Overview

This article delves into the pivotal role of primary containers within the nutraceutical industry, underscoring their critical importance in safeguarding product integrity and enhancing consumer appeal. By examining various container types, materials, and design considerations, it highlights the factors that influence safety, efficacy, and market success. Strategic packaging choices not only protect products but also significantly shape brand image and foster consumer trust.

Introduction

In the competitive world of nutraceuticals, the importance of primary containers is paramount. These vital packaging elements not only protect products from environmental threats but also significantly enhance brand appeal and foster consumer trust. As manufacturers navigate the complexities of material selection, regulatory compliance, and shifting consumer preferences, the challenge lies in selecting the right container that harmonizes functionality with aesthetic appeal.

What strategies can companies adopt to master the art of primary container selection and ensure their products stand out on the shelves?

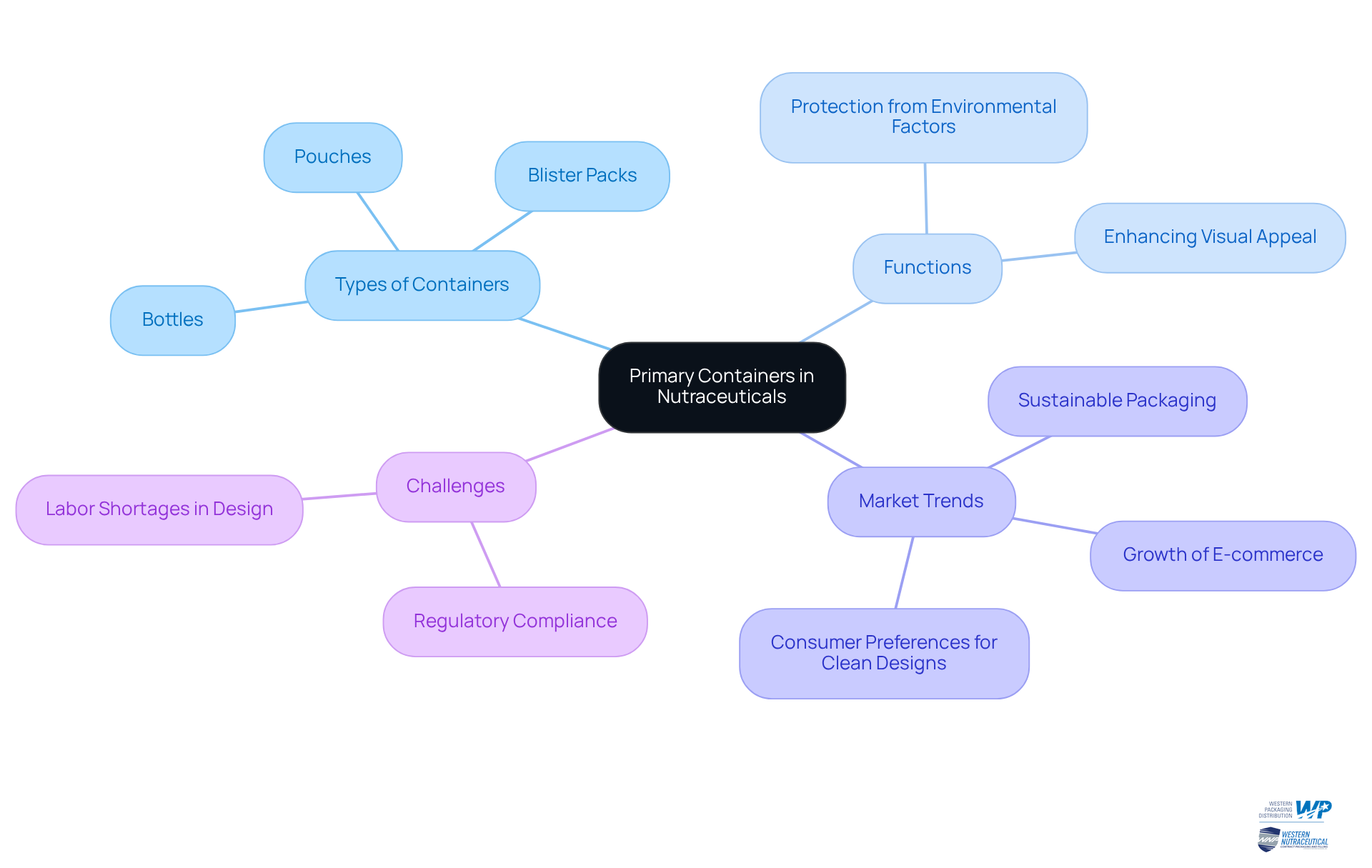

Define Primary Containers and Their Importance in Nutraceuticals

Main packaging components serve as crucial elements that directly engage with nutraceutical items, including bottles, blister packs, and pouches. Their primary function is to protect the item from environmental factors such as moisture, light, and air, which can undermine quality and efficacy. In the nutraceutical industry, where preserving item integrity is essential, the choice of primary container can significantly affect shelf life, user safety, and brand image.

A carefully crafted primary container not only safeguards the item but also enhances its visual appeal on retail displays, influencing purchasing decisions. As buyer preferences increasingly lean towards clean and modern wrappings, manufacturers must prioritize innovative vessel designs that align with these trends to ensure their products stand out in a competitive market.

Moreover, the use of high-barrier materials in the primary container is essential for preserving the potency of sensitive ingredients, thereby reinforcing consumer trust and satisfaction. The nutraceutical container market faces challenges such as regulatory compliance and a shortage of skilled labor in design, which can impact the effectiveness of strategies.

Ultimately, the strategic selection of the primary container design, supported by the creativity and precision of Western Packaging's innovative solutions, is a vital component of a successful strategy in the nutraceutical sector.

