Overview

This article delves into best practices for nutraceutical packaging, underscoring the critical importance of:

- Quality standards

- Effective design strategies

- Operational efficiency

- Supply chain optimization

It articulates how adherence to:

- Regulatory compliance

- Innovative packaging design

- Automation in filling processes

- Collaboration with third-party logistics

can significantly enhance product integrity, foster consumer trust, and drive overall market success within the nutraceutical industry. By implementing these strategies, businesses can not only meet but exceed industry expectations, positioning themselves as leaders in the field.

Introduction

The nutraceutical industry is witnessing remarkable growth, fueled by a surge in consumer awareness and demand for health supplements. In this competitive landscape, the significance of effective packaging cannot be underestimated; it acts as both a protective barrier and a vital marketing instrument.

How can manufacturers adeptly navigate the intricacies of quality standards, design strategies, and logistics to ensure their products distinguish themselves while complying with rigorous regulations?

This article explores best practices for nutraceutical packaging, providing insights that can enhance compliance, improve operational efficiency, and ultimately drive greater success in the marketplace.

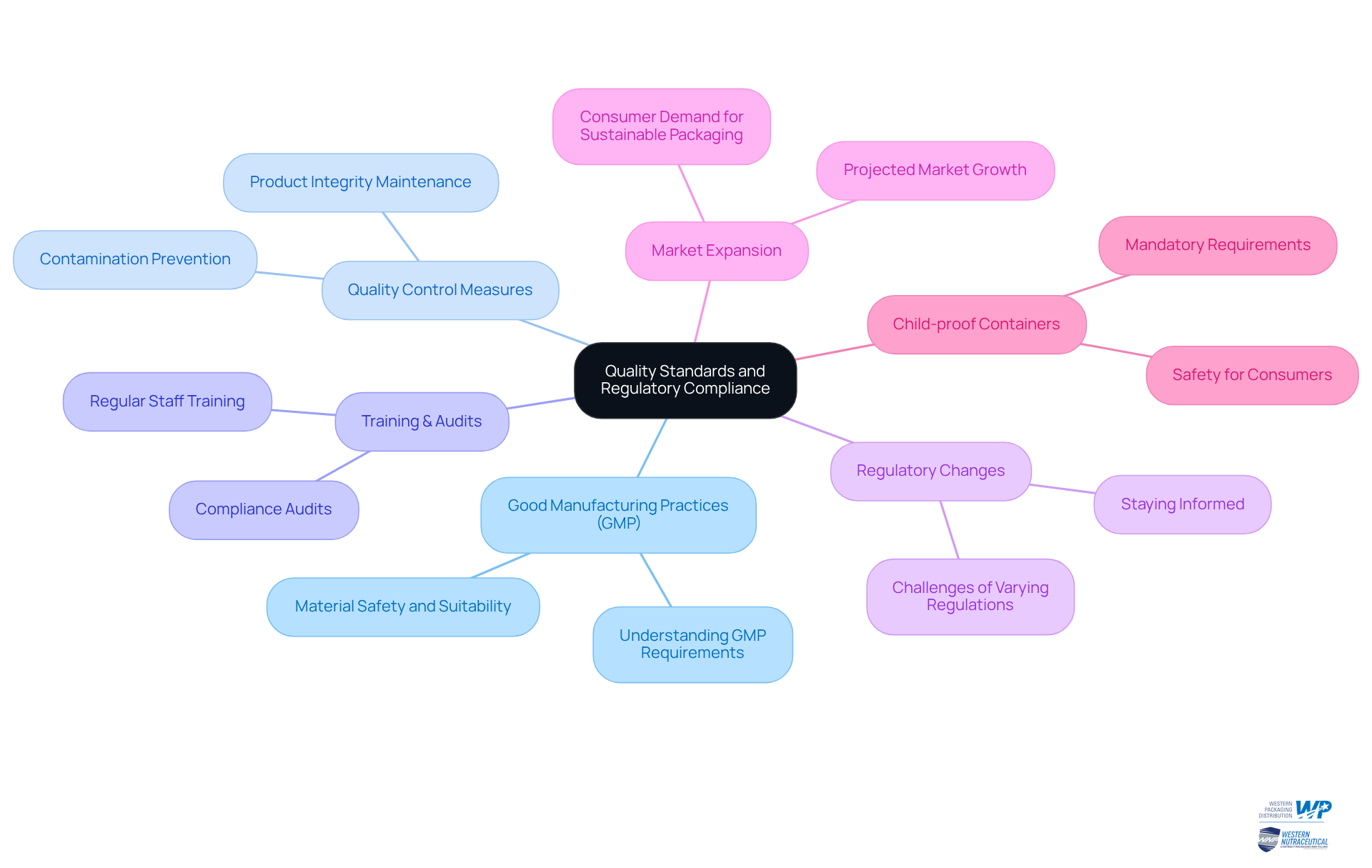

Understand Quality Standards and Regulatory Compliance

