Overview

The primary focus of this article is to delineate the critical factors involved in selecting a Contract Manufacturing Organization (CMO) for nutraceuticals. Brands must prioritize:

- Regulatory compliance

- Experience

- Technical capabilities

- Effective communication strategies

to forge successful partnerships. These elements are indispensable for maintaining product quality and meeting market demands in an ever-evolving industry. By understanding and implementing these key considerations, companies can ensure that they are well-equipped to navigate the complexities of the nutraceutical market.

Introduction

In the rapidly expanding nutraceutical market, projected to reach USD 513.20 billion by 2025, the role of Contract Manufacturing Organizations (CMOs) has never been more critical. These specialized partners not only streamline production processes but also uphold stringent quality standards and regulatory compliance essential for success.

However, with a plethora of CMOs available, how can companies ensure they choose the right partner that aligns with their vision and operational needs?

This guide delves into the intricacies of CMO selection, offering insights into essential criteria and best practices that can empower brands to navigate this vital partnership effectively.

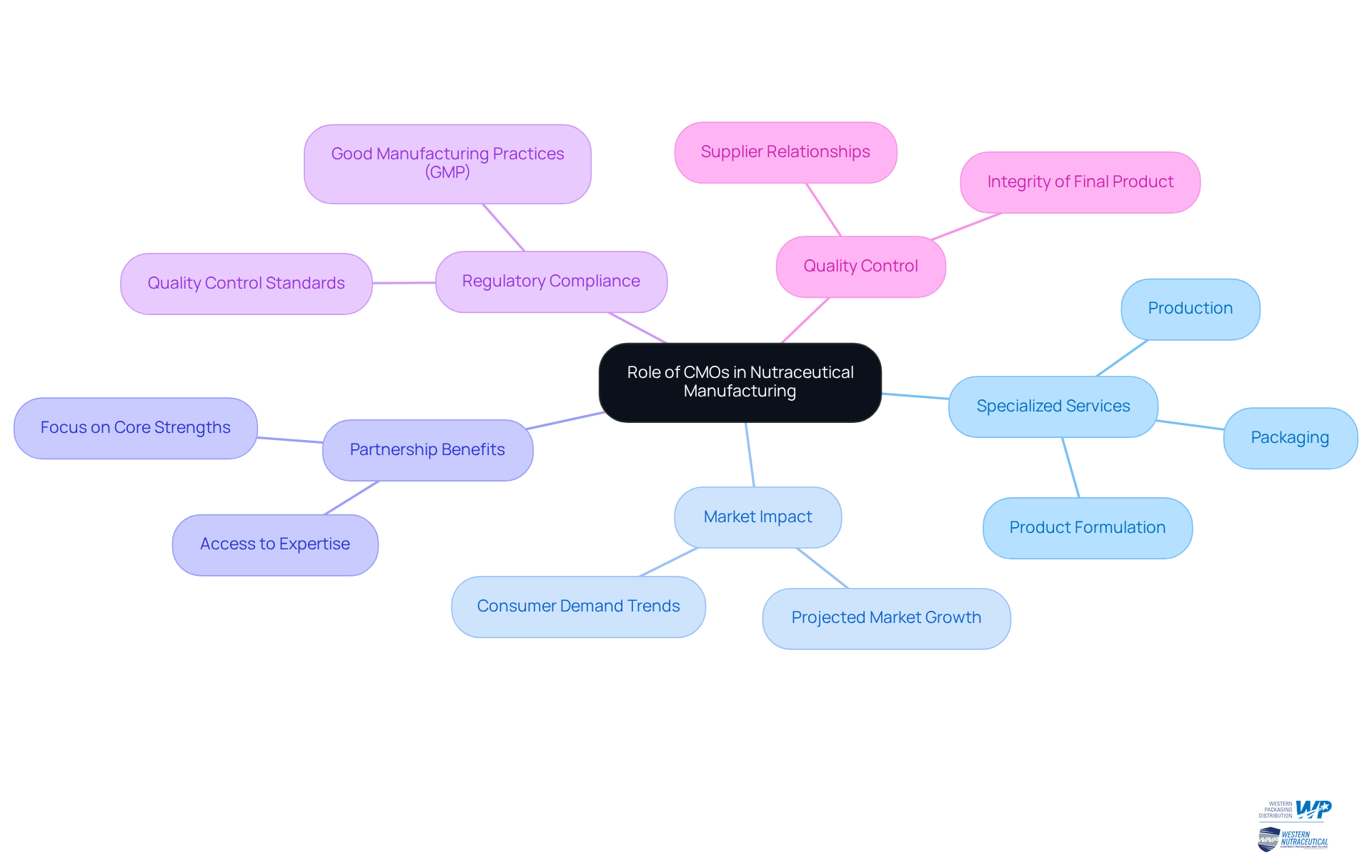

Understand the Role of CMOs in Nutraceutical Manufacturing

Contract manufacturing CMO organizations play a pivotal role in the nutraceutical manufacturing landscape by providing specialized services that encompass product formulation, production, packaging, and adherence to regulatory compliance. By collaborating with contract manufacturing CMOs, companies can focus on their core strengths while leveraging the manufacturing expertise of the CMO. This partnership is particularly crucial in 2025, as the nutraceutical market is projected to reach USD 513.20 billion, with a significant emphasis on standards and compliance.

Understanding the capabilities of a contract manufacturing CMO, including their commitment to Good Manufacturing Practices (GMP) and scalability, is vital for companies aiming to effectively launch high-quality nutraceutical products. CMOs often maintain established relationships with suppliers, enhancing the quality and consistency of raw materials, which ultimately impacts the integrity of the final product. Industry leaders assert that successful collaborations between brands and CMOs can foster innovative formulations that address the evolving demands of health-conscious consumers seeking preventive solutions.

