Overview

Mastering packaging order management requires the efficient coordination of inventory, processing requests, and managing logistics to significantly enhance operational efficiency and customer satisfaction. This article delineates five critical steps:

- Preparing the packaging order

- Selecting appropriate materials

- Executing the packing process

- Finalizing the order

Each step collectively contributes to minimizing errors, reducing costs, and improving overall service delivery within the supply chain.

Introduction

Efficient packaging order management serves as the backbone of successful supply chain operations; however, many businesses find themselves grappling with its complexities. By mastering this critical process, companies can unlock substantial benefits, such as reduced errors, cost savings, and enhanced customer satisfaction. The challenge persists: how can businesses streamline their packaging order management to not only meet but exceed customer expectations in an increasingly competitive landscape? This guide explores five essential steps designed to transform packaging order management into a seamless and efficient operation.

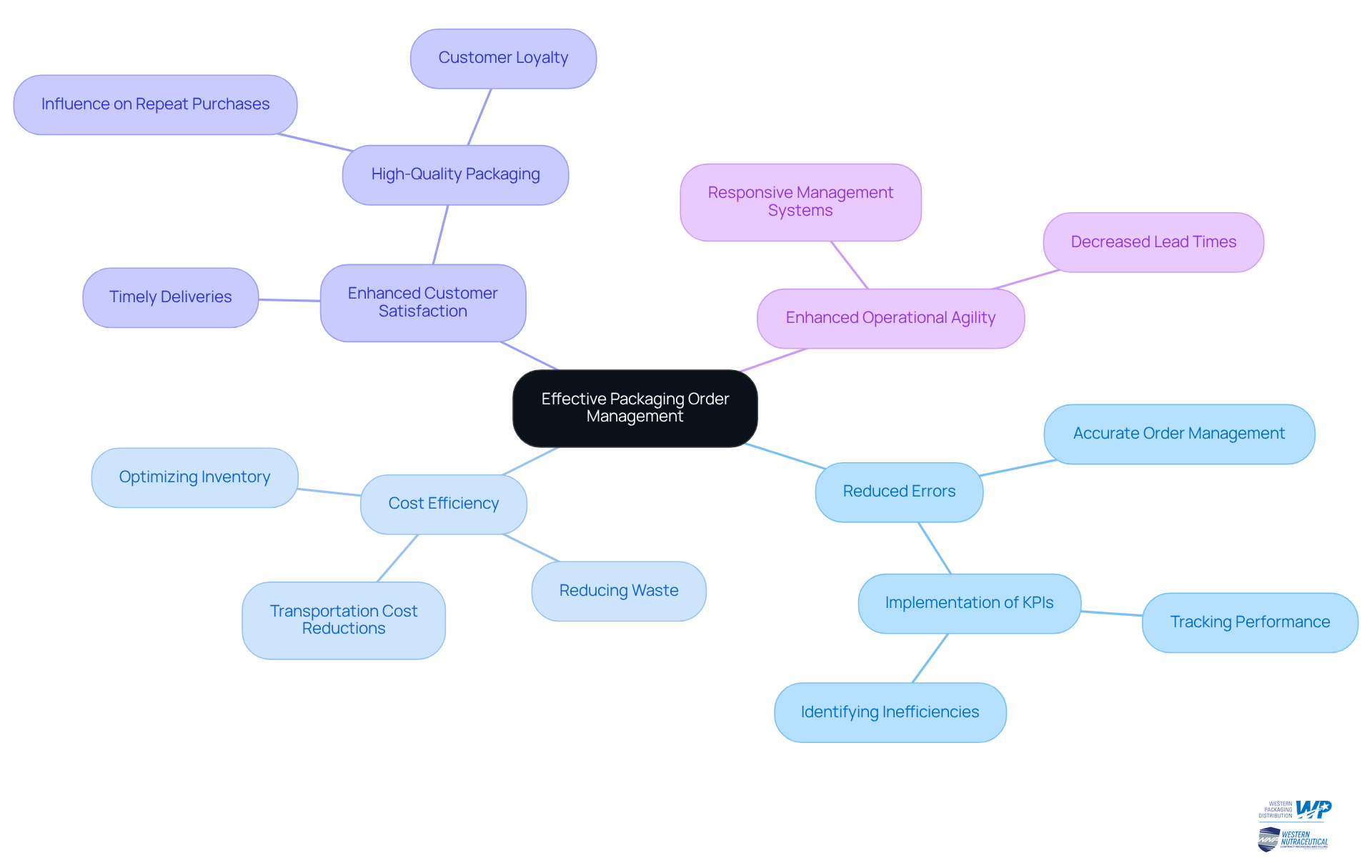

Understand the Importance of Effective Packaging Order Management

Efficient container management is essential for companies aiming to enhance their packaging order and supply chain procedures. This involves the seamless coordination of inventory levels, processing of requests, and the management of packaging order logistics. By mastering this aspect of the packaging order, companies can significantly reduce lead times, minimize errors, and enhance customer satisfaction. Recognizing the importance of this management process enables businesses to pinpoint pain points and implement strategies