Explore Types of Primary Containers Used in Nutraceutical Packaging

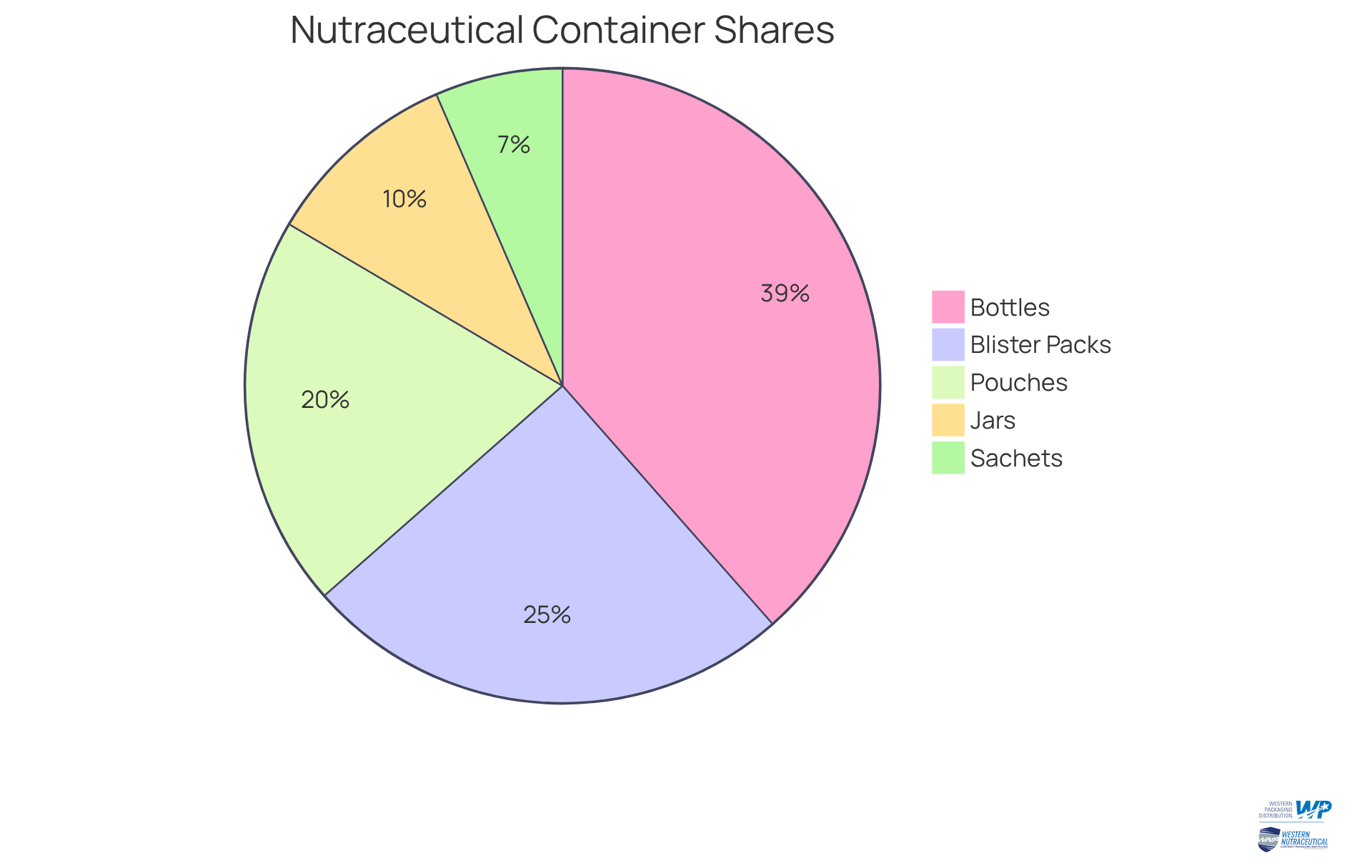

In the nutraceutical landscape, various primary containers serve crucial roles in ensuring product safety, convenience, and consumer appeal. The most common types include:

-

Bottles: Available in glass or plastic, bottles are highly versatile, accommodating liquids, powders, and capsules. They often incorporate child-resistant caps, enhancing safety for households with children. The bottles segment represented more than 38.5% of the nutraceutical container market revenue in 2024, indicating their broad acceptance. Notably, the dietary supplements segment led the nutraceutical packaging market with a revenue share of 46.2% in the same year, underscoring the importance of bottles in this sector.

-

Blister Packs: Known for their exceptional protection against moisture and contamination, blister packs are ideal for single-dose applications such as tablets and capsules. Their design not only maintains item integrity but also provides ease for users, making them a favored option in the dietary supplement industry. Experts highlight that blister packs offer substantial advantages, such as enhanced protection for items and convenience for buyers, which are essential in a competitive market.

-

Pouches: Lightweight and flexible, pouches can be designed with resealable features, making them particularly popular for powders and granulated items. The demand for pouches is expected to increase at a CAGR of 6.1% during the forecast period, fueled by preferences for convenience and portability.

-

Jars: Typically made from glass or plastic, jars are commonly used for products like gummies and powders. They provide a secure seal that maintains freshness, appealing to consumers who prioritize quality and longevity in their nutraceuticals.

-

Sachets: These single-serving packets are designed for on-the-go consumption, often used for powders and supplements. Their convenience aligns with the rising trend of personalized health solutions, catering to busy lifestyles.

Recent innovations in nutraceutical container designs focus on sustainability and functionality. For instance, advancements in tamper-evident seals and moisture-resistant barriers enhance product safety and shelf life. Key participants in the nutraceutical container industry, such as Amcor, Berry Global, and Gerresheimer, are investing in these innovations to meet changing buyer demands.

As the nutraceutical market evolves, understanding the advantages and applications of primary containers will be essential for manufacturers aiming to meet consumer demands and regulatory standards effectively.

