Overview

This article examines the vital strategies necessary for mastering assembly and fulfillment processes within the nutraceutical industry, a critical factor for ensuring product success. Understanding specific requirements, such as regulatory compliance and quality control, is paramount. Furthermore, it delves into effective fulfillment models and the integration of packaging and logistics, which are essential for enhancing operational efficiency. These elements collectively foster consumer trust and bolster market competitiveness, positioning your business for success in a dynamic landscape.

Introduction

Navigating the intricate landscape of nutraceutical assembly and fulfillment presents a unique set of challenges and opportunities for businesses in this thriving sector. With products requiring specialized handling and strict adherence to regulatory standards, understanding the nuances of effective assembly processes is crucial for ensuring product integrity and consumer safety. As companies strive to meet the evolving demands of the market, the question arises: how can they effectively balance compliance, quality control, and innovative fulfillment strategies to achieve success in a competitive environment? This balance is not merely a goal; it is an imperative for those seeking to thrive in this dynamic field.

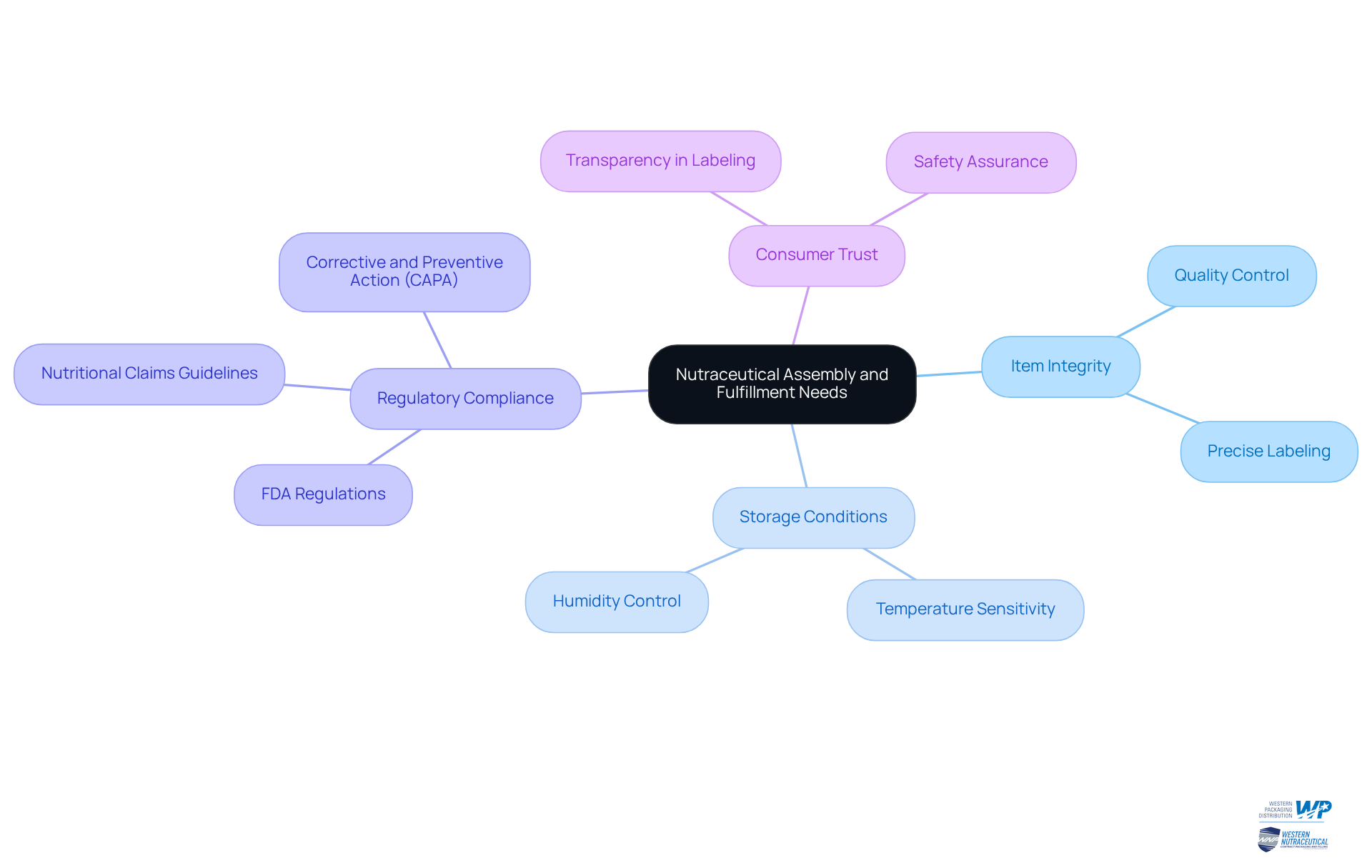

Understand the Unique Needs of Nutraceutical Assembly and Fulfillment

Nutraceutical items, which include dietary supplements and health foods, have unique assembly and fulfillment requirements that significantly differ from those of conventional consumer goods. These products often demand specialized handling due to their delicate nature, diverse formulations, and stringent regulatory standards. Understanding these needs necessitates recognizing the critical importance of item integrity, shelf life, and consumer safety.

For example, manufacturers must account for the specific storage conditions essential for certain ingredients, such as probiotics, which are particularly sensitive to temperature and humidity. Furthermore, adherence to regulations established by organizations like the FDA is crucial, as any oversight can result in costly recalls or legal complications.

By comprehensively grasping these unique requirements, businesses can tailor their assembly and fulfillment processes, thereby ensuring product quality and fostering consumer trust.

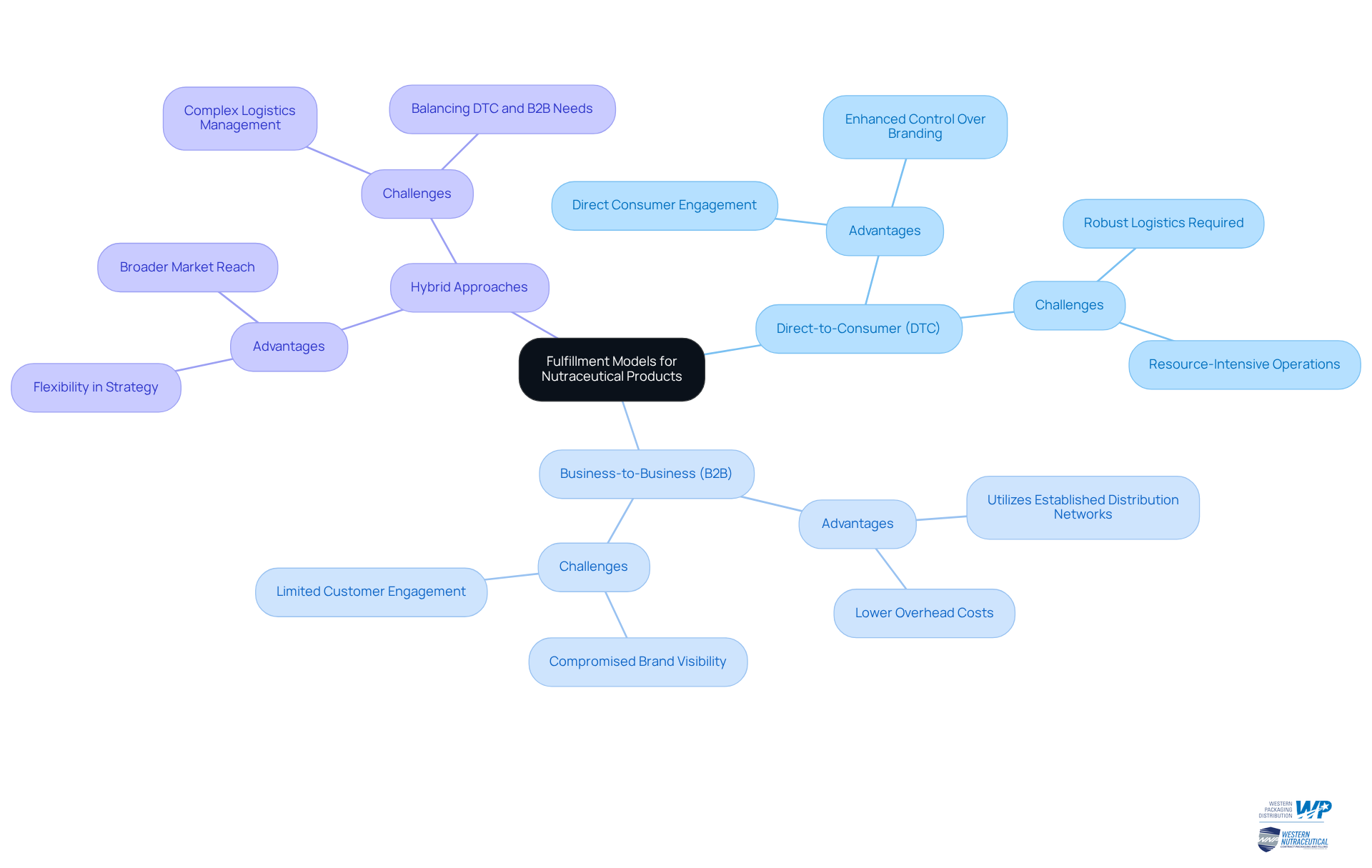

Explore Effective Fulfillment Models for Nutraceutical Products

In the nutraceutical sector, businesses have the opportunity to adopt various delivery models, including:

- Direct-to-consumer (DTC)

- Business-to-business (B2B)

- Hybrid approaches

Each model presents distinct advantages and challenges that warrant careful consideration. The DTC model provides enhanced control over branding and customer experience, allowing companies to engage directly with consumers. However, this approach necessitates robust logistics capabilities to efficiently manage the assembly and fulfillment of shipping and returns, which can be resource-intensive.

On the other hand, the B2B model capitalizes on established distribution networks, potentially lowering overhead costs and streamlining operations. Yet, this approach may compromise brand visibility and customer engagement, which are critical in today’s market.

Companies must meticulously evaluate their target market, product varieties, and operational strengths to identify the most efficient strategy for assembly and fulfillment. Furthermore, implementing a flexible assembly and fulfillment framework that can adapt to evolving market dynamics is essential for sustained success in this competitive landscape.

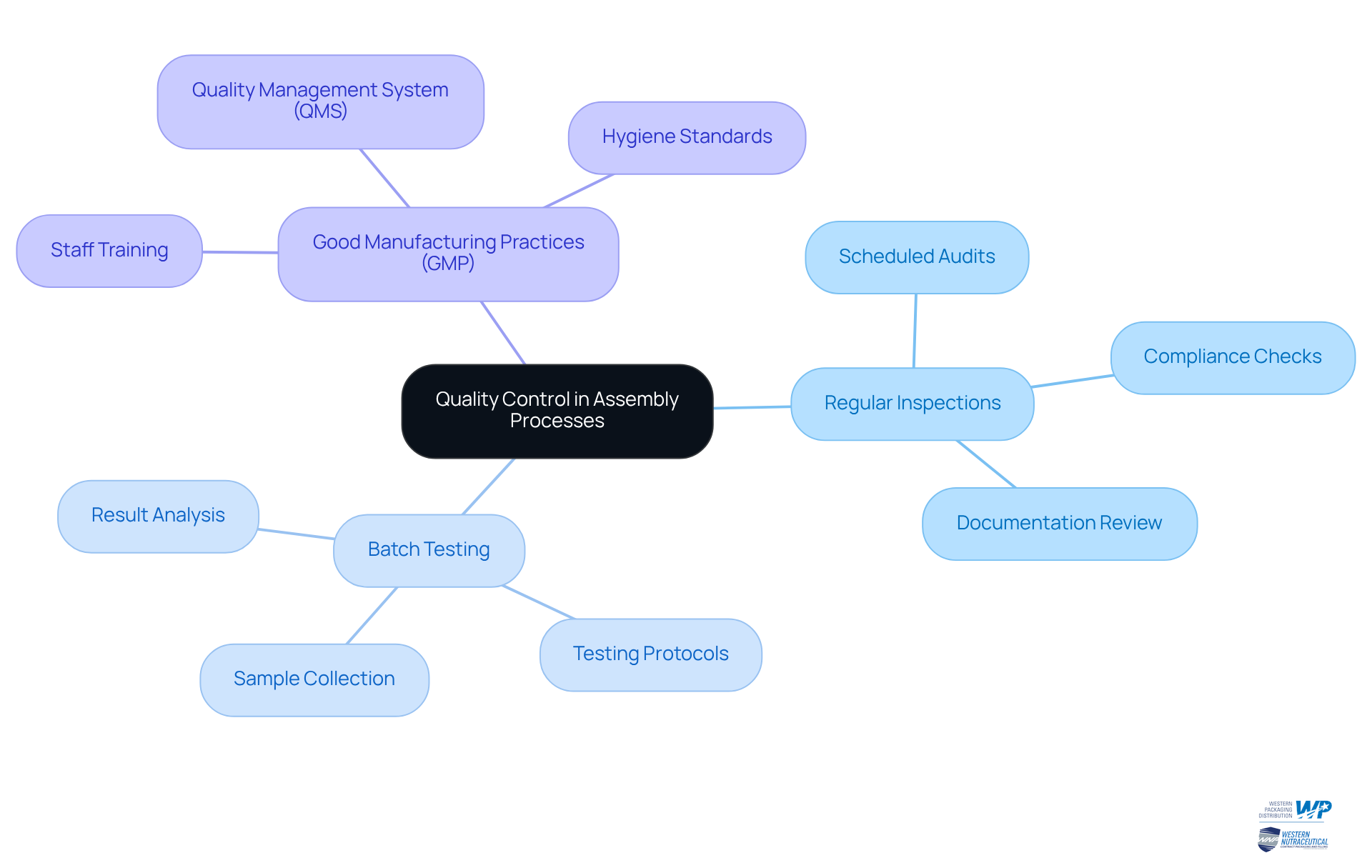

Ensure Compliance and Quality Control in Assembly Processes

To uphold high standards in nutraceutical assembly, businesses must implement comprehensive quality control measures throughout the production process. This includes:

- Regular inspections

- Batch testing

- Adherence to Good Manufacturing Practices (GMP)

Establishing a quality management system (QMS) simplifies compliance efforts and ensures that all items meet regulatory standards. Furthermore, training staff on quality assurance protocols and the significance of compliance fosters a culture of accountability and excellence. Notably, a nutraceutical firm that recently implemented a robust QMS reported a 30% decrease in recalls, underscoring the tangible benefits of prioritizing quality and compliance.