that streamline the packaging order, ultimately leading to increased efficiency and profitability. Western Packaging provides extensive 3PL services, including warehousing and inventory management, that can further improve your management of shipment requests. Our tailored solutions allow you to focus on what you do best while we optimize your supply chain.

Key benefits include:

- Reduced Errors: Accurate order management minimizes mistakes in packaging and shipping, ensuring that customers receive the correct products. Studies show that implementing key performance indicators (KPIs) can help warehouse managers track performance and identify inefficiencies, leading to a reduction in errors.

- Cost Efficiency: Optimizing inventory and reducing waste can lower operational costs. Effective management processes assist companies in lowering expenses and optimizing the packaging order by removing inefficiencies. Moreover, efficient container design minimizes material usage while ensuring item protection, leading to considerable transportation cost reductions.

- Enhanced Customer Satisfaction: Timely deliveries and precise requests improve the packaging order and customer experience, promoting loyalty and repeat business. Studies show that 52% of customers are more inclined to buy again from an online seller if they receive their items in high-quality wrapping, emphasizing the influence of efficient management on customer loyalty.

- Enhanced Operational Agility: In today's dynamic business environment, agile management systems enable companies to respond swiftly to market fluctuations, decreasing lead times and enhancing overall supply chain responsiveness. This agility is essential for ensuring timely packaging orders to maintain competitiveness in a rapidly evolving marketplace.

