Overview

Mastering contract manufacturing of supplements necessitates a comprehensive understanding of essential steps, including the selection of the right manufacturer, ensuring compliance with regulations, and effectively managing production logistics. This article delineates key strategies that are vital for success:

- Evaluating manufacturer certifications

- Maintaining cGMP standards

- Optimizing supply chain logistics

These are crucial elements that collectively enhance product quality and market competitiveness. By implementing these strategies, businesses can position themselves as reliable leaders in the supplement industry.

Introduction

The landscape of dietary supplements is evolving, with contract manufacturing emerging as a pivotal strategy for companies aiming to streamline production and enhance product quality. By outsourcing to specialized manufacturers, businesses can not only reduce costs and accelerate their time-to-market but also leverage advanced technologies that elevate their offerings.

However, the path to successful contract manufacturing is fraught with challenges, ranging from navigating stringent FDA regulations to selecting the right partner.

How can companies ensure they harness the full potential of contract manufacturing while maintaining compliance and quality standards? This question underscores the importance of strategic partnerships in achieving operational excellence.

Understand Contract Manufacturing for Supplements

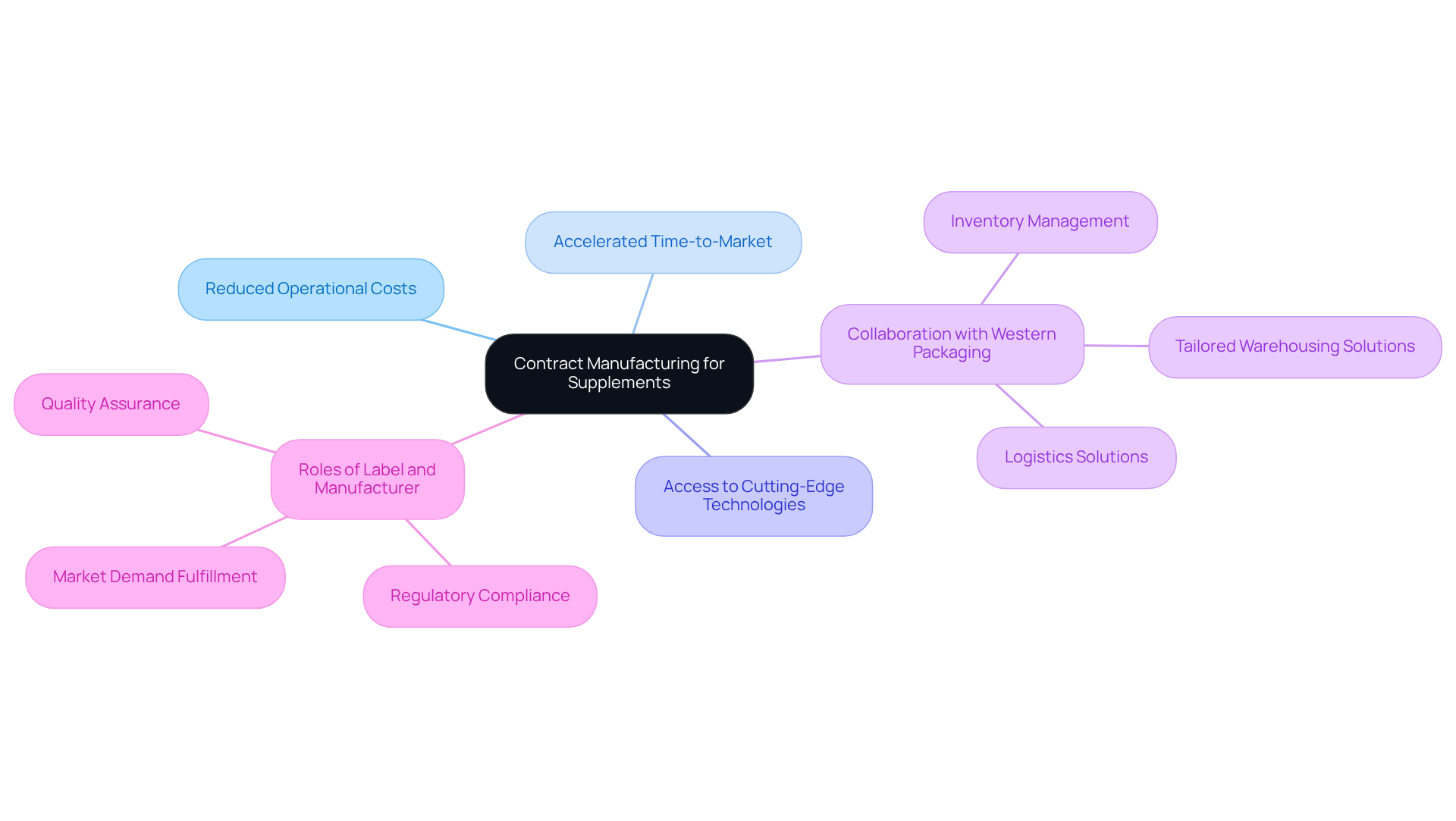

Contract manufacturing of supplements involves outsourcing the production of dietary supplements to specialized manufacturers. This strategic approach allows companies to focus on their core competencies while leveraging the expertise and resources of seasoned producers. The key benefits of this model are:

- Reduced operational costs

- Accelerated time-to-market

- Access to cutting-edge technologies in contract manufacturing of supplements

Furthermore, collaborating with Western Packaging for tailored warehousing, inventory management, and logistics solutions can significantly enhance this process. Understanding the roles of both the label and the manufacturer, alongside the support of a robust 3PL provider, is essential for cultivating a successful partnership that yields high-quality products meeting market demands.