To ensure compliance with regulations established by the FDA, nutraceutical companies must thoroughly understand Good Manufacturing Practices (GMP) and labeling requirements. This involves utilizing materials that are safe, non-toxic, and suitable for contact with food. Implementing stringent quality control measures throughout the kit packaging process is essential to prevent contamination and maintain product integrity. Regular audits and staff training on compliance issues can significantly enhance adherence to these standards. For instance, a company that adopted a comprehensive quality management system reported a 30% reduction in compliance-related issues, fostering greater consumer trust and boosting sales. This example demonstrates the effectiveness of applying strong compliance measures in the dietary supplement sector.

Staying informed about regulatory changes is equally crucial. Subscribing to industry newsletters and engaging in relevant workshops can help manufacturers keep abreast of new compliance requirements and best practices. Additionally, it is important to recognize the challenges posed by varying regulations across regions, which can complicate compliance efforts. The nutraceutical container market is anticipated to expand at a compound annual growth rate of 5.6% from 2025 to 2030, with projections to achieve approximately USD 6.95 billion by 2030. This highlights the significance of upholding high standards in kit packaging to satisfy changing buyer expectations and regulatory requirements. Moreover, the use of child-proof containers (CRP) for supplements such as gummies is a necessary obligation that must be followed, guaranteeing safety for individuals.