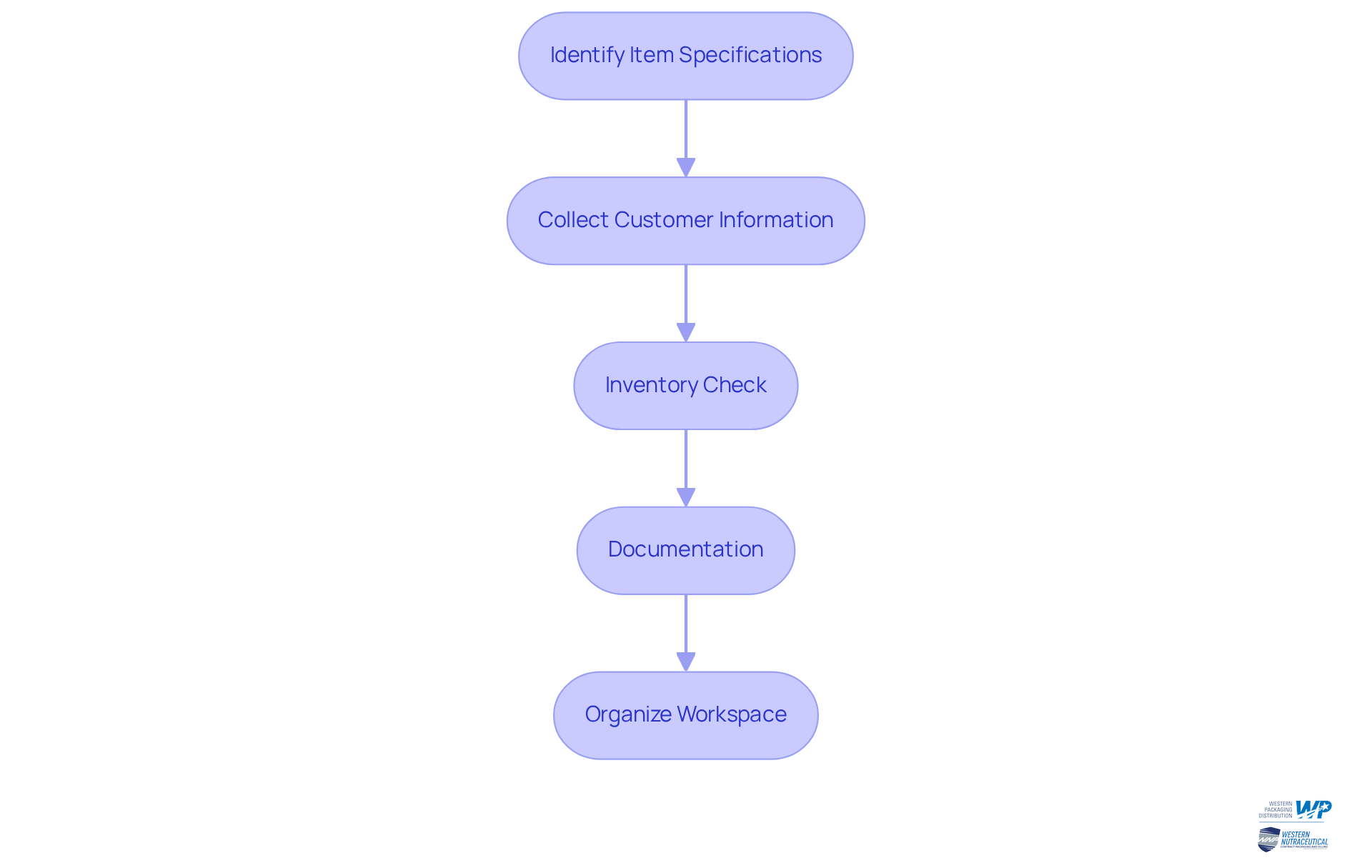

Prepare Your Packaging Order: Gather Necessary Information and Materials

To effectively prepare your packaging order, it is essential to adhere to these crucial steps:

-

Identify Item Specifications: Gather comprehensive details about the items to be packaged, including dimensions, weight, and any special handling requirements. This guarantees that the container is customized to safeguard the product during transport and storage.

-

Collect Customer Information: Accurate customer information is crucial for order fulfillment. Ensure you have precise shipping addresses, contact details, and any specific instructions from customers to avoid delays and errors.

-

Inventory Check: Conduct a thorough inventory assessment to confirm that you have sufficient materials on hand, including boxes, cushioning supplies, and labels. Inadequate inventory can lead to stockouts, disrupting operations and increasing costs. In fact, estimated inventory wastage due to packaging material failures in 2023 ranges from 5-10%, underscoring the importance of diligent inventory management.

-

Documentation: Prepare all necessary paperwork, such as shipping slips, invoices, and shipping labels, to accompany the order. Proper documentation not only facilitates smooth logistics but also enhances customer satisfaction by ensuring transparency in the packaging order process.

-

Organize Workspace: Set up a dedicated assembly area where all materials are easily accessible. An organized workspace streamlines the packing process, reducing lead times and improving overall efficiency.

By adhering to these best practices, you can enhance your product management, ensuring that your operations run smoothly and effectively meet customer expectations. Successful inventory checks and accurate information gathering are vital for maintaining operational efficiency and minimizing waste. As emphasized in the case study on 'Strategies to Reduce Inventory Waste Caused by Packaging Failures in 2023,' implementing effective inventory management strategies can significantly decrease the occurrence of container failures and the associated inventory waste. Additionally, as Maria Vargas notes, "Companies that implement automated inventory tracking gain real-time visibility over stock levels," which is essential for effective order management.

