Overview

The article underscores the critical role of mastering package validation testing to ensure compliance and uphold quality within the nutraceutical industry. It highlights that effective validation testing practices, strict adherence to regulatory standards, and seamless integration with logistics are essential for maintaining product integrity. These practices not only prevent recalls but also foster consumer trust, ultimately enhancing the overall reputation of the brand. By prioritizing these elements, companies can secure their position as reliable players in the market.

Introduction

In an industry where safety and efficacy are paramount, nutraceutical manufacturers face the critical task of ensuring that their packaging meets stringent compliance and quality standards. Mastering package validation testing not only safeguards consumer health but also enhances brand reputation and market competitiveness. However, navigating the complex web of regulatory requirements and best practices can be daunting.

How can manufacturers effectively implement validation testing to ensure their products consistently meet the highest standards of quality and compliance?

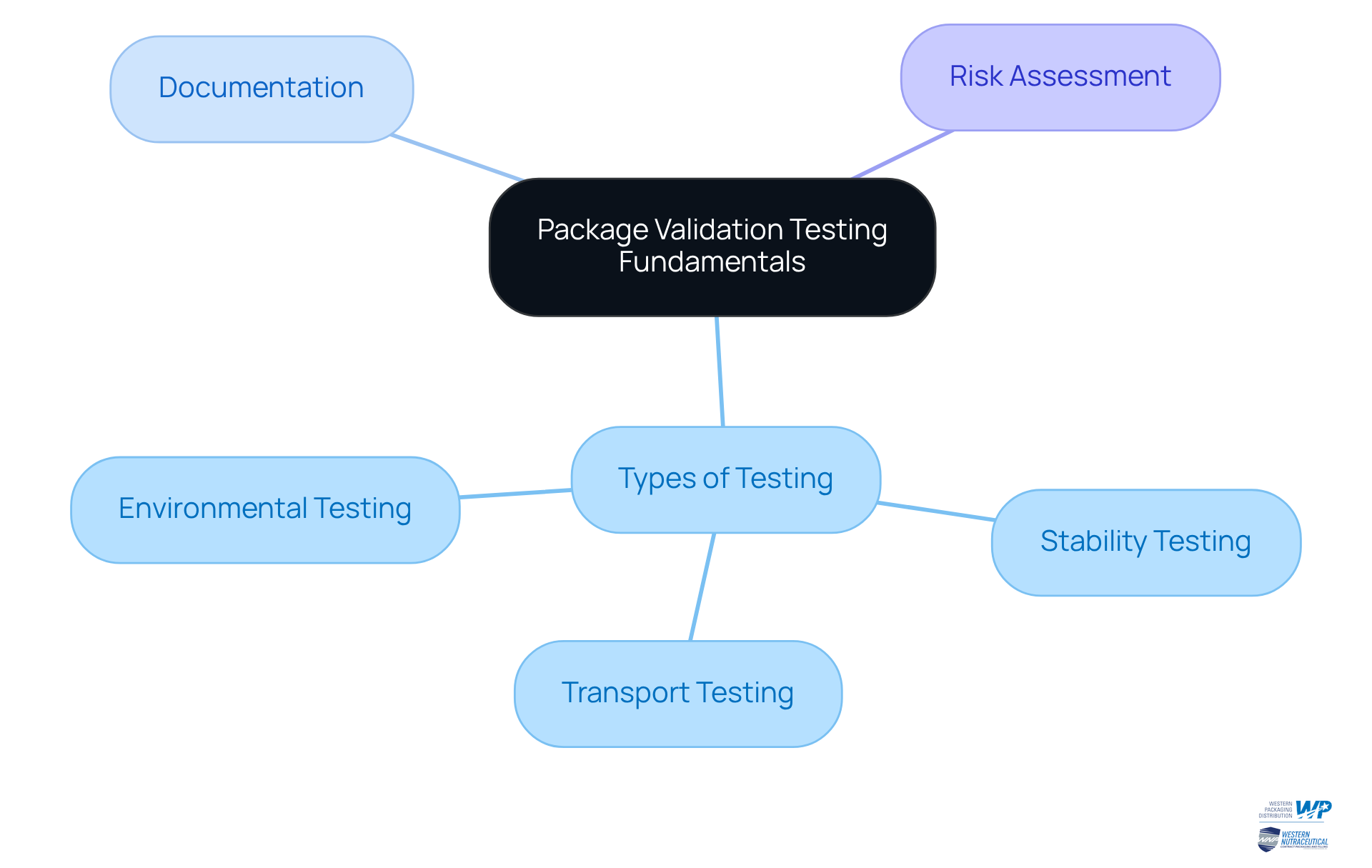

Understand Package Validation Testing Fundamentals

Package validation testing acts as a systematic approach to ensure that container materials and processes comply with specified requirements for safety, quality, and performance. This method involves a series of evaluations for package validation testing, designed to assess the integrity of packaging, which includes barrier properties, seal strength, and compatibility with the product. Understanding these fundamentals is crucial for manufacturers, as it ensures their products remain safe and effective throughout their shelf life. Key aspects include:

- Types of Testing: Familiarize yourself with various testing methods such as stability testing, transport testing, and environmental testing.

- Documentation: Maintain thorough records of all testing procedures and results to ensure compliance and facilitate audits.

- Risk Assessment: Conduct risk evaluations to identify potential failure points in the wrapping process and address them proactively.

By mastering these fundamentals, manufacturers can effectively navigate the complexities of compliance and quality assurance within the nutraceutical sector.