Moreover, the impact of CMOs on product standards is profound. As the nutraceutical sector expands, the reliance on contract manufacturing CMOs to maintain stringent quality control and ensure regulatory compliance becomes indispensable. This trend is highlighted by the rising incidence of lifestyle-related diseases, which fuels the demand for nutraceuticals that are effective, safe, and compliant with health regulations. In this dynamic landscape, the role of CMOs is essential in ensuring that companies can deliver high-quality products that resonate with consumers and align with market expectations. By partnering with a CMO such as Western Packaging, companies can access customized flexible packaging solutions and integrated filling services that streamline production while enhancing brand recognition and shelf appeal through innovative packaging design. Additionally, Western Packaging's comprehensive 3PL solutions optimize supply chain management, empowering nutraceutical manufacturers to enhance operational efficiency and focus on delivering exceptional products.

Identify Key Selection Criteria for CMOs

When selecting a Contract Manufacturing Organization (CMO) for nutraceuticals, brands must prioritize several essential criteria:

-

Regulatory Compliance: Ensuring that the CMO adheres to industry regulations, including Current Good Manufacturing Practices (cGMP), is crucial for guaranteeing the safety and efficacy of the items. Non-adherence to these standards can lead to serious repercussions, such as recalls, fines, and legal actions, which not only threaten consumer safety but also damage the brand's reputation.

-

Experience and Expertise: It is vital to choose a CMO with a proven history in developing similar nutraceuticals. The typical experience of CMOs in contract manufacturing CMO for nutraceuticals serves as a benchmark; their knowledge of specific formulations and processes significantly impacts the quality of the final product.

-

Technical Capabilities: Evaluating the CMO's manufacturing abilities, including their equipment, technology, and capacity to manage various forms such as powders, capsules, and gummies, is essential. A contract manufacturing CMO with advanced technical skills can deliver innovative solutions tailored to your requirements.

-

Assurance Processes: Assess the CMO's control measures, including rigorous testing protocols and supplier evaluations. Adhering to the regulations specified in 21 CFR Part 111 ensures consistent product standards and mitigates the risk of contamination or defects.

-

Flexibility and Scalability: Consider whether the CMO can adapt to changing production needs and scale operations as your business grows. An adaptable contract manufacturing CMO can accommodate fluctuations in demand, ensuring timely delivery without compromising standards.

-

Communication and Collaboration: A CMO that fosters open communication and teamwork can align more effectively with your organization's goals and respond adeptly to any challenges that arise. Strong partnerships facilitate smoother operations and enhance overall project success.