Select Suitable Packaging Materials for Your Products

Selecting the appropriate materials for containers is vital for guaranteeing safety and boosting brand attractiveness. To effectively navigate this decision, consider the following key factors:

-

Item Category: Different items necessitate specific wrapping solutions. For instance, delicate items may require protective materials such as bubble wrap or foam, whereas powders and similar goods benefit from airtight containers to preserve freshness and prevent contamination. At Western Packaging, we specialize in discovering optimal flexible solutions tailored to your needs—whether it's large pouches for protein products or stick packs for nutraceuticals.

-

Shipping Method: The choice of shipping option significantly influences material selection. Lightweight materials are ideal for air transport to minimize costs, while sturdier options may be more suitable for ground shipping, where weight considerations are less critical.

-

Sustainability: With 81% of consumers demanding environmentally friendly options, the selection of eco-conscious materials is increasingly essential. Brands prioritizing sustainability not only meet consumer expectations but also enhance their market presence; over 60% of shoppers are likely to repurchase products packaged sustainably. Furthermore, nearly 70% of US consumers favor biodegradable and reusable materials such as paper and cardboard, underscoring the shift towards eco-friendly options.

-

Cost: Striking a balance between quality and cost-effectiveness is crucial. While premium materials may offer superior protection, they can also elevate overall shipping expenses. It is essential to assess the long-term advantages of resilient materials against initial costs for efficient budgeting.

-

Branding: Packaging is a direct reflection of your brand. Custom wrapping solutions from Western Packaging can significantly enhance brand recognition and consumer appeal. It is vital to ensure that your containers align with your brand image and values. Engaging designs can create memorable unboxing experiences, fostering customer loyalty. Research indicates that 72% of buyers are influenced by item presentation when making purchasing decisions. Additionally, incorporating cohesive graphic assets, such as labels and brochures, can further strengthen your brand identity.

By thoughtfully evaluating these elements, companies can select materials for their packaging order that not only safeguard their items but also resonate with their target audience and support sustainability initiatives. With our innovative packaging design solutions, Western Packaging is poised to elevate your product's shelf appeal and brand recognition.