Identify Key Considerations for Choosing Primary Containers

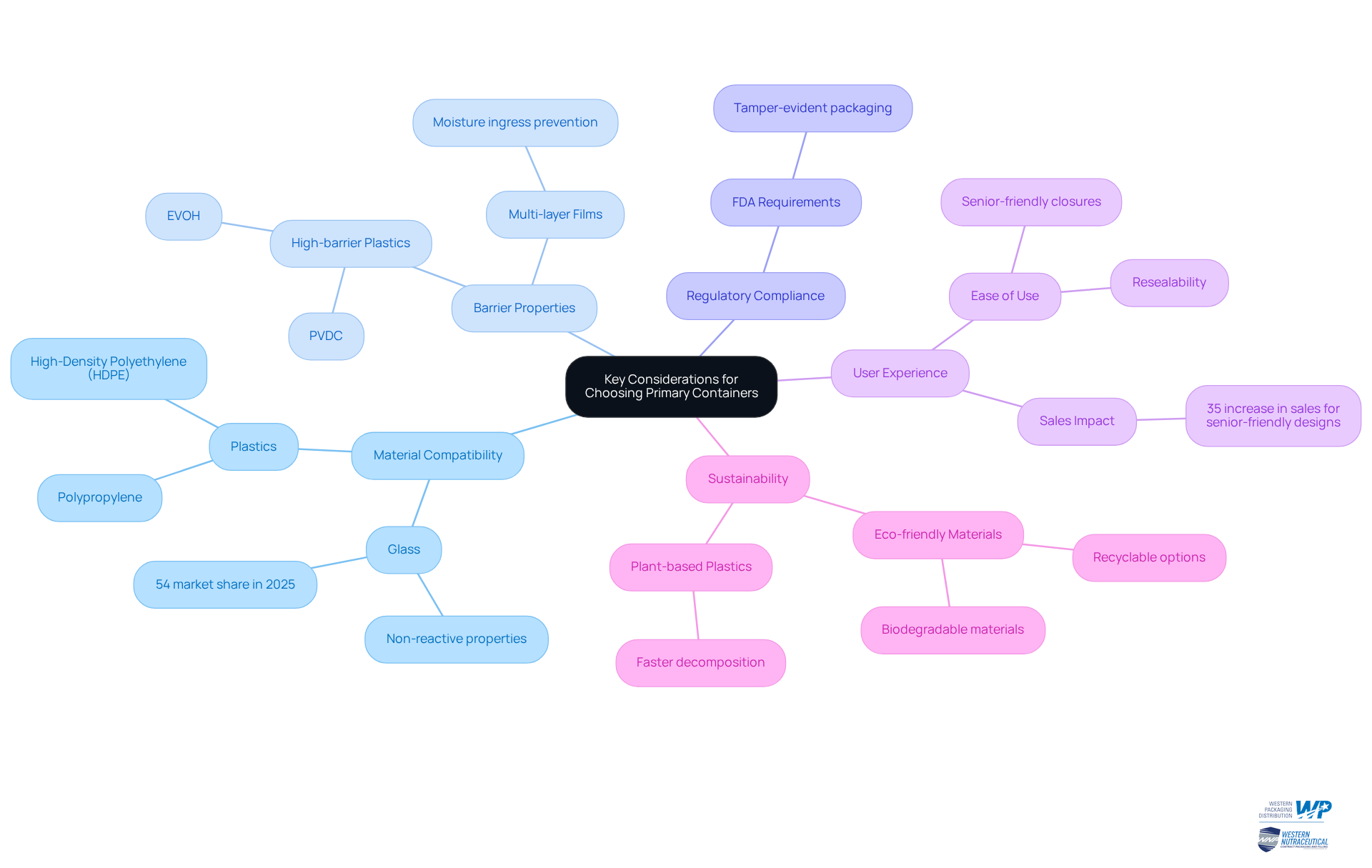

When selecting primary containers, it is crucial to consider several key factors that can significantly impact the safety and efficacy of nutraceuticals.

-

Material Compatibility: It is essential to ensure that the container material does not react with the product, as this could compromise safety and efficacy. Glass is favored for its non-reactive properties and superior barrier qualities, holding a 54% share in the nutraceutical rigid packaging market in 2025. Additionally, polypropylene and high-density polyethylene (HDPE) are recognized as primary containers for their chemical inertness, making them suitable selections for preserving product integrity.

-

Barrier Properties: Evaluating the container's ability to protect against moisture, oxygen, and light is critical for maintaining product integrity. High-barrier plastics like ethylene vinyl alcohol (EVOH) and polyvinylidene chloride (PVDC) are engineered for this purpose, ensuring that sensitive ingredients remain stable and effective. For instance, multi-layer films or pouches are employed to prevent moisture ingress for hygroscopic ingredients.