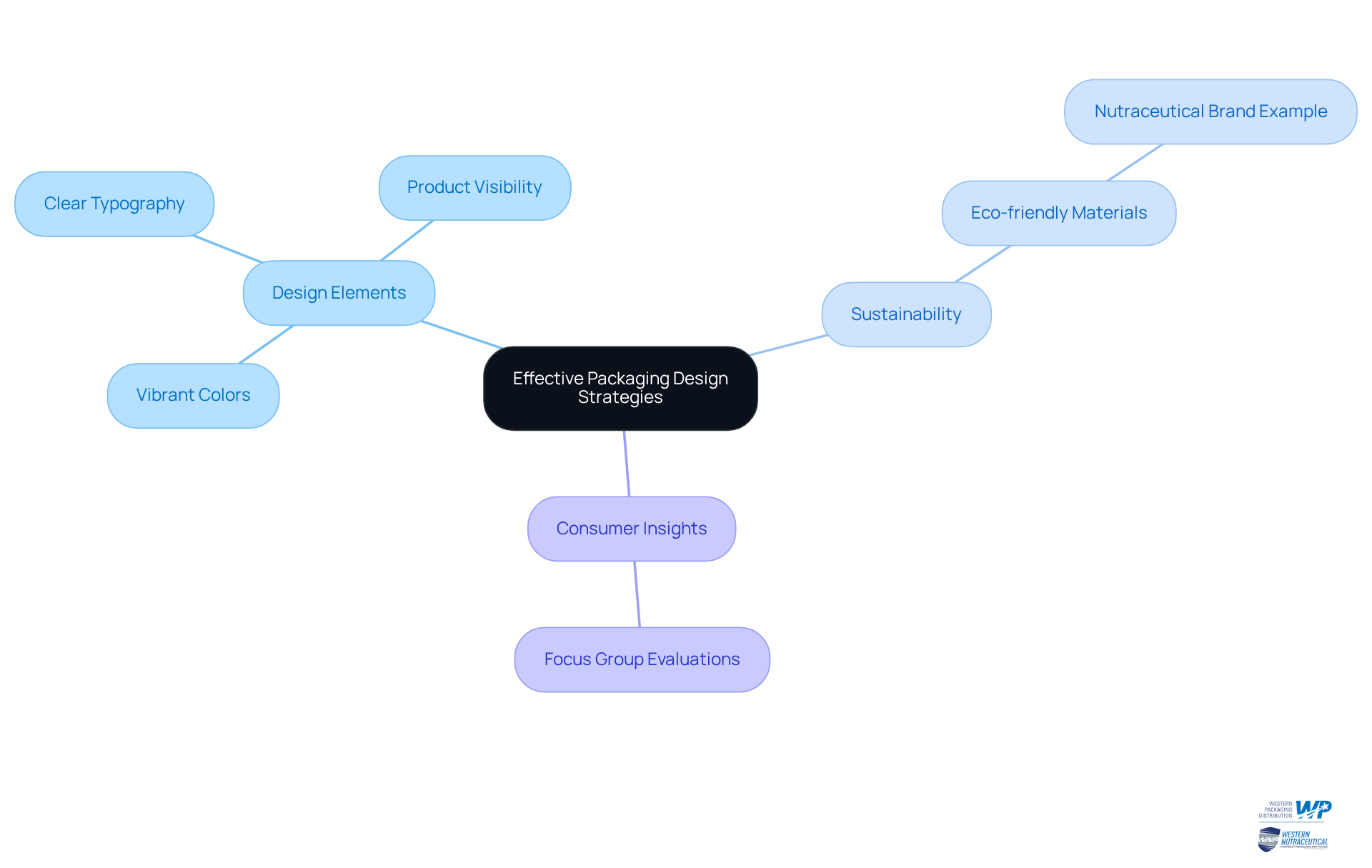

Implement Effective Packaging Design Strategies

To create impactful packaging, manufacturers must prioritize several key design elements. Vibrant hues and clear typography are crucial for making items stand out on shelves, as they improve visibility and draw shopper attention. Brands that utilize bright colors and legible fonts have reported increased customer engagement and brand recognition. Additionally, including clear windows enables customers to view the item, building trust and increasing attractiveness. The container should also clearly convey vital details such as dosage, advantages, and components, ensuring that buyers can swiftly grasp the product's worth.

Sustainability is becoming increasingly essential in design; utilizing eco-friendly materials can greatly appeal to environmentally aware buyers. A significant example is a nutraceutical brand that shifted to eco-friendly containers, leading to a 25% rise in sales due to favorable feedback from buyers. This shift not only addresses the demand for sustainable options but also positions the brand advantageously in a competitive market.

Evaluating packaging designs through focus groups can provide valuable insights into buyer preferences, enabling manufacturers to enhance their final offering effectively. By focusing on these design strategies, nutraceutical brands can strengthen their market presence and drive sales while aligning with modern consumer values.