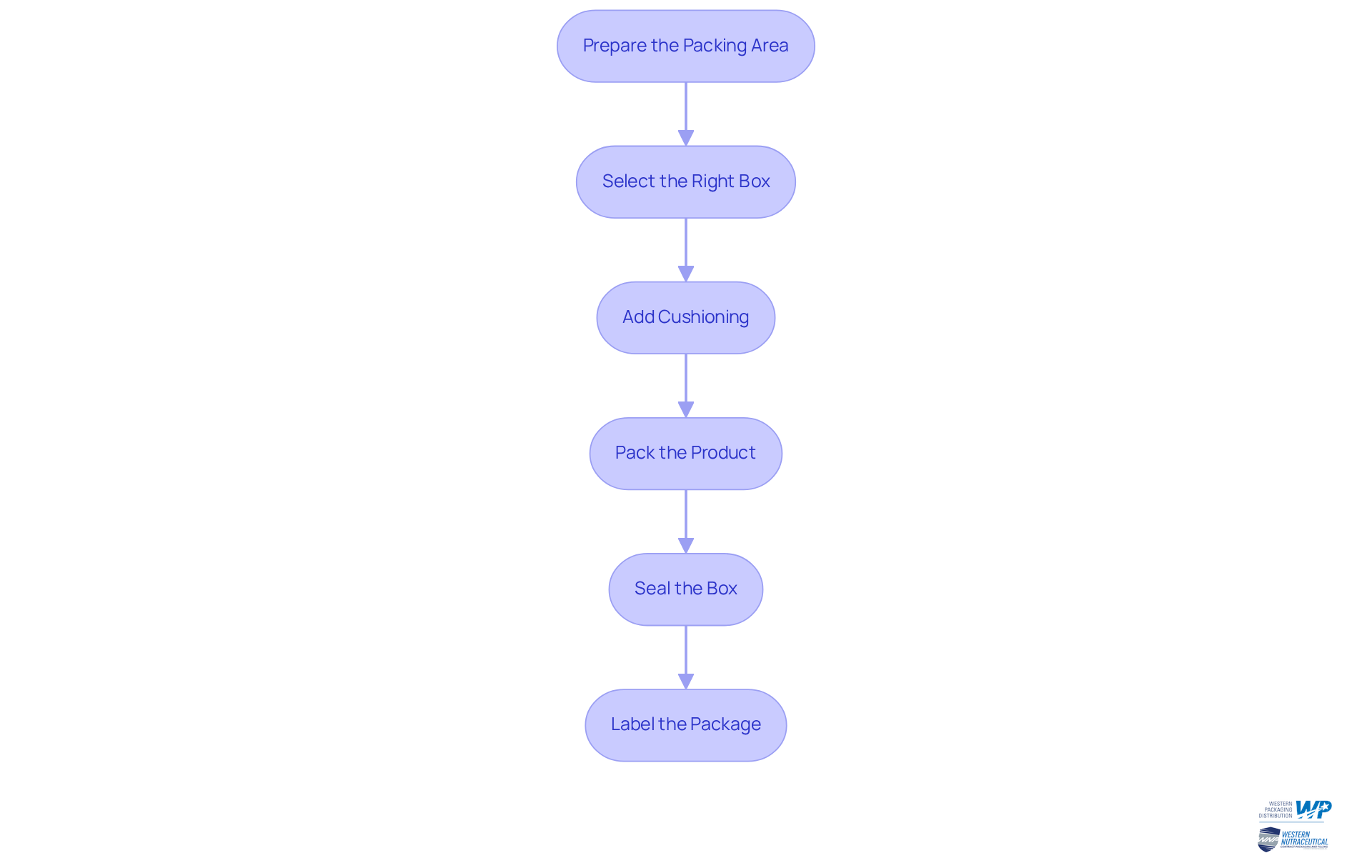

Execute the Packing Process: Step-by-Step Instructions

To execute an efficient packing process, follow these essential steps:

-

Prepare the Packing Area: A clean and organized workspace is crucial. Ensure that all necessary materials, such as boxes, tape, and cushioning, are within easy reach. A well-structured storage area can result in a 25% rise in orders handled per hour, emphasizing the significance of efficiency in your operations. Additionally, reducing travel time can account for up to 50% of picking activities, further underscoring the need for an optimized layout.

-

Select the Right Box: Choose a box that fits the item snugly to minimize movement during transit. Using appropriately sized boxes not only reduces shipping costs but also aligns with sustainability goals by minimizing waste.

-

Add Cushioning: Place cushioning materials, such as bubble wrap or packing peanuts, at the bottom of the box to safeguard the item. Proper cushioning is vital to prevent damage during shipping, ensuring customer satisfaction and reducing the likelihood of returns.

-

Pack the Product: Carefully place the product in the box, ensuring it is secure and surrounded by cushioning on all sides. Implementing quality control systems to ensure that packages are packed accurately can enhance precision and customer satisfaction. Remember, the key to an efficient shipping station is to have all the materials and equipment needed to process an order at hand.

-

Seal the Box: Use strong packing tape to seal all open edges of the box securely. Ensure the tape is at least 2 inches wide for optimal sealing. A well-sealed package is essential for preventing damage and ensuring that products arrive safely.

-

Label the Package: Clearly label the package with the shipping address and any necessary handling instructions. Accurate labeling is critical for efficient order fulfillment and helps avoid costly delays.

By following these steps, you can streamline your preparation process and enhance operational efficiency, ultimately leading to an improved packaging order and customer satisfaction. Investing in ergonomic shipping stations and utilizing mobile technology can further enhance your operations, leading to increased productivity and reduced labor expenses. Additionally, monitoring key performance indicators (KPIs) related to packing efficiency can provide insights for continuous improvement, ensuring your operations remain competitive.

