Overview

Mastering order packaging in the nutraceutical sector is essential for enhancing product integrity and consumer appeal. This involves adhering to best practices related to:

- Material selection

- Design

- Regulatory compliance

- Integrated logistics

Implementing robust quality control measures is critical, as is staying attuned to consumer trends such as:

- Sustainability

- Personalization

These elements are not just beneficial; they are vital for boosting brand recognition and ensuring compliance with industry standards. By focusing on these areas, businesses can establish themselves as leaders in the market, demonstrating their commitment to quality and consumer satisfaction.

Introduction

Navigating the intricate landscape of nutraceutical packaging necessitates a strategic approach that harmonizes protection, compliance, and consumer appeal. With the increasing demand for dietary supplements, manufacturers encounter the challenge of ensuring their products not only adhere to stringent regulatory standards but also resonate with a discerning audience.

What best practices can be implemented to enhance product integrity and foster brand loyalty in this competitive market? This article explores essential packaging strategies designed to elevate nutraceutical success while addressing the evolving expectations of consumers and regulators alike.

Understand Nutraceutical Packaging Requirements

Nutraceutical containers must effectively address several essential requirements, including protection from environmental factors, compliance with labeling regulations, and alignment with evolving consumer preferences. Key considerations include:

-

Material Selection: Choosing materials that provide robust barriers against moisture, light, and oxygen is crucial for maintaining product integrity. Flexible wrapping options, such as pouches, are particularly effective, offering excellent moisture protection while remaining lightweight and cost-efficient. In fact, the plastics segment represented more than 52% of the nutraceutical container market share in 2024, underscoring its versatility and effectiveness. Western Packaging focuses on order packaging with customized flexible solutions that enhance appeal and fulfill specific needs, ensuring your items stand out on the shelf.

-

Design Considerations: The packaging design should be visually appealing and functional. Attributes such as resealable closures not only improve user convenience but also contribute to product longevity, addressing the increasing demand for easy-to-use formats. With Western Packaging's innovative order packaging design solutions, brands can enhance their shelf appeal and recognition, aligning with customer preferences for convenience and aesthetics.

-

Consumer Trends: Staying attuned to trends such as sustainability and personalization is vital. The growing preference for eco-friendly materials and customizable options can significantly enhance brand appeal and foster consumer loyalty. With 74% of U.S. adults indicating use of dietary supplements, based on the Council for Responsible Nutrition, brands that align their presentation strategies with these trends are likely to experience enhanced market performance. Streamlining the discussion on these trends is essential to avoid repetition and enhance clarity.

-

Regulatory Compliance: Adherence to labeling regulations is crucial in the nutraceutical container sector. Manufacturers must ensure that their containers meet all necessary guidelines to protect consumers and maintain item integrity.

-

Integrated Filling Services: Alongside design and material selection, integrated filling services play a crucial role in delivering comprehensive solutions. Western Packaging provides these services to guarantee that your items are not only packaged effectively but also filled with precision, enhancing overall efficiency and standards.

By comprehending and applying these requirements, manufacturers can develop solutions for order packaging that not only safeguard the item but also connect with their intended audience, ultimately boosting sales and improving brand recognition through innovative and customized strategies.