-

Regulatory Compliance: Familiarizing yourself with industry regulations regarding primary container materials and labeling to avoid compliance issues is essential. The FDA mandates tamper-evident packaging for dietary supplements, ensuring safety and trust for purchasers. This requirement is essential for preserving the integrity of the item and maintaining public trust.

-

User Experience: Considering how easy the container is to open, reseal, and store can significantly affect customer satisfaction. Innovative designs, such as senior-friendly closures, have been shown to boost sales among older individuals by 35% for specific items. This underscores the importance of user-friendly containers in enhancing sales.

-

Sustainability: With the increasing consumer demand for eco-friendly products, it is prudent to consider using recyclable or biodegradable materials to enhance brand appeal. The transition towards sustainable materials is evident, as companies increasingly adopt plant-based plastics and other environmentally friendly options. Additionally, paper-based materials are gaining popularity for vitamins and supplements due to their recyclability.

By focusing on these essential elements, manufacturers can enhance their packaging strategies, ensuring product safety, adherence to regulations, and customer satisfaction while also addressing the growing demand for sustainable solutions.

Integrate Primary Containers into Your Packaging Strategy for Optimal Efficiency

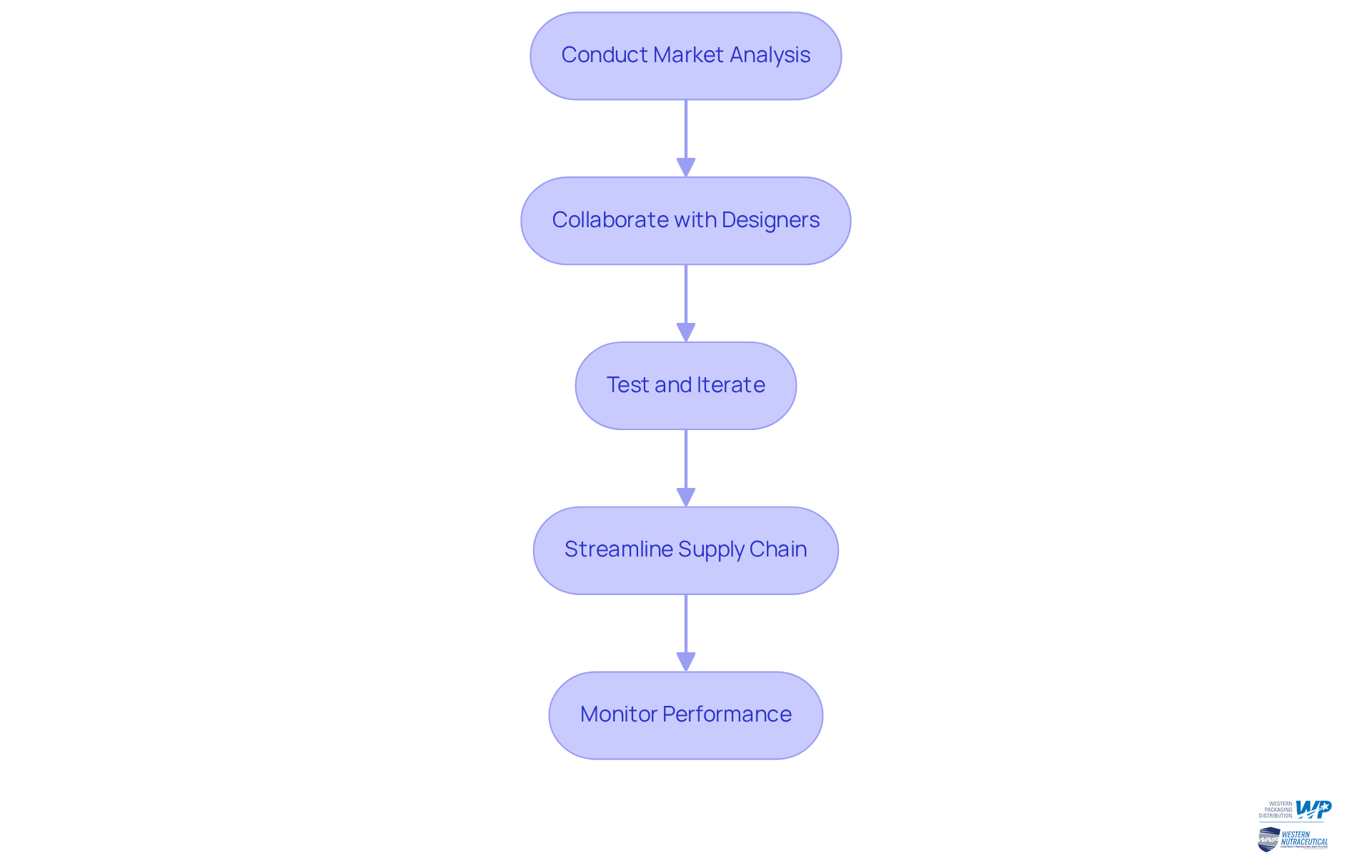

To effectively integrate primary containers into your packaging strategy, consider the following essential steps:

-

Conduct Market Analysis: Understand buyer preferences and trends in packaging to guide your vessel selections.

-

Collaborate with Designers: Partner with packaging creators to develop designs that not only protect the product but also enhance brand visibility and appeal.

-

Test and Iterate: Perform trials with various types of receptacles to evaluate performance and gather user feedback, enabling adjustments prior to full-scale production.

-

Streamline Supply Chain: Leverage Western Packaging's comprehensive 3PL services to work with suppliers, ensuring your selected packaging is readily available and compatible with your production processes. Our customized solutions in warehousing, inventory management, and logistics can significantly boost your supply chain efficiency.

-

Monitor Performance: Post-launch, continuously assess the effectiveness of your primary containers regarding product protection, consumer satisfaction, and sales performance.

Conclusion

The selection of primary containers is critical to the success of nutraceutical products, functioning not only as protective barriers but also as essential elements that shape consumer perception and foster brand loyalty. A comprehensive understanding of the various types, materials, and design considerations of primary containers is vital for manufacturers aiming to thrive in this competitive landscape.