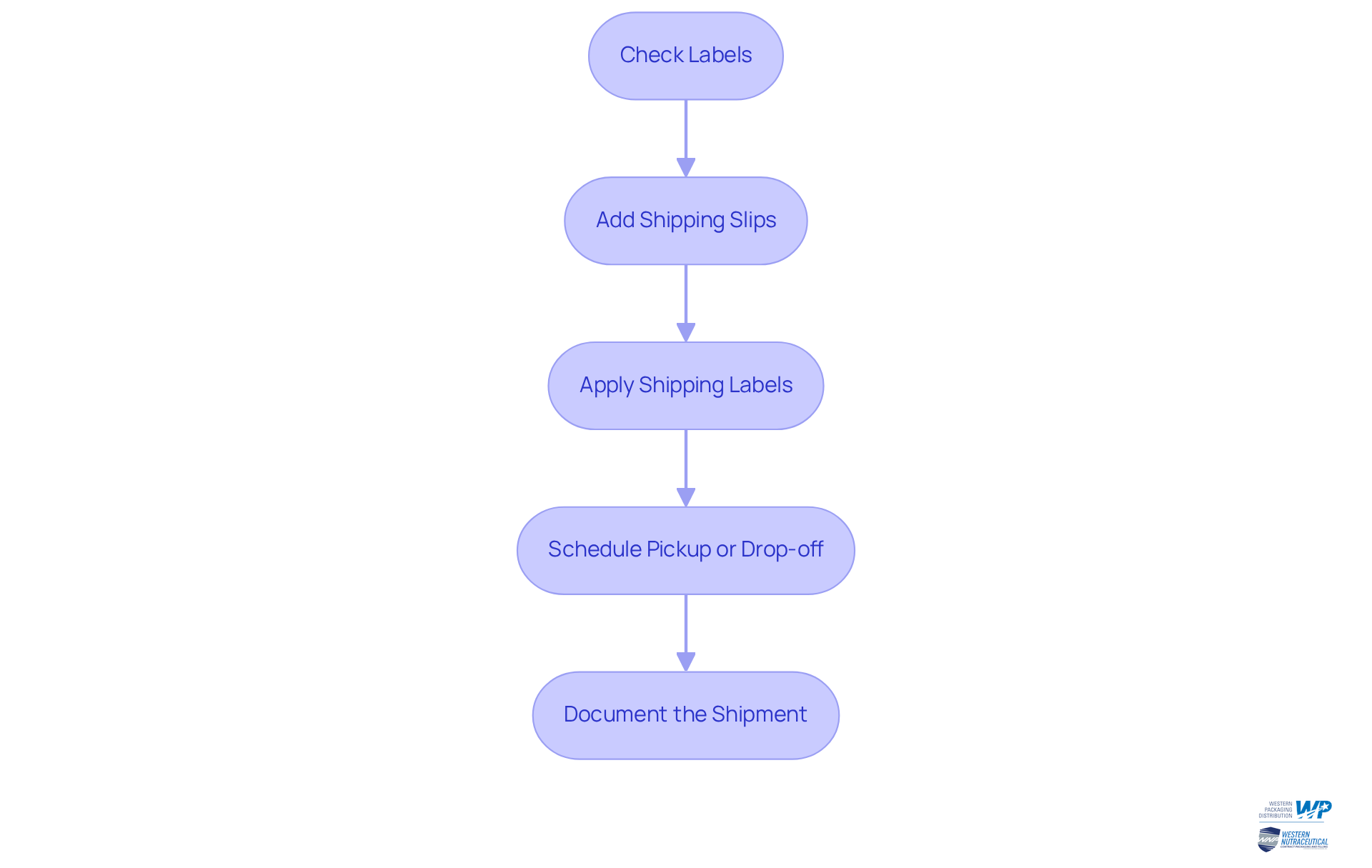

Finalize Your Order: Labeling and Preparing for Shipment

To finalize your order, adhere to these essential steps:

-

Check Labels: Verify that all labels are accurately filled out, including the recipient's name, address, and any special instructions. Proper labeling is crucial; it minimizes shipping errors and enhances delivery efficiency. Notably, 94% of consumers are more likely to remain loyal to brands that provide clear and accurate product labeling. Aim for an accuracy of 98% or higher in the packaging order to ensure optimal performance.