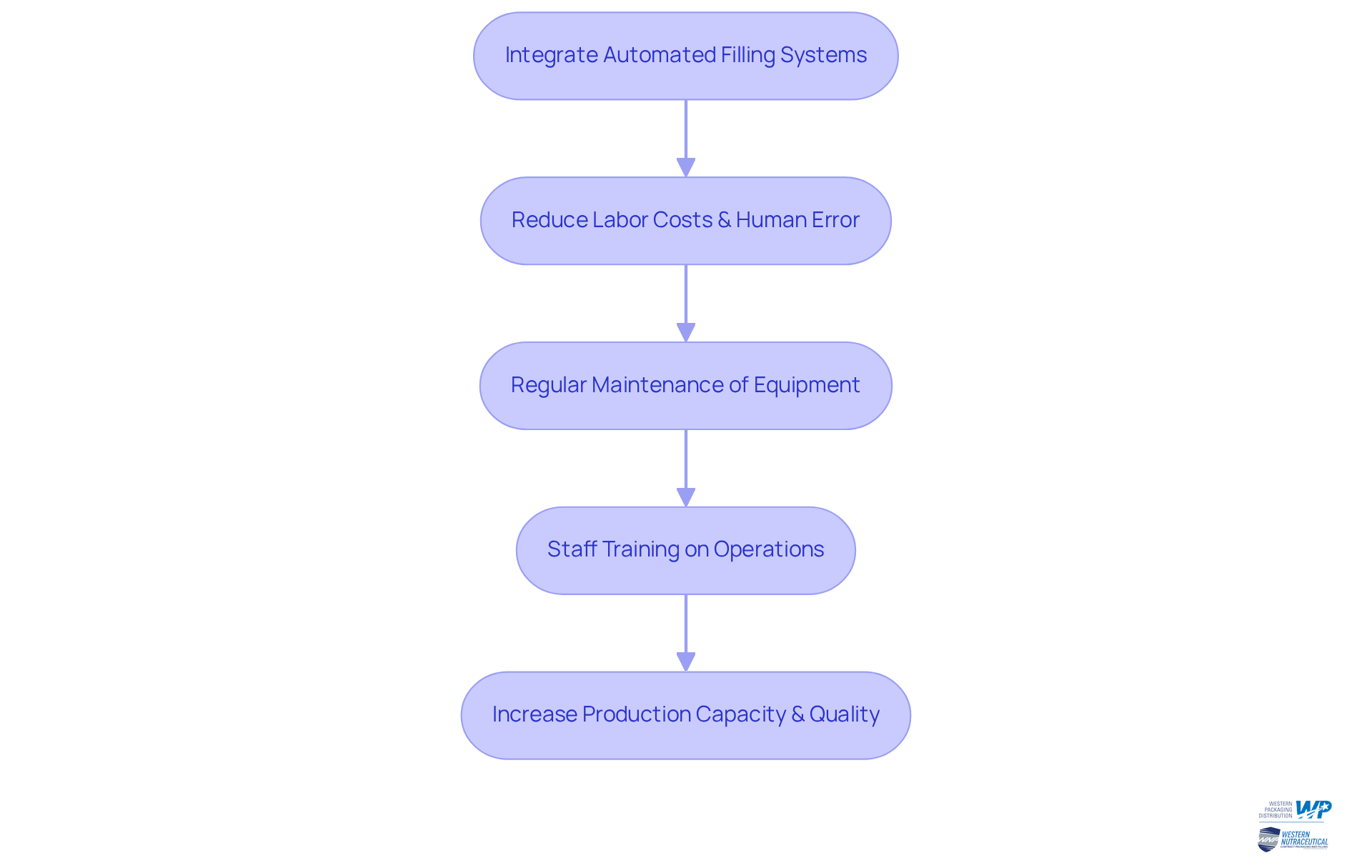

Integrate Filling Services for Operational Efficiency

To enhance operational efficiency, companies must prioritize the automation of their filling processes. Automated filling systems excel at managing a diverse range of items, including powders, gummies, and soft gels, with remarkable precision and speed. By implementing these systems, businesses can significantly reduce labor expenses and minimize human error, ultimately leading to enhanced quality.

Regular maintenance of filling equipment is essential to prevent downtime and ensure consistent performance. For instance, a dietary supplement manufacturer that integrated automated filling solutions experienced a remarkable 40% increase in production capacity while upholding stringent quality standards. Furthermore, investing in staff training on the operation and troubleshooting of filling machines can further boost efficiency and mitigate operational disruptions. This comprehensive approach not only streamlines production but also positions manufacturers to effectively meet growing market demands.