Implement Quality Control Measures in Packaging

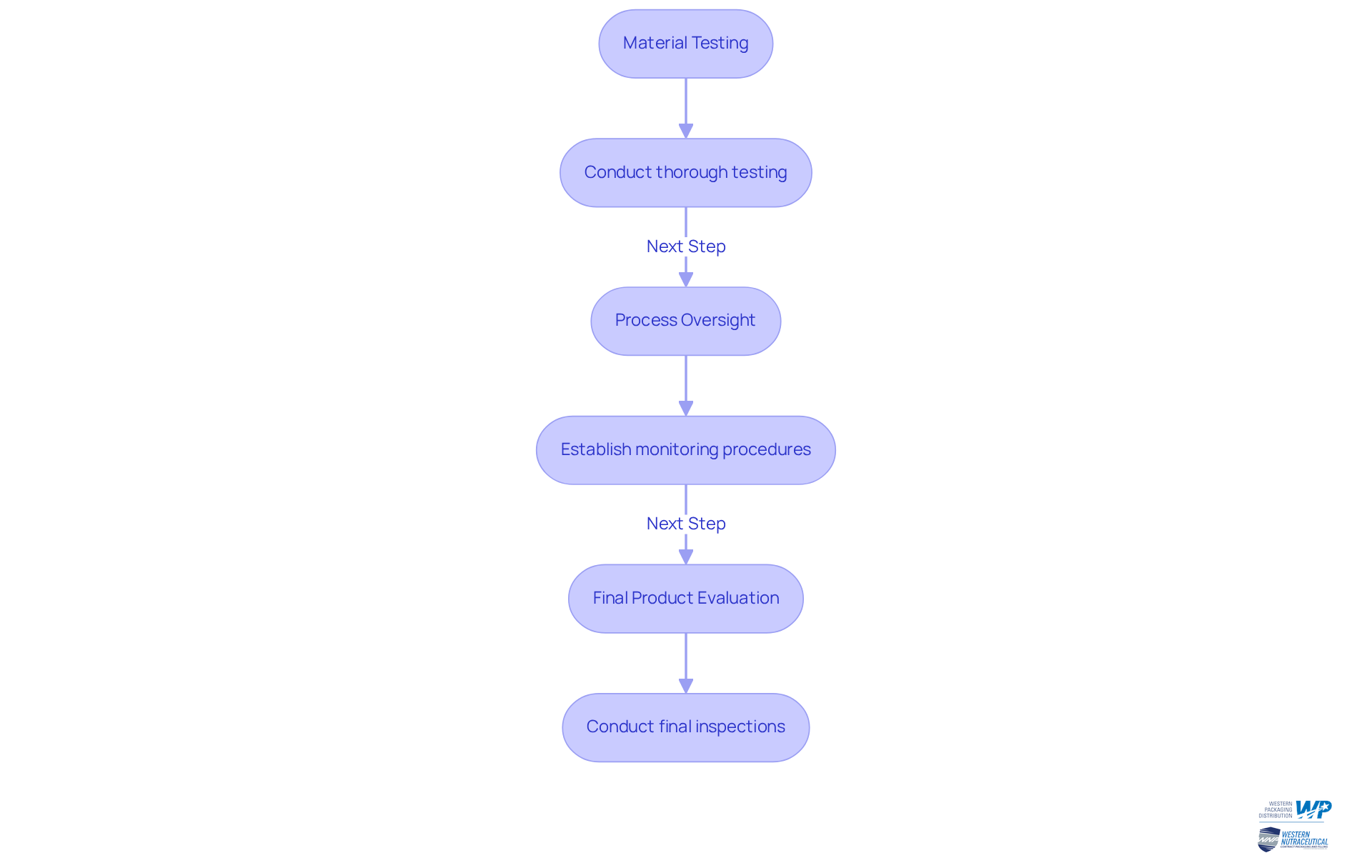

Implementing robust quality control measures in packaging necessitates several critical steps:

-

Material Testing: Conduct thorough testing of packaging materials to ensure compliance with safety and performance standards. This includes checking for contaminants and verifying that materials are suitable for the specific nutraceuticals being packaged. For instance, a probiotic supplement firm effectively prolonged its item's shelf life by as much as 24 months by incorporating oxygen scavengers into their design. Furthermore, a prominent vitamin producer reported a 30% extension in shelf life for their vitamin C offerings due to multi-layer laminate wrapping, underscoring the importance of customized material testing.

-

Process Oversight: Establish monitoring procedures during the packing process to detect and rectify any deviations from standards. Routine evaluations and assessments of the assembly line can prevent common flaws such as printing errors and structural vulnerabilities, which may lead to significant returns. In fact, implementing stringent quality control measures has been shown to reduce returns by up to 40% due to spoilage, particularly when utilizing antimicrobial coatings on containers.

-

Final Product Evaluation: Prior to shipping, conduct final inspections to ensure that container integrity is maintained and that labeling is accurate. This step is essential for compliance with regulatory requirements and for sustaining consumer trust. A robust Quality Management System (QMS) that includes a comprehensive control checklist covering material standards, design specifications, structural integrity, printing standards, assembly, and final inspection can help ensure that all aspects of packaging meet required benchmarks, ultimately enhancing brand reputation and customer satisfaction. As Hayley Chesshir emphasizes, "By investing in strong control and assurance processes, you not only safeguard your items but also foster trust with your clients."

By prioritizing quality control, manufacturers can protect their products and elevate their market reputation, leading to increased customer loyalty and sales.