-

Add Shipping Slips: Place a shipping slip inside the box that outlines the items contained in the delivery. Incorporating shipping slips not only improves order precision but also enhances the customer experience by offering clarity about the packaging order. A case study has shown that adhering to slip guidelines significantly minimizes mistakes in shipments.

-

Apply Shipping Labels: Securely affix the shipping label to the top of the box, ensuring it is visible and legible. Labels should be placed on a flat surface and not near the edges to avoid issues during transit. Accurate labeling accelerates the shipping process and aids in the efficient identification and routing of packages. Many carriers now offer user-friendly websites for easy label creation, streamlining this process.

-

Schedule Pickup or Drop-off: Arrange for the package to be picked up by the shipping carrier or prepare it for drop-off at the designated location. Utilizing carrier websites can simplify this process, allowing for easy label creation and scheduling.

-

Document the Shipment: Keep a record of the shipment details, including tracking numbers and shipping dates, for future reference. This documentation is vital for tracking the shipment and addressing any potential issues that may arise during delivery. Additionally, ensure that packing staff receive adequate training to minimize errors and maintain high packing accuracy.

Conclusion

Mastering packaging order management stands as a pivotal element for businesses aiming to optimize their supply chain and elevate customer satisfaction. By implementing effective strategies, companies can streamline their processes, reduce errors, and ultimately enhance their bottom line. This article delineates a comprehensive approach to mastering packaging order management through five essential steps, underscoring the significance of:

- Understanding

- Preparation

- Material selection

- Execution

- Finalization

Key insights include the critical nature of accurate inventory management, the selection of suitable packaging materials, and the execution of a streamlined packing process. Each step plays a vital role in reducing operational costs, minimizing errors, and enhancing customer experiences, which are essential for fostering loyalty and encouraging repeat business. By concentrating on these areas, businesses can ensure they not only meet but exceed customer expectations in every packaging order.

In a rapidly evolving marketplace, the ability to adapt and refine packaging order management processes is paramount. Companies are urged to take proactive steps towards implementing these strategies, leveraging innovative solutions, and prioritizing sustainability to align with consumer demands. By doing so, they can enhance their operational efficiency and position themselves as leaders in their industry, ultimately driving growth and success in an increasingly competitive landscape.

Frequently Asked Questions

What is the importance of effective packaging order management?

Effective packaging order management is crucial for enhancing packaging order and supply chain procedures, leading to reduced lead times, minimized errors, and improved customer satisfaction.

How can companies reduce errors in packaging order management?

Companies can reduce errors by implementing key performance indicators (KPIs) to track performance and identify inefficiencies, ensuring accurate order management and correct product delivery.

What are the cost benefits of optimizing packaging order management?

Optimizing packaging order management can lower operational costs by reducing waste and enhancing inventory management processes, while efficient container design minimizes material usage and transportation costs.

How does effective packaging order management enhance customer satisfaction?

Timely deliveries and accurate order fulfillment improve the customer experience, with studies indicating that high-quality packaging increases customer loyalty and the likelihood of repeat purchases.

What role does operational agility play in packaging order management?

Operational agility allows companies to respond quickly to market changes, reducing lead times and enhancing supply chain responsiveness, which is essential for maintaining competitiveness.

What steps should be taken to prepare a packaging order effectively?

Steps include identifying item specifications, collecting accurate customer information, conducting an inventory check, preparing necessary documentation, and organizing the workspace.

Why is inventory management important in packaging order preparation?

Effective inventory management prevents stockouts and reduces inventory wastage, which can range from 5-10% due to packaging material failures, thereby maintaining operational efficiency.

How can companies enhance their inventory management practices?

Companies can enhance inventory management by implementing automated tracking systems that provide real-time visibility over stock levels, improving order management and reducing errors.