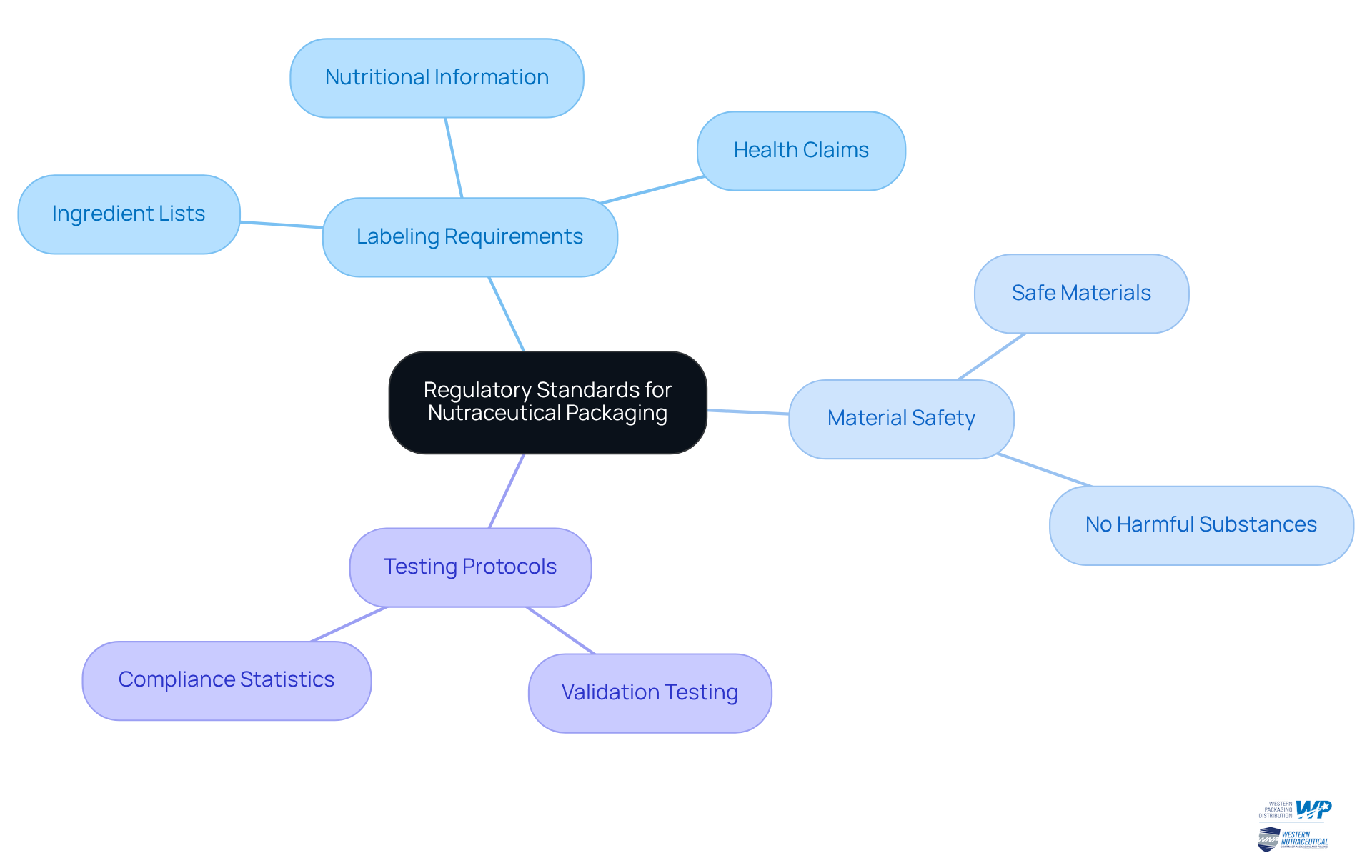

Navigate Regulatory Standards for Nutraceutical Packaging

Regulatory standards for nutraceutical packaging are established by various organizations, including the FDA in the United States and EFSA in Europe. Understanding these regulations is essential to ensure that products are safe for consumers and comply with legal requirements. Key considerations include:

- Labeling Requirements: It is crucial that all product labels adhere to regulatory guidelines, encompassing ingredient lists, nutritional information, and health claims. According to FDA officials, accurate labeling is fundamental for fostering consumer trust and ensuring compliance.

- Material Safety: It is imperative to confirm that container materials are safe for food interaction and do not release harmful substances into the product. This aspect is vital for maintaining product integrity and safeguarding consumer safety.

- Testing Protocols: Familiarization with the required testing protocols for package validation testing of packaging materials is necessary, including any specific tests mandated by regulatory bodies. Statistics indicate that compliance rates for nutraceuticals have improved; however, producers must remain vigilant to avert recalls.

By effectively navigating these standards, producers can prevent costly recalls and enhance their brand reputation. For example, companies that have successfully implemented rigorous labeling compliance have experienced a notable increase in consumer confidence and market presence. Compliance not only protects consumers but also positions brands advantageously in a competitive landscape.