Ensure Compliance with FDA Regulations and cGMP Standards

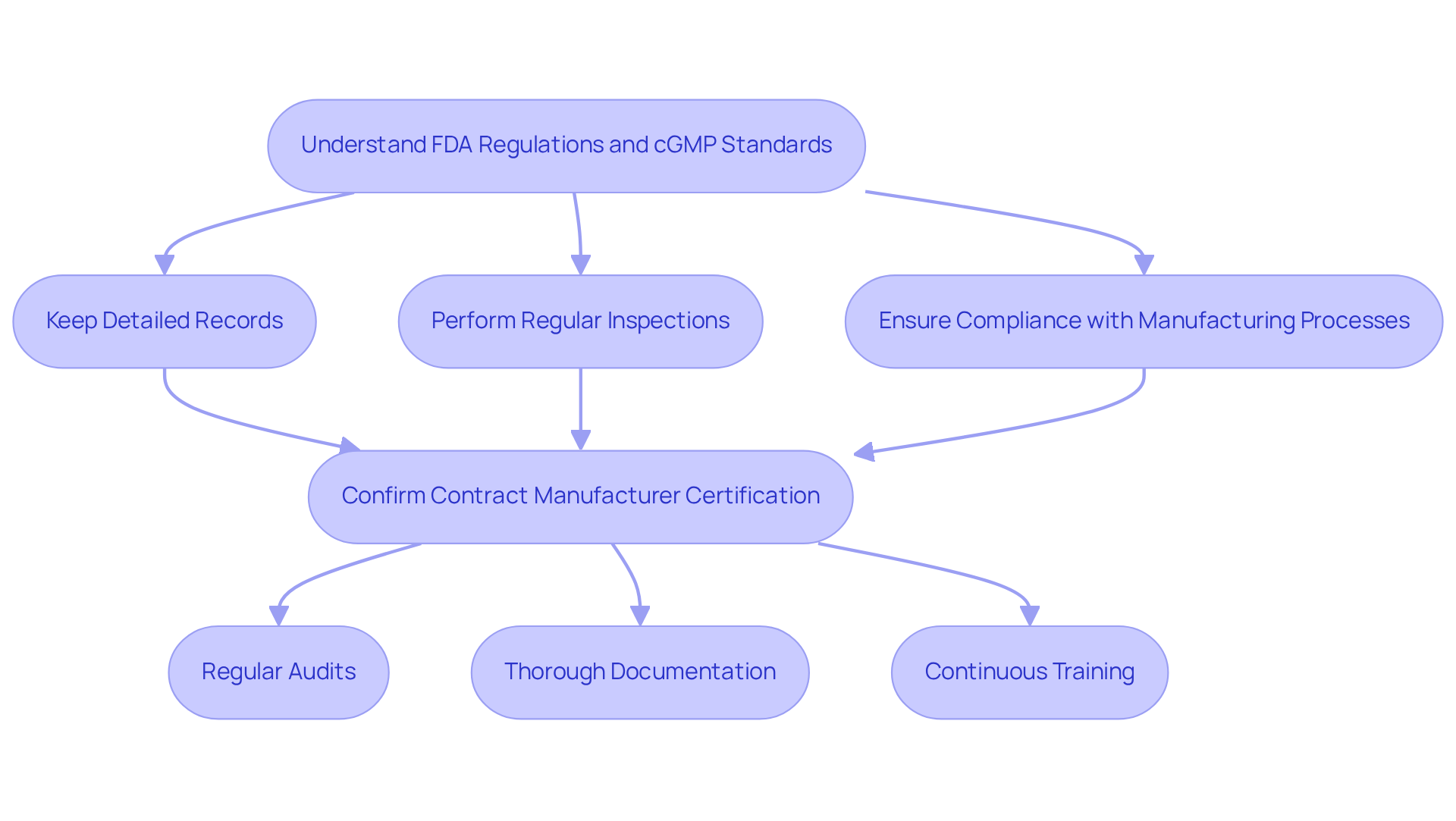

To achieve compliance with FDA regulations and cGMP standards, companies must thoroughly understand the guidelines governing dietary supplement manufacturing. This entails:

- Keeping detailed records

- Performing regular inspections

- Ensuring that all manufacturing processes comply with established standards

It is vital for brands to confirm that their contract manufacturing of supplements producers are certified and adhere to cGMP, ensuring that items are consistently created and regulated according to these quality standards.

In 2025, compliance rates among those involved in contract manufacturing of supplements are expected to be closely monitored, with a significant emphasis on adherence to the latest FDA regulations. Regular training and updates on regulatory changes are essential to maintain compliance and avoid costly penalties, as the FDA has intensified its enforcement efforts, conducting over 18,000 inspections in 2023 alone, a notable increase from 15,443 inspections in 2022.

Expert opinions highlight that companies maintaining cGMP standards not only enhance product safety but also improve market competitiveness. For example, case studies show that producers who prioritize cGMP compliance encounter fewer recalls and regulatory challenges, underscoring the significance of a strong quality control system.

By implementing these practices, such as:

- Regular audits

- Thorough documentation

- Continuous training

brands can safeguard their operations and ensure the integrity of their dietary supplements.