Ensure Regulatory Compliance in Packaging Processes

To ensure regulatory compliance in nutraceutical packaging, manufacturers must prioritize several key areas:

-

Labeling Requirements: Understanding the FDA's guidelines for dietary supplement labeling is crucial. This includes mandatory statements, ingredient lists, and nutritional information. Precise labeling not only protects public safety but also guarantees legal adherence, as mislabeling can result in substantial penalties and harm to brand reputation. Statistics indicate that many companies face compliance issues due to misunderstandings of labeling requirements, highlighting the importance of thorough training and adherence to established guidelines.

-

Good Manufacturing Practices (GMP): Adhering to GMP standards throughout the order packaging process is essential. This encompasses maintaining sanitary conditions, providing proper employee training, and meticulously documenting all processes. Adherence to GMP promotes trust among consumers and regulators, enhancing the integrity of the item. As mentioned by Maria Abi Hanna, non-compliance with FDA labeling requirements can result in serious repercussions, including recalls and legal action.

-

Regular Audits: Implementing regular internal audits is vital for assessing compliance with regulatory standards. This proactive strategy allows manufacturers to identify and address potential issues before they escalate into serious problems, thereby maintaining operational efficiency and product quality. Case studies have shown that companies that conduct regular audits are better positioned to avoid compliance pitfalls.

By concentrating on these compliance areas, manufacturers can safeguard their brand and clients while improving their credibility through effective order packaging in the competitive nutraceutical market.