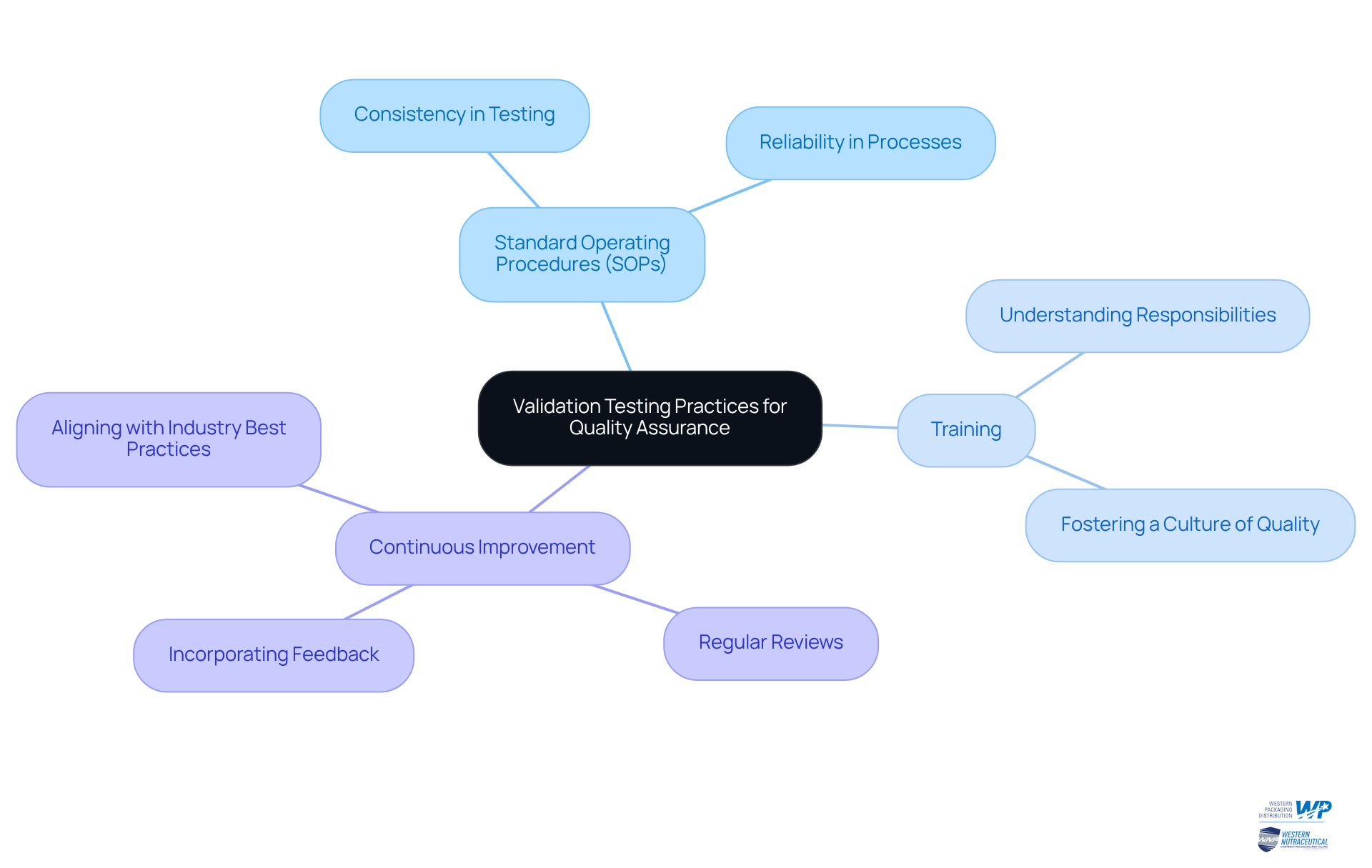

Implement Effective Validation Testing Practices for Quality Assurance

To uphold the highest quality standards in nutraceutical packaging, manufacturers must implement effective validation examination practices. These practices are essential to ensure consistency and reliability in the validation process.

- Standard Operating Procedures (SOPs): It is crucial to develop and adhere to SOPs for all validation testing processes. This ensures that every step taken is consistent and reliable, forming the backbone of quality assurance.

- Training: Providing extensive instruction for personnel engaged in validation assessments is vital. This guarantees that they fully understand the significance of their responsibilities and the evaluation protocols, fostering a culture of quality.

- Continuous Improvement: Regularly reviewing and updating assessment practices based on new research, technological advancements, and feedback from quality audits is imperative. This commitment to improvement not only enhances processes but also aligns with industry best practices.

By adopting these practices, manufacturers can significantly mitigate the risk of product failures and bolster consumer trust in their brands.