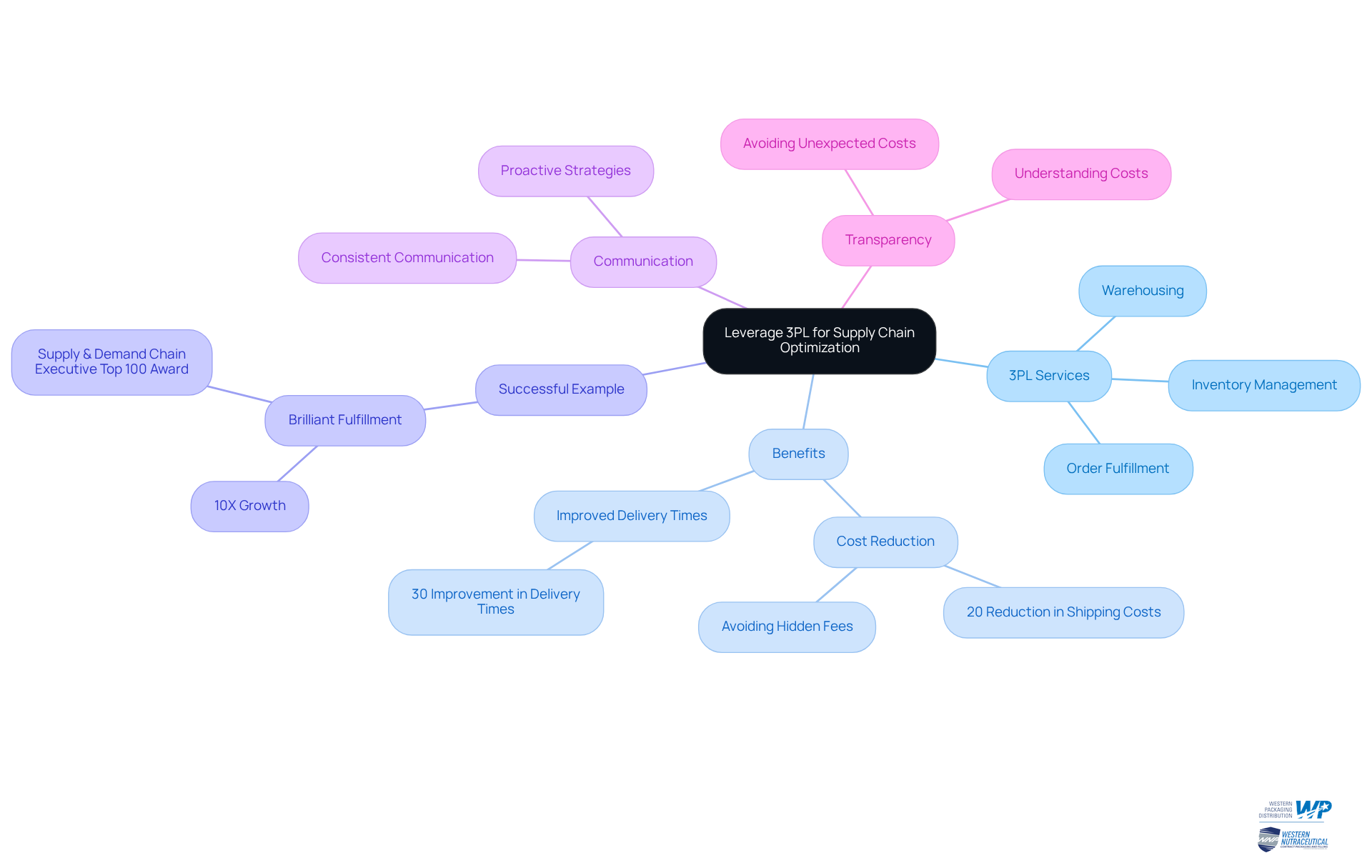

Leverage Third-Party Logistics for Supply Chain Optimization

Collaborating with a reputable third-party logistics (3PL) provider like Western Packaging significantly enhances the distribution process for health supplements. Our extensive 3PL services include:

- Warehousing

- Inventory management

- Order fulfillment

This allows manufacturers to focus on their core competencies. By leveraging advanced technologies, Western Packaging optimizes inventory levels, ensuring product availability when needed while minimizing excess stock.