Select the Right Contract Manufacturer: Key Evaluation Steps

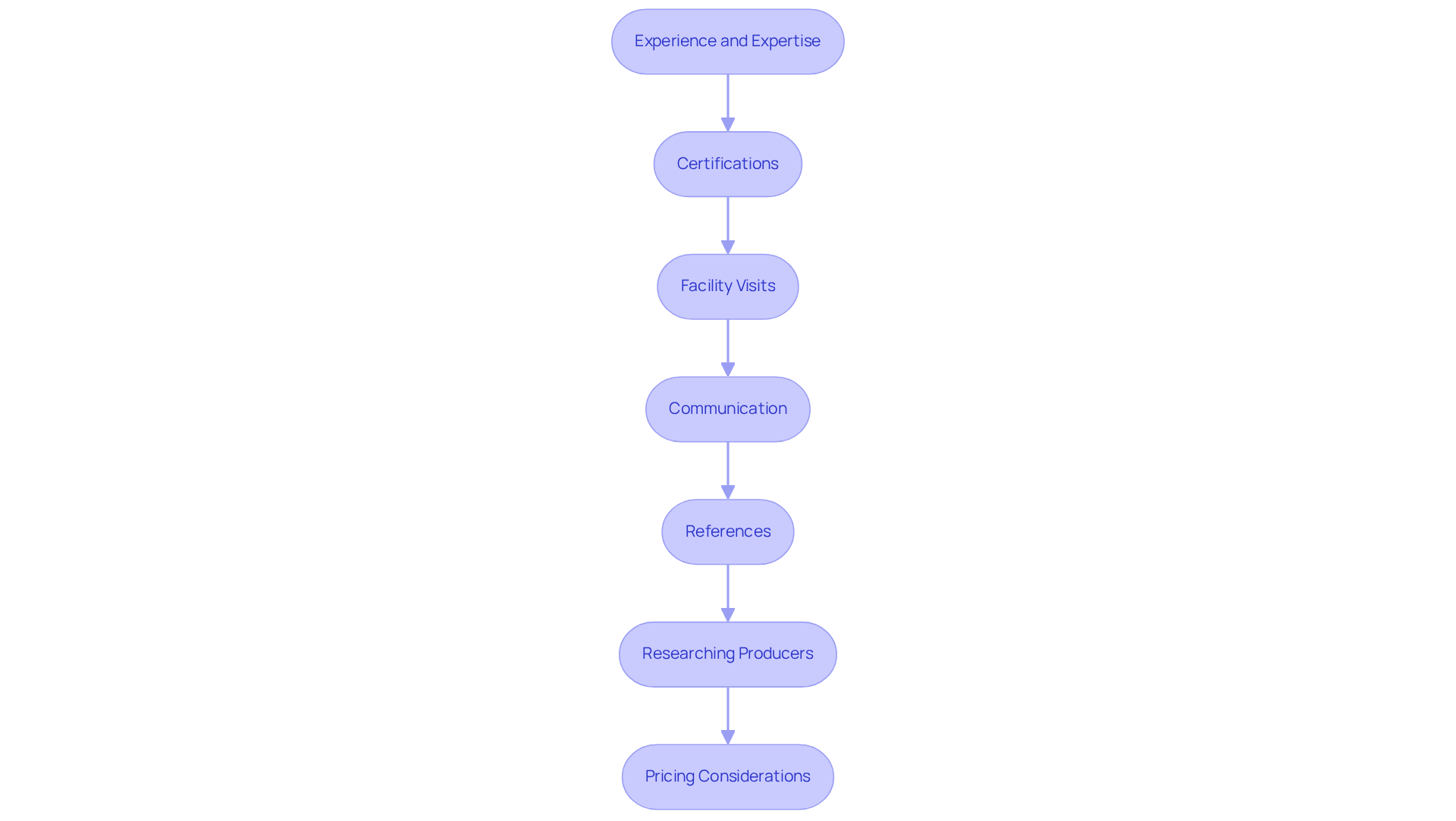

When selecting a contract producer, it is crucial to follow these key evaluation steps:

- Experience and Expertise: Assess the producer's background in creating similar products. Look for a proven track record of successful partnerships within the nutraceutical sector.

- Certifications: Verify that the producer holds relevant certifications, such as GMP (Good Manufacturing Practice) or NSF International, which indicate adherence to high standards. Additionally, ensure they assist in formatting Supplement Facts Panels in accordance with FDA guidelines and avoid making improper health claims.

- Facility Visits: If feasible, conduct site visits to observe the manufacturing environment and processes firsthand. Witnessing operations can provide valuable insights into their control practices, including microbial contamination screening for Salmonella, E. coli, mold, and yeast.

- Communication: Confirm that the producer fosters open lines of communication and is responsive to inquiries.

- References: Request testimonials from other brands that have partnered with the producer to evaluate their reliability and quality of service.

- Researching Producers: Investigate potential producers through online reviews, testimonials, and case studies to gauge their reputation and performance.