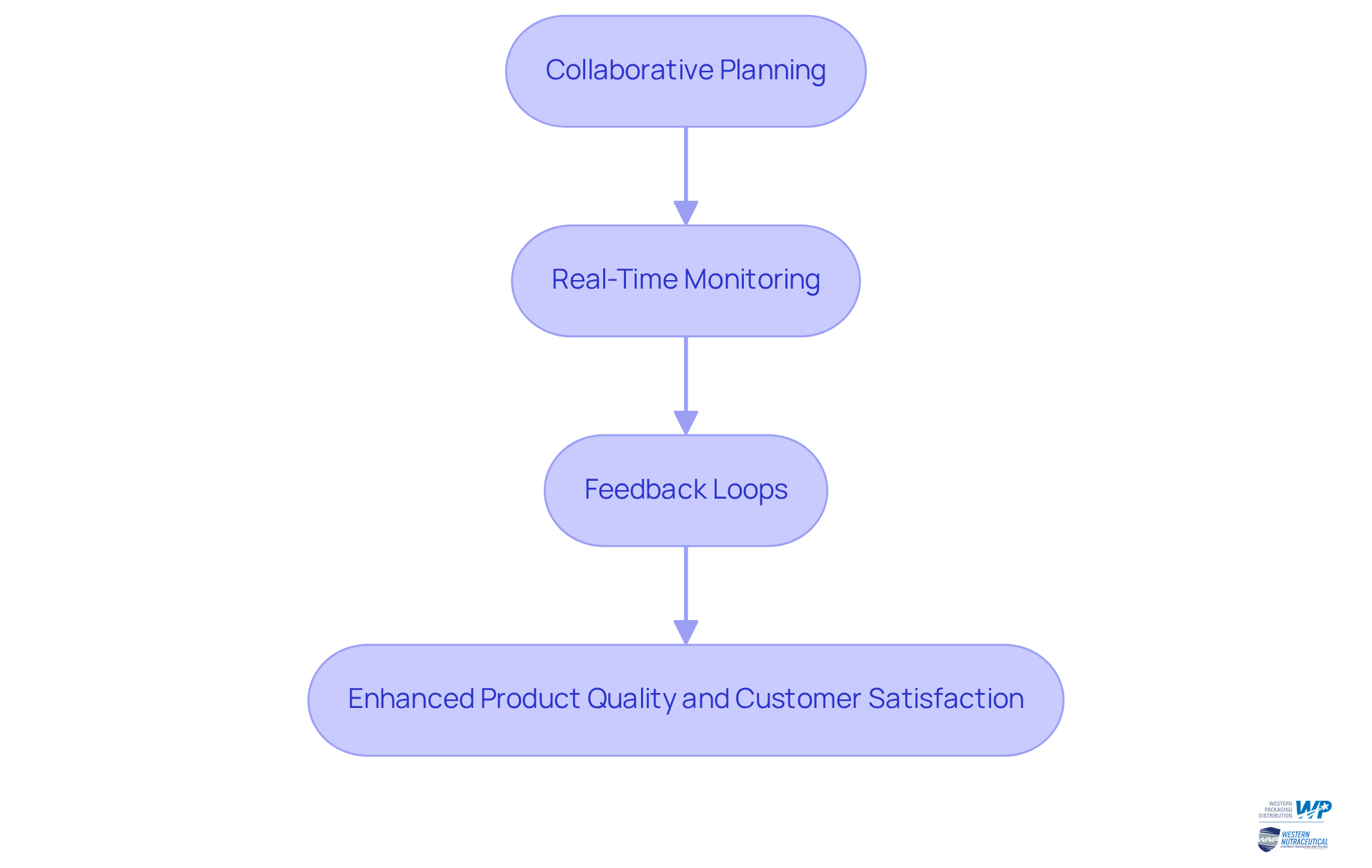

Integrate Validation Testing with Packaging and Logistics Solutions

Integrating validation assessments with distribution and logistics solutions is essential for optimizing the entire supply chain. This integration can be achieved through a strategic approach:

- Collaborative Planning: Collaborate closely with packaging and logistics teams to ensure that validation testing aligns seamlessly with production schedules and distribution timelines.

- Real-Time Monitoring: Leverage advanced technology to oversee packaging integrity and item conditions throughout the supply chain, enabling immediate corrective actions when issues arise.

- Feedback Loops: Establish robust feedback mechanisms between package validation testing and logistics, allowing for continuous improvement of processes based on real-world performance data.

By effectively integrating these elements, manufacturers can significantly enhance product quality, reduce lead times, and ultimately improve customer satisfaction.

Conclusion

Mastering package validation testing is essential for ensuring compliance and quality within the nutraceutical industry. This systematic approach not only safeguards product integrity but also builds consumer trust by adhering to regulatory standards. By understanding the fundamentals of validation testing, manufacturers can effectively navigate the complexities of packaging requirements, ensuring their products remain safe and effective throughout their shelf life.

The article highlights several key aspects, including:

- The importance of familiarizing oneself with various testing methods

- Maintaining thorough documentation

- Conducting risk assessments

Additionally, it emphasizes the necessity of understanding regulatory standards related to:

- Labeling

- Material safety

- Required testing protocols

Implementing effective practices such as:

- Standard operating procedures

- Personnel training