Leverage Integrated Packaging and Logistics Solutions

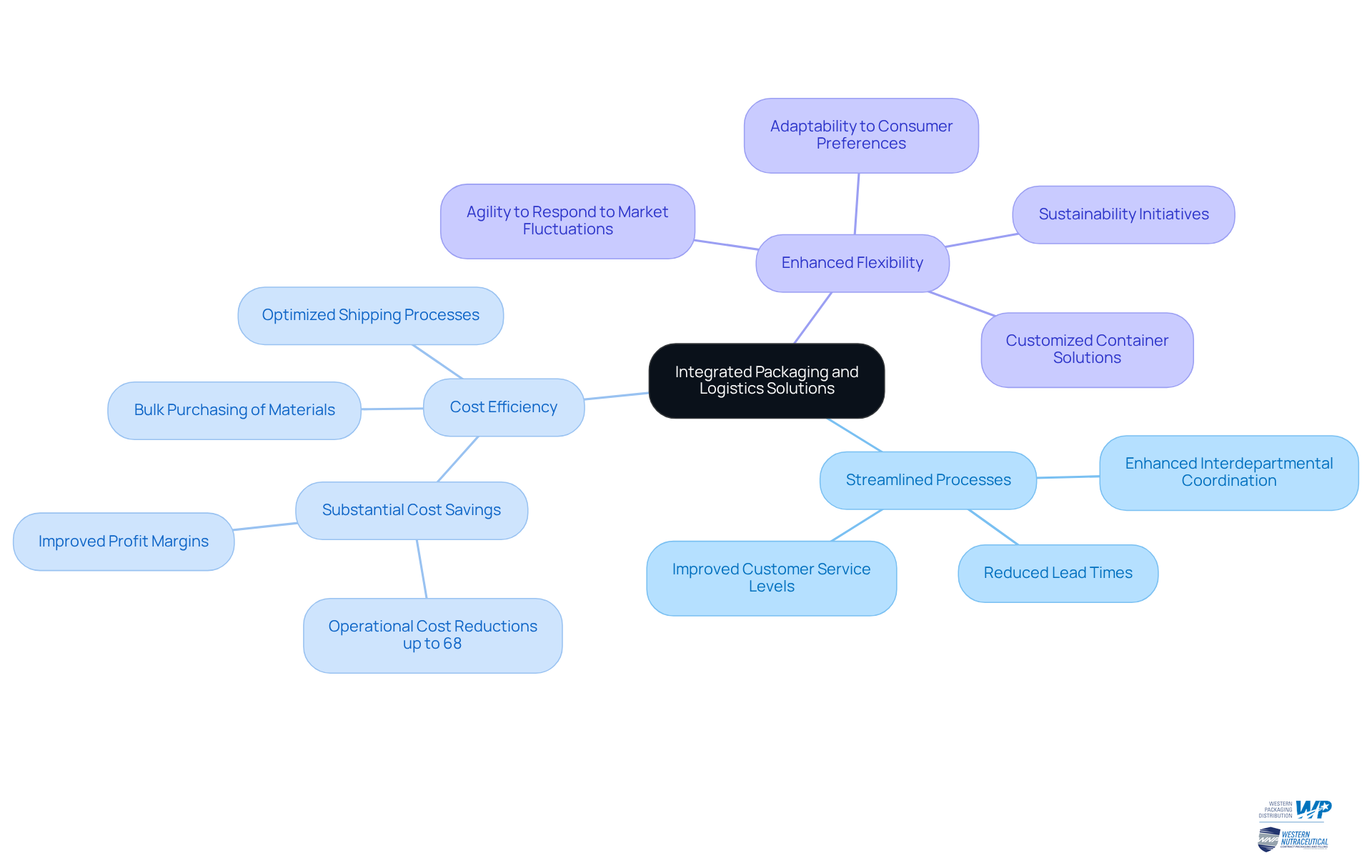

Leveraging integrated packaging and logistics solutions involves:

-

Streamlined Processes: By consolidating packaging and logistics functions, manufacturers can significantly reduce lead times and enhance interdepartmental coordination. This integration fosters quicker turnaround times and elevates customer service levels, ultimately leading to improved satisfaction.

-

Cost Efficiency: Integrated solutions frequently yield substantial cost savings through bulk purchasing of materials and optimized shipping processes. For instance, companies that have adopted such strategies have reported operational cost reductions of up to 68%, translating into improved profit margins and financial health.

-

Enhanced Flexibility: An integrated approach provides manufacturers with the agility to swiftly respond to market fluctuations and consumer preferences. This adaptability is essential in addressing changing trends, such as sustainability initiatives and customized container solutions.

By embracing integrated logistics solutions and order packaging, nutraceutical manufacturers can not only enhance their operational efficiency but also achieve significant cost reductions, thereby bolstering their competitive edge in the market.

Conclusion

Mastering order packaging in the nutraceutical sector is essential for ensuring product integrity, regulatory compliance, and consumer satisfaction. Understanding the unique requirements of nutraceutical packaging allows manufacturers to create solutions that not only protect their products but also resonate with their target audience. This strategic approach is pivotal in a competitive market where brand visibility and consumer trust are paramount.

Key practices include:

- Selecting appropriate materials that safeguard products against environmental factors.

- Integrating quality control measures to maintain high standards throughout the packaging process.

- Adhering to regulatory guidelines to avoid compliance issues.

- Leveraging integrated packaging and logistics solutions to streamline operations, reduce costs, and enhance responsiveness to market demands.

Ultimately, the success of nutraceutical products hinges on effective packaging strategies that prioritize quality, compliance, and consumer trends. Embracing these best practices not only safeguards the product but also fosters brand loyalty and drives market performance. Manufacturers are encouraged to continuously innovate and adapt their packaging solutions to meet evolving consumer expectations and regulatory standards, ensuring long-term success in the nutraceutical industry.

Frequently Asked Questions

What are the essential requirements for nutraceutical packaging?

Nutraceutical packaging must address protection from environmental factors, compliance with labeling regulations, and alignment with evolving consumer preferences.

Why is material selection important in nutraceutical packaging?

Material selection is crucial for providing robust barriers against moisture, light, and oxygen, which helps maintain product integrity. Flexible wrapping options, like pouches, are effective in offering moisture protection while being lightweight and cost-efficient.

What materials dominate the nutraceutical container market?

In 2024, plastics represented more than 52% of the nutraceutical container market share, highlighting their versatility and effectiveness.

What design considerations should be taken into account for nutraceutical packaging?

The packaging design should be visually appealing and functional, incorporating features like resealable closures to enhance user convenience and product longevity.

How can brands enhance their shelf appeal and recognition?

Brands can enhance shelf appeal and recognition by utilizing innovative packaging design solutions that align with customer preferences for convenience and aesthetics.

What consumer trends are important for nutraceutical packaging?

Key consumer trends include sustainability and personalization. The preference for eco-friendly materials and customizable options can significantly enhance brand appeal and foster consumer loyalty.

What is the significance of regulatory compliance in nutraceutical packaging?

Adherence to labeling regulations is crucial for protecting consumers and maintaining item integrity, ensuring that manufacturers meet all necessary guidelines.

How do integrated filling services contribute to nutraceutical packaging?

Integrated filling services ensure that items are packaged effectively and filled with precision, enhancing overall efficiency and standards in the packaging process.

How can manufacturers boost sales and brand recognition through packaging?

By understanding and applying packaging requirements, manufacturers can develop solutions that safeguard the product while connecting with their audience, ultimately boosting sales and improving brand recognition through innovative and customized strategies.