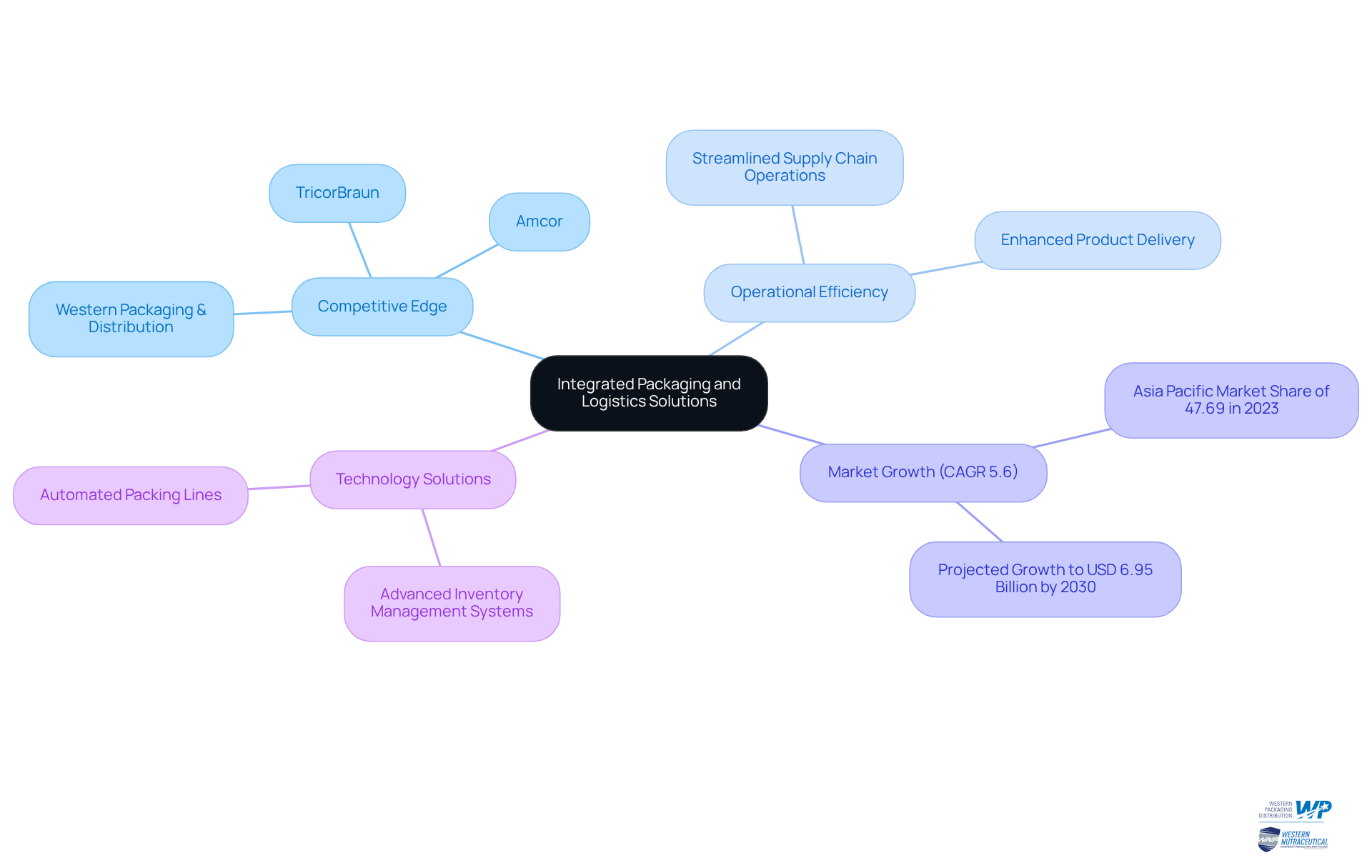

Leverage Integrated Packaging and Logistics Solutions for Efficiency

Combining design for containers and logistics solutions provides nutraceutical firms with a significant competitive edge. By integrating container design, filling services, and logistics with assembly and fulfillment into a single framework, businesses can effectively reduce lead times and enhance product delivery. For instance, Western Packaging & Distribution exemplifies this approach by offering a comprehensive suite of services that streamline supply chain operations. This integration not only boosts operational efficiency but also empowers companies in their assembly and fulfillment processes, allowing them to swiftly adapt to market fluctuations and evolving consumer demands.

Based on industry insights, the global nutraceutical market for containers is anticipated to expand at a compound annual growth rate (CAGR) of 5.6% from 2025 to 2030, underscoring the significance of effective solutions in a competitive environment. Moreover, the adoption of technology solutions, such as advanced inventory management systems and automated packing lines, can optimize these processes. Firms such as Amcor and TricorBraun are leading the way with innovative container technologies that enhance item integrity and consumer satisfaction.

The impact of effective packaging design on supply chain efficiency is profound; it enhances assembly and fulfillment by ensuring product integrity and facilitating smoother logistics, ultimately contributing to a more responsive and agile business model. Embracing these strategies will not only position companies for success but also enable them to thrive in an ever-evolving market landscape.

Conclusion

The intricacies of nutraceutical assembly and fulfillment are paramount for businesses aiming for success in this specialized market. A comprehensive understanding of the unique requirements surrounding these products—including regulatory compliance, quality control, and effective logistics—is pivotal in ensuring that companies not only meet consumer expectations but also uphold product integrity throughout the supply chain.