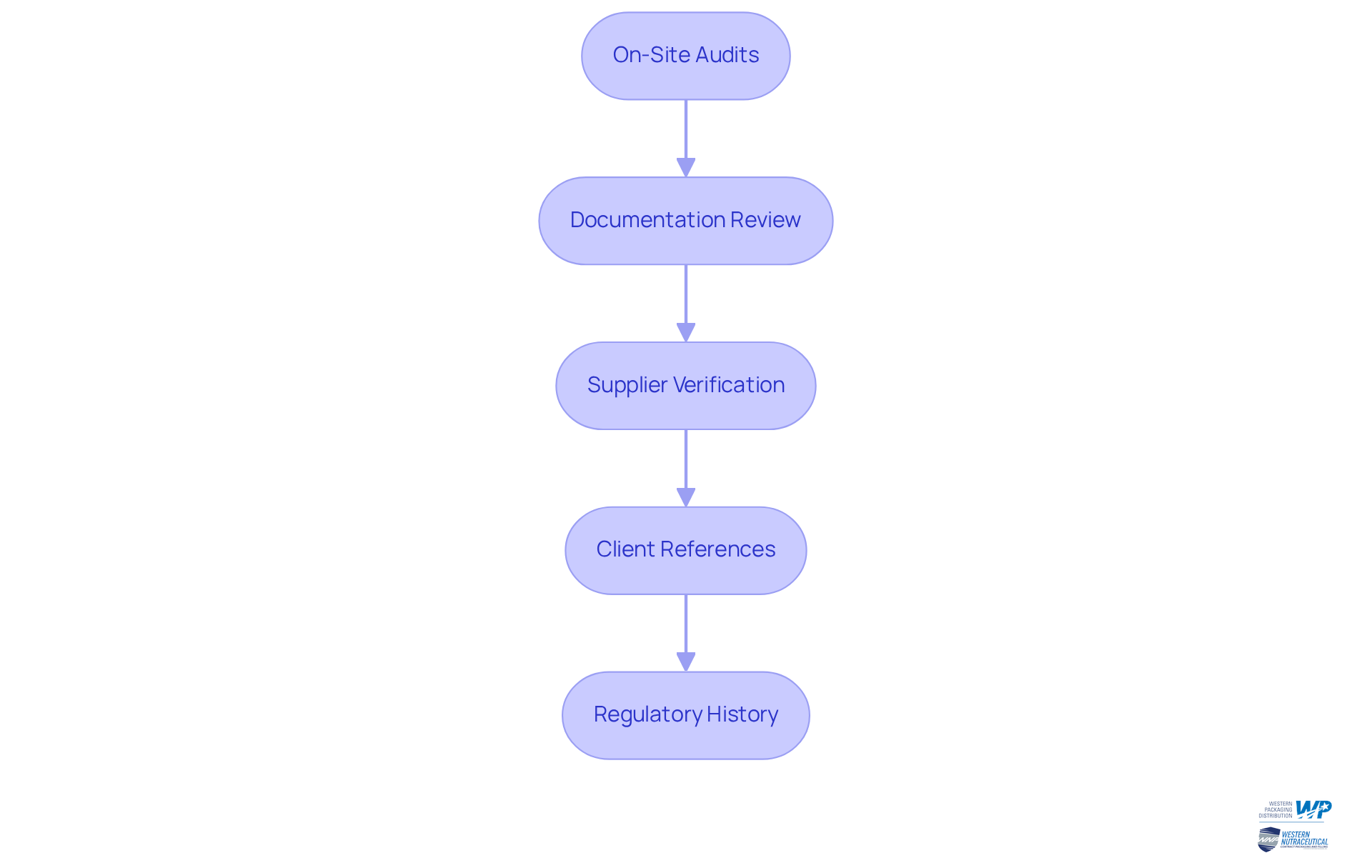

Conduct Due Diligence and Quality Audits

To ensure that a CMO is a suitable partner, brands must conduct thorough due diligence and quality audits. On-Site Audits are essential; arrange visits to the CMO's facilities to evaluate their operations, cleanliness, and compliance with standards. This firsthand observation can reveal significant insights into their capabilities. Next, a Documentation Review is crucial; examine the CMO's quality management system documentation, including their standard operating procedures (SOPs), batch records, and compliance certifications. Furthermore, Supplier Verification is imperative; investigate the CMO's suppliers to ensure they source high-quality raw materials, which may involve reviewing supplier audits and certifications. Additionally, seeking Client References is beneficial; request references from other companies that have collaborated with the CMO, as their experiences can provide valuable insights into the CMO's reliability and performance. Finally, it is vital to assess the Regulatory History; check for any past regulatory issues or violations that could indicate potential risks in partnering with the CMO. A clean regulatory history is a strong indicator of a responsible manufacturer.