- Continuous improvement

can significantly enhance quality assurance efforts, ultimately preventing costly recalls and fostering brand reputation.

In a competitive landscape, integrating validation testing with packaging and logistics solutions is paramount. By collaborating with logistics teams, utilizing real-time monitoring, and establishing feedback loops, manufacturers can optimize their supply chains, improve product quality, and boost customer satisfaction. Embracing these best practices not only ensures compliance but also positions brands for success in the nutraceutical market, where consumer safety and trust are of utmost importance.

Frequently Asked Questions

What is package validation testing?

Package validation testing is a systematic approach to ensure that container materials and processes meet specified requirements for safety, quality, and performance. It involves evaluations designed to assess the integrity of packaging, including barrier properties, seal strength, and product compatibility.

Why is understanding package validation testing fundamentals important for manufacturers?

Understanding these fundamentals is crucial for manufacturers as it ensures their products remain safe and effective throughout their shelf life, helping them navigate compliance and quality assurance complexities.

What are the types of testing involved in package validation?

The types of testing involved in package validation include stability testing, transport testing, and environmental testing.

Why is documentation important in package validation testing?

Documentation is important because it maintains thorough records of all testing procedures and results, ensuring compliance and facilitating audits.

How can manufacturers address potential failure points in the wrapping process?

Manufacturers can address potential failure points by conducting risk assessments to identify these issues proactively and implement corrective measures.