For example, a health supplement company that outsourced its logistics to Western Packaging experienced a remarkable 20% reduction in shipping costs and a 30% improvement in delivery times. This efficiency stems from our capability to monitor inventory fluctuations and employ sophisticated tracking systems that enhance visibility into the fulfillment process and identify potential errors, thereby preventing shortages and back-orders.

Furthermore, maintaining consistent communication with your 3PL partner is crucial for synchronizing inventory levels and order fulfillment processes. This proactive strategy boosts supply chain efficiency and cultivates a collaborative relationship that can adjust to evolving market demands, ultimately resulting in heightened customer satisfaction and loyalty. Additionally, Western Packaging emphasizes transparency regarding potential hidden fees associated with 3PL services, ensuring that manufacturers are well-informed and can evade unexpected costs. With the nutraceutical industry anticipated to reach a net worth of $722.49 billion by 2027, optimizing logistics through customized solutions from Western Packaging is essential for seizing market opportunities.

Conclusion

Mastering kit packaging in the nutraceutical sector is pivotal for ensuring product success and consumer satisfaction. By adhering to quality standards and regulatory compliance, companies can build trust and enhance their market presence. The integration of effective packaging design strategies not only attracts consumers but also aligns with their growing preference for sustainability.

Key points highlighted in the article underscore the importance of:

- Understanding regulatory requirements

- Implementing innovative design elements

- Utilizing automation in filling processes

Additionally, leveraging third-party logistics can optimize supply chain efficiency, ultimately leading to reduced costs and improved service delivery. These practices collectively contribute to a robust operational framework that supports growth in the nutraceutical industry.

To thrive in this competitive landscape, manufacturers must commit to continuous improvement and adaptation. Embracing these best practices will not only meet regulatory demands but also resonate with consumer values, ensuring long-term success in the nutraceutical market. The time to act is now; optimizing packaging strategies can set brands apart and capitalize on emerging trends in the industry.

Frequently Asked Questions

What are Good Manufacturing Practices (GMP) in the context of nutraceutical companies?

Good Manufacturing Practices (GMP) are regulations that nutraceutical companies must follow to ensure the safety, quality, and integrity of their products. This includes using safe and non-toxic materials suitable for food contact and implementing stringent quality control measures during the packaging process.

Why is quality control important in nutraceutical packaging?

Quality control is essential in nutraceutical packaging to prevent contamination and maintain product integrity. It helps ensure that the products meet safety standards and comply with regulatory requirements.

How can nutraceutical companies enhance compliance with regulations?

Companies can enhance compliance by conducting regular audits, providing staff training on compliance issues, and adopting comprehensive quality management systems. For example, one company reported a 30% reduction in compliance-related issues after implementing such measures.

How can manufacturers stay informed about regulatory changes?

Manufacturers can stay informed by subscribing to industry newsletters and participating in relevant workshops that address new compliance requirements and best practices.

What challenges do nutraceutical companies face regarding compliance?

One of the challenges is the varying regulations across different regions, which can complicate compliance efforts for companies operating in multiple markets.

What is the projected growth of the nutraceutical container market?

The nutraceutical container market is expected to expand at a compound annual growth rate of 5.6% from 2025 to 2030, with projections to reach approximately USD 6.95 billion by 2030.

Why is the use of child-proof containers important in nutraceutical packaging?

The use of child-proof containers (CRP) for supplements, such as gummies, is a necessary obligation to ensure safety for individuals, particularly children, preventing accidental ingestion.