This article presents key insights into the significance of diverse container types, including:

- Bottles

- Blister packs

- Pouches

- Jars

- Sachets

Each type delivers distinct advantages tailored to specific product requirements and consumer preferences. Moreover, critical factors such as material compatibility, barrier properties, regulatory compliance, user experience, and sustainability have emerged as pivotal considerations in the selection of the appropriate primary container. Collectively, these elements influence product safety, efficacy, and overall market success.

In a marketplace characterized by ever-evolving consumer expectations, it is imperative for nutraceutical manufacturers to embrace a strategic approach to packaging. By prioritizing innovative designs and sustainable materials, they not only comply with regulatory standards but also connect with environmentally conscious consumers. Integrating these insights into packaging strategies enables businesses to enhance product integrity, elevate customer satisfaction, and ultimately drive sales growth. The significance of primary containers in nutraceuticals is paramount; they are foundational to both product quality and brand reputation.

Frequently Asked Questions

What are primary containers in the context of nutraceuticals?

Primary containers are the main packaging components, such as bottles, blister packs, and pouches, that directly engage with nutraceutical items.

Why are primary containers important for nutraceuticals?

They protect the items from environmental factors like moisture, light, and air, which can undermine quality and efficacy, thereby affecting shelf life, user safety, and brand image.

How do primary containers influence consumer behavior?

A well-designed primary container enhances visual appeal on retail displays, which can influence purchasing decisions, especially as consumers prefer clean and modern packaging.

What materials are important for primary containers in preserving nutraceuticals?

High-barrier materials are essential for preserving the potency of sensitive ingredients, which helps to reinforce consumer trust and satisfaction.

What challenges does the nutraceutical container market face?

The market faces challenges such as regulatory compliance and a shortage of skilled labor in design, which can impact the effectiveness of packaging strategies.

How can manufacturers ensure their products stand out in the nutraceutical market?

Manufacturers should prioritize innovative vessel designs that align with current consumer preferences to ensure their products are competitive in the market.

What role does Western Packaging play in the nutraceutical sector?

Western Packaging provides innovative solutions that support the strategic selection of primary container designs, which is vital for success in the nutraceutical industry.