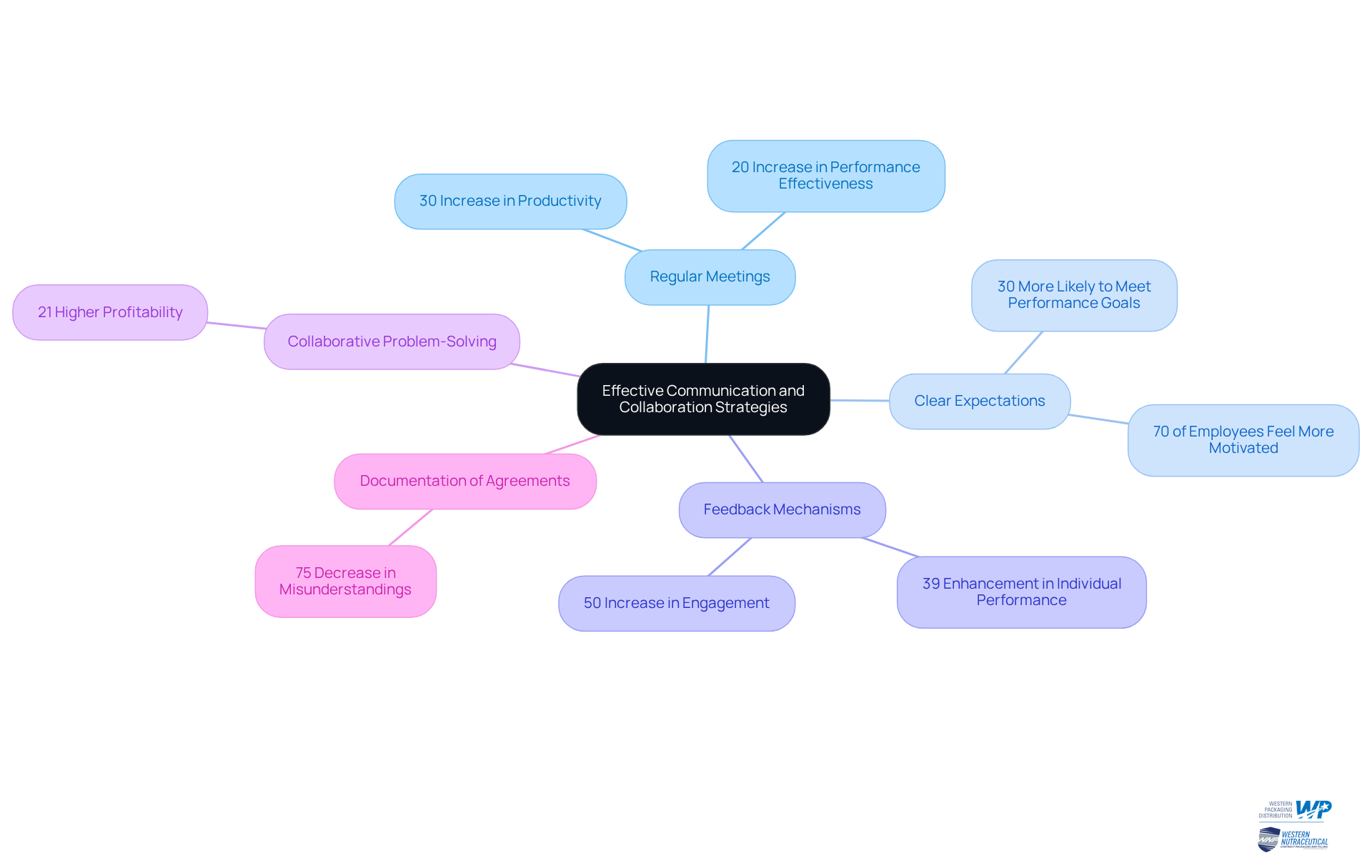

Establish Effective Communication and Collaboration Strategies

To foster effective communication and collaboration with a CMO, brands should adopt the following strategies:

-

Regular Meetings: Establish a routine of consistent check-ins to discuss project updates, address concerns, and align on goals. This practice not only promotes transparency but also enhances accountability, leading to a 30% increase in productivity for teams that maintain regular status meetings. Additionally, teams with frequent check-ins experience a 20% increase in performance effectiveness.

-

Clear Expectations: Clearly define roles, responsibilities, and expectations from the outset. This proactive approach minimizes misunderstandings and ensures that both parties are aligned, making teams 30% more likely to meet their performance goals. Furthermore, 70% of employees feel more motivated when their roles and responsibilities are clearly defined.

