufacturers can implement effective strategies in the aseptic manufacturing of pharmaceutical products to minimize risks and enhance product quality, ensuring compliance with stringent regulatory standards. For instance, the rise of single-use technology in sterile filling has transformed operations by reducing the need for intricate cleaning and sterilization between batches, showcasing a successful application of sterile manufacturing methods.

Implement Best Practices: Quality Control and Assurance in Aseptic Manufacturing

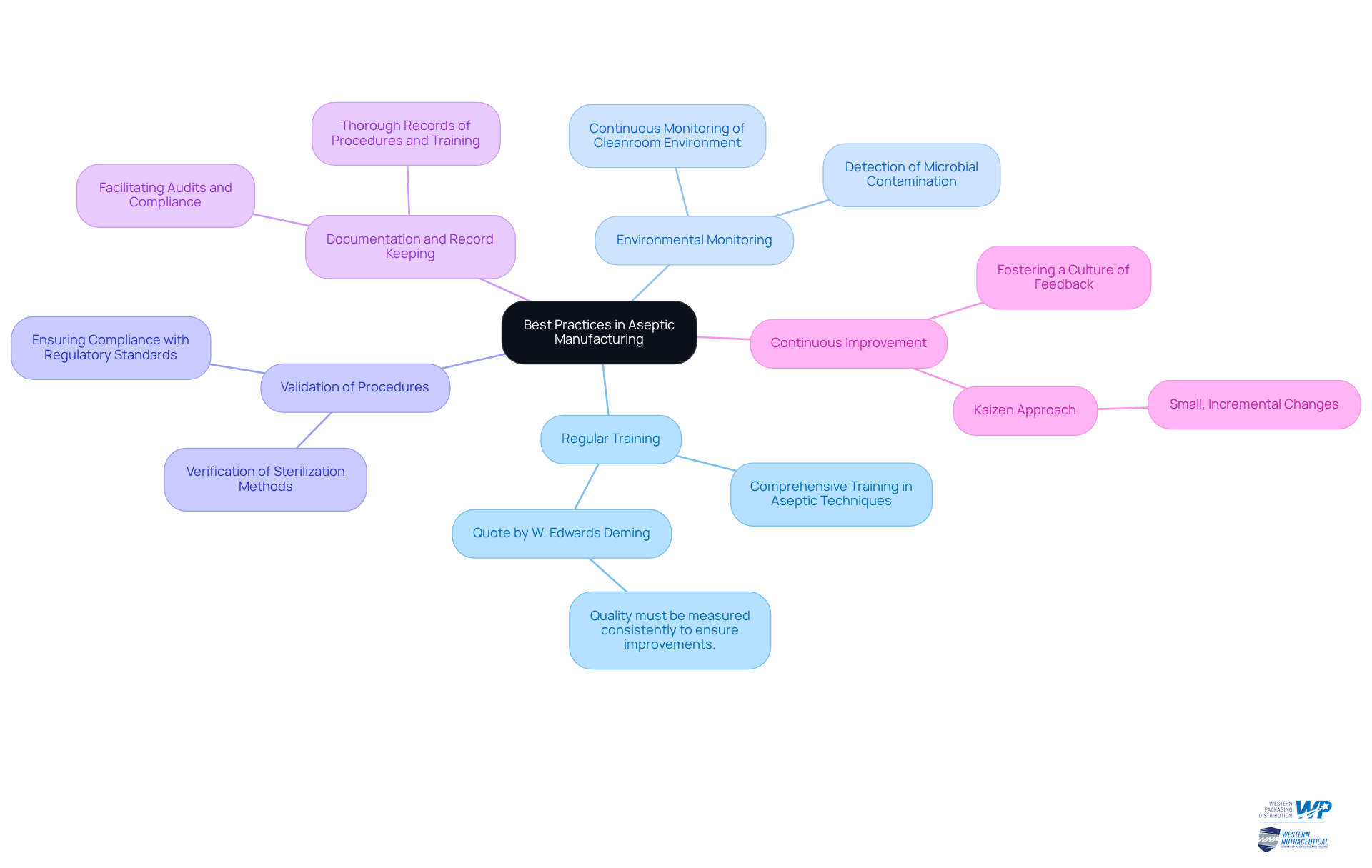

Implementing best practices in quality control and assurance is crucial for the aseptic manufacturing of pharmaceutical products. Key practices include:

-

Regular Training for Personnel: Comprehensive training in aseptic techniques is essential. Staff must understand their roles in maintaining sterility, as their actions directly impact product safety and compliance. As W. Edwards Deming noted, "Quality must be measured consistently to ensure improvements."