Key insights from the article underscore the necessity of adopting appropriate fulfillment models, whether direct-to-consumer, business-to-business, or hybrid approaches, each presenting its own set of advantages and challenges. Moreover, implementing robust quality control measures alongside integrated packaging solutions can significantly boost operational efficiency, reduce lead times, and ultimately cultivate a more agile business capable of adapting to market fluctuations.

In conclusion, the pathway to success in nutraceutical fulfillment lies in recognizing and addressing the distinct challenges of this industry. By prioritizing compliance, investing in quality assurance, and leveraging innovative logistics solutions, companies can not only guarantee the safety and efficacy of their products but also nurture lasting consumer trust and loyalty. Embracing these best practices will empower businesses to flourish in a competitive landscape, distinguishing them as leaders in the nutraceutical market.

Frequently Asked Questions

What are nutraceuticals?

Nutraceuticals are products that include dietary supplements and health foods, designed to provide health benefits beyond basic nutrition.

How do the assembly and fulfillment needs of nutraceuticals differ from conventional consumer goods?

Nutraceuticals require specialized handling due to their delicate nature, diverse formulations, and stringent regulatory standards, unlike conventional consumer goods.

Why is item integrity important in nutraceutical assembly and fulfillment?

Item integrity is critical to ensure the quality, safety, and efficacy of nutraceutical products, which can be affected by factors like storage conditions and handling processes.

What specific storage conditions are necessary for certain nutraceutical ingredients?

Some ingredients, such as probiotics, require specific storage conditions, particularly sensitive to temperature and humidity, to maintain their effectiveness.

What role do regulations play in the assembly and fulfillment of nutraceuticals?

Adherence to regulations established by organizations like the FDA is essential; non-compliance can lead to costly recalls or legal issues.

How can businesses ensure product quality in nutraceutical assembly and fulfillment?

By understanding the unique requirements of nutraceuticals, businesses can tailor their assembly and fulfillment processes to maintain product quality and build consumer trust.