-

Feedback Mechanisms: Implement structured channels for providing and receiving feedback on product quality, timelines, and any arising issues. Regular feedback can enhance individual performance by 39% and significantly improve engagement levels, fostering a culture of continuous improvement. Teams with regular feedback mechanisms see a 50% increase in engagement, which directly correlates with improved productivity.

-

Collaborative Problem-Solving: Tackle challenges as a unified team, encouraging open dialogue to explore solutions that benefit both parties. This collaborative mindset not only strengthens partnerships but also cultivates a sense of ownership and accountability among team members. Higher levels of team engagement can result in 21% higher profitability, underscoring the financial benefits of collaboration.

-

Documentation of Agreements: Maintain detailed records of all agreements, changes, and communications. This documentation serves as a clear reference point throughout the partnership, reducing misunderstandings and ensuring that both parties are on the same page. Implementing documentation practices can decrease misunderstandings by up to 75%, further emphasizing the importance of this strategy.

By implementing these strategies, brands can enhance their collaboration with contract manufacturing CMOs, ultimately leading to improved project outcomes and stronger partnerships.

Conclusion

Selecting the right Contract Manufacturing Organization (CMO) for nutraceuticals is a pivotal step for brands seeking to excel in a competitive market. Understanding the critical role CMOs play in manufacturing—ranging from product formulation to regulatory compliance—enables companies to leverage these partnerships, enhancing both operational efficiency and product quality. As the nutraceutical industry experiences continuous growth, the necessity of choosing a CMO that aligns with specific business needs becomes increasingly vital.

Key considerations in the CMO selection process encompass:

- Regulatory compliance

- Experience

- Technical capabilities

- Effective communication strategies

Conducting thorough due diligence and quality audits is essential to ensure that the selected CMO meets industry standards and can adapt to evolving demands. By establishing clear expectations and fostering collaboration, companies can significantly enhance the success of these partnerships, leading to innovative product offerings that resonate with health-conscious consumers.

Ultimately, partnering with a CMO represents a strategic investment in quality and compliance, driving growth within the nutraceutical sector. Companies are urged to prioritize these relationships and adopt best practices in selection and collaboration, ensuring they can deliver safe, effective, and high-quality products that meet the needs of an increasingly discerning market. The future of nutraceuticals hinges on these partnerships; thus, informed CMO selection and collaboration are not merely beneficial but essential for sustained success.

Frequently Asked Questions

What is the role of Contract Manufacturing Organizations (CMOs) in nutraceutical manufacturing?

CMOs provide specialized services in product formulation, production, packaging, and regulatory compliance, allowing companies to focus on their core strengths while leveraging the CMO's manufacturing expertise.

Why is collaboration with CMOs particularly important in 2025?

In 2025, the nutraceutical market is projected to reach USD 513.20 billion, making it crucial for companies to collaborate with CMOs to ensure adherence to standards and compliance in a competitive market.

What are Good Manufacturing Practices (GMP) and why are they important for CMOs?

Good Manufacturing Practices (GMP) are guidelines that ensure products are consistently produced and controlled according to quality standards. They are vital for CMOs to maintain high-quality production and regulatory compliance.

How do CMOs enhance the quality and consistency of nutraceutical products?

CMOs often have established relationships with suppliers, which helps improve the quality and consistency of raw materials, ultimately impacting the integrity of the final nutraceutical product.

What benefits do successful collaborations between brands and CMOs provide?

Successful collaborations can lead to innovative formulations that meet the evolving demands of health-conscious consumers seeking effective preventive solutions.

How do CMOs contribute to maintaining product standards in the nutraceutical sector?

CMOs play a crucial role in maintaining stringent quality control and ensuring regulatory compliance, which is essential as the nutraceutical sector expands and the demand for safe and effective products increases.

What packaging solutions do CMOs like Western Packaging offer to nutraceutical manufacturers?

CMOs like Western Packaging provide customized flexible packaging solutions and integrated filling services, which streamline production and enhance brand recognition through innovative packaging design.

How can CMOs optimize supply chain management for nutraceutical manufacturers?

CMOs can offer comprehensive 3PL (third-party logistics) solutions that optimize supply chain management, helping nutraceutical manufacturers enhance operational efficiency and focus on delivering high-quality products.