- Pricing Considerations: Take into account pricing factors such as ingredient costs, production fees, and shipping & fulfillment options, as these are essential for making informed decisions.

By adhering to these steps, businesses can make well-informed choices when selecting a contract manufacturer for contract manufacturing of supplements, ultimately enhancing their product offerings and improving their market presence.

Manage Production Capacity and Supply Chain Logistics

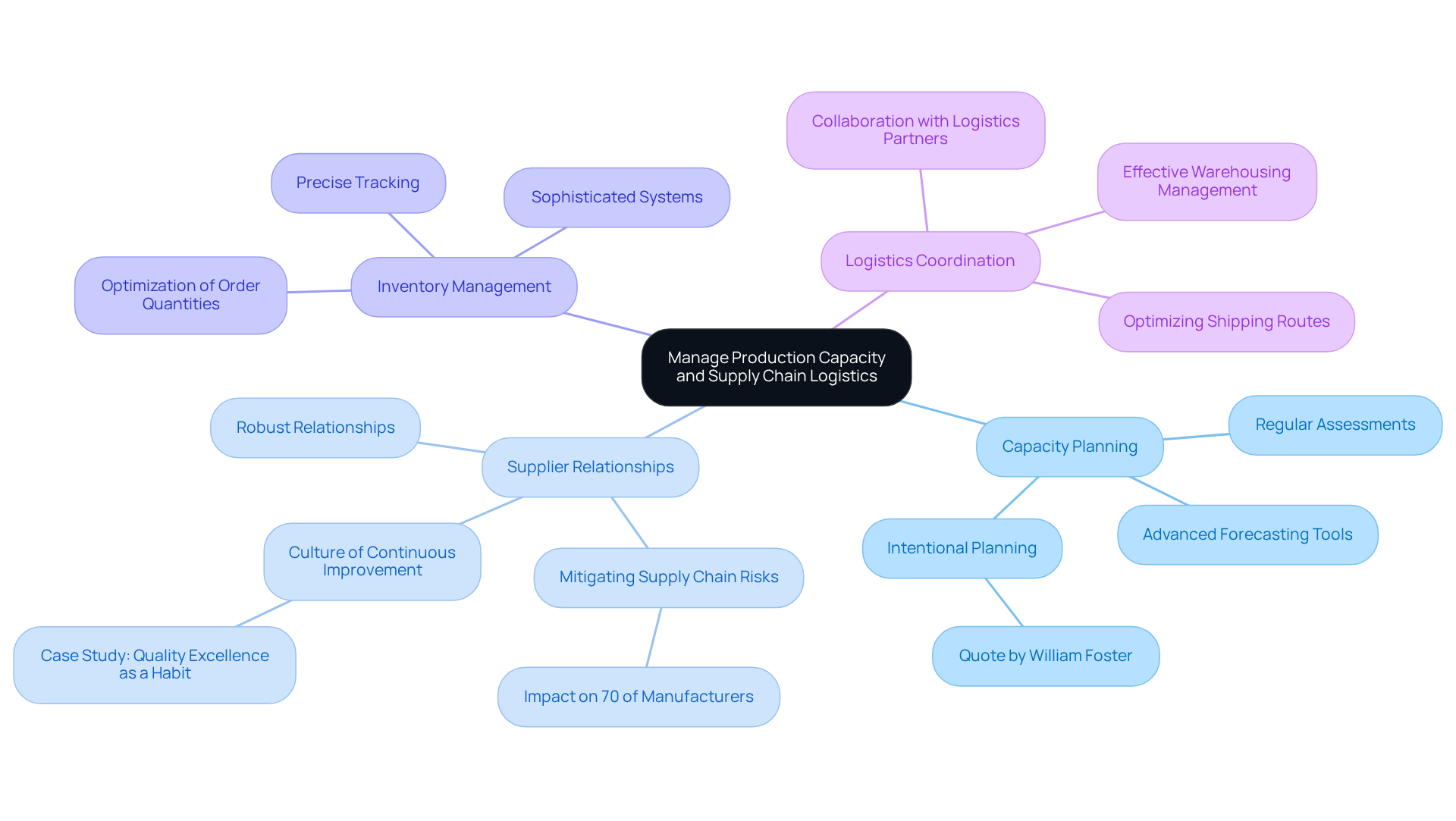

To effectively manage production capacity and supply chain logistics, brands in the nutraceutical sector must adopt key strategies that ensure their competitive edge:

- Capacity Planning: Regular assessments of production capacity are essential to ensure alignment with market demand. By utilizing advanced forecasting tools, brands can predict future needs and proactively adjust production schedules. As William Foster aptly stated, "Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution," underscoring the importance of intentional planning in achieving quality outcomes.

- Supplier Relationships: Establishing robust relationships with suppliers is crucial for maintaining a reliable flow of raw materials. Strong partnerships significantly mitigate risks associated with supply chain disruptions, which have affected over 70% of nutraceutical manufacturers in recent years. Companies that cultivate a culture of continuous improvement can better balance short-term results with long-term objectives, as noted in the case study "Quality Excellence as a Habit."

- Inventory Management: Implementing sophisticated inventory management systems allows for precise tracking of stock levels and optimization of order quantities. This practice reduces excess inventory costs while ensuring product availability when needed, thereby enhancing overall operational efficiency.

- Logistics Coordination: Collaborating closely with logistics partners is vital for streamlining distribution processes. This includes optimizing shipping routes and effectively managing warehousing to minimize lead times, ultimately improving customer satisfaction.

By focusing on these strategies, nutraceutical brands can enhance their supply chain logistics and remain competitive in a rapidly evolving market. The integration of quality management practices across all departments fosters a culture of continuous improvement, which is essential for long-term success.

Conclusion

Mastering contract manufacturing of supplements represents a strategic opportunity that can significantly enhance the market presence of companies. By outsourcing production to specialized manufacturers, businesses can concentrate on their core competencies while benefiting from reduced operational costs, expedited time-to-market, and access to advanced technologies. This collaborative approach streamlines operations and ensures that products meet the high standards demanded by consumers and regulatory bodies alike.

The article outlines essential steps for successful contract manufacturing. Key considerations include:

- Understanding FDA regulations and cGMP standards

- Selecting the right manufacturer through thorough evaluation processes

- Effectively managing production capacity and supply chain logistics

Each of these components is vital in ensuring product quality, safety, and compliance, which are crucial for maintaining a competitive edge in the nutraceutical sector.

Ultimately, embracing best practices in contract manufacturing transcends mere operational efficiency; it fosters a culture of quality and innovation that resonates with consumers. As the dietary supplement industry evolves, companies must prioritize strategic partnerships and rigorous compliance to thrive. Engaging with experienced contract manufacturers and implementing robust quality control measures will position brands for long-term success in a dynamic marketplace.

Frequently Asked Questions

What is contract manufacturing for supplements?

Contract manufacturing for supplements involves outsourcing the production of dietary supplements to specialized manufacturers, allowing companies to focus on their core competencies while utilizing the expertise of seasoned producers.

What are the key benefits of contract manufacturing for supplements?

The key benefits include reduced operational costs, accelerated time-to-market, and access to cutting-edge technologies in supplement production.

How can collaboration with Western Packaging enhance the contract manufacturing process?

Collaborating with Western Packaging can enhance the contract manufacturing process by providing tailored warehousing, inventory management, and logistics solutions.

Why is it important to understand the roles of the label and the manufacturer in contract manufacturing?

Understanding the roles of both the label and the manufacturer is essential for cultivating a successful partnership that yields high-quality products meeting market demands.

What is the role of a 3PL provider in contract manufacturing?

A robust 3PL (third-party logistics) provider supports the contract manufacturing process by managing logistics and supply chain functions, which can contribute to the overall success of the partnership.