-

Environmental Monitoring: Continuous monitoring of the cleanroom environment is vital to detect microbial contamination, particulate matter, and other potential hazards. This proactive approach aids in preserving the integrity of the aseptic manufacturing of pharmaceutical products.

-

Validation of Procedures: Regular verification of sterilization methods and equipment ensures they function effectively. This step is critical for confirming that all methods meet stringent regulatory standards.

-

Documentation and Record Keeping: Keeping thorough records of procedures, training, and testing outcomes is essential for adherence to regulatory standards. Thorough documentation facilitates audits and demonstrates adherence to quality standards.

-

Continuous Improvement: Fostering a culture of continuous improvement encourages feedback and regular reviews of processes. This commitment to optimization not only enhances operational efficiency but also reinforces a dedication to quality and safety. As highlighted in the Kaizen approach, small, incremental changes can lead to significant improvements over time.

Furthermore, the upcoming Aseptic Processing and Validation Course scheduled for October 20th - October 21st, 2025, presents an excellent opportunity for personnel to enhance their knowledge and skills in aseptic techniques.

By adhering to these best practices in aseptic manufacturing of pharmaceutical products, manufacturers can ensure compliance with regulatory requirements while enhancing their market presence through a demonstrated commitment to quality and safety.

Conclusion

Aseptic manufacturing of pharmaceutical products stands as a cornerstone in ensuring the safety and efficacy of items, particularly those vulnerable to contamination. By establishing a sterile environment, manufacturers effectively shield their products from harmful microorganisms, thereby safeguarding patient health and adhering to stringent regulatory standards.

This article delineates the essential stages of aseptic manufacturing, encompassing the preparation of cleanrooms, sterilization of equipment, filling, sealing, and rigorous quality control testing. Each phase is meticulously designed to uphold the highest standards of sterility and product quality. Furthermore, the implementation of best practices—such as personnel training, environmental monitoring, and comprehensive documentation—fortifies the integrity of the aseptic process, enabling manufacturers to confidently deliver safe pharmaceutical products to the market.

Ultimately, mastering aseptic manufacturing transcends mere procedural compliance; it embodies the cultivation of a culture centered on quality and continuous improvement. As the industry progresses, the adoption of these practices will not only enhance operational efficiency but also manifest a steadfast commitment to patient safety and regulatory compliance. Engaging in further education, such as the upcoming Aseptic Processing and Validation Course, empowers professionals to remain at the forefront of this critical field, ensuring that the pharmaceutical products they manufacture consistently meet the highest standards of quality and safety.

Frequently Asked Questions

What is aseptic manufacturing in the pharmaceutical industry?

Aseptic manufacturing is a process used in the production of pharmaceutical products, especially injectables and biologics, that creates a hygienic environment to prevent contamination during filling and packaging.

Why is aseptic manufacturing important?

Aseptic manufacturing is crucial because contamination can lead to product recalls, threaten patient safety, and result in significant financial losses.

What methods are used to ensure aseptic manufacturing?

Aseptic manufacturing employs stringent sterilization methods, controlled environments, and strict adherence to Good Manufacturing Practices (GMP).

What are some key principles of sterile techniques in aseptic manufacturing?

Key principles include the use of sanitized instruments, following cleanroom protocols, and conducting environmental monitoring to maintain sterility.

How does understanding aseptic manufacturing benefit manufacturers?

Mastering the principles of aseptic manufacturing helps manufacturers maintain the integrity of their products and ensures compliance with regulatory standards.